Revolutionizing Grain Drying: Farmonaut’s Guide to Cutting-Edge Equipment and Continuous Flow Technology in Queensland

“Modern continuous flow grain dryers can process up to 100 metric tons of barley per hour in Queensland.”

Welcome to Farmonaut’s comprehensive guide on revolutionizing grain drying in Queensland! As pioneers in satellite-based farm management solutions, we’re excited to explore the latest innovations in grain drying equipment and agricultural machinery. Our focus today is on cutting-edge continuous flow technology and how it’s transforming the landscape of grain production across the Darling Downs, Riverina, and beyond.

In this blog post, we’ll delve into the world of advanced grain drying solutions, from small-scale batch dryers to large-capacity systems capable of processing impressive metric tons of barley and other crops. We’ll also examine how precision agriculture techniques, including our own satellite-based crop monitoring technology, can optimize your grain drying operations and boost overall farm productivity.

The Evolution of Grain Drying Technology in Queensland

Grain drying has come a long way in Queensland, evolving from traditional sun-drying methods to sophisticated, high-capacity continuous flow systems. This progression has been driven by the need for efficiency, consistency, and quality in grain production. Let’s explore the key developments that have shaped the current landscape of grain drying equipment in the region.

- Transition from batch to continuous flow systems: The shift towards continuous flow grain dryers has revolutionized the industry, allowing for higher throughput and more consistent drying results.

- Integration of hydraulic air blowers: Modern grain dryers now incorporate advanced hydraulic air blowers, improving energy efficiency and drying uniformity.

- Adoption of precision agriculture techniques: The integration of satellite-based crop monitoring and AI-driven advisory systems has optimized the entire grain production process, from planting to drying.

As we explore these advancements, it’s important to note how they’ve impacted various aspects of farming in Queensland, from large-scale grain production to smaller operations managing livestock and cultivating pastures.

Continuous Flow Grain Dryers: The Game-Changer in Queensland Agriculture

Continuous flow grain dryers have emerged as a game-changing technology in Queensland’s agricultural landscape. These advanced systems offer numerous benefits over traditional batch dryers, making them an increasingly popular choice among farmers and agribusinesses in the region.

Key Advantages of Continuous Flow Grain Dryers

- High Capacity: Capable of processing large volumes of grain, often exceeding 100 metric tons per hour for crops like barley.

- Consistent Quality: Ensures uniform drying across all grains, reducing the risk of over or under-drying.

- Energy Efficiency: Modern designs incorporate energy-saving features, reducing operational costs.

- Versatility: Suitable for a wide range of crops, from wheat and barley to oilseeds.

- Automation: Many systems can be integrated with smart controls, allowing for remote monitoring and management.

These advantages make continuous flow grain dryers particularly well-suited to the diverse agricultural landscape of Queensland, from the expansive farms of the Darling Downs to the varied terrain of the Granite Belt.

Integrating Continuous Flow Dryers with Precision Agriculture

At Farmonaut, we recognize the potential of combining continuous flow drying technology with advanced precision agriculture techniques. Our satellite-based crop monitoring system can provide valuable insights that optimize the entire grain production process, including the drying stage.

Here’s how our technology enhances continuous flow grain drying:

- Real-time crop health monitoring to predict optimal harvest times

- AI-driven advisory on ideal drying parameters based on crop conditions

- Integration with farm management systems for seamless workflow

- Data-driven insights to maximize energy efficiency and grain quality

By leveraging these advanced tools, farmers in Queensland can take full advantage of their continuous flow grain dryers, ensuring maximum efficiency and quality in their grain production.

Hydraulic Air Blowers: Enhancing Efficiency in Grain Drying

One of the key components in modern grain drying equipment is the hydraulic air blower. These advanced blowers play a crucial role in improving the efficiency and effectiveness of grain drying processes, particularly in continuous flow systems.

Benefits of Hydraulic Air Blowers in Grain Drying

- Precise Airflow Control: Hydraulic systems allow for more accurate control of airflow, ensuring optimal drying conditions.

- Energy Efficiency: Compared to traditional blowers, hydraulic air blowers often consume less energy, reducing operational costs.

- Durability: Built to withstand the demands of continuous operation, these blowers offer extended service life.

- Reduced Noise: Many hydraulic blowers operate more quietly than their conventional counterparts, improving working conditions around the dryer.

- Versatility: Suitable for various grain types and drying configurations, making them ideal for Queensland’s diverse crop production.

The integration of hydraulic air blowers in grain drying equipment has significantly contributed to the advancement of agricultural practices in regions like the Central Slopes and Plains of Queensland.

Farmonaut’s Role in Optimizing Grain Drying Operations

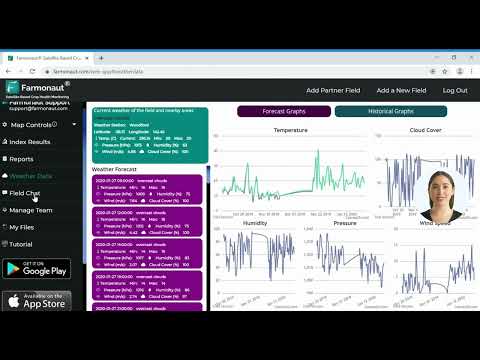

While we at Farmonaut don’t manufacture or sell grain drying equipment, our advanced satellite-based farm management solutions play a crucial role in optimizing the entire grain production process, including drying operations. Here’s how our technology supports farmers and agribusinesses in Queensland:

- Crop Health Monitoring: Our satellite imagery provides real-time insights into crop health, helping farmers determine the optimal time for harvest and subsequent drying.

- Yield Prediction: Accurate yield predictions allow for better planning of drying capacity and resource allocation.

- Weather Forecasting: Our AI-driven weather predictions help farmers anticipate and prepare for conditions that might affect grain drying operations.

- Resource Management: Our platform assists in optimizing the use of drying equipment, fuel, and labor, enhancing overall farm efficiency.

By integrating Farmonaut’s technology with modern grain drying equipment, farmers can achieve higher levels of efficiency and quality in their grain production.

Comparing Continuous Flow and Batch Dryers in Queensland

To better understand the advantages of modern grain drying technologies, let’s compare continuous flow dryers with traditional batch dryers in the context of Queensland agriculture:

| Features | Continuous Flow Dryers | Batch Dryers | Farmonaut’s Remote Sensing Benefits |

|---|---|---|---|

| Capacity (metric tons/hour) | 50-100+ | 10-30 | Optimize capacity utilization through accurate yield predictions |

| Energy Efficiency | High | Moderate | Enhance energy efficiency with AI-driven operational insights |

| Labor Requirements | Low (highly automated) | Moderate to High | Reduce labor needs with remote monitoring capabilities |

| Drying Uniformity | Excellent | Good | Improve uniformity through precise moisture content analysis |

| Suitable Crops | Wide range (wheat, barley, oilseeds) | Limited range | Provide crop-specific drying recommendations |

| Integration with Precision Agriculture | High potential | Limited potential | Seamless integration with Farmonaut’s satellite-based monitoring |

This comparison highlights the significant advantages of continuous flow dryers, especially when combined with Farmonaut’s remote sensing technology, in meeting the demands of modern grain production in Queensland.

Grain Drying Solutions for Different Farm Sizes

Queensland’s agricultural landscape is diverse, with farm sizes ranging from small family operations to large commercial enterprises. Let’s explore how different grain drying solutions cater to various farm sizes:

Small-Scale Farms

- Portable Batch Dryers: Ideal for farms with limited space and lower production volumes.

- In-Bin Drying Systems: Cost-effective solution for small to medium-sized farms.

- Farmonaut’s Benefit: Our satellite-based monitoring can help small farms optimize their limited resources and improve crop quality.

Medium-Sized Farms

- Mixed-Flow Dryers: Offer a balance between efficiency and capacity, suitable for mid-range production volumes.

- Continuous Flow Dryers (Smaller Models): Provide higher capacity than batch dryers while maintaining energy efficiency.

- Farmonaut’s Benefit: Our AI-driven advisory system can help medium-sized farms make informed decisions about when to harvest and how to optimize drying processes.

Large Commercial Farms

- High-Capacity Continuous Flow Dryers: Capable of handling large volumes of grain, ideal for extensive operations in areas like the Darling Downs.

- Integrated Drying and Storage Systems: Combine drying, cooling, and storage for maximum efficiency.

- Farmonaut’s Benefit: Our comprehensive farm management platform can help large operations coordinate complex harvesting and drying schedules across vast areas.

“Farmonaut’s satellite-based crop monitoring covers over 1 million hectares across the Darling Downs and Riverina regions.”

Regardless of farm size, integrating Farmonaut’s technology with appropriate grain drying equipment can significantly enhance productivity and grain quality.

Explore Farmonaut’s API for advanced agricultural insights

The Role of Precision Agriculture in Grain Drying

Precision agriculture has revolutionized farming practices, and its impact on grain drying is no exception. By leveraging advanced technologies, farmers in Queensland can significantly improve the efficiency and effectiveness of their grain drying operations.

Key Precision Agriculture Technologies in Grain Drying

- Satellite-Based Crop Monitoring: Farmonaut’s technology provides real-time data on crop health and maturity, helping farmers determine the optimal time for harvest and drying.

- IoT Sensors: In-field sensors can measure grain moisture content, allowing for precise adjustment of drying parameters.

- AI-Driven Advisory Systems: Advanced algorithms can analyze multiple data points to provide recommendations on drying times and temperatures.

- Automated Climate Control: Smart systems can adjust drying conditions based on real-time weather data and grain moisture levels.

Benefits of Precision Agriculture in Grain Drying

- Improved Grain Quality: Precise control over drying conditions leads to more consistent and higher-quality grain.

- Energy Efficiency: Optimized drying processes reduce energy consumption and operational costs.

- Reduced Waste: Accurate moisture content monitoring minimizes the risk of over-drying or under-drying.

- Enhanced Productivity: Automation and data-driven decision-making increase overall farm efficiency.

By integrating Farmonaut’s satellite-based monitoring with precision agriculture techniques, farmers in Queensland can take their grain drying operations to the next level of efficiency and quality.

Sustainable Practices in Grain Drying

As the agricultural industry in Queensland moves towards more sustainable practices, grain drying operations are also evolving to reduce their environmental impact. Here are some key sustainable practices being adopted in grain drying:

- Heat Recovery Systems: Capturing and reusing heat from the drying process to improve energy efficiency.

- Renewable Energy Integration: Incorporating solar or biomass energy sources to power drying equipment.

- Precision Moisture Control: Using advanced sensors and Farmonaut’s satellite data to avoid over-drying and conserve energy.

- Optimized Logistics: Efficient planning of harvesting and drying schedules to minimize fuel consumption in transportation.

- Water Conservation: Implementing closed-loop systems to recycle and reuse water in the drying process.

Farmonaut’s technology plays a crucial role in supporting these sustainable practices by providing accurate data on crop conditions, weather patterns, and resource utilization.

The Future of Grain Drying in Queensland

As we look towards the future, several emerging trends and technologies are set to further transform grain drying practices in Queensland:

- AI and Machine Learning: Advanced algorithms will optimize drying processes in real-time, adapting to changing conditions and crop characteristics.

- Blockchain Integration: Enhancing traceability and quality assurance in the grain supply chain, from drying to distribution.

- Advanced Materials: Development of new, more efficient materials for dryer construction and components.

- Autonomous Systems: Increased automation in grain handling and drying operations, reducing labor requirements.

- Climate-Adaptive Technologies: Drying systems that can efficiently handle varying moisture levels due to changing climate patterns.

Farmonaut is at the forefront of these technological advancements, continuously evolving our satellite-based monitoring and AI advisory systems to meet the future needs of Queensland’s grain producers.

Conclusion: Embracing Innovation in Grain Drying

The landscape of grain drying in Queensland is rapidly evolving, driven by advancements in technology and the pressing need for efficiency and sustainability. From continuous flow dryers to precision agriculture techniques, the tools available to farmers today are more sophisticated and effective than ever before.

At Farmonaut, we’re committed to supporting this evolution by providing cutting-edge satellite-based monitoring and AI-driven insights. Our technology empowers farmers to make informed decisions about their grain drying operations, optimize resource use, and improve overall productivity.

As we move forward, the integration of advanced technologies like those offered by Farmonaut with state-of-the-art grain drying equipment will be crucial in meeting the challenges of feeding a growing population while maintaining sustainable farming practices.

We encourage Queensland’s farmers and agribusinesses to embrace these innovations, leveraging the power of data-driven agriculture to revolutionize their grain drying processes and secure a prosperous future for the region’s agricultural sector.

FAQs: Grain Drying Equipment and Technology in Queensland

- What are the main types of grain dryers used in Queensland?

The main types include continuous flow dryers, batch dryers, and in-bin drying systems. Continuous flow dryers are becoming increasingly popular for their high capacity and efficiency. - How does Farmonaut’s technology enhance grain drying operations?

Farmonaut provides satellite-based crop monitoring and AI-driven insights, helping farmers optimize harvest timing, predict yields, and manage resources more efficiently during the drying process. - What are the benefits of continuous flow grain dryers?

Continuous flow dryers offer higher capacity, more consistent drying quality, improved energy efficiency, and better integration with automated systems compared to traditional batch dryers. - How can small-scale farmers in Queensland benefit from modern grain drying technology?

Small-scale farmers can use portable batch dryers or in-bin drying systems, which are more cost-effective. Integrating these with Farmonaut’s monitoring technology can further optimize their operations. - What role does precision agriculture play in grain drying?

Precision agriculture techniques, including satellite monitoring and IoT sensors, help optimize drying processes by providing accurate data on crop conditions, moisture levels, and weather patterns. - How are sustainable practices being incorporated into grain drying operations?

Sustainable practices include using heat recovery systems, integrating renewable energy sources, implementing precision moisture control, and optimizing logistics to reduce environmental impact. - What future technologies are expected to impact grain drying in Queensland?

Future technologies include AI and machine learning for process optimization, blockchain for traceability, advanced materials for dryer construction, and autonomous systems for grain handling and drying operations. - How can farmers choose the right grain drying equipment for their needs?

Farmers should consider factors such as farm size, crop types, production volume, energy efficiency, and integration with existing systems. Farmonaut’s advisory services can assist in making informed decisions. - What maintenance is required for grain drying equipment?

Regular maintenance includes cleaning, lubricating moving parts, checking electrical connections, and calibrating sensors. Following manufacturer guidelines and using Farmonaut’s predictive maintenance insights can help ensure optimal performance. - How does climate change impact grain drying practices in Queensland?

Climate change may lead to more variable moisture levels in crops. Adaptable drying systems and the use of Farmonaut’s real-time monitoring can help farmers adjust their practices to changing conditions.

Explore Farmonaut’s API Developer Documentation