Revolutionizing Digital Dentistry: Dual-Cure 3D Printing Innovations Unveiled in Chicago

“Dual-cure 3D printing technology in dentistry improves flexibility and strength of dental appliances by up to 30%.”

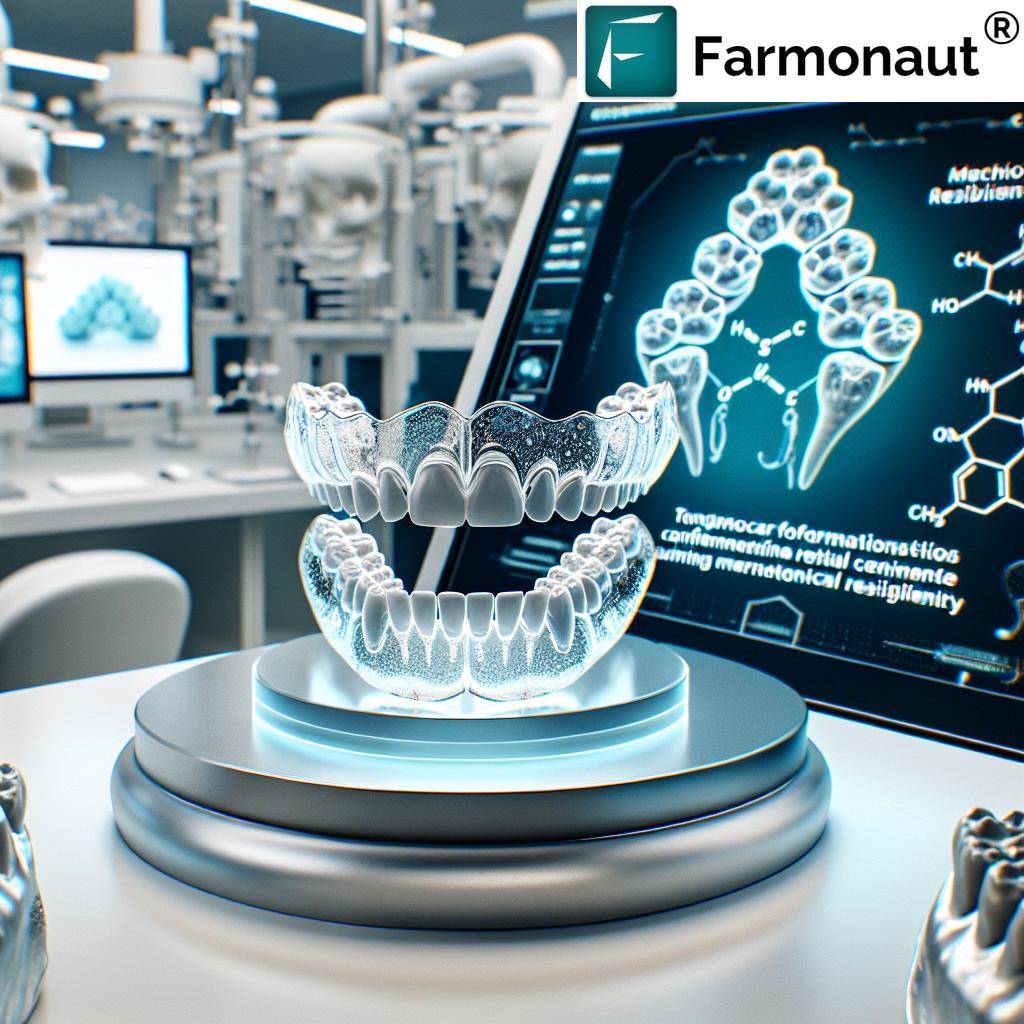

In the heart of Chicago, a groundbreaking revolution in digital dentistry is unfolding. We’re witnessing the dawn of a new era in dental technology, where 3D printing innovations are reshaping the landscape of the industry. At the forefront of this transformation are flexible removable partial dentures (FRPDs), pushing the boundaries of what’s possible in dental appliances.

As pioneers in the field of 3D printing technology, we at Carbon are thrilled to announce our latest breakthrough: FP3D, a game-changing flexible, removable partial denture resin. This innovative material introduces our proven dual-cure chemistry to the dental industry, promising significant advancements in the performance and reliability of dental appliances.

FP3D: Setting a New Standard in Flexible Removable Partial Dentures

FP3D is not just another dental resin; it’s a paradigm shift in what’s achievable with 3D-printed dental materials. As Carbon’s first dental resin leveraging our proprietary dual-cure chemistry, FP3D is engineered to redefine the boundaries of durability, flexibility, and strength in dental appliances.

Our dual-cure technology has already proven its mettle across various industries, from sports equipment to footwear. Now, we’re bringing this revolutionary chemistry to the dental sector, aiming to achieve properties similar to traditionally produced, polymer-based flexible partial denture materials.

- Enhanced durability for longer-lasting dental appliances

- Improved flexibility for better patient comfort

- Increased strength to withstand daily wear and tear

With an expected launch in late 2025, pending FDA clearance, FP3D is poised to redefine the future of 3D-printed removable partial dentures.

The Significance of Dual-Cure Chemistry in Dental Applications

Traditional single-cure resins have long been the standard in dental 3D printing. However, they often fall short when it comes to demanding dental applications, lacking the necessary durability, retention, and longevity required for flexible partial dentures.

Our FP3D material is designed to overcome these limitations by embedding secondary heat-activated chemistry within the resin. This innovative approach enables the material to build strength and durability in a bake step without sacrificing viscosity and accuracy during the printing process.

The result? Robust, engineering-grade parts with isotropic mechanical responses and high durability. This proprietary chemistry is set to elevate the performance and reliability of dental appliances, offering dental professionals and patients the benefits of advanced material science.

Proven Dual-Cure Chemistry Across Industries

Our dual-cure technology has already made waves in various sectors, showcasing its versatility and effectiveness:

- Sports Equipment: In collaboration with Riddell, we developed the first-ever 3D-printed football helmet liner featuring a lattice structure for enhanced protection and comfort.

- Footwear: Partnerships with leading athletic brands have resulted in high-performance midsoles that deliver improved energy return and durability.

- Cycling: Customized bike saddles created in partnership with top cycling companies utilize our dual-cure technology to provide unprecedented comfort and performance.

Now, we’re bringing this proven technology to the dental industry, promising to revolutionize the way dental appliances are manufactured and used.

Expanding the Automatic Operation Suite: Enhancing Dental Lab Efficiency

“New automated dental workflows can reduce lab processing time for 3D-printed dental appliances by 50%.”

Building on the success of our AO Suite launched in 2024, we’re introducing new tools designed to further automate and streamline dental lab workflows:

- Automatic Print Preparation Software: This no-code, user-friendly software automates critical steps in the printing process, from nesting to queuing. It reduces manual intervention, enhances operational efficiency, and empowers labs to scale their production with consistency and ease.

- AO Polishing Cassette Expansion: Now compatible with our M3 and M3 Max printers, the AO Polishing Cassette utilizes advanced light-scattering technology to polish parts directly during printing. This results in smoother and clearer parts right off the printer, reducing manual labor and preserving intricate design details.

These advancements in dental lab automation software and automated dental workflows are set to transform the efficiency and productivity of dental labs worldwide.

Advancing Digital Dentistry with Carbon’s Vision

Our developments underscore Carbon’s dedication to advancing digital dentistry. By introducing dual-cure technology and expanding automation solutions, we continue to set the standard for reliability and innovation in the dental industry.

These breakthroughs in dental material science and 3D printing for dental labs are driving innovation in the field of dentistry, promising to impact dental labs, clinicians, and patients alike.

The Impact of 3D Printing Innovations on Digital Dentistry

The introduction of dual-cure 3D printing technology in dentistry marks a significant milestone in the evolution of dental appliances. This innovative approach addresses many of the limitations associated with traditional manufacturing methods and single-cure 3D printing resins.

- Enhanced Material Properties: The dual-cure chemistry allows for a unique combination of flexibility and strength, previously difficult to achieve in 3D-printed dental appliances.

- Improved Patient Comfort: The flexibility of FP3D material translates to more comfortable dental appliances, potentially increasing patient satisfaction and compliance.

- Increased Durability: The secondary heat-activated chemistry results in more durable appliances, potentially reducing the need for frequent replacements.

- Precision and Accuracy: The ability to maintain low viscosity during printing while achieving high strength post-curing allows for intricate designs with high accuracy.

These advancements in 3D-printed dental appliances are set to redefine patient care and clinical outcomes in dentistry.

Revolutionizing Dental Lab Workflows

The impact of these innovations extends beyond just the end product. Our new automated dental workflows and lab automation software are set to transform the entire production process in dental labs:

- Increased Efficiency: Automated print preparation and polishing processes significantly reduce manual labor and processing time.

- Consistency: Automation ensures consistent results across multiple print jobs, reducing variability and potential errors.

- Scalability: With reduced manual intervention, dental labs can more easily scale their production to meet increasing demand.

- Cost-Effectiveness: Streamlined processes and reduced labor requirements can lead to more cost-effective production of dental appliances.

These advancements in digital dentistry are not just incremental improvements; they represent a paradigm shift in how dental labs operate and deliver services.

The Future of 3D-Printed Dental Appliances

As we look to the future, the potential applications of dual-cure 3D printing technology in dentistry are vast. Some exciting possibilities include:

- Customized Orthodontic Appliances: The ability to create highly customized, flexible orthodontic devices could revolutionize treatments like clear aligners.

- Advanced Prosthetics: The combination of strength and flexibility could lead to more comfortable and durable dental prosthetics.

- Surgical Guides: Precise, durable surgical guides could improve the accuracy of dental implant procedures.

- Temporary Restorations: Quick production of accurate, durable temporary restorations could enhance patient care during multi-step dental procedures.

The potential for innovation in digital dentistry is immense, and we’re just scratching the surface of what’s possible with these new materials and technologies.

Comparison: Traditional vs. 3D Printed Dental Appliances

| Characteristics | Traditional Dental Appliances | 3D Printed Dental Appliances (Dual-Cure Technology) |

|---|---|---|

| Material Properties | Limited flexibility, moderate strength | Enhanced flexibility, high strength |

| Production Time | Several days to weeks | Hours to a few days |

| Cost Efficiency | Higher labor costs, material waste | Reduced labor, minimal material waste |

| Customization Potential | Limited by manual processes | Highly customizable digital designs |

| Patient Comfort | Variable, depends on manual craftsmanship | Consistently high, due to precise digital design |

This comparison clearly illustrates the advantages of the new dual-cure 3D printing technology in dentistry, showcasing improvements across multiple key aspects of dental appliance production and performance.

The Role of Material Science in Advancing Dentistry

The development of FP3D and the application of dual-cure chemistry in dentistry underscore the critical role of material science in advancing the field. These innovations are not just about creating new materials; they’re about fundamentally rethinking the properties and capabilities of dental appliances.

- Biocompatibility: Advanced materials science allows for the development of dental appliances that are not only functional but also highly biocompatible, reducing the risk of adverse reactions.

- Longevity: By enhancing the durability and wear resistance of dental materials, we can create appliances that last longer and perform better over time.

- Aesthetics: New materials and printing technologies allow for the creation of dental appliances that are not only functional but also aesthetically pleasing, improving patient satisfaction.

- Functionality: The ability to fine-tune material properties at the molecular level opens up new possibilities for creating dental appliances with specific functional characteristics.

These advancements in dental material science are set to have a profound impact on patient care, clinical outcomes, and the overall practice of dentistry.

Challenges and Considerations

While the future of 3D printing in dentistry looks bright, there are still challenges and considerations to address:

- Regulatory Approval: New materials and technologies must undergo rigorous testing and approval processes to ensure safety and efficacy.

- Training and Education: Dental professionals will need to be trained in the use of new technologies and materials to fully leverage their benefits.

- Initial Costs: While 3D printing can be cost-effective in the long run, there may be significant initial investments required for equipment and training.

- Integration with Existing Workflows: Dental labs and clinics will need to adapt their processes to incorporate these new technologies effectively.

Addressing these challenges will be crucial for the widespread adoption and success of 3D printing innovations in dentistry.

Conclusion: A New Era in Digital Dentistry

The unveiling of dual-cure 3D printing innovations in Chicago marks the beginning of a new era in digital dentistry. These advancements promise to revolutionize the way dental appliances are designed, manufactured, and used, offering benefits to dental professionals and patients alike.

From enhanced material properties and improved patient comfort to streamlined production processes and increased customization potential, the impact of these innovations will be far-reaching. As we continue to push the boundaries of what’s possible in 3D printing technology and dental material science, we’re excited about the potential to transform dental care and improve oral health outcomes for patients worldwide.

The future of dentistry is digital, and with these groundbreaking innovations, that future is closer than ever before.

FAQs

- What is dual-cure 3D printing technology?

Dual-cure 3D printing technology involves a two-step curing process. The first cure occurs during printing, while a secondary heat-activated cure enhances the material’s properties post-printing. - How does FP3D differ from traditional dental resins?

FP3D offers improved flexibility, strength, and durability compared to traditional resins, thanks to its dual-cure chemistry. - When will FP3D be available for use in dental practices?

FP3D is expected to launch in late 2025, pending FDA clearance. - How does automated print preparation software benefit dental labs?

It streamlines the printing process, reduces manual intervention, and improves overall efficiency in dental lab operations. - What are the potential applications of dual-cure 3D printing in dentistry?

Applications include flexible removable partial dentures, customized orthodontic appliances, advanced prosthetics, and surgical guides.

Explore advanced agricultural solutions with Farmonaut:

For developers: Farmonaut API | API Developer Docs

Earn With Farmonaut: Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!