Revolutionizing Australian Automotive: Geelong’s Lightweight Carbon Fiber Wheel Innovation Drives Sustainable Manufacturing

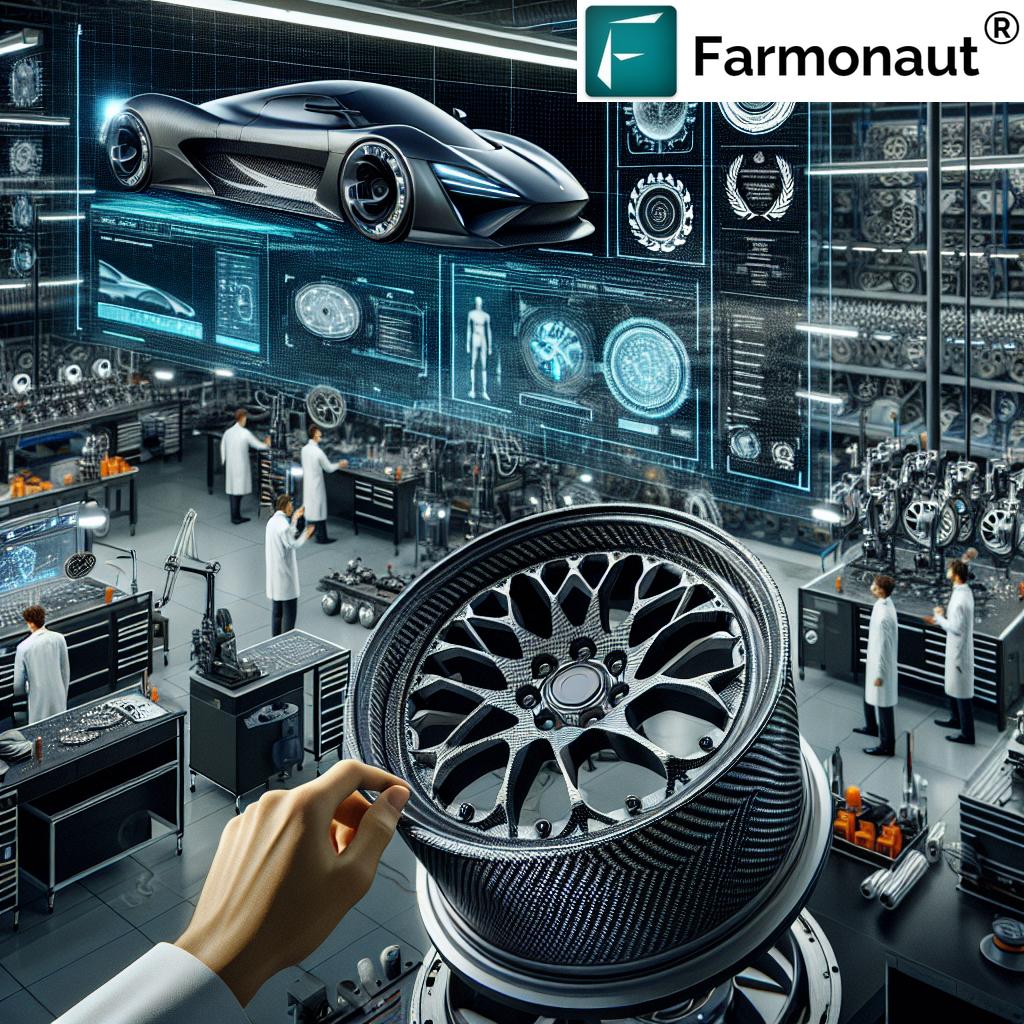

In the heart of Australia’s automotive innovation landscape, Geelong is emerging as a powerhouse of advanced technology and sustainable manufacturing solutions. We’re witnessing a revolution in the industry, driven by lightweight carbon fiber wheels that are reshaping the future of high-performance automotive parts. As we delve into this exciting world of innovation, we’ll explore how a leading manufacturer is transforming from designing prototypes to producing cutting-edge components for luxury car brands across the globe.

“Carbon fiber wheels can reduce a vehicle’s weight by up to 40-50% compared to traditional aluminum wheels.”

The Rise of Carbon Fiber in Automotive Innovation

The automotive industry is undergoing a significant transformation, with advanced automotive technology at the forefront of this change. Lightweight carbon fiber wheels represent a pinnacle of innovation in this space, offering unparalleled benefits in terms of performance, efficiency, and sustainability. As we explore this revolution, it’s important to understand the context of this innovation and its impact on the global automotive market.

Carbon Revolution plc, operating as Carbon Revolution Pty Ltd, stands at the forefront of this innovation. Based in Geelong, Australia, this company has transitioned from creating single prototypes to becoming a key supplier of advanced, lightweight wheels for high-performance, premium, and luxury automotive sectors worldwide.

The Journey from Prototypes to Global Supplier

The evolution of Carbon Revolution from a small-scale innovator to a global manufacturer is a testament to the power of persistence and technological advancement in the automotive industry. This journey involves several key stages:

- Designing Prototypes: The initial phase focused on creating innovative designs that could revolutionize wheel technology.

- Manufacturing Challenges: Overcoming the complexities of mass-producing carbon fiber components required significant investment in advanced material manufacturing processes.

- Commercialization: Successfully transitioning from prototype to commercial production, meeting the stringent quality standards of luxury car brands.

- Global Expansion: Establishing partnerships with international automotive manufacturers and expanding market presence.

This transformation not only highlights the company’s innovative spirit but also underscores the growing importance of sustainable manufacturing solutions in the automotive sector.

The Technology Behind Lightweight Carbon Fiber Wheels

At the core of this automotive revolution is the advanced technology used in creating lightweight carbon fiber wheels. These components represent a significant leap forward in automotive engineering, offering several advantages over traditional materials:

- Weight Reduction: Carbon fiber wheels can be up to 50% lighter than conventional aluminum wheels, significantly reducing overall vehicle weight.

- Improved Performance: The reduced weight translates to better acceleration, handling, and braking performance.

- Fuel Efficiency: Lighter wheels contribute to improved fuel economy, aligning with global efforts towards more sustainable transportation.

- Durability: Despite their lightweight nature, carbon fiber wheels offer exceptional strength and durability.

The manufacturing process of these wheels involves sophisticated techniques, including:

- Advanced composite layering

- Precision molding

- High-temperature curing

- Rigorous quality control measures

This level of technological sophistication positions Carbon Revolution at the forefront of advanced material manufacturing in the automotive sector.

Challenges and Opportunities in the Evolving Market

As with any groundbreaking technology, the journey of lightweight carbon fiber wheels from concept to market leader is fraught with challenges and opportunities:

Challenges:

- Regulatory Compliance: Meeting diverse international safety and environmental standards.

- Economic Factors: Navigating fluctuating raw material costs and economic uncertainties.

- Market Acceptance: Overcoming initial skepticism and proving long-term reliability.

- Competition: Staying ahead in a rapidly evolving technological landscape.

Opportunities:

- Global Growth: Expanding into new markets and forging partnerships with leading automotive brands.

- Technological Advancements: Continuous innovation in materials and manufacturing processes.

- Sustainability Focus: Aligning with global trends towards more eco-friendly automotive solutions.

- Performance Vehicle Market: Capitalizing on the growing demand for high-performance, lightweight components in luxury and sports vehicles.

These challenges and opportunities shape the strategy of companies like Carbon Revolution as they navigate the complex landscape of automotive innovation.

“Geelong-based manufacturers have invested over $100 million in developing lightweight carbon fiber wheel technology.”

The Impact on Vehicle Performance and Efficiency

The adoption of lightweight carbon fiber wheels has a profound impact on overall vehicle performance and efficiency. Let’s break down these benefits:

- Enhanced Acceleration: Reduced rotational mass allows for quicker acceleration and improved responsiveness.

- Better Handling: Lower unsprung weight improves suspension performance and vehicle dynamics.

- Increased Fuel Efficiency: Lighter wheels contribute to overall weight reduction, leading to improved fuel economy.

- Reduced Emissions: As a consequence of improved fuel efficiency, vehicles equipped with carbon fiber wheels typically produce fewer emissions.

These performance enhancements are particularly valuable in the high-performance and luxury car segments, where every aspect of vehicle dynamics is crucial.

Navigating Financial, Political, and Legal Landscapes

The journey of innovation and commercialization in the automotive industry is inherently complex, involving various financial, political, and legal considerations:

Financial Aspects:

- Investment in R&D: Significant capital is required for ongoing research and development.

- Scaling Production: Balancing production capacity with market demand and financial resources.

- Global Economic Factors: Adapting to currency fluctuations and international trade dynamics.

Political Considerations:

- Government Support: Leveraging government initiatives for advanced manufacturing and innovation.

- Trade Policies: Navigating changing international trade agreements and tariffs.

- Environmental Regulations: Aligning with evolving global environmental policies.

Legal Challenges:

- Intellectual Property: Protecting innovations through patents and managing potential infringement issues.

- Compliance: Adhering to diverse international safety and quality standards.

- Contractual Obligations: Managing complex supplier agreements with global automotive manufacturers.

Successfully navigating these landscapes is crucial for companies like Carbon Revolution to maintain their position as industry leaders and continue driving innovation.

The Future of Carbon Fiber Innovation in Automotive Engineering

As we look towards the future, the potential of carbon fiber innovation in shaping automotive engineering is immense. Here are some key trends and predictions:

- Expanded Applications: Beyond wheels, carbon fiber is likely to be integrated into more vehicle components, further reducing weight and improving performance.

- Advanced Manufacturing Techniques: Continued development in manufacturing processes will likely reduce production costs, making carbon fiber components more accessible to a broader market.

- Integration with Other Technologies: Combining carbon fiber with other advanced materials and technologies, such as embedded sensors for real-time performance monitoring.

- Sustainability Focus: Increased emphasis on developing more sustainable production methods and recyclable carbon fiber composites.

The future of automotive engineering is intrinsically linked to these advancements in carbon fiber technology, promising vehicles that are lighter, faster, more efficient, and more environmentally friendly.

Comparative Analysis of Lightweight Wheel Technologies

| Material Type | Weight Reduction (%) | Fuel Efficiency Improvement (%) | Performance Enhancement (1-10 scale) | Manufacturing Complexity (1-10 scale) | Estimated Cost Premium (%) |

|---|---|---|---|---|---|

| Carbon Fiber | 40-50 | 5-7 | 9 | 9 | 200-300 |

| Aluminum Alloy | 15-25 | 2-3 | 6 | 5 | 20-50 |

| Steel | 0 (baseline) | 0 (baseline) | 4 | 3 | 0 (baseline) |

| Magnesium Alloy | 25-35 | 3-5 | 7 | 7 | 100-150 |

This comparative analysis clearly illustrates the significant advantages of carbon fiber wheels in terms of weight reduction and performance enhancement. While the manufacturing complexity and cost premium are higher, the benefits in fuel efficiency and overall vehicle performance make carbon fiber an attractive option for high-end and performance vehicles.

The Role of Sustainable Practices in Manufacturing

In the context of growing environmental concerns, sustainable manufacturing practices are becoming increasingly important in the automotive industry. Companies like Carbon Revolution are at the forefront of implementing these practices:

- Energy-Efficient Production: Implementing energy-saving technologies in manufacturing processes.

- Waste Reduction: Developing methods to minimize waste and increase the recyclability of carbon fiber components.

- Lifecycle Assessment: Conducting comprehensive analyses of the environmental impact of carbon fiber wheels from production to end-of-life.

- Supply Chain Sustainability: Working with suppliers to ensure environmentally responsible sourcing of raw materials.

These sustainable practices not only benefit the environment but also contribute to long-term cost savings and improved brand reputation in an increasingly eco-conscious market.

Global Growth Strategies for Automotive Suppliers

For companies like Carbon Revolution to succeed in the global automotive market, strategic growth initiatives are crucial. Key strategies include:

- Market Diversification: Expanding into new geographic markets and vehicle segments.

- Strategic Partnerships: Collaborating with automotive manufacturers and technology companies to drive innovation.

- Continuous Innovation: Investing in R&D to stay ahead of technological advancements.

- Operational Excellence: Optimizing production processes to improve efficiency and reduce costs.

- Talent Acquisition and Development: Attracting and retaining skilled professionals in advanced manufacturing and engineering.

These strategies are essential for navigating the complex and competitive landscape of the global automotive industry.

The Impact of Economic Factors on Innovation

Economic factors play a significant role in shaping the trajectory of innovation in the automotive industry. Key considerations include:

- Market Demand: Fluctuations in consumer preferences and purchasing power influence investment in new technologies.

- Raw Material Costs: Changes in the prices of carbon fiber and other essential materials impact production costs and pricing strategies.

- Currency Exchange Rates: As a global industry, automotive suppliers must navigate the complexities of international finance.

- Economic Cycles: The cyclical nature of the automotive industry requires careful planning and risk management.

Successfully managing these economic factors is crucial for sustained innovation and growth in the competitive automotive supply industry.

Regulatory Compliance and Industry Standards

Navigating the complex landscape of regulatory compliance is a critical aspect of operating in the global automotive industry. Key areas of focus include:

- Safety Standards: Meeting and exceeding international safety regulations for automotive components.

- Environmental Regulations: Complying with evolving emissions and sustainability standards across different markets.

- Quality Certifications: Maintaining industry-standard quality certifications like ISO 9001 and IATF 16949.

- Trade Compliance: Adhering to international trade regulations and export control laws.

Staying ahead of regulatory requirements not only ensures legal compliance but also positions companies as responsible and trustworthy partners in the automotive supply chain.

The Role of Technology in Sustainable Manufacturing

Advanced technology plays a crucial role in driving sustainable manufacturing practices in the automotive industry. Here’s how technology is shaping the future of sustainable production:

- AI and Machine Learning: Optimizing production processes and predicting maintenance needs to reduce waste and energy consumption.

- Internet of Things (IoT): Implementing smart sensors for real-time monitoring of production efficiency and resource usage.

- 3D Printing: Utilizing additive manufacturing techniques to reduce material waste and enable more complex, lightweight designs.

- Robotics: Enhancing precision in manufacturing processes, leading to improved quality and reduced material waste.

These technological advancements are crucial in the journey towards more sustainable and efficient manufacturing practices in the automotive industry.

Frequently Asked Questions (FAQ)

- Q: What are the main advantages of carbon fiber wheels over traditional materials?

A: Carbon fiber wheels offer significant weight reduction (up to 50%), improved vehicle performance, better fuel efficiency, and enhanced durability compared to traditional wheel materials. - Q: How do carbon fiber wheels contribute to sustainability in the automotive industry?

A: By reducing vehicle weight, carbon fiber wheels improve fuel efficiency and reduce emissions. Additionally, ongoing research is focused on developing more sustainable production methods and improving the recyclability of carbon fiber components. - Q: Are carbon fiber wheels safe for everyday use?

A: Yes, carbon fiber wheels undergo rigorous testing and must meet or exceed safety standards set for traditional wheel materials. They are designed to withstand the demands of daily driving as well as high-performance applications. - Q: What challenges does the carbon fiber wheel industry face?

A: Key challenges include high production costs, complex manufacturing processes, regulatory compliance across different markets, and the need for continuous innovation to stay competitive. - Q: How is the automotive industry adapting to incorporate more sustainable practices?

A: The industry is focusing on energy-efficient production methods, waste reduction, lifecycle assessments of components, and developing more recyclable materials. There’s also an increased emphasis on electric and hybrid vehicle technologies.

Conclusion: Driving Towards a Sustainable Future

As we’ve explored throughout this article, the revolution in lightweight carbon fiber wheel technology, spearheaded by innovative companies like Carbon Revolution in Geelong, Australia, is transforming the automotive industry. This shift towards advanced materials and sustainable manufacturing practices is not just about creating faster, more efficient vehicles; it’s about paving the way for a more sustainable future in transportation.

The journey from designing prototypes to becoming a global supplier of high-performance automotive parts demonstrates the power of innovation and perseverance. As the industry continues to evolve, the focus on lightweight technologies, advanced manufacturing processes, and sustainable practices will undoubtedly shape the future of automotive engineering.

While challenges remain, including navigating complex regulatory landscapes and economic uncertainties, the potential benefits of these innovations far outweigh the obstacles. As we look to the future, it’s clear that the automotive industry’s commitment to innovation and sustainability will continue to drive progress, creating vehicles that are not only high-performing but also environmentally responsible.

The revolution in Australian automotive manufacturing, particularly in Geelong, serves as a beacon of innovation for the global industry. It demonstrates how cutting-edge technology, coupled with a commitment to sustainability, can lead to transformative changes in how we think about and produce vehicles. As this technology continues to evolve and become more accessible, we can look forward to a future where high-performance, efficiency, and sustainability coexist in harmony in the automotive world.

As we continue to witness the evolution of automotive technology, it’s crucial to stay informed about the latest developments and their potential impact on the industry and our environment. The journey of innovation in lightweight carbon fiber wheels is just one example of how technology can drive us towards a more sustainable and efficient future in transportation.

Earn With Farmonaut: Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!

For more information on how technology is revolutionizing various industries, including agriculture, check out Farmonaut’s innovative solutions:

Download the Farmonaut app to explore how satellite technology and AI are transforming agriculture:

Stay connected with the latest in agricultural technology and sustainable practices by exploring Farmonaut’s web application:

As we continue to push the boundaries of innovation in various sectors, from automotive to agriculture, the future holds exciting possibilities for sustainable and efficient technologies that will shape our world for generations to come.