Revolutionizing Dairy Farms: How Robotic Milking Systems Boost Efficiency and Yield

“Robotic milking systems helped one farm increase annual milk yield from 7,000 to 9,000 litres per cow.”

In the ever-evolving landscape of modern agriculture, we are witnessing a remarkable transformation in dairy farming. The introduction of robotic milking systems has ushered in a new era of efficiency, productivity, and animal welfare. As representatives of Farmonaut, a leading agricultural technology company, we are excited to explore how these innovative systems are revolutionizing the dairy industry.

The Rise of Robotic Milking Systems

Robotic milking systems, also known as automatic milking systems (AMS), have emerged as a game-changing technology in dairy farm management. These systems leverage advanced robotics and artificial intelligence to automate the milking process, allowing cows to be milked on their own schedule without human intervention. This technological leap forward is reshaping the way we approach dairy farming, offering numerous benefits for both farmers and their herds.

How Robotic Milking Systems Work

Robotic milking systems operate on a voluntary basis, allowing cows to enter the milking stall when they feel ready. Here’s a step-by-step breakdown of the process:

- Cow Identification: As a cow enters the milking stall, an RFID tag identifies her and retrieves her individual milking data.

- Udder Preparation: Robotic arms clean and stimulate the udder using brushes and water jets.

- Teat Detection: Laser technology precisely locates each teat.

- Attachment: The robotic arm attaches milking cups to each teat.

- Milking: The system monitors milk flow and quality in real-time.

- Detachment: Once milking is complete, the cups are automatically removed.

- Post-Milking Treatment: Teats are sprayed with a disinfectant solution.

- Data Collection: The system records milk yield, quality, and other health indicators.

This automated process not only streamlines milking but also provides valuable data for herd management and individual cow health monitoring.

Boosting Efficiency and Yield

One of the most significant advantages of robotic milking systems is their ability to increase milk yield and overall farm efficiency. Let’s explore how these systems are making a substantial impact:

- Increased Milking Frequency: Cows can be milked up to 3-4 times per day, compared to the traditional twice-daily milking. This increased frequency can lead to higher milk production.

- Optimized Cow Comfort: By allowing cows to choose when they want to be milked, stress levels are reduced, contributing to better overall health and productivity.

- Labor Optimization: Robotic systems free up labor resources, allowing farmers to focus on other aspects of herd management and farm operations.

- Precision Feeding: Many robotic systems integrate with automated feeding systems, enabling precise nutrition management based on each cow’s production level and stage of lactation.

- Data-Driven Decision Making: The wealth of data collected by these systems empowers farmers to make informed decisions about breeding, health management, and culling.

“Fullwood Merlin units, a type of robotic milking system, can significantly reduce labor requirements on dairy farms.”

Case Study: From 7,000 to 9,000 Litres

A compelling example of the impact of robotic milking systems comes from a dairy farm that saw a remarkable increase in milk yield after adopting this technology. The farm’s annual milk production per cow rose from 7,000 litres to an impressive 9,000 litres. This 28.5% increase in yield demonstrates the potential of robotic milking systems to transform dairy farm productivity.

Several factors contributed to this significant boost in milk production:

- Increased milking frequency allowed for more consistent udder emptying, stimulating higher milk production.

- Reduced stress on cows led to better overall health and productivity.

- Precision feeding, tailored to each cow’s needs, optimized nutrition for milk production.

- Early detection of health issues through data monitoring prevented production losses.

This case study highlights the transformative potential of robotic milking systems in maximizing dairy farm efficiency and productivity.

Investment in Dairy Farm Automation

While the benefits of robotic milking systems are clear, it’s important to consider the investment required to implement this technology. The initial cost of installing robotic milking systems can be substantial, but many farmers find that the long-term benefits outweigh the upfront expenses.

Key considerations for investment include:

- Equipment Costs: The price of robotic milking units, such as Fullwood Merlin systems, can vary based on herd size and specific features.

- Facility Modifications: Existing barns may need to be retrofitted to accommodate the new system.

- Training and Support: Both farmers and cows require an adjustment period to adapt to the new technology.

- Maintenance and Upkeep: Regular servicing and potential repairs should be factored into the long-term cost analysis.

Despite higher initial costs, many farmers report a positive return on investment due to increased productivity, reduced labor costs, and improved herd health.

Impact on Labor Optimization

One of the most significant benefits of robotic milking systems is their impact on labor management. Traditional dairy farming is labor-intensive, with milking tasks requiring significant time and physical effort. Robotic systems dramatically reduce the labor required for milking, allowing farmers to reallocate their workforce to other critical areas of farm management.

Benefits of labor optimization include:

- Reduced Physical Strain: Automated milking eliminates the repetitive physical tasks associated with traditional milking.

- Flexible Schedules: Farmers are no longer tied to strict milking schedules, improving work-life balance.

- Skilled Labor Focus: Staff can focus on higher-value tasks such as herd health management and business planning.

- Addressing Labor Shortages: In areas where finding skilled dairy workers is challenging, robotic systems can help farms remain operational and competitive.

By optimizing labor resources, robotic milking systems not only improve efficiency but also enhance the overall quality of life for dairy farmers and their employees.

Challenges and Considerations

While robotic milking systems offer numerous benefits, it’s important to acknowledge the challenges and considerations that come with adopting this technology:

- Initial Learning Curve: Both farmers and cows need time to adjust to the new system.

- Technical Skills Required: Farmers must be comfortable with technology and data management.

- Potential for Technical Issues: Like any advanced technology, robotic systems can experience malfunctions that require prompt attention.

- Herd Management Changes: Grazing patterns and overall farm layout may need to be adjusted to accommodate the new system.

- Energy Consumption: Robotic systems may increase electricity usage on the farm.

Despite these challenges, many farmers find that the benefits of robotic milking systems far outweigh the potential drawbacks.

The Role of Data in Modern Dairy Farming

One of the most valuable aspects of robotic milking systems is the wealth of data they generate. This data-driven approach to dairy farming opens up new possibilities for herd management and farm optimization.

Key data points collected by robotic milking systems include:

- Individual cow milk yield and quality

- Milking frequency and duration

- Cow activity and behavior patterns

- Feed intake and efficiency

- Early indicators of health issues

By leveraging this data, farmers can make more informed decisions about breeding, nutrition, and overall herd management. This precision approach to dairy farming can lead to significant improvements in productivity and animal welfare.

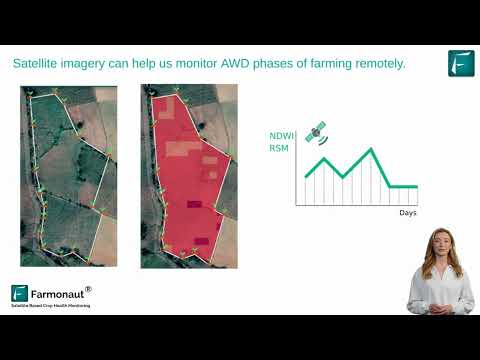

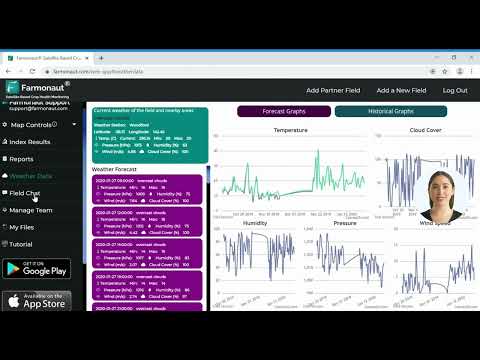

At Farmonaut, we understand the importance of data in modern agriculture. Our satellite-based farm management solutions complement robotic milking systems by providing additional layers of information about crop health, weather patterns, and resource management. By combining these technologies, dairy farmers can create a comprehensive, data-driven approach to farm management.

Learn more about our satellite-based solutions: Farmonaut Web App

Impact on Holstein Cow Management

Holstein cows, known for their high milk production, particularly benefit from robotic milking systems. These systems cater to the specific needs of Holstein herds:

- Frequent Milking: Holsteins often produce large volumes of milk, making them ideal candidates for more frequent milking offered by robotic systems.

- Individual Cow Monitoring: The detailed data collected helps manage the health and productivity of each Holstein cow more effectively.

- Customized Feeding: Integrated feeding systems can be tailored to meet the high nutritional demands of Holstein cows.

- Udder Health: Consistent milking and teat cleaning procedures help maintain udder health in high-producing Holsteins.

By catering to the specific needs of Holstein cows, robotic milking systems can help maximize the genetic potential of this popular dairy breed.

The Future of Dairy Farming Techniques

As we look to the future, it’s clear that robotic milking systems are just the beginning of a technological revolution in dairy farming. We anticipate several exciting developments:

- Integration with AI and Machine Learning: Advanced algorithms will provide even more precise predictions about cow health and productivity.

- Improved Sensor Technology: More sophisticated sensors will offer deeper insights into cow health and milk quality.

- Virtual Reality Training: VR technology may be used to train both farmers and cows in using robotic systems more effectively.

- Sustainable Energy Integration: Solar and other renewable energy sources may be integrated to power robotic milking systems, reducing operational costs and environmental impact.

- Blockchain for Traceability: Blockchain technology could be used to track milk from cow to consumer, ensuring quality and transparency throughout the supply chain.

At Farmonaut, we’re excited about these developments and how they align with our mission to make precision agriculture more accessible. Our satellite-based technologies complement these advancements, providing a holistic approach to farm management.

Explore our API for custom agricultural solutions: Farmonaut API

Environmental Considerations

As the dairy industry evolves, environmental sustainability becomes increasingly important. Robotic milking systems can contribute to more environmentally friendly dairy farming practices:

- Reduced Water Usage: Automated cleaning systems often use water more efficiently than traditional methods.

- Energy Efficiency: While robotic systems do consume electricity, many are designed with energy efficiency in mind.

- Precision Resource Management: By optimizing feeding and milking, these systems can reduce waste and improve resource utilization.

- Smaller Environmental Footprint: Increased efficiency can lead to higher milk production with fewer cows, potentially reducing the overall environmental impact of dairy farming.

At Farmonaut, we’re committed to promoting sustainable agricultural practices. Our satellite monitoring technology can help dairy farmers track their environmental impact and make data-driven decisions to improve sustainability.

Learn more about our sustainability tools: Farmonaut API Documentation

Economic Impact on Dairy Businesses

The adoption of robotic milking systems can have a significant economic impact on dairy businesses. While the initial investment is substantial, the long-term benefits can lead to improved profitability:

- Increased Milk Production: Higher milking frequency and optimized cow comfort can boost overall milk yield.

- Labor Cost Savings: Reduced labor requirements can lead to significant cost savings over time.

- Improved Milk Quality: Consistent milking procedures and early detection of health issues can result in higher quality milk, potentially commanding better prices.

- Extended Lactation Periods: Some farms report longer productive lives for their cows due to reduced stress and better health management.

- Diversification Opportunities: With more time available, farmers can explore additional revenue streams or focus on value-added products.

While every farm’s situation is unique, many dairy businesses find that robotic milking systems provide a positive return on investment over time.

Comparing Traditional and Robotic Milking Systems

To better understand the impact of robotic milking systems, let’s compare them to traditional milking methods:

| Metric | Traditional Milking | Robotic Milking |

|---|---|---|

| Average milk yield (litres/cow/year) | 7,000 | 9,000 |

| Milking frequency (times/day) | 2-3 | 2-4 |

| Labor hours required (hours/day) | 6-8 | 2-4 |

| Operational costs ($/year) | Lower initial, higher ongoing labor costs | Higher initial, lower ongoing labor costs |

| Cow stress levels | Moderate | Low |

| Data collection capabilities | Limited | Extensive |

| Herd management efficiency | Moderate | High |

This comparison highlights the significant improvements in efficiency and productivity that robotic milking systems can offer to dairy farms.

Integrating Robotic Milking with Other Farm Technologies

To maximize the benefits of robotic milking systems, many farms are integrating them with other advanced agricultural technologies. At Farmonaut, we see great potential in combining our satellite-based solutions with robotic milking systems for comprehensive farm management:

- Crop Health Monitoring: Our satellite imagery can help dairy farmers optimize their feed production, ensuring high-quality forage for their herds.

- Weather Forecasting: Accurate weather predictions can help farmers plan grazing schedules and outdoor access for robotically milked herds.

- Resource Management: Combining robotic milking data with satellite-based insights can lead to more efficient use of water, fertilizer, and other resources.

- Sustainability Tracking: Our carbon footprinting tools can work alongside robotic milking systems to monitor and improve the overall environmental impact of dairy operations.

Explore our mobile app for on-the-go farm management:

The Global Impact of Robotic Milking Systems

The adoption of robotic milking systems is not limited to any one region. Dairy farms around the world are embracing this technology, leading to a global transformation of the industry:

- Europe: Countries like the Netherlands and Denmark have been early adopters, with a high percentage of farms using robotic systems.

- North America: The U.S. and Canada are seeing rapid growth in robotic milking adoption, particularly on medium to large-scale farms.

- Oceania: Australia and New Zealand, known for their dairy industries, are increasingly incorporating robotic systems, especially in regions facing labor shortages.

- Asia: Countries like Japan and South Korea are exploring robotic milking as a solution to aging farmer populations and the need for increased efficiency.

This global adoption is driving innovation in the field, with manufacturers continually improving their systems to meet diverse farming needs worldwide.

The Role of Education and Training

As robotic milking systems become more prevalent, education and training play a crucial role in their successful implementation:

- Farmer Training: Comprehensive training programs are essential for farmers transitioning to robotic systems.

- Agricultural Education: Agricultural schools and universities are incorporating robotic milking technology into their curricula.

- Ongoing Support: Manufacturers and agricultural extension services offer continuous support and education for farmers using robotic systems.

- Community Learning: Farmer-to-farmer knowledge sharing has become invaluable in the adoption of this technology.

At Farmonaut, we believe in the power of education to drive agricultural innovation. Our platform includes learning resources and webinars to help farmers make the most of advanced agricultural technologies.

Access our learning resources: Farmonaut Web App

The Future of Dairy Consumption and Production

As we look to the future, robotic milking systems are poised to play a significant role in meeting the changing demands of dairy consumption:

- Increased Global Demand: Rising populations and changing diets in developing countries are driving up the demand for dairy products.

- Focus on Quality: Consumers are increasingly interested in high-quality, ethically produced dairy products.

- Sustainability Concerns: There’s growing pressure on the dairy industry to reduce its environmental impact.

- Traceability: Consumers want to know where their food comes from, driving the need for transparent production methods.

Robotic milking systems, combined with technologies like those offered by Farmonaut, are well-positioned to address these trends by improving efficiency, quality, and transparency in dairy production.

Conclusion: The New Era of Dairy Farming

Robotic milking systems represent a significant leap forward in dairy farm management. By boosting efficiency, improving animal welfare, and providing valuable data insights, these systems are transforming the industry. From increasing milk yields to optimizing labor resources, the benefits are clear and substantial.

As we’ve explored, the adoption of robotic milking systems comes with its challenges, including initial investment costs and the need for new skills. However, the long-term benefits in terms of productivity, animal welfare, and quality of life for farmers make it a compelling option for many dairy operations.

At Farmonaut, we’re excited about the potential of combining robotic milking systems with our satellite-based agricultural technologies. Together, these innovations can create more efficient, sustainable, and productive dairy farms that are ready to meet the challenges of the future.

As the dairy industry continues to evolve, embracing technologies like robotic milking systems and satellite-based farm management will be key to success. We encourage dairy farmers to explore these options and consider how they might benefit their operations.

Ready to take your farm management to the next level? Explore Farmonaut’s solutions:

FAQ Section

Q: What is the average cost of installing a robotic milking system?

A: The cost can vary widely depending on herd size and specific features, but typically ranges from $150,000 to $200,000 per unit. Each unit can usually handle 50-70 cows.

Q: How long does it take for cows to adapt to a robotic milking system?

A: Most cows adapt within 1-2 weeks, but some may take up to a month. The transition is usually smoother for heifers entering the milking herd for the first time.

Q: Can robotic milking systems work with all breeds of dairy cows?

A: While robotic systems can work with most dairy breeds, they are most commonly used with Holstein cows. Some adjustments may be needed for breeds with different udder configurations.

Q: How does robotic milking affect milk quality?

A: Generally, robotic milking systems maintain or improve milk quality due to consistent milking procedures and early detection of potential health issues.

Q: What happens if there’s a power outage or system failure?

A: Most robotic systems have backup power sources. In case of prolonged outages, farms typically have backup manual milking systems in place.