Revolutionizing High Tunnel Farming: How Plastic Selection Boosts Crop Health and Yield in Lancaster, PA

“UV-transparent films in high tunnels can increase basil biomass by up to 30% compared to standard plastics.”

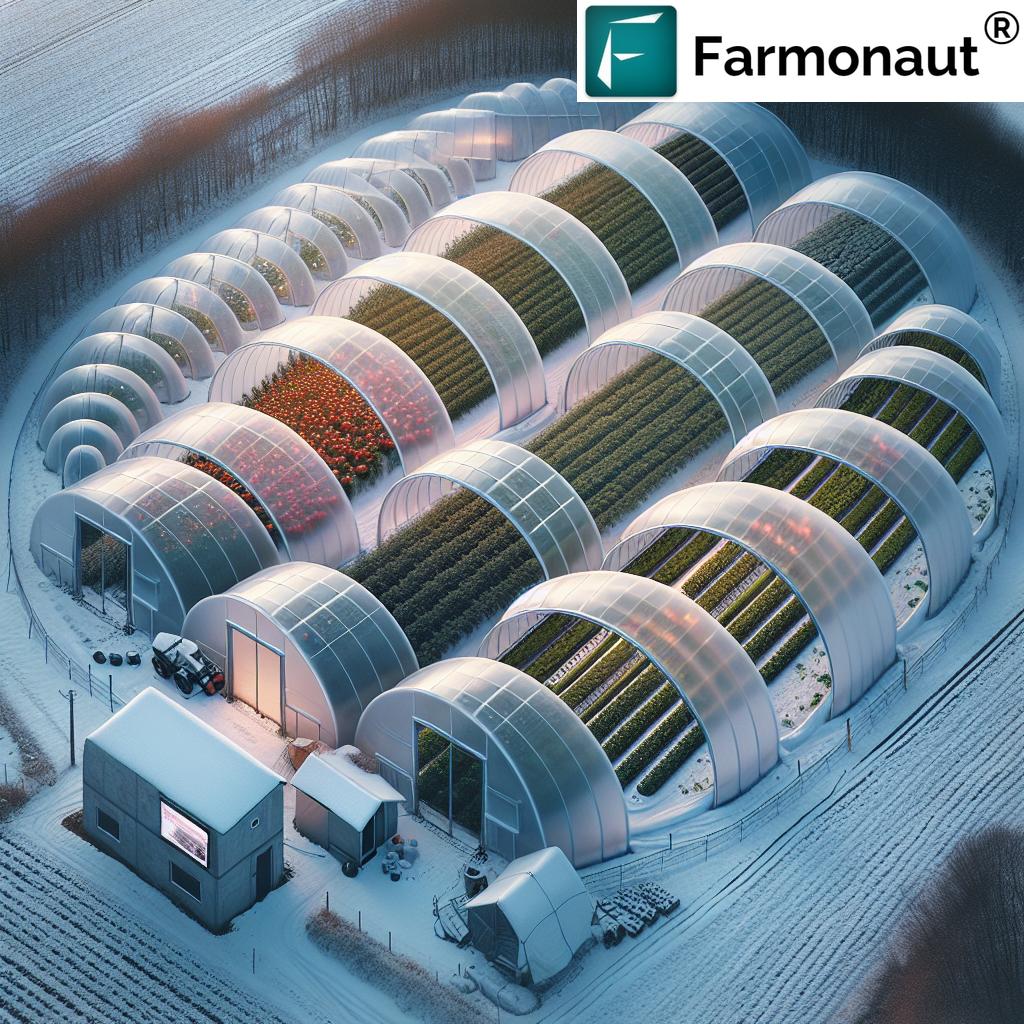

In the heart of Lancaster, PA, a revolution is taking place in the world of agriculture. High tunnel farming, also known as hoophouse cultivation, is transforming the way we grow crops and maximize yields. At the forefront of this agricultural innovation is the careful selection of plastic coverings, a decision that can make or break a farmer’s success. In this comprehensive guide, we’ll explore how the right choice of hoophouse plastic can significantly boost crop health and yield, particularly in the unique climate of Lancaster.

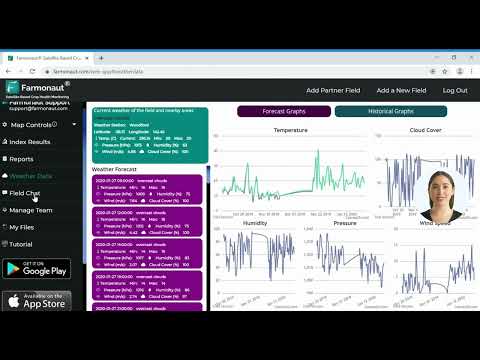

As we delve into the intricacies of high tunnel farming, it’s essential to understand the role of technology in modern agriculture. At Farmonaut, we’re committed to providing cutting-edge solutions that complement these innovative farming practices. Our satellite-based crop monitoring services offer valuable insights that can help farmers make informed decisions about their high tunnel operations.

Understanding High Tunnel Farming

High tunnel farming is a method of crop production that utilizes large, semi-circular structures covered with plastic film. These structures, often called hoophouses, create a controlled environment that extends the growing season and protects crops from harsh weather conditions. In Lancaster, PA, where the climate can be unpredictable, high tunnels have become an invaluable tool for farmers looking to increase their productivity and crop quality.

The Importance of Plastic Selection in High Tunnels

The type of plastic covering used in a high tunnel plays a crucial role in determining the success of crop production. Different plastics offer varying levels of light transmission, heat retention, and UV protection, all of which directly impact plant growth, disease resistance, and overall yield. For Lancaster growers, selecting the right plastic can mean the difference between a bountiful harvest and a disappointing season.

Types of Plastic Coverings for High Tunnels

Let’s explore the various types of plastic coverings available for high tunnel farming and their unique properties:

- Polyethylene (PE) Films: These are the most common and cost-effective options. They come in different thicknesses and can be treated to enhance specific properties.

- UV-Transparent Films: These films allow more ultraviolet light to penetrate, which can boost plant growth and flavonoid production in certain crops.

- Infrared (IR) Films: Designed to trap heat, these films are excellent for maintaining warmer temperatures inside the tunnel during cooler months.

- Anti-Condensation Films: These prevent water droplets from forming on the inside of the tunnel, reducing the risk of disease and improving light transmission.

- Diffused Light Films: These scatter incoming light, providing more uniform illumination throughout the tunnel and reducing plant stress.

Each type of plastic offers unique benefits, and the best choice often depends on the specific crops being grown and the local climate conditions in Lancaster, PA.

Impact of Plastic Selection on Crop Health

The choice of hoophouse plastic can significantly influence the health of your crops in several ways:

Light Transmission and Plant Growth

Different plastics allow varying amounts and types of light to pass through. UV-transparent films, for instance, can increase the production of beneficial compounds in plants. In basil cultivation, research has shown that UV-transparent films can lead to a 30% increase in biomass compared to standard plastics. This is particularly relevant for Lancaster farmers looking to maximize their herb production.

Temperature Regulation

Heat-retaining films can help maintain optimal temperatures inside the tunnel, especially during Lancaster’s cooler months. This can lead to faster growth rates and earlier harvests, giving local farmers a competitive edge in the market.

Disease Management

Certain plastic types can help manage diseases by altering the light spectrum or reducing condensation. For example, films that reduce humidity can help control downy mildew, a common problem in Lancaster’s vegetable crops.

Explore Farmonaut’s API for advanced agricultural insights

Boosting Crop Yield with the Right Plastic

The impact of proper plastic selection on crop yield cannot be overstated. Here’s how the right covering can lead to increased production:

Extended Growing Season

“Proper plastic selection in hoophouses can extend the growing season by 2-3 months in temperate climates.”

In Lancaster, PA, where the growing season is limited by cold winters, the right high tunnel plastic can extend the productive period by several months. This allows farmers to harvest crops earlier in spring and later into fall, significantly increasing annual yield.

Improved Light Diffusion

Diffused light films scatter sunlight more evenly throughout the tunnel. This reduces shadows and ensures that lower leaves receive adequate light, leading to more uniform crop growth and higher overall yields.

Enhanced Environmental Control

By selecting plastics with specific properties, growers can create an ideal microclimate within their high tunnels. This level of control allows for optimized growing conditions, resulting in healthier plants and increased production.

Case Study: Basil Cultivation in Lancaster High Tunnels

Recent research conducted at Penn State University has shed light on the significant impact of plastic selection on basil cultivation in high tunnels. The study, which is particularly relevant to Lancaster’s agricultural community, compared the effects of UV-transparent and UV-blocking films on basil growth and quality.

Key Findings:

- Basil grown under UV-transparent films showed a 30% increase in biomass compared to those under UV-blocking films.

- The concentration of valuable phenolic compounds and flavonoids was significantly higher in basil grown under UV-transparent conditions.

- UV-transparent films led to improved plant architecture, with more branching and larger leaf areas.

These findings highlight the potential for Lancaster farmers to significantly boost their basil production and quality through careful selection of high tunnel plastics.

Sustainable Farming Practices in High Tunnels

As we strive for more sustainable agricultural practices, the selection of high tunnel plastics plays a crucial role. Here’s how proper plastic choice contributes to sustainability:

Resource Efficiency

By creating an optimized growing environment, high tunnels with appropriate plastics can reduce water usage and minimize the need for pesticides and fertilizers. This is particularly important in Lancaster, where conservation of natural resources is a priority.

Energy Conservation

Heat-retaining plastics can reduce the energy required to maintain optimal temperatures in high tunnels, especially during Lancaster’s colder months. This leads to lower energy costs and a reduced carbon footprint.

Waste Reduction

Choosing durable, long-lasting plastics can minimize waste and reduce the frequency of replacements. Some modern plastics are also recyclable, further contributing to sustainability efforts.

Check out Farmonaut’s API Developer Docs for integration options

Choosing the Right Plastic for Your High Tunnel

Selecting the ideal plastic covering for your high tunnel in Lancaster, PA requires careful consideration of several factors:

Climate Considerations

Lancaster’s climate features hot summers and cold winters. Consider plastics that offer good insulation for winter protection while allowing adequate ventilation in summer.

Crop-Specific Needs

Different crops have varying light and temperature requirements. For example, tomatoes and peppers benefit from high light transmission, while leafy greens may prefer more diffused light.

Durability and Lifespan

Invest in high-quality plastics that can withstand Lancaster’s weather conditions and offer a longer lifespan to maximize your return on investment.

Light Transmission Properties

Consider the specific light needs of your crops. UV-transparent films might be ideal for basil and other herbs, while diffused light films could benefit a wider range of vegetable crops.

Implementing High Tunnel Plastic Solutions in Lancaster, PA

For Lancaster farmers looking to implement or upgrade their high tunnel systems, here are some practical steps:

- Assess Your Needs: Evaluate your specific crop requirements, climate challenges, and production goals.

- Consult Local Experts: Reach out to Penn State Extension or local agricultural consultants for advice tailored to Lancaster’s unique conditions.

- Compare Options: Use the table below to compare different plastic types and their properties.

- Consider a Trial: If possible, test different plastics on a small scale before making a large investment.

- Monitor and Adjust: Once implemented, closely monitor crop performance and be prepared to make adjustments as needed.

Comparison of High Tunnel Plastic Film Types

| Plastic Film Type | Light Transmission (%) | UV Blocking Capability | Heat Retention | Durability (years) | Impact on Crop Health | Effect on Yield | Best Suited Crops |

|---|---|---|---|---|---|---|---|

| Standard Polyethylene | 85-90% | Moderate | Low | 1-3 | Good | Moderate | General purpose |

| UV-Transparent | 90-95% | Low | Low | 2-4 | Excellent | High | Herbs, fruiting vegetables |

| Infrared (IR) Film | 80-85% | High | High | 3-5 | Very Good | High in cold climates | Cold-sensitive crops |

| Anti-Condensation Film | 85-90% | Moderate | Moderate | 2-4 | Very Good | High | Humidity-sensitive crops |

| Diffused Light Film | 80-85% | Moderate | Moderate | 3-5 | Excellent | Very High | Leafy greens, most vegetables |

This table provides a comprehensive overview of the most common plastic film types used in high tunnel farming. It allows Lancaster farmers to quickly compare the key characteristics of each option and make an informed decision based on their specific needs and crop types.

The Role of Technology in High Tunnel Farming

While selecting the right plastic is crucial, combining this with modern agricultural technology can further enhance the benefits of high tunnel farming. At Farmonaut, we offer advanced satellite-based crop monitoring services that can provide valuable insights for high tunnel growers:

- Real-time Crop Health Monitoring: Our satellite imagery can help detect early signs of stress or disease, even in covered environments.

- Climate Data Integration: By combining local weather data with high tunnel conditions, farmers can make more informed decisions about ventilation and irrigation.

- Yield Prediction: Advanced algorithms can help estimate potential yields, allowing for better planning and resource allocation.

By leveraging these technologies, Lancaster farmers can take their high tunnel operations to the next level, maximizing the benefits of their carefully selected plastic coverings.

Future Trends in High Tunnel Plastic Technology

As we look to the future of high tunnel farming in Lancaster and beyond, several exciting developments in plastic technology are on the horizon:

Smart Films

Researchers are developing “smart” plastic films that can adapt their properties based on environmental conditions. These films could automatically adjust light transmission or heat retention to optimize growing conditions throughout the day and across seasons.

Biodegradable Options

With a growing focus on sustainability, biodegradable high tunnel plastics are becoming more viable. These options could significantly reduce the environmental impact of high tunnel farming while maintaining excellent growing conditions.

Nanotechnology Integration

The incorporation of nanoparticles into plastic films could enhance their performance, offering improved durability, light manipulation, and even pest-resistant properties.

Conclusion: Embracing Innovation for Sustainable Agriculture

The selection of appropriate plastic coverings for high tunnels represents a crucial decision for Lancaster’s agricultural community. By carefully considering factors such as light transmission, heat retention, and crop-specific needs, farmers can significantly boost their crop health and yield. The case study on basil cultivation clearly demonstrates the potential for substantial improvements in both quantity and quality of produce.

As we continue to face challenges such as climate change and the need for increased food production, innovative approaches like optimized high tunnel farming will play an increasingly important role. By combining the right plastic selection with advanced technologies like those offered by Farmonaut, Lancaster farmers can lead the way in sustainable, efficient, and productive agriculture.

We encourage all growers to explore the possibilities offered by modern high tunnel plastics and to stay informed about emerging technologies in this field. The future of farming in Lancaster, PA, and beyond looks bright, with high tunnels illuminating the path to a more sustainable and productive agricultural landscape.

Frequently Asked Questions (FAQ)

Q: How long do high tunnel plastic coverings typically last?

A: The lifespan of high tunnel plastic coverings can vary depending on the type and quality of the plastic used. Generally, they can last anywhere from 3 to 5 years, with some high-quality options lasting up to 7-10 years with proper care and maintenance.

Q: Can I use the same plastic covering for all types of crops?

A: While some plastics are versatile enough for various crops, different plants have specific light and temperature requirements. It’s often best to choose a plastic that suits the majority of your crops or consider using different plastics for different sections of your high tunnel.

Q: How does plastic selection affect pest and disease management in high tunnels?

A: Certain plastics can help manage pests and diseases by altering the light spectrum or reducing humidity. For example, UV-blocking films can deter some insects, while anti-condensation films can reduce the risk of fungal diseases by minimizing water droplets on plants.

Q: Are there any environmental concerns with using plastic in high tunnel farming?

A: While plastic use is a concern, high tunnel farming can be more environmentally friendly than traditional open-field farming due to reduced water and pesticide use. Additionally, many plastics are now recyclable, and research is ongoing into biodegradable options.

Q: How can I determine the best plastic type for my specific location in Lancaster, PA?

A: Consider factors such as your local microclimate, the crops you plan to grow, and your specific goals (e.g., season extension, yield increase). Consulting with local agricultural extension services or experienced high tunnel growers in the area can provide valuable insights tailored to Lancaster’s conditions.