Anaerobic Digestion Technology Powers York’s 165,000 Tonne Biogas Leap

“York’s new facility processes 165,000 tonnes of organic waste annually, converting it into renewable biogas for clean energy.”

Introduction: A Landmark Leap for Anaerobic Digestion in Canada

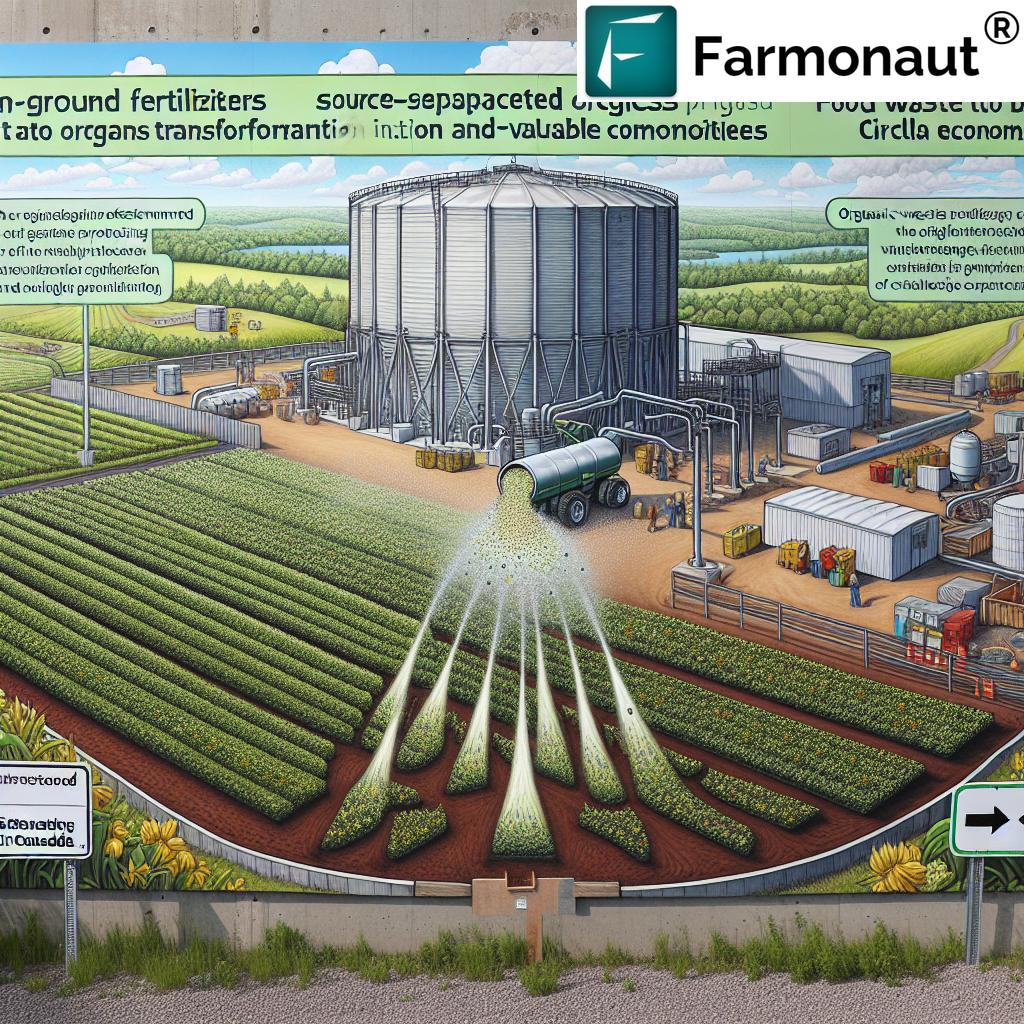

Canada is on the brink of a major transformation in sustainable waste management. Right here in Ontario, a landmark organic waste processing facility is under construction, set to redefine how we convert food waste and source-separated organics into valuable resources. The Convertus York Biofuels Facility in East Gwillimbury is scheduled to open in 2027, equipped with cutting-edge anaerobic digestion technology designed by the North American subsidiary of the renowned PlanET Biogas Group.

As committed advocates for sustainable infrastructure in Canada, we are excited to see this project begin a new era of organic waste conversion: transforming 165,000 tonnes per annum of food and other organics into biogas, upgraded biomethane (renewable natural gas), and nutrient-rich fertilizer. Not only does this facility promise to reduce greenhouse gas emissions by up to 115,000 metric tonnes of CO2 annually, but it will also generate enough renewable energy to power 5,000 homes in the region.

In this comprehensive guide, we take a detailed journey through every aspect of this facility—from the science of anaerobic digestion to the circular economy of fertilizer production, and how advanced technology (like ours at Farmonaut) and AI are helping Canada lead the world in sustainable, smart agriculture.

What Is Anaerobic Digestion Technology?

Anaerobic digestion (AD) technology is a powerful biological process where microorganisms break down organic waste (like food scraps or agricultural leftovers) in the absence of oxygen. The core outcome is twofold:

- Biogas production: Mainly methane (CH4) and carbon dioxide (CO2), used for heat, electricity, or upgraded into renewable natural gas (RNG)/biomethane.

- Digestate: The fibrous, nutrient-rich material left after digestion, which is further processed into high-quality fertilizer for agriculture.

This is the heart of the Convertus York facility: not just eliminating waste, but unlocking value from every tonne of food waste processed. Anaerobic digestion technology lies at the intersection of waste management and renewable energy generation—a cornerstone of sustainable infrastructure in Canada’s fight against climate change.

Key Principles of Anaerobic Digestion

- Feedstock Flexibility: Able to process both pre-consumer (food manufacturing, supermarket) and post-consumer organics (household food waste) — critical for comprehensive source-separated organics processing in Ontario.

- Closed-Loop System: Converts waste into useful products (energy and fertilizer) with minimal external inputs, closing the loop between urban waste generation and rural agriculture.

- Emissions Reduction: Prevents methane release from landfill decomposition; instead, it captures this potent greenhouse gas for controlled renewable energy generation.

Convertus York Biofuels Facility: Vision and Scope

The Convertus York Biofuels Facility is not just another waste processing plant. It’s a pioneering piece of sustainable infrastructure for Ontario and a model for North America. What sets it apart?

- Location: Strategically situated in East Gwillimbury, this facility will serve the entire Regional Municipality of York and possibly neighboring communities.

- Processing Capacity: Handling up to 165,000 tonnes of SSO (source-separated organics) and food waste annually—making it one of the largest facilities of its kind in Canada.

- Outputs:

- Generation of up to 350,000 GJ (gigajoules) of upgraded biomethane (renewable natural gas Ontario), enough to power 5,000 homes annually.

- Production of 165,000 tonnes of nutrient-rich digestate – an excellent fertilizer for local agricultural use.

- Annual reduction in greenhouse gas emissions by up to 115,000 metric tonnes of CO2 – a massive step toward regional climate targets.

- Opening Timeline: Construction began in late 2024, with full operations scheduled for 2027.

The Convertus York Biofuels Facility is designed to redefine organic waste processing in our region. It represents an investment not only in technology, but in the well-being of present and future generations. By closing the loop on waste and energy, we are setting new standards for environmental stewardship in Canada.

“Anaerobic digestion at the Ontario plant significantly reduces CO2 emissions while producing upgraded biomethane from local organic waste.”

How the Facility Processes 165,000 Tonnes of Waste Annually

Let’s step through how the Convertus York Biofuels Facility converts waste to energy and fertilizer, serving as the central hub of organic waste processing in Ontario:

-

Receiving & Pre-treatment:

- Accepts both pre-consumer (commercial/industrial) and post-consumer (household/residential) food waste and source-separated organics (SSO) collected by municipal programs.

- Pre-sorting removes plastics, packaging, and non-organic contaminants, optimizing feedstock for efficient digestion.

-

Anaerobic Digestion (AD) Reactors:

- The carefully prepared organic slurry is pumped into airtight digesters, where specific bacteria break down the material in the absence of oxygen over several weeks.

- This biological process generates raw biogas (about 60% methane, 40% carbon dioxide, with trace contaminants).

-

Biogas Upgrading:

- Raw biogas is scrubbed in sophisticated upgrading units to remove CO2 and impurities, yielding high-purity biomethane—also called RNG (renewable natural gas Ontario).

- This upgraded biomethane is injected directly into the local gas grid, enabling thousands of households to benefit from clean renewable energy for heating, cooking, and hot water.

-

Digestate Processing:

- The solid and liquid fractions left after digestion—the digestate—are stabilized and refined, producing 165,000 tonnes of nutrient-rich fertilizer suitable for local agricultural use.

- This material returns essential nutrients to the land, perfecting the organic loop between cities and rural farms.

In effect, the facility transforms what would otherwise be a landfill liability into a trio of regional assets: clean gas, climate action, and soil health!

From Food Waste to Biogas & Upgraded Biomethane—The Journey

Let’s spotlight how the facility’s anaerobic digestion technology delivers on three sustainability promises:

-

1. Food Waste to Biogas:

- Instead of food scraps decomposing in landfill (where methane, a potent greenhouse gas, is released to the atmosphere), the facility recovers this carbon-rich energy.

- Biogas produced on site is captured and efficiently managed—no flaring or waste.

-

2. Upgraded Biomethane Production:

- Using advanced cleaning/upgrading systems, biogas is refined into pure biomethane indistinguishable in quality from conventional natural gas but sourced from local waste.

- This renewable natural gas Ontario is climate neutral, since the carbon comes from recently living plants, not fossil reserves.

-

3. Net GHG Reductions According to Scale:

- Annually, our project will remove up to 115,000 metric tonnes of carbon dioxide (CO2)—the equivalent of taking 25,000 cars off the road.

- Replacing fossil-derived heating fuel with RNG slashes regional greenhouse gas footprints.

Related Solutions for Maximum Impact

-

Carbon Footprinting with Farmonaut:

Track, analyze, and manage agricultural GHG emissions with real-time, satellite-driven reporting. Tools like these complement the region’s efforts to reduce greenhouse gas emissions from field to facility. -

Supply Chain Traceability:

Delivered via blockchain technology, this ensures every bag of nutrient-rich fertilizer from waste or any crop input is accounted for, creating trust from farm gate to table. -

Large-Scale Farm Management:

Farmonaut’s cloud platform provides AI, satellite-based analytics, and operational tools—empowering local agriculture to use bio-based fertilizer and optimize fields for soil and energy efficiency. -

Fleet and Resource Management:

When biofuels or fertilizers are distributed regionally, efficient fleet tracking minimizes the carbon footprint further and supports sustainable agricultural logistics. -

Satellite Crop, Plantation & Forest Advisory:

Optimize the application of digestate with data-driven precision. Our advisors help farmers and foresters maximize yield and sustainability.

A Leap in Sustainable Infrastructure for Ontario and Canada

What sets the biofuels facility in East Gwillimbury apart is its holistic approach to regional waste and energy challenges:

- Design & Planning: Engineered for scalability and resilience, with capacity to grow as Ontario’s population and waste streams evolve.

- Integration into the Regional Municipality: Embedded in local waste-sorting, collection, and renewable energy strategies, creating synergies across municipal programs and regional carbon goals.

- Innovation-Driven: Features high-efficiency AD units, automated control, and robust odor/contaminant management, making it a model for facilities nationwide.

- Green Energy Infrastructure: The upgraded biomethane produced substitutes for imported gas, directly powering Ontario homes and businesses.

Closing the Loop: Nutrient-Rich Fertilizer from Waste

Perhaps the most quietly transformative aspect of anaerobic digestion technology is its ability to close the nutrient loop within the organic waste processing facility:

- The digestate output (both solid and liquid forms) is refined and stabilized, creating a pathogen-free, nutrient-rich fertilizer from waste.

- This digestate is offered to local agricultural use—no synthetic chemicals, no mined minerals, just the nutrients recycled from every carrot top and eggshell collected by the region’s households.

- Agronomically, these fertilizers restore soil organic matter, delivering improved yields, soil structure, and water retention on York-area fields.

This completes the circle: waste becomes food, which becomes waste again, but fortified and ready for another cycle, achieving what every sustainable infrastructure in Canada seeks—the repair of nature’s food-energy-neutrality loop.

Before-and-After Impact: Quantifying the Benefits of Anaerobic Digestion Technology

Here’s a simple comparison illustrating the environmental impacts before versus after implementing anaerobic digestion at the York facility:

| Metric | Before Facility Implementation | After Facility Implementation | Estimated Improvement (%) |

|---|---|---|---|

| Organic Waste Processed (tonnes/annum) | 30,000 | 165,000 | +450% |

| Biogas/Biomethane Produced (cubic meters/year) | ~10 million (landfill-gas capture) | ~25 million | +150% |

| Equivalent Homes Powered (per annum) | ~600 | ~5,000 | +733% |

| CO2 Emissions Avoided (tonnes/annum) | ~8,000 | ~115,000 | +1338% |

Key takeaway: The leap in organic waste processing capacity, renewable energy produced, and GHG reductions is exponential—not incremental. This shows the true climate and resource potential of advanced anaerobic digestion technology at scale in Ontario.

Farmonaut: Enabling Precision & Sustainability in Agriculture

To maximize the benefits of such biofuels facilities, it’s essential to connect with on-the-ground agricultural technology. That’s where we, at Farmonaut, are proud to empower farmers and agribusinesses nationwide:

- Satellite-Based Crop Health Monitoring: Our platform uses multispectral imagery and AI analytics to reveal how crops respond to digestate applications, track soil carbon, and detect areas needing improvement—making every tonne of recycled fertilizer count.

- Jeevn AI Advisory System: We deliver personalized, real-time crop and weather insights, so local farms using bio-derived fertilizers can optimize timing, maximize yields, and minimize risks.

- Blockchain-Based Product Traceability: Our solution ensures transparency from facility to farm: every sack of digestate, every tonne of food waste, and every field application tracked for quality, compliance, and consumer trust. Learn more.

- Fleet and Resource Management: Efficient fertilizer and resource distribution reduces operational emissions, supporting regional sustainability and cost savings. Discover Farmonaut’s fleet solutions.

- Carbon Footprint Tracking: Monitor your agricultural emissions in real time, make data-driven choices, and demonstrate compliance with climate initiatives—the ultimate tool in closing the sustainability loop. See how Farmonaut helps reduce your carbon footprint.

Through these innovations, stakeholders in York and beyond benefit from a seamless bridge between waste valorization, energy production, and agricultural prosperity. Together, we advance sustainable infrastructure in Canada.

Want to build your agri-solution powered by satellite and weather data? Access Farmonaut’s API or View Developer Docs today!

Get Started With Farmonaut

Whether you’re an individual farmer, agribusiness, cooperative, or government institution, our subscription plans scale with your needs—helping you manage every hectare sustainably and profitably.

Frequently Asked Questions (FAQ)

- Q: What makes anaerobic digestion technology so effective in reducing greenhouse gas emissions?

A: AD captures methane that would otherwise escape from landfill, converting it into usable energy (biogas/RNG). This process both mitigates direct emissions and replaces fossil fuel-based energy sources. - Q: How does the York facility ensure the waste processed is free from contamination?

A: Pre-sorting and screening technologies remove non-organic materials before digestion, creating high-quality feed for the biogas process and producing clean digestate for fertilizer use. - Q: Why is upgraded biomethane (RNG) so valuable as a renewable energy source?

A: Upgraded biomethane is nearly identical to natural gas but comes from renewable, carbon-neutral sources (e.g., food waste). It integrates directly with gas grids, powering homes and industries sustainably. - Q: Can digestate fertilizer fully replace synthetic fertilizers in local agriculture?

A: Digestate provides essential macronutrients and organic matter, improving soil quality. While some farmers may supplement with other amendments, digestate significantly reduces dependency on synthetic inputs. - Q: What role does Farmonaut play in this shift toward sustainable circular agriculture?

A: Farmonaut’s satellite and AI-based tools empower farmers to track, optimize, and report on the use and benefits of bio-based fertilizers, supporting climate-smart agriculture and verifying sustainability claims. - Q: What is the annual impact of the Convertus York Biofuels Facility compared to traditional waste management?

A: The facility handles 165,000 tonnes of organics per year, creating 350,000 GJ of RNG, enough to power 5,000 homes, and preventing up to 115,000 tonnes of CO2 emissions—a dramatic improvement over landfill disposal.

Conclusion: Redefining Organic Waste Processing in the Region

York’s new organic waste processing facility in East Gwillimbury, Ontario is much more than an infrastructure upgrade—it’s a bold leap forward for Canada’s renewable energy, circular agriculture, and sustainable infrastructure goals. Through anaerobic digestion technology, we are turning every tonne of wasted food into biogas, RNG, and nutrient-rich fertilizer that closes the agro-ecological loop and delivers local value for years to come.

With ongoing commitment across the Regional Municipality of York and the power of AI and satellite-driven platforms like Farmonaut, we are confident that this project’s success will serve as a blueprint nationally and globally for a climate-resilient, waste-wise future.

Together, let’s power the next generation of clean energy, agriculture, and sustainable communities—one tonne of waste at a time.