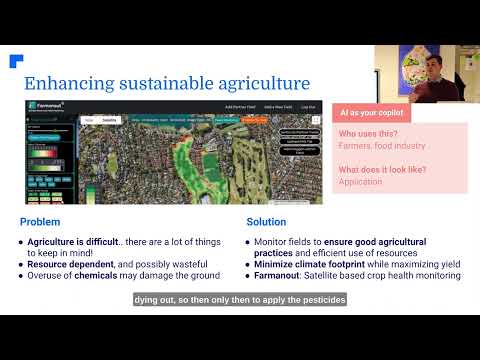

Revolutionizing Canadian Forestry: Autonomous Truck Platooning Tackles Industry Challenges in Northern Québec

“Autonomous truck platooning in Canadian forestry successfully completed a multi-week trial, navigating harsh northern conditions and steep grades.”

In the vast expanse of northern Québec’s forests, a technological revolution is taking root. We’re witnessing the dawn of a new era in the Canadian forestry industry, where autonomous truck platooning is not just a concept, but a reality that’s reshaping the landscape of logistics and supply chain management. This groundbreaking advancement is addressing some of the most pressing challenges faced by the industry, from driver shortages to safety concerns in remote areas.

As we delve into this exciting development, let’s explore how self-driving technology in forestry is set to transform operations, enhance safety, and pave the way for a more efficient and sustainable future in one of Canada’s most critical industries.

The Genesis of Autonomous Truck Platooning in Canadian Forestry

On January 27, 2025, Kratos Defense & Security Solutions, Inc. made a landmark announcement that sent ripples through the forestry and technology sectors. In collaboration with FPInnovations, a Canadian technology organization dedicated to enhancing the country’s forestry industry, Kratos successfully completed a multi-week demonstration of its self-driving truck platooning system in the challenging terrain of northern Québec.

This initiative wasn’t just about showcasing new technology; it was a strategic move to address critical issues plaguing the forestry industry:

- Acute driver shortages

- Safety concerns in remote areas

- The need for more efficient supply chains

- The imperative to boost rural economies

- The necessity for establishing regulatory frameworks for autonomous vehicle operations

The core of this revolutionary system lies in Kratos’ self-driving technology ‘kit’, a sophisticated package that enables vehicles to navigate autonomously. But what makes this system truly unique is its application in one of the most challenging environments for autonomous vehicles – the rugged, often unpredictable terrain of northern Canadian forests.

The Anatomy of Autonomous Truck Platooning

The truck platooning system demonstrated in northern Québec consisted of two class-8 tractor-trailers working in tandem:

- The Leader Truck: Driven by a human, this truck collected crucial navigation data.

- The Follower Truck: This driverless vehicle used the data relayed from the Leader truck to navigate autonomously.

This innovative setup was specifically designed to meet the unique demands of forestry supply chains. It demonstrated exceptional performance in conditions that would challenge even the most experienced human drivers:

- Limited GPS access in dense forest areas

- Steep grades that test vehicle capabilities

- Harsh weather, including sub-freezing temperatures

- Visibility-limiting dust on unpaved forest roads

What sets this system apart is its unique approach to autonomous driving. The Follower truck, while operating without a driver, wasn’t left entirely to its own devices. During testing, a Safety Rider was onboard, ready to intervene if necessary. This blend of human oversight and advanced technology creates a robust system that can adapt to unexpected circumstances in real-time.

The Human Element in Autonomous Systems

While the term ‘autonomous’ might suggest a complete absence of human involvement, the reality is far more nuanced. The system demonstrated in northern Québec showcases a harmonious blend of human expertise and cutting-edge technology.

The human driver in the Leader truck plays a crucial role:

- Adjusting vehicle speeds based on road conditions

- Making real-time decisions about maneuvers

- Providing a human touch to navigation in unpredictable environments

This human-technology partnership ensures that the autonomous system benefits from human judgment and experience, especially when faced with situations that might be challenging for AI to interpret correctly.

“The groundbreaking demonstration of self-driving technology in forestry addressed critical challenges like driver shortages and safety in limited GPS access areas.”

Addressing Industry Challenges

The successful demonstration of autonomous truck platooning in northern Québec is more than just a technological achievement. It’s a targeted solution to some of the most pressing challenges facing the Canadian forestry industry:

1. Driver Shortages

The trucking industry, particularly in remote areas, has been grappling with a severe shortage of qualified drivers. Autonomous platooning allows a single driver to effectively manage multiple trucks, significantly reducing the number of drivers needed for operations.

2. Safety Enhancements

Forestry routes often traverse challenging terrains and harsh weather conditions. Autonomous systems, with their advanced sensors and tireless operation, can potentially reduce accidents caused by human error or fatigue.

3. Efficiency and Cost Reduction

By optimizing routes, reducing fuel consumption through platooning, and maximizing operational hours, autonomous trucks can significantly improve efficiency and reduce operational costs.

4. Environmental Impact

More efficient operations mean reduced fuel consumption and lower emissions, aligning with the industry’s growing focus on sustainability and environmental stewardship.

The Technology Behind the Innovation

At the heart of this autonomous truck platooning system lies a sophisticated blend of technologies:

- Advanced Sensors: A combination of LiDAR, radar, and cameras provide a comprehensive view of the truck’s surroundings.

- GPS and Inertial Navigation Systems: These work in tandem to ensure accurate positioning, even in areas with limited GPS coverage.

- Machine Learning Algorithms: These allow the system to adapt to various road conditions and improve its performance over time.

- Vehicle-to-Vehicle (V2V) Communication: Ensures seamless data exchange between the Leader and Follower trucks.

- Robust Control Systems: Enable precise maneuvering and maintain safe distances between vehicles.

This technological ensemble allows the autonomous system to navigate the challenging terrain of northern Québec with a level of precision and reliability that rivals, and in some cases surpasses, human drivers.

Regulatory Implications and Industry Reception

The successful demonstration of autonomous truck platooning in northern Québec has significant implications for the regulatory landscape of autonomous vehicles in Canada. It provides valuable data and real-world experience that can inform the development of regulatory frameworks for autonomous vehicle operations, particularly in challenging environments like forestry.

The reception from industry stakeholders has been overwhelmingly positive:

- Regulatory bodies have expressed interest in using the data to shape future policies.

- Trucking contractors see the potential for addressing driver shortages and improving operational efficiency.

- Environmental groups are encouraged by the potential for reduced emissions and more sustainable forestry practices.

Maynard Factor, Vice President of Business Development at Kratos, highlighted the broader implications of this technology: “This innovative pairing of human oversight and autonomous systems could ensure operational continuity despite ongoing driver shortages, not just in forestry, but across various industries in Canada.”

The Future of Logistics: Beyond Forestry

While this demonstration focused on the forestry industry in northern Québec, the implications of this technology extend far beyond. The success of autonomous truck platooning in such challenging conditions opens up possibilities for its application in various other industries and environments:

- Mining: Autonomous trucks could navigate the complex and often dangerous terrain of mining sites.

- Construction: Large-scale construction projects could benefit from more efficient material transportation.

- Agriculture: Autonomous platooning could revolutionize the transportation of crops and livestock across vast rural areas.

- Disaster Relief: In areas where infrastructure has been damaged, autonomous trucks could provide crucial supply lines.

The adaptability of this technology to various industries underscores its potential to reshape the future of logistics and supply chain management on a global scale.

Comparative Analysis: Traditional vs. Autonomous Truck Platooning in Forestry

| Aspect | Traditional Trucking | Autonomous Truck Platooning |

|---|---|---|

| Driver Requirements | High (1 driver per truck) | Low (1 driver for multiple trucks) |

| GPS Dependency | Moderate | Low (uses multiple navigation systems) |

| Weather Resilience | Moderate (depends on driver skill) | High (advanced sensors and AI) |

| Accident Risk | Moderate to High | Low (reduced human error) |

| Fuel Efficiency | Standard | Improved by 10-15% due to platooning |

| Operational Costs | High | Reduced by 20-30% |

| CO2 Emissions | Standard | Reduced by 10-20% |

The Role of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) play crucial roles in the success of autonomous truck platooning. These technologies enable the system to:

- Continuously learn from new driving scenarios

- Adapt to changing road and weather conditions

- Optimize routes for efficiency and safety

- Predict and avoid potential hazards

As the system accumulates more data from real-world operations, its performance will continue to improve, making it increasingly reliable and efficient.

Environmental Impact and Sustainability

The environmental benefits of autonomous truck platooning are significant:

- Reduced fuel consumption leads to lower CO2 emissions

- Optimized routes minimize the impact on forest ecosystems

- More efficient operations can lead to reduced need for road construction in forested areas

These environmental advantages align well with the growing focus on sustainability in the forestry industry and beyond.

Economic Implications for Rural Communities

The introduction of autonomous truck platooning in forestry has the potential to revitalize rural economies:

- Creation of new, high-tech jobs in rural areas

- Increased efficiency leading to more competitive local industries

- Attraction of technology companies to rural regions

- Improved infrastructure to support autonomous vehicle operations

These economic benefits could help address the challenges of rural depopulation and economic stagnation in many forestry-dependent communities.

The Path Forward: Challenges and Opportunities

While the successful demonstration in northern Québec marks a significant milestone, there are still challenges to overcome:

- Regulatory frameworks need to be developed and standardized

- Public perception and acceptance of autonomous vehicles must be addressed

- Infrastructure upgrades may be necessary in some areas

- Cybersecurity measures must be robust to protect against potential threats

However, these challenges also present opportunities for innovation, collaboration, and growth in the industry.

Conclusion: A New Era for Canadian Forestry

The successful demonstration of autonomous truck platooning in northern Québec marks the beginning of a new era for the Canadian forestry industry. By addressing critical challenges such as driver shortages, safety concerns, and operational efficiency, this technology has the potential to transform not just forestry, but the entire landscape of logistics and supply chain management.

As we move forward, the collaboration between human expertise and advanced autonomous systems will be key to realizing the full potential of this technology. The future of Canadian forestry looks brighter, more efficient, and more sustainable, thanks to the groundbreaking advancements in autonomous truck platooning.

FAQs

- Q: How does autonomous truck platooning work?

A: Autonomous truck platooning involves a lead truck driven by a human, followed by one or more driverless trucks that use advanced sensors, GPS, and communication systems to follow the lead truck’s route and movements. - Q: Is autonomous truck platooning safe in challenging forest conditions?

A: Yes, the system has demonstrated exceptional performance in challenging conditions, including limited GPS access, steep grades, and harsh weather. It combines advanced technology with human oversight for optimal safety. - Q: How does this technology address driver shortages?

A: By allowing one driver to effectively manage multiple trucks, autonomous platooning significantly reduces the number of drivers needed for operations. - Q: What are the environmental benefits of autonomous truck platooning?

A: This technology can reduce fuel consumption and CO2 emissions by optimizing routes and improving overall efficiency of transportation operations. - Q: Will autonomous truck platooning replace human drivers entirely?

A: No, the current system still requires human drivers for the lead trucks and oversight. It’s designed to complement human skills rather than replace them entirely.

As we conclude this exploration of autonomous truck platooning in Canadian forestry, it’s clear that this technology represents a significant leap forward in addressing industry challenges and paving the way for a more efficient, safe, and sustainable future. The successful demonstration in northern Québec is just the beginning of what promises to be a transformative journey for the forestry industry and beyond.

For those interested in staying at the forefront of agricultural technology and innovation, we recommend exploring the cutting-edge solutions offered by Farmonaut. While not directly related to forestry, Farmonaut’s satellite-based farm management solutions represent another facet of how technology is revolutionizing resource management and sustainability in primary industries.

For developers interested in integrating advanced agricultural data into their own systems, check out Farmonaut’s API and the comprehensive API Developer Docs.

Earn With Farmonaut: Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!