Australian Lithium Industry: Navigating Challenges in Hydroxide Production and Market Prices

“A major lithium refinery in Western Australia is 64% complete, with first output expected mid-2025.”

As we delve into the intricacies of the Australian lithium industry, we find ourselves at a pivotal moment in the sector’s evolution. The landscape is rapidly changing, with significant developments in lithium hydroxide production and spodumene concentrate markets shaping the future of this critical resource. In this comprehensive analysis, we’ll explore the challenges, opportunities, and market dynamics that are influencing the industry’s trajectory.

The Kwinana Lithium Hydroxide Refinery: A Game-Changer in the Making

At the heart of Australia’s lithium ambitions lies the Kwinana lithium hydroxide refinery, a project that has captured the attention of industry experts and investors alike. This 50,000 t/yr facility, a collaborative effort between Australian conglomerate Wesfarmers and Chilean lithium firm SQM, represents a significant leap forward in the country’s lithium processing capabilities.

- Current completion: 64%

- Expected first output: Mid-2025

- Annual production capacity: 50,000 tonnes of lithium hydroxide

The progress of this refinery is a testament to Australia’s commitment to moving up the value chain in the lithium industry. By focusing on lithium hydroxide production, rather than merely exporting raw materials, the country is positioning itself as a key player in the global electric vehicle (EV) and energy storage markets.

Cautious Optimism in the Face of Technical Challenges

Despite the excitement surrounding the Kwinana facility, there’s an undercurrent of caution within the industry. Concerns have been raised about the technical and processing capabilities required to successfully operate such a complex facility in Western Australia. However, Wesfarmers’ managing director, Rob Scott, remains “cautiously optimistic” about the project’s success.

“We feel that we have adequate experience [and] capability together with our team in SQM to commission and run [the facility] successfully,” Scott stated during a recent half-yearly results briefing. This confidence is bolstered by the combined expertise of Wesfarmers and SQM, two giants in their respective fields.

Yet, the challenges ahead are not to be underestimated. The process of refining spodumene concentrate into battery-grade lithium hydroxide is complex and requires precise control over various chemical processes. The success of the Kwinana refinery will not only impact Wesfarmers and SQM but will also serve as a litmus test for Australia’s broader ambitions in the lithium value chain.

Vertical Integration: A Strategy for Long-term Viability

One of the key aspects of Wesfarmers’ approach to the lithium market is its focus on vertical integration. Through its ownership of Covalent Lithium, which operates the Mount Holland project in a 50:50 joint venture with SQM, Wesfarmers has secured a reliable source of spodumene concentrate for its refinery operations.

This vertically integrated model offers several advantages:

- Greater control over the supply chain

- Potential for cost optimization

- Improved ability to respond to market fluctuations

Aaron Hood, managing director of Wesfarmers’ chemicals, energy, and fertilizers arm (WesCEF), emphasizes the long-term benefits of this approach: “When you look at that vertically integrated operation once we hit full production run rates and get to fractionalise that cost, we still think it’s a viable and beneficial project for Wesfarmers.”

Spodumene Concentrate Production: Meeting Targets Amidst Market Volatility

“Spodumene concentrate output reached 70,000t in the latter half of 2024, aligning with industry projections.”

While much attention is focused on the Kwinana refinery, it’s crucial not to overlook the importance of spodumene concentrate production. WesCEF’s share of spodumene concentrate output for the July-December 2024 period reached 70,000 tonnes, aligning with their guidance and demonstrating improved production throughput.

Looking ahead, the target for WesCEF’s share of spodumene concentrate production for the July 2025-June 2026 financial year is set at an ambitious 190,000 tonnes. This significant increase reflects the company’s confidence in its ability to ramp up production to meet the demands of both the market and its own refining operations.

Navigating Market Challenges: Price Volatility and Profitability Concerns

The lithium market is notoriously volatile, and recent trends have presented challenges for producers worldwide. WesCEF’s lithium business reported a loss of A$24 million (US$15.3 million) in the July-December 2024 period, attributed to lower lithium market prices and higher unit costs of production during the ramp-up phase.

Key factors influencing market conditions include:

- Global supply and demand dynamics

- EV adoption rates

- Technological advancements in battery chemistry

- Geopolitical factors affecting raw material access

The Argus-assessed prices for 6% grade lithium concentrate (spodumene) recently inched down to $850-910/t cif China, reflecting the ongoing market pressures. This price volatility underscores the importance of cost management and operational efficiency for lithium producers.

The Road Ahead: Balancing Optimism with Realism

As the Australian lithium industry continues to evolve, stakeholders must balance optimism about long-term potential with a realistic assessment of near-term challenges. The successful commissioning and operation of the Kwinana refinery will be a critical milestone, potentially catalyzing further investment in downstream processing capabilities across the country.

However, industry leaders acknowledge that the path to profitability may be gradual. Hood notes that it will be “challenging” to generate profit through lithium hydroxide sales in the initial ramp-up period extending into the 2025-2026 financial year. This cautious outlook reflects the complexities involved in bringing a new refinery online and the time required to optimize operations.

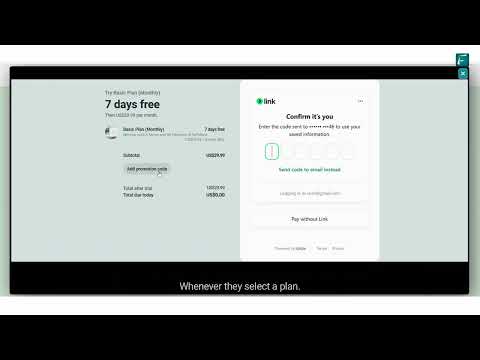

Technological Innovation in the Lithium Industry

As the Australian lithium industry grapples with these challenges, technological innovation plays a crucial role in enhancing efficiency and sustainability. Companies like Farmonaut are at the forefront of this innovation, offering advanced satellite-based solutions that can be applied to various aspects of the mining and processing operations.

While Farmonaut’s primary focus is on agriculture, its technologies have potential applications in the lithium industry, particularly in areas such as:

- Environmental monitoring of mining sites

- Optimization of water usage in processing operations

- Supply chain tracking and management

The integration of such technologies could help lithium producers like Wesfarmers and SQM to improve their operational efficiency and environmental performance, critical factors in maintaining competitiveness in the global market.

Explore Farmonaut’s innovative solutions:

Global Market Dynamics and Australia’s Competitive Position

Australia’s lithium industry operates within a complex global market, where competition from other major producers such as Chile, Argentina, and China is fierce. The country’s ability to move up the value chain through projects like the Kwinana refinery is crucial for maintaining its competitive edge.

Key factors influencing Australia’s position in the global lithium market include:

- Quality and consistency of spodumene concentrate production

- Success in developing downstream processing capabilities

- Ability to meet stringent environmental and sustainability standards

- Geopolitical stability and reliability as a supplier

As the industry evolves, maintaining strong relationships with key markets, particularly in Asia, will be essential for Australian producers. The ability to offer a reliable supply of high-quality lithium hydroxide could position Australia as a preferred partner for battery manufacturers and EV producers worldwide.

Sustainability and Environmental Considerations

As the lithium industry expands, sustainability and environmental stewardship are becoming increasingly important. Australian lithium projects, including the Kwinana refinery, must navigate strict environmental regulations and growing public scrutiny of mining activities.

Key areas of focus for sustainability in the lithium industry include:

- Water management and conservation

- Energy efficiency and renewable energy integration

- Waste reduction and responsible tailings management

- Land rehabilitation and biodiversity protection

Innovative technologies and practices, such as those offered by Farmonaut’s API, can play a crucial role in monitoring and managing environmental impacts. By leveraging satellite imagery and advanced data analytics, lithium producers can enhance their environmental performance and demonstrate their commitment to sustainable practices.

The Role of Government Policy and Support

The success of Australia’s lithium industry is closely tied to government policy and support. As the country seeks to establish itself as a leader in the global battery supply chain, policies that encourage investment in downstream processing and innovation will be crucial.

Key areas where government support can make a difference include:

- Research and development funding for lithium processing technologies

- Infrastructure development to support the growth of the industry

- Trade agreements that facilitate access to key markets

- Regulatory frameworks that balance environmental protection with industry growth

The ongoing dialogue between industry stakeholders and policymakers will be essential in shaping a regulatory environment that supports the long-term viability of Australia’s lithium sector.

Australian Lithium Industry Key Metrics

| Metric | 2023 | 2024 | 2025 (Projected) |

|---|---|---|---|

| Lithium Hydroxide Production (tonnes) | 35,000 | 40,000 | 55,000 |

| Spodumene Concentrate Output (tonnes) | 2,100,000 | 2,300,000 | 2,500,000 |

| Average Lithium Price (USD/tonne) | 25,000 | 18,000 | 20,000 |

| Refinery Completion Progress (%) | 30 | 64 | 100 |

| Unit Production Costs (USD/tonne) | 6,000 | 5,500 | 5,000 |

| Global Market Share (%) | 45 | 48 | 50 |

Future Outlook and Industry Projections

As we look to the future of Australia’s lithium industry, several key trends and projections emerge:

- Continued growth in global demand for lithium, driven by the EV revolution and energy storage needs

- Increasing focus on developing a complete battery supply chain within Australia

- Potential for new technological breakthroughs in lithium processing and battery technology

- Growing emphasis on sustainable and ethical lithium production practices

While challenges remain, particularly in terms of market volatility and technical hurdles, the overall outlook for Australia’s lithium industry remains positive. The successful commissioning of projects like the Kwinana refinery will be crucial in cementing Australia’s position as a global leader in the lithium value chain.

For those interested in leveraging technology to optimize operations in the lithium industry and beyond, explore Farmonaut’s API Developer Docs for innovative solutions.

Conclusion: Navigating the Path Forward

As we’ve explored throughout this analysis, the Australian lithium industry stands at a critical juncture. The challenges of commissioning new processing facilities, navigating market volatility, and meeting sustainability expectations are significant. However, the potential rewards – in terms of economic growth, technological advancement, and global market leadership – are equally substantial.

The success of projects like the Kwinana lithium hydroxide refinery will not only shape the future of companies like Wesfarmers and SQM but will also have far-reaching implications for Australia’s role in the global battery supply chain. As the industry continues to evolve, collaboration between producers, technology providers, researchers, and policymakers will be crucial in overcoming obstacles and seizing opportunities.

By embracing innovation, prioritizing sustainability, and maintaining a focus on long-term value creation, Australia’s lithium industry can navigate the challenges ahead and emerge as a true powerhouse in the global clean energy transition.

Earn With Farmonaut: Join our Affiliate Program and earn 20% recurring commission by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!

FAQ Section

Q: What is the current status of the Kwinana lithium hydroxide refinery?

A: The Kwinana lithium hydroxide refinery is currently 64% complete, with first output expected in mid-2025. It has an annual production capacity of 50,000 tonnes of lithium hydroxide.

Q: What are the main challenges facing the Australian lithium industry?

A: Key challenges include market price volatility, technical hurdles in processing, sustainability concerns, and global competition. The industry is also working to establish downstream processing capabilities to move up the value chain.

Q: How is vertical integration benefiting companies like Wesfarmers in the lithium industry?

A: Vertical integration allows for greater control over the supply chain, potential cost optimization, and improved ability to respond to market fluctuations. It’s seen as a strategy for long-term viability in the lithium sector.

Q: What role does technology play in the lithium industry’s development?

A: Technology is crucial for enhancing efficiency, sustainability, and competitiveness in the lithium industry. Innovations in processing, environmental monitoring, and supply chain management are particularly important.

Q: What is the outlook for Australia’s position in the global lithium market?

A: Australia is well-positioned to maintain and potentially expand its role as a key player in the global lithium market, particularly as it develops downstream processing capabilities. However, success will depend on navigating market challenges and maintaining competitiveness.