Revolutionary Ultra High-Density Baler: Transforming Iowa’s Agricultural Efficiency and Cost-Effectiveness

“Ultra high-density balers can achieve remarkable densities of up to 13.5 pounds per cubic foot, revolutionizing crop residue management.”

Welcome to the future of agriculture! In this comprehensive blog post, we’ll explore how the latest advancements in ultra high-density balers are revolutionizing farm efficiency and cost-effectiveness, particularly in Iowa’s agricultural landscape. As leaders in agricultural biosystems engineering, we’re excited to share these groundbreaking developments that promise to transform crop residue management and significantly reduce costs for farmers across the state and beyond.

The Dawn of Ultra High-Density Baling Technology

The agricultural industry is witnessing a paradigm shift with the introduction of ultra high-density balers. These innovative machines are not just an incremental improvement over traditional balers; they represent a quantum leap in baling technology. By achieving remarkable densities of up to 13.5 pounds per cubic foot, these advanced balers are setting new standards in crop residue management and hay production.

The impact of this technology extends far beyond the farm gate. From cellulosic ethanol feedstock production to particleboard manufacturing, these ultra high-density bales are opening up new possibilities and efficiencies across various industries. Let’s delve deeper into how this revolutionary equipment is transforming Iowa’s agricultural landscape.

Understanding Ultra High-Density Balers

Ultra high-density balers are the latest evolution in baling machinery. These advanced systems utilize cutting-edge technology to compress crop residue and hay into incredibly dense bales. The key features that set these balers apart include:

- Increased Compression Force: Ultra HD balers employ significantly higher hydraulic pressure to achieve unprecedented bale densities.

- Advanced Sensor Technology: Real-time density monitoring ensures consistent bale quality throughout the baling process.

- Improved Feed Systems: Enhanced crop flow mechanisms maximize baling efficiency and reduce plugging.

- Robust Construction: Reinforced frames and components withstand the increased forces involved in high-density baling.

These features combine to create bales that are not only denser but also more uniform, leading to significant improvements in transportation, storage, and overall farm economics.

The Impact on Iowa’s Agricultural Landscape

Iowa, known for its vast agricultural expanses, is at the forefront of adopting this revolutionary baling technology. The state’s farmers are experiencing transformative benefits, including:

- Reduced Transportation Costs: Heavier, denser bales mean fewer trips to transport the same amount of material, leading to substantial fuel savings.

- Improved Storage Efficiency: Ultra high-density bales occupy less space, allowing farmers to store more crop residue or hay in existing facilities.

- Enhanced Market Opportunities: The ability to produce high-density bales opens up new markets, particularly in the bioenergy and manufacturing sectors.

- Increased Labor Efficiency: With fewer bales to handle, labor requirements for bale management are significantly reduced.

These advancements are not just improving individual farm operations; they’re contributing to the overall economic vitality of Iowa’s agricultural sector.

Maximizing Bale Capacity: A Game-Changer for Farmers

One of the most significant advantages of ultra high-density balers is their ability to maximize bale capacity. Traditional balers typically produce bales with densities ranging from 8 to 10 pounds per cubic foot. In contrast, ultra HD balers can achieve densities of up to 13.5 pounds per cubic foot – a remarkable increase of over 35%.

This increased density translates to numerous benefits:

- More Material per Bale: Each bale contains significantly more crop residue or hay, reducing the total number of bales produced.

- Optimized Load Capacity: Trucks can carry more material per load, maximizing transportation efficiency.

- Extended Storage Life: Denser bales are less susceptible to moisture penetration, leading to better long-term storage quality.

- Reduced Handling Costs: Fewer bales mean less time and equipment needed for handling and stacking.

For Iowa farmers, this increased capacity is revolutionizing how they manage their hay and crop residue, leading to substantial cost savings and operational efficiencies.

Cost-Effective Hay Transportation: A New Reality

Transportation costs have long been a significant concern for hay producers and buyers. The introduction of ultra high-density balers is addressing this challenge head-on. By increasing bale density, these machines are making hay transportation more cost-effective than ever before.

Here’s how ultra HD balers are transforming hay transportation:

- Increased Payload: Trucks can now carry more hay per trip, reducing the number of trips required.

- Fuel Efficiency: Fewer trips translate to lower fuel consumption and reduced carbon emissions.

- Labor Savings: Less time spent on transportation means more time for other productive farm activities.

- Extended Market Reach: The ability to transport hay over longer distances cost-effectively opens up new market opportunities for producers.

These improvements in transportation efficiency are not just benefiting individual farmers; they’re contributing to a more sustainable and economically viable agricultural sector in Iowa and beyond.

“Class 8 balers are transforming Iowa’s agricultural efficiency, significantly reducing labor and depreciation costs for farmers.”

Efficient Crop Residue Management with Advanced Baling Technology

Crop residue management is a critical aspect of modern farming, and ultra high-density balers are revolutionizing this process. These advanced machines are enabling farmers to handle crop residues more efficiently, leading to numerous agronomic and economic benefits:

- Improved Soil Health: Efficient removal of excess residue prevents nutrient tie-up and promotes better soil structure.

- Enhanced Seeding Efficiency: Cleaner fields allow for more precise seed placement and improved germination rates.

- Reduced Tillage Requirements: Effective residue management can lead to reduced tillage needs, saving time and fuel.

- Value-Added Byproducts: High-density crop residue bales can be sold for various industrial applications, creating an additional revenue stream.

By leveraging ultra high-density baling technology, Iowa farmers are turning what was once considered a waste product into a valuable resource, all while improving their farm’s overall productivity.

The Role of Agricultural Biosystems Engineering in Baler Innovation

The development of ultra high-density balers is a testament to the advancements in agricultural biosystems engineering. This interdisciplinary field combines principles of engineering, biology, and agriculture to create innovative solutions for farming challenges. In the context of baling technology, agricultural biosystems engineers have made significant contributions:

- Material Science: Developing stronger, more durable materials to withstand the increased pressures of high-density baling.

- Hydraulic Systems: Designing more efficient and powerful hydraulic systems to achieve higher compression forces.

- Sensor Technology: Integrating advanced sensors for real-time monitoring and adjustment of baling parameters.

- Automation: Implementing smart systems that optimize baler performance based on crop conditions and desired bale characteristics.

These engineering advancements have not only improved baler performance but have also contributed to increased safety, reduced maintenance requirements, and extended equipment lifespan.

Cellulosic Ethanol Feedstock: Powering the Future

The advent of ultra high-density balers is having a profound impact on the cellulosic ethanol industry. These advanced machines are transforming how feedstock is harvested, stored, and transported, making cellulosic ethanol production more economically viable than ever before.

Key benefits for the cellulosic ethanol industry include:

- Increased Feedstock Density: Higher density bales reduce transportation and storage costs for ethanol plants.

- Improved Feedstock Quality: Denser bales are less susceptible to degradation during storage, maintaining higher quality for processing.

- Year-Round Supply: Efficient storage of high-density bales allows for a more consistent supply of feedstock throughout the year.

- Reduced Processing Costs: Uniform, high-density bales can lead to more efficient processing at ethanol plants.

As Iowa continues to be a leader in ethanol production, the adoption of ultra high-density baling technology is positioning the state at the forefront of the cellulosic ethanol revolution.

Reducing Farm Storage Costs Through Innovation

Storage costs have long been a significant expense for farmers, particularly when dealing with large volumes of hay or crop residues. Ultra high-density balers are addressing this challenge by dramatically increasing the amount of material that can be stored in a given space.

Here’s how these innovative balers are helping reduce farm storage costs:

- Increased Storage Density: More material can be stored in existing facilities, reducing the need for additional storage infrastructure.

- Improved Stacking Efficiency: Uniform, high-density bales stack more securely, allowing for higher stacks and better space utilization.

- Reduced Spoilage: Denser bales are less prone to moisture penetration, leading to less spoilage during storage.

- Flexible Storage Options: The durability of high-density bales allows for more outdoor storage options, reducing the need for covered storage in some cases.

By maximizing storage efficiency, farmers can defer or avoid costly expansions of storage facilities, leading to significant long-term cost savings.

Innovative Farm Equipment: Beyond Baling

While ultra high-density balers are at the forefront of this agricultural revolution, they are part of a broader trend of innovative farm equipment transforming Iowa’s agricultural landscape. Other cutting-edge technologies complementing these advanced balers include:

- Precision Planting Systems: Enhancing seed placement accuracy and improving crop yields.

- Autonomous Tractors: Reducing labor requirements and increasing operational efficiency.

- Drone Technology: Providing real-time crop monitoring and precision application of inputs.

- Smart Irrigation Systems: Optimizing water usage based on real-time soil moisture data.

These technologies, when combined with ultra high-density baling, are creating a synergistic effect that is propelling Iowa’s agriculture into a new era of efficiency and sustainability.

Maximizing Agricultural Bale Density: Techniques and Best Practices

Achieving maximum bale density with ultra high-density balers requires more than just advanced machinery; it involves a combination of proper techniques and best practices. Here are some key strategies for maximizing agricultural bale density:

- Optimal Moisture Content: Baling at the right moisture level (typically 15-20% for hay) ensures maximum compression without risking mold or heat damage.

- Proper Windrow Formation: Creating uniform windrows allows for consistent feeding into the baler, resulting in more even density throughout the bale.

- Baler Speed Adjustment: Matching baler speed to crop conditions and desired density is crucial for achieving optimal results.

- Regular Maintenance: Keeping the baler in top condition, particularly the compression components, ensures consistent high-density performance.

- Operator Training: Skilled operators who understand the nuances of high-density baling can significantly impact the quality and consistency of bales produced.

By implementing these techniques, Iowa farmers can fully leverage the capabilities of their ultra high-density balers, maximizing both efficiency and profitability.

The Economic Impact: Reducing Labor and Depreciation Costs

The adoption of ultra high-density balers is having a profound economic impact on Iowa’s farms, particularly in terms of reducing labor and depreciation costs. Here’s how these advanced machines are contributing to improved farm economics:

- Reduced Labor Requirements: Fewer bales to handle means less time spent on baling, stacking, and transportation tasks.

- Increased Labor Efficiency: Operators can cover more acreage in less time, allowing for more efficient use of labor resources.

- Lower Equipment Depreciation: While ultra HD balers may have a higher initial cost, their increased efficiency often results in fewer machine hours per ton of material processed, potentially extending equipment life.

- Reduced Fuel Costs: More efficient baling and transportation processes lead to lower overall fuel consumption.

These cost reductions are helping Iowa farmers improve their bottom line, making their operations more resilient in the face of market fluctuations and economic challenges.

Comparative Analysis: Ultra High-Density Balers vs. Traditional Balers

To fully appreciate the impact of ultra high-density balers, it’s essential to compare them directly with traditional baling systems. The following table provides a comprehensive comparison:

| Characteristic | Traditional Balers | Ultra High-Density Balers |

|---|---|---|

| Bale Density (lbs/cubic foot) | 8-10 | Up to 13.5 |

| Estimated Cost Savings (%) | Baseline | 20-30% |

| Labor Efficiency (man-hours/ton) | 0.5-0.7 | 0.3-0.4 |

| Transportation Capacity (bales/truck) | 30-36 | 40-48 |

| Storage Efficiency (% space saved) | Baseline | 25-35% |

| Applications | Hay, straw | Hay, straw, cellulosic ethanol feedstock, particleboard manufacturing |

This comparison clearly illustrates the significant advantages offered by ultra high-density balers across various operational and economic metrics.

The Future of Baling Technology: What’s Next?

As we look to the future, the evolution of baling technology shows no signs of slowing down. Here are some potential developments we might see in the coming years:

- AI-Driven Baling: Artificial intelligence could optimize baling parameters in real-time based on crop conditions and desired outcomes.

- Integrated Biomass Analysis: On-the-go analysis of bale composition could provide instant feedback on feed quality or biofuel potential.

- Self-Driving Balers: Autonomous baling systems could operate 24/7, maximizing efficiency during optimal baling conditions.

- Advanced Materials: New, stronger materials could allow for even higher bale densities without increasing machine size or weight.

These advancements promise to further revolutionize baling operations, continuing to improve efficiency and profitability for Iowa’s farmers.

Complementary Technologies: Enhancing Ultra High-Density Baling

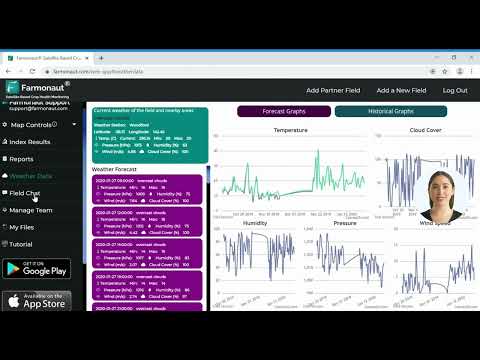

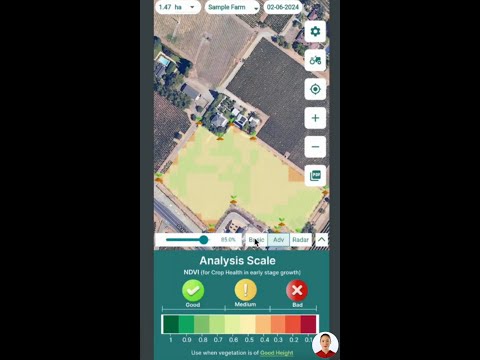

While ultra high-density balers are transforming Iowa’s agricultural landscape, their impact is further amplified when combined with other cutting-edge technologies. One such complementary solution is Farmonaut’s precision agriculture platform.

Farmonaut offers a suite of satellite-based farm management tools that can enhance the efficiency of baling operations:

- Crop Health Monitoring: Real-time satellite imagery helps farmers optimize harvest timing for maximum yield and quality.

- Weather Forecasting: Accurate weather predictions enable better planning of baling activities, ensuring optimal moisture content.

- Field Mapping: Precise field mapping assists in planning efficient baling routes and identifying areas that may require special attention.

By integrating Farmonaut’s technology with ultra high-density baling practices, Iowa farmers can further optimize their operations, leading to even greater efficiency and cost savings.

Explore Farmonaut’s solutions:

Conclusion: Embracing the Future of Agriculture

The revolution in ultra high-density baling technology represents a significant leap forward for Iowa’s agricultural sector. By dramatically increasing bale density, improving transportation efficiency, and reducing storage costs, these innovative machines are helping farmers across the state to optimize their operations and improve their bottom line.

As we’ve explored throughout this blog post, the benefits of ultra high-density balers extend far beyond the farm gate. From supporting the growth of the cellulosic ethanol industry to enabling more sustainable farming practices, these machines are playing a crucial role in shaping the future of agriculture.

For Iowa farmers looking to stay competitive in an ever-evolving industry, embracing these technological advancements is not just an option—it’s a necessity. By combining ultra high-density baling technology with complementary solutions like Farmonaut’s precision agriculture platform, farmers can position themselves at the forefront of agricultural innovation, ensuring their operations remain efficient, profitable, and sustainable for years to come.

As we look to the future, it’s clear that the agricultural landscape will continue to evolve. By staying informed about the latest technological advancements and being willing to adapt, Iowa’s farmers can ensure they remain leaders in this new era of smart, efficient, and sustainable agriculture.

FAQ Section

- What is an ultra high-density baler?

An ultra high-density baler is an advanced agricultural machine that compresses crop residues or hay into extremely dense bales, achieving densities of up to 13.5 pounds per cubic foot. - How do ultra high-density balers benefit farmers?

These balers reduce transportation and storage costs, improve labor efficiency, and open up new market opportunities for agricultural products. - Are ultra high-density balers suitable for all types of crops?

While they excel with many crop types, they are particularly effective for hay, straw, and certain crop residues used in cellulosic ethanol production. - How do ultra high-density balers impact the cellulosic ethanol industry?

By producing denser, more uniform bales, these balers improve the efficiency of feedstock transportation and storage for ethanol plants, making cellulosic ethanol production more economically viable. - What maintenance is required for ultra high-density balers?

Regular maintenance includes checking hydraulic systems, lubricating moving parts, and inspecting compression components. Specific requirements may vary by manufacturer.