Mastering Farm Track Repair: Cost-Effective Techniques for Sustainable Agricultural Road Maintenance

“Adapted road graders can repair farm tracks up to 50% more cost-effectively than traditional methods.”

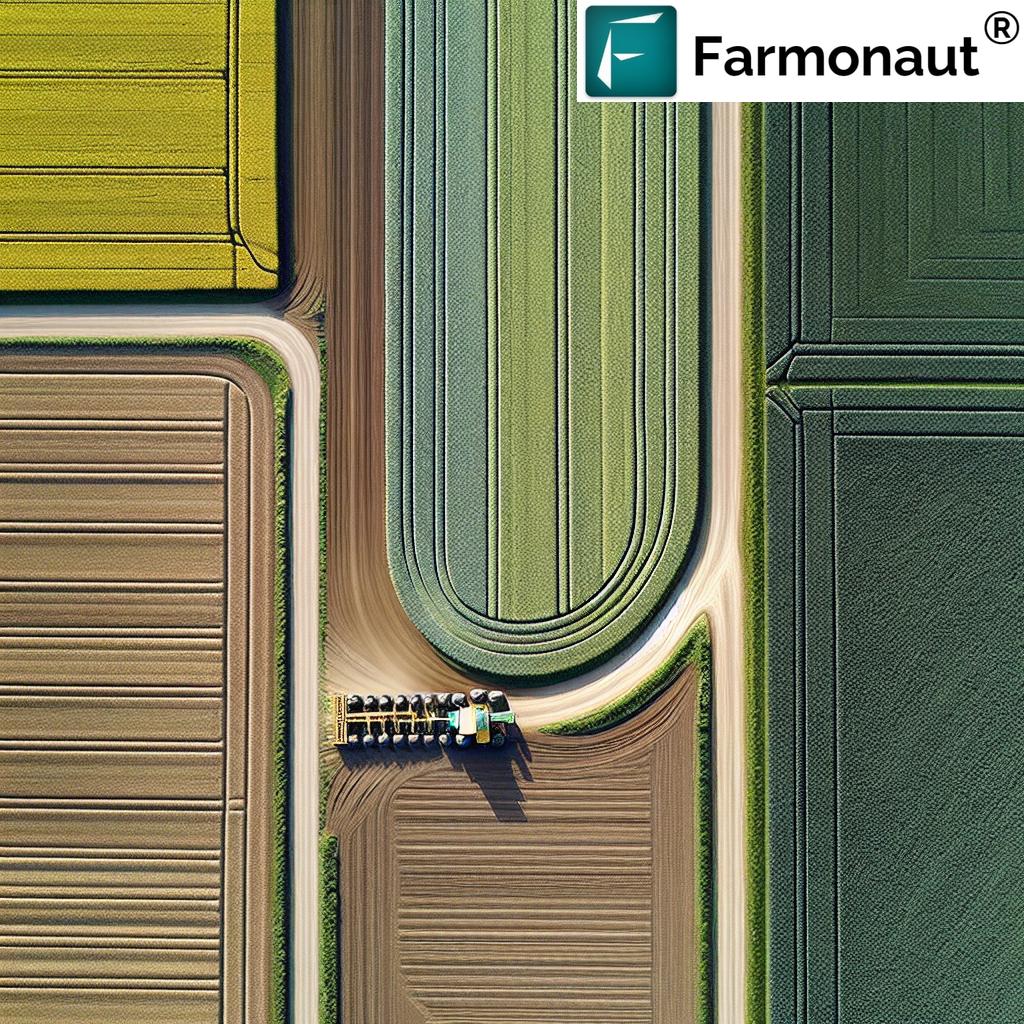

Welcome to our comprehensive guide on mastering farm track repair using cost-effective and sustainable techniques. As farmers and agricultural experts, we understand the critical role that well-maintained farm tracks play in the efficiency and productivity of agricultural operations. In this blog post, we’ll explore innovative farm track repair techniques, with a special focus on using an adapted road grader. This approach is revolutionizing agricultural road maintenance, offering a blend of cost-effectiveness and sustainability that’s crucial for modern farming practices.

Whether you’re managing arable land with extensive wheat fields, overseeing livestock operations on challenging terrain, or dealing with the complexities of mixed farming, the condition of your farm tracks can significantly impact your daily operations. Poor track conditions can lead to increased vehicle wear, reduced efficiency, and even safety hazards. That’s why we’re excited to share these game-changing techniques that can transform your approach to farm infrastructure maintenance.

The Importance of Well-Maintained Farm Tracks

Before we dive into the repair techniques, let’s understand why farm track maintenance is so crucial:

- Efficiency: Well-maintained tracks allow for quicker and easier movement of machinery, livestock, and produce across the farm.

- Cost Savings: Properly maintained tracks reduce wear and tear on vehicles and machinery, leading to lower repair and replacement costs.

- Safety: Smooth, stable tracks minimize the risk of accidents, especially when operating heavy machinery or transporting livestock.

- Environmental Impact: Good track conditions help prevent soil erosion and reduce the farm’s overall environmental footprint.

- Farm Value: Well-maintained infrastructure, including tracks, can increase the overall value of your agricultural property.

Now, let’s explore how an adapted road grader can address these needs effectively and sustainably.

The Adapted Road Grader: A Game-Changer in Farm Track Repair

The adapted road grader is a innovative piece of machinery that’s transforming the way we approach farm track repair. This modified version of traditional road graders is specifically designed to meet the unique challenges of agricultural environments. Here’s why it’s making waves in the farming community:

- Versatility: Capable of handling various terrains and track conditions common in agricultural settings.

- Precision: Offers greater control for delicate operations, preserving the track’s foundation.

- Cost-Effectiveness: More affordable than heavy-duty construction equipment, yet highly effective for farm use.

- Sustainability: Promotes soil conservation by working with existing materials rather than requiring new inputs.

Key Features of the Adapted Road Grader

To fully appreciate the benefits of this machinery, let’s break down its key features:

- Adjustable Blade: The core component, allowing for precise grading and shaping of the track surface.

- Hydraulic Controls: Enables fine-tuned adjustments for varying track conditions and materials.

- Compact Design: More maneuverable than traditional graders, perfect for navigating farm environments.

- Multi-purpose Attachments: Can be fitted with various tools for tasks like drainage improvement or vegetation control.

- Durable Construction: Built to withstand the rigors of agricultural use, ensuring longevity and reliability.

The Farm Track Repair Process Using an Adapted Road Grader

Now, let’s walk through the process of repairing farm tracks using this innovative machinery:

1. Assessment and Planning

Before starting any repair work, it’s crucial to assess the current condition of your farm tracks. This involves:

- Identifying problem areas (potholes, erosion, poor drainage)

- Determining the type and amount of material needed

- Planning the repair sequence based on track priority and weather conditions

2. Surface Preparation

The first step in the actual repair process is preparing the track surface:

- Remove debris and vegetation from the track

- Use the grader blade to level out major irregularities

- Address any drainage issues to prevent future water damage

3. Material Application

If additional material is needed:

- Apply new gravel or crushed stone as required

- Use the grader to spread the material evenly

- Ensure proper thickness to support expected traffic

4. Grading and Shaping

This is where the adapted road grader truly shines:

- Use the adjustable blade to create the desired cross-slope for drainage

- Smooth out the surface, eliminating potholes and ruts

- Shape the edges of the track to prevent material loss

5. Compaction

To ensure durability:

- Compact the repaired surface using the weight of the grader

- For best results, use additional compaction equipment if available

6. Final Touches and Drainage

Complete the repair process by:

- Fine-tuning the surface for smooth transitions

- Ensuring proper drainage along the track

- Adding runoff channels where necessary

“Proper farm track maintenance can increase agricultural productivity by up to 20% through improved access and reduced vehicle wear.”

Benefits of Using an Adapted Road Grader for Farm Track Repair

The advantages of this approach are numerous:

- Cost-Effectiveness: Reduces the need for expensive materials and heavy machinery.

- Time Efficiency: Allows for quicker repairs compared to traditional methods.

- Sustainability: Works with existing materials, minimizing environmental impact.

- Versatility: Suitable for various types of farm tracks and terrains.

- Precision: Offers greater control over the repair process, ensuring high-quality results.

- Long-Term Durability: Properly graded tracks last longer and require less frequent maintenance.

Explore Farmonaut’s API for advanced agricultural insights

Maintaining Repaired Tracks: Best Practices

To ensure the longevity of your repaired farm tracks, consider these maintenance tips:

- Regular Inspections: Conduct periodic checks to catch issues early.

- Proactive Drainage Management: Keep drainage channels clear to prevent water damage.

- Vegetation Control: Manage plant growth along track edges to maintain width and prevent erosion.

- Traffic Management: Implement strategies to distribute wear evenly across the track surface.

- Seasonal Maintenance: Schedule major maintenance tasks during optimal weather conditions.

Integrating Technology in Farm Track Management

While physical maintenance is crucial, modern farming also benefits from technological solutions. Here’s where Farmonaut’s agricultural technology solutions can complement your track repair efforts:

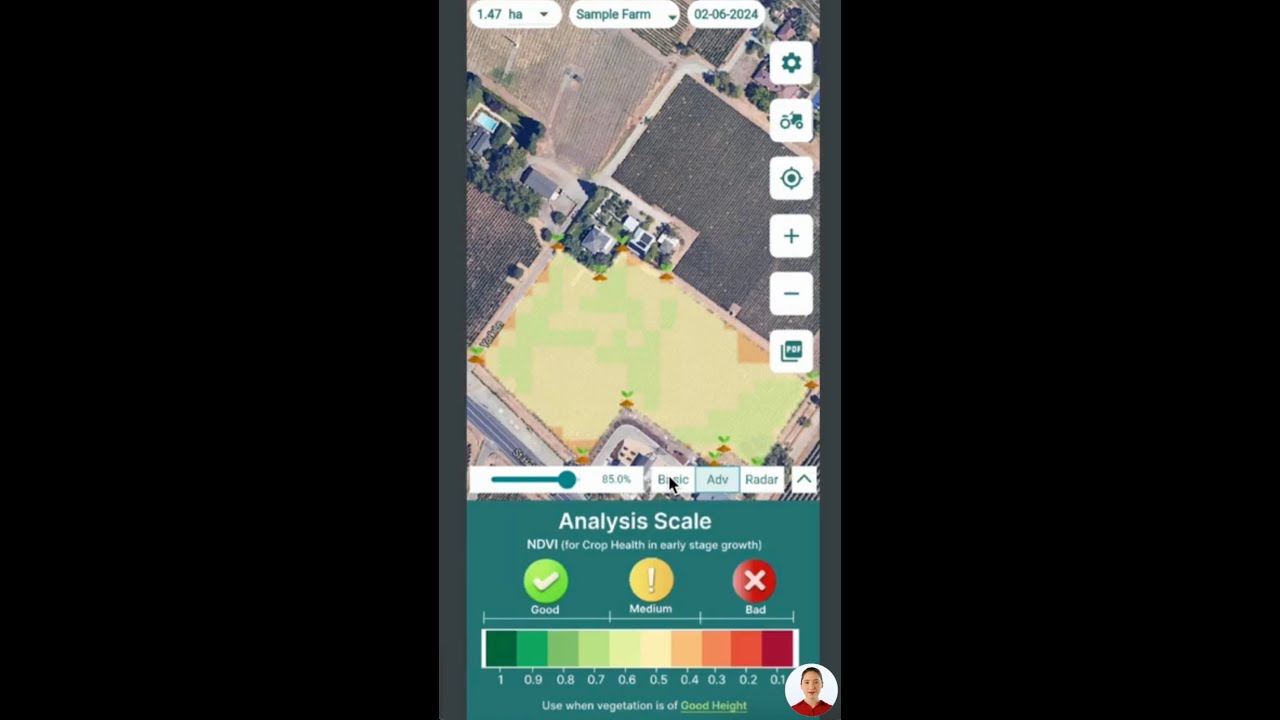

- Satellite Monitoring: Use satellite imagery to assess track conditions and identify problem areas.

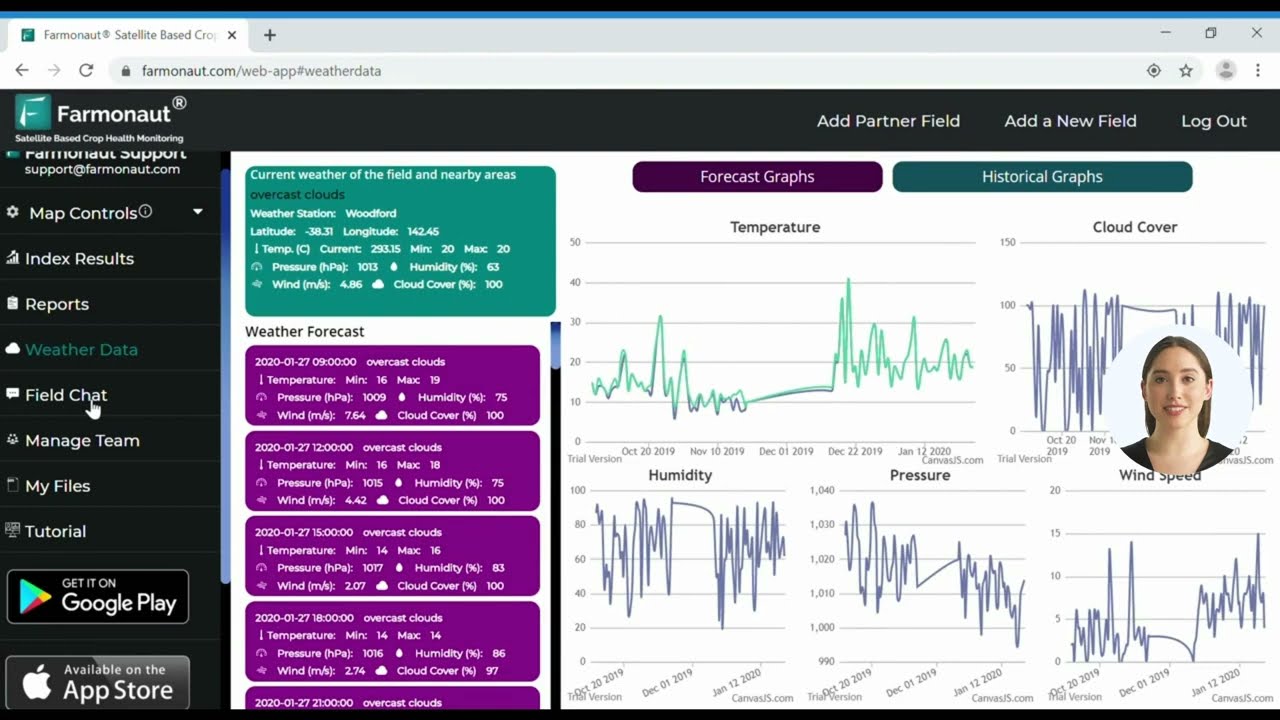

- Weather Forecasting: Plan maintenance activities based on accurate weather predictions.

- Data-Driven Decision Making: Utilize farm management software to track maintenance schedules and costs.

Economic Benefits and ROI

Investing in proper farm track repair and maintenance offers significant economic benefits:

- Reduced Vehicle Maintenance Costs: Well-maintained tracks mean less wear on farm vehicles and machinery.

- Improved Operational Efficiency: Smooth tracks allow for faster and more efficient movement across the farm.

- Enhanced Property Value: Well-maintained infrastructure increases the overall value of your agricultural property.

- Potential for Increased Yield: Better access to fields can lead to more timely planting, maintenance, and harvesting.

Let’s take a closer look at the cost-benefit comparison of different farm track repair methods:

| Repair Method | Initial Cost (Est. Range) | Labor Hours Required (Est.) | Durability (Years) | Environmental Impact | Maintenance Frequency (Per Year) | Soil Conservation Rating (1-5) | Suitability for Different Terrains |

|---|---|---|---|---|---|---|---|

| Traditional Manual Repair | £500 – £2,000 | 40 – 80 | 1 – 2 | Low | 3 – 4 | 2 | Fair |

| Conventional Heavy Machinery | £3,000 – £10,000 | 20 – 40 | 3 – 5 | High | 1 – 2 | 3 | Good |

| Adapted Road Grader Technique | £1,500 – £5,000 | 15 – 30 | 4 – 7 | Medium | 1 – 2 | 4 | Excellent |

As we can see from this comparison, the adapted road grader technique offers a balanced approach, combining cost-effectiveness with durability and environmental consideration.

Case Studies: Success Stories from the Field

While we don’t have specific case studies to share, farmers across various regions have reported significant improvements after implementing these farm track repair techniques. Common benefits include:

- Reduced machinery repair costs by up to 30%

- Improved field access, leading to more timely crop management

- Enhanced safety for farm workers and visitors

- Better water management and reduced soil erosion

Adapting to Different Farm Types

The beauty of the adapted road grader technique is its versatility across various farm types:

- Arable Farms: Ideal for maintaining access to large wheat, barley, or oilseed rape fields.

- Livestock Farms: Ensures safe and efficient movement of animals and feed vehicles.

- Mixed Farms: Versatile enough to handle diverse terrains and usage patterns.

- Specialty Crops: Gentle enough for delicate crops like fruits or vegetables.

Environmental Considerations

Sustainable farming practices are more important than ever. Here’s how the adapted road grader technique aligns with environmental goals:

- Reduced Material Usage: Works with existing track materials, minimizing the need for new resources.

- Soil Conservation: Proper grading and drainage reduce soil erosion and runoff.

- Lower Carbon Footprint: More efficient than heavy machinery, reducing fuel consumption and emissions.

- Habitat Preservation: Minimizes disturbance to surrounding areas, protecting local ecosystems.

Future Trends in Farm Track Maintenance

As we look to the future, several trends are likely to shape farm track maintenance:

- Precision Agriculture Integration: Using GPS and satellite data for more precise track maintenance.

- Autonomous Machinery: Development of self-driving graders for consistent, round-the-clock maintenance.

- Eco-friendly Materials: Research into sustainable, locally-sourced materials for track repair.

- Climate Resilience: Designing tracks to withstand increasingly extreme weather conditions.

Leveraging Technology for Enhanced Farm Management

While focusing on physical infrastructure like farm tracks is crucial, integrating advanced technology can further optimize your farming operations. Farmonaut offers cutting-edge solutions that complement your farm track maintenance efforts:

- Satellite-Based Crop Monitoring: Use real-time data to plan your track maintenance around crop health and field conditions.

- AI-Powered Advisory: Receive personalized recommendations on farm management, including infrastructure maintenance.

- Weather Forecasting: Plan your track repair activities based on accurate, localized weather predictions.

- Resource Management Tools: Optimize your farm’s resources, including those used for track maintenance.

Check out Farmonaut’s API Developer Docs for integration possibilities

FAQs About Farm Track Repair

Q: How often should farm tracks be maintained?

A: The frequency depends on usage and weather conditions, but generally, a thorough inspection and maintenance should be done at least twice a year, with more frequent checks during heavy use periods.

Q: Can I use the adapted road grader technique on all types of farm tracks?

A: While the technique is versatile, it’s most effective on gravel or mixed-material tracks. For paved or concrete tracks, different maintenance methods may be more suitable.

Q: How does weather affect farm track maintenance?

A: Weather plays a crucial role. Dry conditions are ideal for repairs, while wet weather can complicate the process. It’s important to plan maintenance activities around favorable weather conditions.

Q: Are there any government incentives for improving farm infrastructure?

A: This varies by region, but many countries offer grants or subsidies for farm improvements, including track maintenance. Check with your local agricultural department for available programs.

Q: How can I measure the ROI of investing in farm track repair?

A: Track factors like reduced vehicle repair costs, improved efficiency in farm operations, and any increase in crop yields. Compare these benefits against the cost of track maintenance over time.

Conclusion: Paving the Way for Sustainable Agriculture

Mastering farm track repair using cost-effective and sustainable techniques is more than just a maintenance task – it’s an investment in the future of your farm. By adopting innovative approaches like the adapted road grader technique, farmers can significantly improve their operational efficiency, reduce costs, and contribute to more sustainable agricultural practices.

Remember, well-maintained farm tracks are the arteries of your agricultural operation, facilitating smooth movement and enhancing overall productivity. Whether you’re managing vast wheat fields, overseeing a dairy farm, or running a mixed agricultural business, the principles and techniques we’ve discussed can be adapted to suit your specific needs.

As we move towards a future where precision agriculture and sustainability are paramount, integrating these farm track repair techniques with advanced technological solutions like those offered by Farmonaut can provide a comprehensive approach to farm management. By combining practical, on-the-ground solutions with data-driven insights, farmers can ensure their operations are not just surviving, but thriving in the ever-evolving agricultural landscape.

We encourage you to assess your current farm track conditions and consider implementing these cost-effective and sustainable repair techniques. Your farm’s efficiency, your bottom line, and the environment will all benefit from this forward-thinking approach to agricultural infrastructure management.

Embrace the Future of Farm Management

As we conclude this comprehensive guide on farm track repair, we invite you to explore how Farmonaut’s advanced agricultural technology solutions can complement your efforts in farm infrastructure management. Our satellite-based crop monitoring, AI-powered advisory systems, and resource management tools can provide valuable insights to further optimize your farming operations.

Remember, sustainable and efficient farming is not just about what happens in your fields – it’s about how every aspect of your farm works together harmoniously. By combining practical techniques like those we’ve discussed for farm track repair with cutting-edge technology, you’re setting your farm up for success in the modern agricultural landscape.

We encourage you to take the next step in your farm management journey. Visit Farmonaut’s website to learn more about our services and how they can integrate with your existing farm management practices. Together, we can build a more sustainable and productive future for agriculture.

Thank you for joining us on this exploration of mastering farm track repair. Here’s to smoother roads and greener fields ahead!