Ohio’s Groundbreaking Plastic Waste Recycling Technology: Revolutionizing Sustainable Waste Management and Decarbonization

In the realm of environmental sustainability and waste management, we are witnessing a groundbreaking revolution. Researchers at The Ohio State University have developed an innovative plastic waste recycling technology that promises to transform how we handle municipal solid waste while simultaneously contributing to the decarbonization of the chemical industry. This cutting-edge approach not only addresses the pressing issue of plastic pollution but also offers a sustainable solution for efficient waste management on a global scale.

“Ohio’s new plastic recycling technology produces syngas with 90% purity, surpassing conventional techniques.”

The Urgent Need for Innovative Waste Management Solutions

As we delve into this revolutionary technology, it’s crucial to understand the context that necessitates such innovation. The Environmental Protection Agency reports that in 2018 alone, the United States generated a staggering 35.7 million tons of plastic waste. A significant portion of this ended up in municipal solid waste streams, highlighting the inadequacy of traditional waste management methods like landfilling and incineration.

Plastics, notorious for their resistance to decomposition, pose a severe threat to our environment. The accumulation of plastic waste in our oceans, landfills, and ecosystems has reached critical levels, demanding urgent and effective solutions. This is where Ohio’s groundbreaking plastic waste recycling technology steps in, offering a beacon of hope in our fight against plastic pollution.

Unveiling the Revolutionary Chemical Looping Technology

At the heart of this innovative approach lies a method known as chemical looping. This process, spearheaded by doctoral student Ishani Karki Kudva and her team at Ohio State University, has demonstrated remarkable efficiency in generating high-quality syngas from various waste materials, including plastics, paper, and food waste.

- Superior Syngas Production: The technology produces syngas with approximately 90% purity, a significant improvement over the 80-85% purity achieved by commercial processes.

- Rapid Processing: This high-quality syngas is produced in just a few minutes, opening doors to new industrial applications.

- Multi-Waste Processing: Unlike earlier technologies limited to processing either biomass or plastics, this method can handle multiple waste types simultaneously, optimizing the conversion process.

Explore Farmonaut’s innovative agricultural solutions

The Two-Reactor System: A Closer Look

The innovative approach employs a sophisticated two-reactor system:

- Moving Bed Reducer: This reactor breaks down waste using oxygen supplied through metal oxide material.

- Fluidized Bed Combustor: This component replenishes the lost oxygen, facilitating material regeneration.

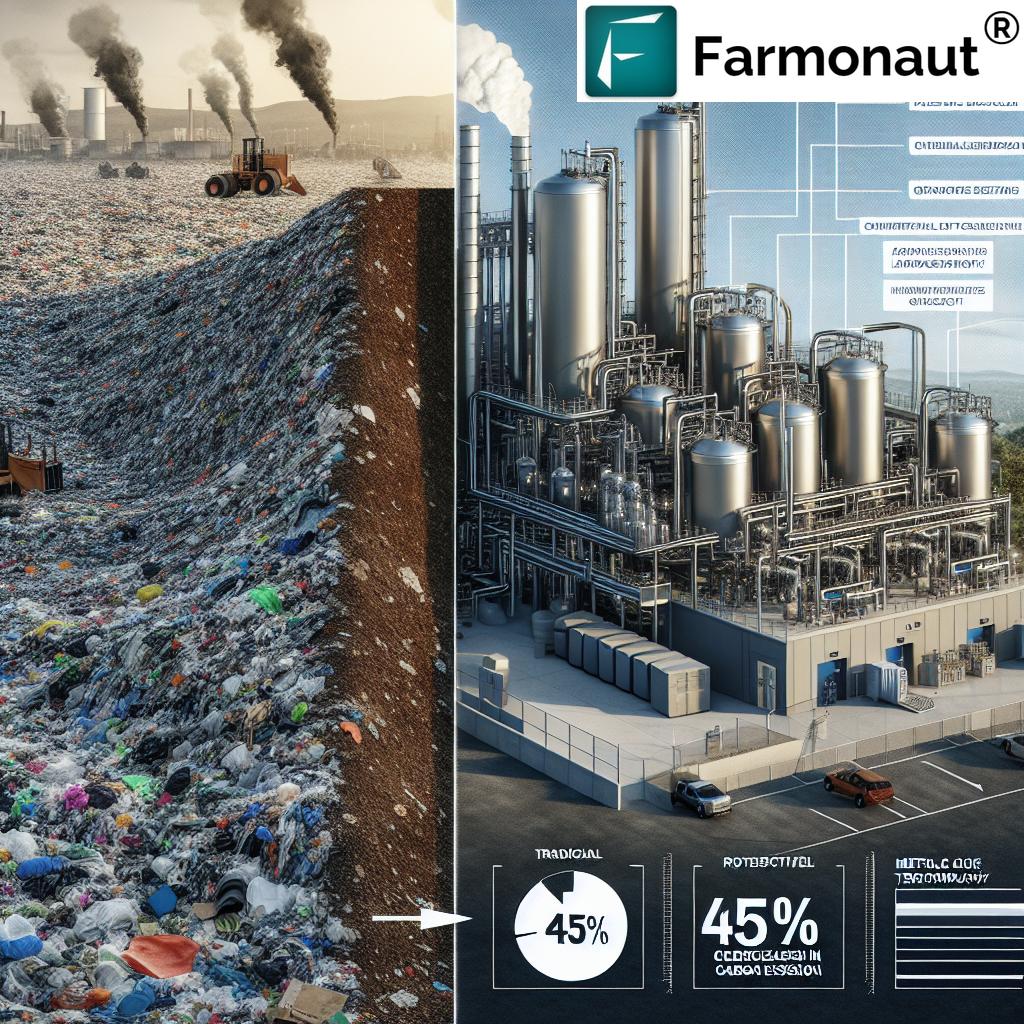

This dual-reactor setup is the key to the system’s exceptional performance. It operates 45% more efficiently than conventional methods and produces syngas that is 10% cleaner. Such advancements not only enhance waste management processes but also make them significantly safer for the environment.

“The groundbreaking waste management process operates 45% more efficiently and could reduce carbon emissions by up to 45%.”

Environmental Impact and Carbon Emission Reduction

One of the most compelling aspects of this new technology is its potential to significantly reduce carbon emissions. Research indicates that implementing this innovative process could lead to a reduction in carbon emissions by up to 45% compared to current industrial practices. This aligns perfectly with the growing emphasis on sustainable industrial practices and the urgent need to address climate change.

Shekhar Shinde, a co-author of the study and fellow doctoral student at Ohio State, emphasizes the shift towards decarbonization research in the chemical sector. Traditional chemical production methods are increasingly scrutinized for their environmental impact, making this technology a timely and crucial development.

Syngas: The Versatile Product of Waste Conversion

At the core of this technological breakthrough is the production of high-quality syngas. But what exactly is syngas, and why is it so valuable?

- Composition: Syngas, short for synthesis gas, is primarily a mixture of carbon monoxide and hydrogen.

- Versatility: It serves as a key component in the production of various chemicals and fuels.

- Applications: Syngas is crucial in manufacturing formaldehyde, methanol, and other essential industrial chemicals.

The ability to produce such high-purity syngas from waste materials represents a significant leap towards a circular economy, where waste is transformed into valuable resources.

Explore Farmonaut’s API for agricultural data integration

Comparative Analysis: New Technology vs. Conventional Methods

To fully appreciate the significance of Ohio’s new plastic waste recycling technology, let’s compare it with existing waste management methods:

| Technology Type | Waste Types Processed | Syngas Purity (%) | Efficiency Improvement (%) | Potential Carbon Emission Reduction (%) | Sustainable Benefits |

|---|---|---|---|---|---|

| Ohio’s New Chemical Looping Technology | Plastic, Paper, Food Waste | 90 | 45 | Up to 45 | Multi-waste processing, High-quality syngas production, Significant carbon reduction |

| Conventional Waste-to-Energy Methods | Mixed Municipal Waste | 80-85 | Baseline | 10-20 | Energy recovery, Waste volume reduction |

| Traditional Recycling Processes | Segregated Waste Streams | N/A | Varies | 20-30 | Material recovery, Resource conservation |

This comparison clearly illustrates the superior performance of the new technology in terms of syngas purity, efficiency, and potential carbon emission reduction.

The Road to Commercialization and Future Prospects

While the research at Ohio State University marks a significant breakthrough, the journey towards widespread implementation is ongoing. The team’s future plans include:

- Expanding the system’s application to include municipal solid waste from recycling centers

- Conducting long-term testing to assess market potential

- Collaborating with industry partners to scale up the technology

The potential impact of this technology extends far beyond waste management. By providing a sustainable alternative to fossil fuel-based chemical production, it paves the way for a greener chemical industry.

Access Farmonaut’s API Developer Docs for advanced integration

Global Implications and Environmental Impact

The development of this plastic waste recycling technology in Ohio has far-reaching implications for global waste management and environmental conservation efforts:

- Addressing the Plastic Crisis: With millions of tons of plastic waste generated annually worldwide, this technology offers a viable solution to reduce plastic pollution in our oceans and landfills.

- Promoting Circular Economy: By converting waste into valuable resources, the technology supports the transition towards a more circular and sustainable economic model.

- Reducing Dependence on Fossil Fuels: The production of high-quality syngas from waste materials could significantly reduce our reliance on fossil fuels for chemical production.

- Combating Climate Change: The potential 45% reduction in carbon emissions aligns with global efforts to mitigate climate change and achieve carbon neutrality.

The Role of Innovation in Sustainable Waste Management

The groundbreaking work at Ohio State University underscores the crucial role of innovation in addressing complex environmental challenges. As we continue to grapple with the global waste crisis, technologies like this chemical looping process offer hope for a more sustainable future.

Key aspects of this innovative approach include:

- Interdisciplinary Collaboration: The research team’s diverse expertise in chemical, biomolecular, and environmental engineering was crucial to the project’s success.

- Adaptive Technology: The ability to process multiple waste types simultaneously makes this technology highly adaptable to various waste management scenarios.

- Efficiency-Driven Design: The focus on improving efficiency and purity in syngas production showcases the potential for technological advancements to drive significant environmental benefits.

Challenges and Considerations

While the potential of this new technology is immense, it’s important to consider the challenges that may arise in its implementation:

- Scalability: Transitioning from laboratory success to large-scale industrial application will require significant investment and engineering expertise.

- Infrastructure Adaptation: Existing waste management facilities may need substantial modifications to incorporate this new technology.

- Regulatory Compliance: As with any new industrial process, ensuring compliance with environmental regulations and safety standards will be crucial.

- Public Acceptance: Educating the public about the benefits of this technology and addressing any concerns will be essential for its widespread adoption.

The Broader Context: Sustainable Industrial Practices

Ohio’s groundbreaking plastic waste recycling technology is part of a larger movement towards sustainable industrial practices. This shift is driven by several factors:

- Growing Environmental Awareness: Increased public consciousness about environmental issues is pushing industries to adopt greener technologies.

- Regulatory Pressures: Stricter environmental regulations are forcing companies to seek innovative solutions for waste management and emissions reduction.

- Economic Incentives: As the costs of traditional waste disposal methods rise, technologies that offer both environmental and economic benefits become more attractive.

- Technological Advancements: Breakthroughs in fields like materials science and chemical engineering are opening new possibilities for sustainable industrial processes.

Discover Farmonaut’s web application for advanced farm management

The Future of Waste Management and Chemical Production

As we look to the future, the implications of this technology extend far beyond waste management. The ability to efficiently convert waste into high-quality syngas opens up new possibilities for the chemical industry:

- Greener Chemical Production: The use of waste-derived syngas could significantly reduce the carbon footprint of chemical manufacturing processes.

- Energy Recovery: Excess syngas could be used for energy generation, further enhancing the efficiency of industrial operations.

- Waste Valorization: This technology transforms waste from a problem into a valuable resource, potentially revolutionizing our approach to waste management.

- Circular Economy: By closing the loop between waste and production, this technology supports the transition towards a more circular and sustainable economic model.

Collaborative Efforts and Research Support

The success of this groundbreaking research is a testament to the power of collaborative scientific efforts. The study, published in the journal Energy and Fuels, involved contributions from several researchers:

- Ishani Karki Kudva (lead researcher)

- Shekhar Shinde

- Rushikesh K. Joshi

- Tanay A. Jawdekar

The research received support from Buckeye Precious Plastic, highlighting the importance of industry-academia partnerships in driving innovation.

Earn With Farmonaut: Join our Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!

Conclusion: A Step Towards a Sustainable Future

Ohio’s groundbreaking plastic waste recycling technology represents a significant leap forward in our quest for sustainable waste management and industrial decarbonization. By efficiently converting multiple types of waste into high-quality syngas, this innovative process not only addresses the pressing issue of plastic pollution but also paves the way for greener chemical production.

As we continue to face global environmental challenges, technologies like this offer hope and tangible solutions. The potential to reduce carbon emissions by up to 45% while simultaneously tackling waste management issues is a powerful example of how innovative thinking can lead to multifaceted environmental benefits.

While the road to widespread implementation may be complex, the promise of this technology is clear. It represents a crucial step towards a more circular economy, where waste is not just managed but transformed into valuable resources. As research continues and the technology evolves, we may be witnessing the dawn of a new era in sustainable industrial practices and environmental stewardship.

The work of researchers at The Ohio State University serves as an inspiration and a call to action for scientists, policymakers, and industries worldwide. It reminds us that with innovation, collaboration, and determination, we can develop solutions to even the most pressing environmental challenges, creating a cleaner, greener future for generations to come.

FAQ Section

Q1: What is the main advantage of Ohio’s new plastic waste recycling technology?

A1: The main advantage is its ability to produce high-purity syngas (90%) from multiple types of waste, including plastics, paper, and food waste, while operating 45% more efficiently than conventional methods.

Q2: How does this technology contribute to environmental sustainability?

A2: It potentially reduces carbon emissions by up to 45% compared to current processes, supports the circular economy by converting waste into valuable resources, and helps address the global plastic pollution crisis.

Q3: What is syngas, and why is it important?

A3: Syngas, or synthesis gas, is a mixture primarily of carbon monoxide and hydrogen. It’s crucial for producing various chemicals and fuels, including formaldehyde and methanol, making it a valuable industrial resource.

Q4: How does the chemical looping process work?

A4: The process uses a two-reactor system: a moving bed reducer that breaks down waste using oxygen from metal oxide material, and a fluidized bed combustor that regenerates the metal oxide by replenishing the lost oxygen.

Q5: What are the challenges in implementing this technology on a large scale?

A5: Challenges include scaling up from laboratory to industrial application, adapting existing infrastructure, ensuring regulatory compliance, and gaining public acceptance for the new technology.