Revolutionizing Glasgow Farms: How Farmonaut’s Smart Irrigation and Crop Monitoring Boost Sustainable Agriculture

“Farmonaut’s smart irrigation systems can reduce water usage by up to 30% in Glasgow farms.”

Welcome to the future of farming in Glasgow! We’re excited to take you on a journey through the lush fields and rolling hills of our beloved city, where a quiet revolution is taking place. In this comprehensive exploration, we’ll delve into how Farmonaut’s cutting-edge technology is transforming the agricultural landscape of Glasgow, making our farms more productive, sustainable, and future-ready.

As we navigate through this blog post, we’ll uncover the secrets of sustainable agriculture technology and how precision farming solutions are changing the game for local farmers. From smart irrigation systems that conserve our precious water resources to advanced crop health monitoring techniques that ensure bountiful harvests, we’re about to discover how digital farming tools are becoming as essential to modern agriculture as the humble spade once was.

So, whether you’re a seasoned farmer looking to optimize your yield, a gardening enthusiast curious about the latest tech, or simply someone who cares about where your food comes from, this article is your gateway to understanding the future of farming. Grab a cup of tea (or a wee dram if you prefer), and let’s dig into the soil of innovation together!

The Agricultural Landscape of Glasgow: A Brief Overview

Before we dive into the technological marvels transforming our farms, let’s take a moment to appreciate the rich agricultural heritage of Glasgow. Our city, known for its vibrant urban life, is also surrounded by fertile lands that have fed generations. From the rolling pastures of the Clyde Valley to the arable fields stretching towards the Campsie Fells, agriculture has long been a cornerstone of our local economy and culture.

However, like many regions around the world, Glasgow’s farming community faces significant challenges:

- Unpredictable weather patterns affecting crop yields

- Increasing pressure to reduce water usage and environmental impact

- The need to produce more food with fewer resources

- Rising costs of labor and farm inputs

- Changing consumer demands for sustainably produced food

These challenges have set the stage for a technological revolution in our fields, and that’s where Farmonaut enters the picture, offering a suite of precision farming solutions tailored to the unique needs of Glasgow’s agricultural sector.

Farmonaut: Bringing the Future to Glasgow’s Farms

Farmonaut isn’t just another tech company; it’s a game-changer in the world of agriculture. By leveraging advanced satellite technology, artificial intelligence, and data analytics, Farmonaut is empowering Glasgow’s farmers with tools that were once the stuff of science fiction. Let’s explore how these innovations are making a real difference on the ground.

Smart Irrigation Systems: Quenching Crops’ Thirst Efficiently

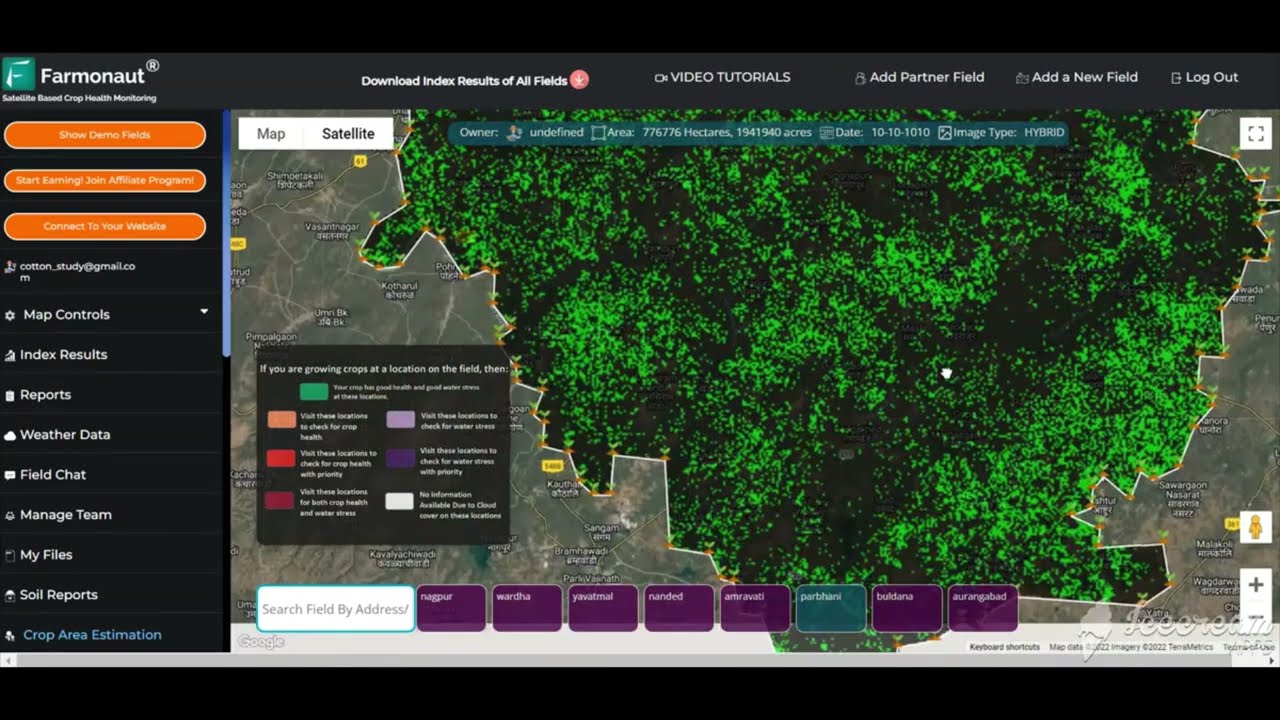

Water is life, especially in agriculture. With Glasgow’s variable climate, managing water resources effectively is crucial. Farmonaut’s smart irrigation systems are revolutionizing how we water our crops:

- Real-time soil moisture monitoring through satellite data

- AI-driven algorithms that predict water needs based on crop type, growth stage, and weather forecasts

- Automated irrigation scheduling that delivers the right amount of water at the right time

- Integration with local weather stations for hyper-local precision

The result? Our farmers are seeing water savings of up to 30% while maintaining or even improving crop health. It’s a win-win for both the environment and the bottom line.

Discover how Farmonaut can transform your farm’s irrigation practices.

Crop Health Monitoring: A Watchful Eye from Above

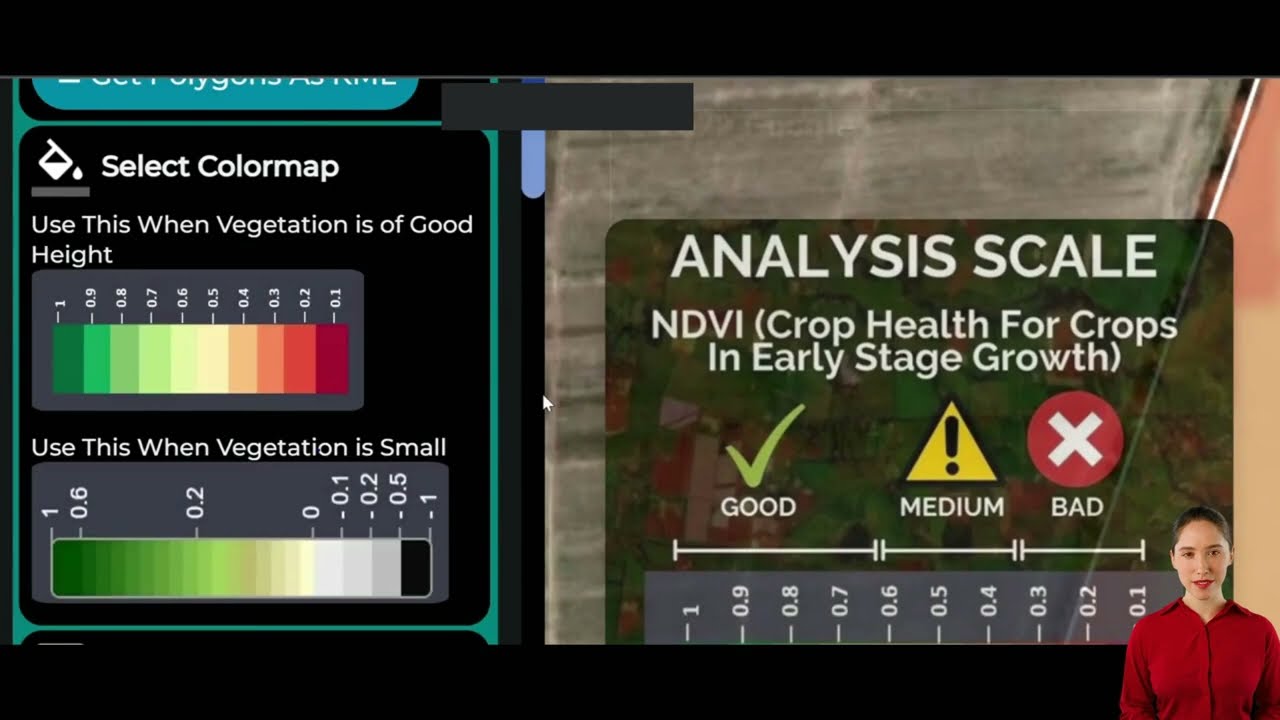

Gone are the days when farmers had to rely solely on their eyes and experience to assess crop health. Farmonaut’s satellite-based crop monitoring system provides a bird’s-eye view of entire fields, offering insights that were previously impossible to obtain:

- Multispectral imaging that detects plant stress before it’s visible to the naked eye

- Vegetation indices like NDVI (Normalized Difference Vegetation Index) to assess crop vigor

- Early detection of pest infestations and diseases

- Historical data analysis for year-on-year comparisons and trend identification

This level of detail allows Glasgow’s farmers to take targeted action, applying treatments only where needed, reducing costs, and minimizing environmental impact.

Soil Analysis Techniques: Understanding the Foundation of Farming

Healthy soil is the bedrock of successful farming, and Farmonaut’s advanced soil analysis techniques are giving Glasgow’s farmers unprecedented insights into their land:

- Satellite-based soil composition mapping

- Integration with ground sensors for real-time pH and nutrient level monitoring

- AI-powered recommendations for soil amendments and crop rotation

- Tracking of soil carbon levels to support sustainable farming practices

By understanding their soil at this granular level, our farmers can make informed decisions about planting, fertilization, and land management, leading to healthier crops and more sustainable practices.

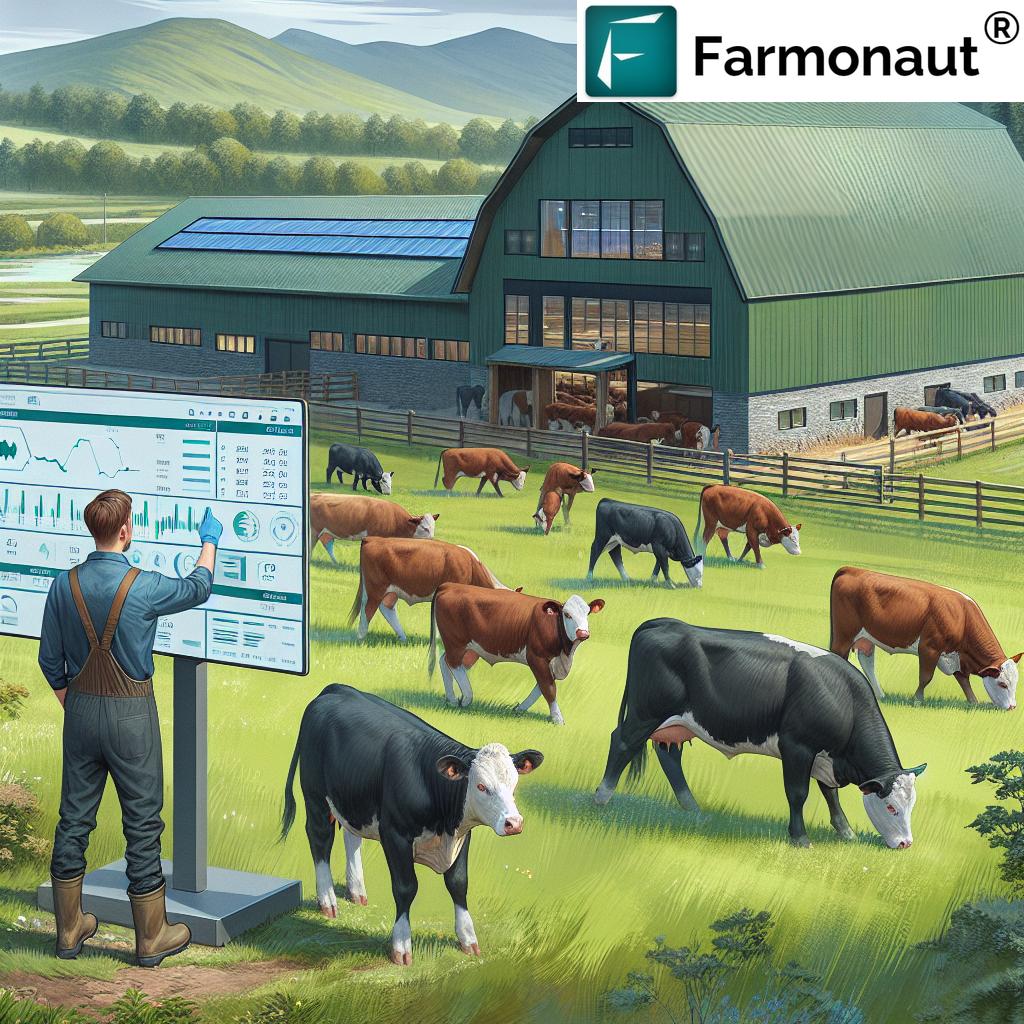

The Digital Farmer’s Toolkit: Farm Management Software

At the heart of Farmonaut’s offerings is its comprehensive farm management software, a digital command center that brings all these technological marvels together in one user-friendly interface. This powerful tool is changing how Glasgow’s farmers plan, execute, and analyze their operations:

- Intuitive dashboards that provide at-a-glance insights into farm performance

- Task management and scheduling features to optimize labor and resource allocation

- Integration with machinery and IoT devices for seamless data collection

- Financial tracking and reporting to support better business decisions

- Mobile app access for on-the-go management

With this software, farmers can manage their operations with unprecedented efficiency, making data-driven decisions that boost productivity and profitability.

Ready to digitize your farm management? Get started with Farmonaut’s mobile apps:

Weather Data for Agriculture: Forecasting Success

In Glasgow, where the weather can change faster than you can say “Och aye,” having accurate forecasts is crucial for farmers. Farmonaut’s integration of advanced weather data into its platform is a game-changer:

- Hyper-local weather predictions tailored to specific farm locations

- Long-term climate trend analysis for better crop planning

- Alerts for extreme weather events to protect crops and livestock

- Integration of weather data with other farm management tools for holistic decision-making

By harnessing the power of weather data, Glasgow’s farmers can make proactive decisions, mitigating risks and maximizing opportunities presented by our ever-changing climate.

Agricultural Drone Technology: A Bird’s-Eye View of Progress

While satellites provide broad coverage, drones offer an up-close and personal view of our fields. Farmonaut’s integration of drone technology adds another layer of precision to farming in Glasgow:

- High-resolution imagery for detailed crop analysis

- Thermal imaging to detect irrigation issues and plant stress

- Automated flight paths for consistent monitoring

- Rapid response capability for addressing localized issues

This eye in the sky complements satellite data, giving farmers a comprehensive view of their land from macro to micro levels.

“Precision farming techniques can increase crop yields by 15-20% while promoting sustainable agriculture practices.”

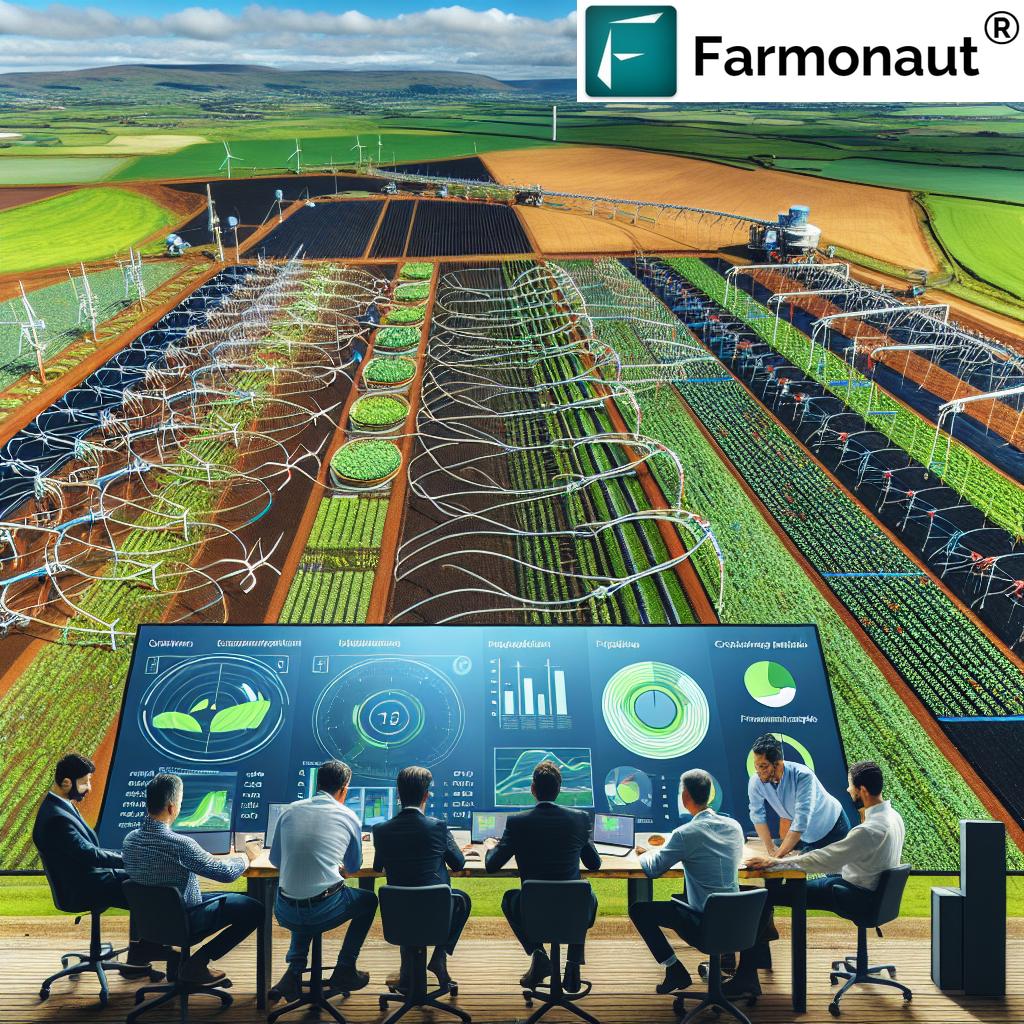

Crop Yield Optimization: The Holy Grail of Farming

Ultimately, the goal of all this technology is to optimize crop yields sustainably. Farmonaut’s integrated approach is helping Glasgow’s farmers achieve this in several ways:

- Data-driven decision-making for planting and harvesting times

- Precision application of inputs (water, fertilizers, pesticides) to maximize efficiency

- Early problem detection and intervention to minimize crop losses

- Continuous learning and improvement through season-over-season data analysis

The results speak for themselves, with many farms reporting yield increases of 15-20% while simultaneously reducing input costs and environmental impact.

Sustainable Agriculture: Growing a Greener Glasgow

Beyond productivity gains, Farmonaut’s technology is playing a crucial role in making Glasgow’s agriculture more sustainable:

- Reduced water usage through smart irrigation

- Minimized chemical inputs through targeted application

- Improved soil health through data-driven management practices

- Lower carbon footprint through optimized machinery use and reduced field operations

This focus on sustainability isn’t just good for the environment; it’s also meeting the growing consumer demand for responsibly produced food, opening new market opportunities for Glasgow’s farmers.

The Economic Impact: Boosting Glasgow’s Agricultural Sector

The adoption of Farmonaut’s technology is having a significant economic impact on Glasgow’s agricultural sector:

- Increased profitability through higher yields and lower input costs

- Creation of new, high-skilled jobs in agricultural technology

- Enhanced competitiveness of Glasgow’s produce in global markets

- Attraction of investment in the local agri-tech ecosystem

As more farms embrace these technologies, we’re seeing a ripple effect throughout the local economy, from equipment suppliers to food processors.

Challenges and Opportunities: Navigating the Future of Farming

While the benefits of precision agriculture are clear, the transition isn’t without its challenges:

- Initial investment costs for technology adoption

- Need for digital literacy and training among farmers

- Data privacy and security concerns

- Ensuring equitable access to technology for farms of all sizes

However, these challenges also present opportunities for innovation, collaboration, and growth within Glasgow’s farming community.

The Road Ahead: Glasgow’s Agricultural Future

As we look to the future, the integration of Farmonaut’s technology into Glasgow’s farms is just the beginning. We anticipate:

- Further advancements in AI and machine learning for even more precise farming

- Greater integration of robotics and automation in field operations

- Development of new, climate-resilient crop varieties guided by data insights

- Expansion of urban farming initiatives powered by precision agriculture technology

The future of farming in Glasgow is bright, sustainable, and technologically advanced, promising a new era of prosperity for our agricultural sector.

Explore the cutting-edge features of Farmonaut’s API for developers: Farmonaut API

For detailed API documentation, visit: Farmonaut API Developer Docs

Comparative Analysis: Traditional vs. Smart Farming Techniques in Glasgow

| Farming Aspect | Traditional Method | Farmonaut’s Smart Solution | Estimated Improvement (%) |

|---|---|---|---|

| Irrigation | Fixed schedule, uniform application | AI-driven, precision application | 30% water reduction |

| Crop Monitoring | Manual field walks, visual inspection | Satellite and drone imagery, AI analysis | 15-20% yield increase |

| Soil Analysis | Periodic lab tests | Continuous satellite and sensor monitoring | 25% improvement in nutrient management |

| Pest Detection | Visual inspection (70% accuracy) | AI and multispectral imaging (95% accuracy) | 25% increase in detection accuracy |

| Weather Forecasting | General regional forecasts | Hyper-local, AI-enhanced predictions | 40% improvement in weather-related decision making |

| Resource Management | Manual record-keeping | Integrated digital farm management software | 30% reduction in administrative time |

Conclusion: Harvesting the Benefits of Innovation

As we wrap up our journey through the fields of Glasgow’s agricultural revolution, it’s clear that the integration of Farmonaut’s technology is more than just a trend—it’s a necessary evolution. By embracing sustainable agriculture technology and precision farming solutions, Glasgow’s farmers are not only boosting their productivity and profitability but also becoming stewards of a more sustainable future.

From smart irrigation systems that preserve our precious water resources to advanced crop health monitoring that ensures bountiful harvests, these digital farming tools are redefining what it means to be a farmer in the 21st century. The fusion of traditional farming wisdom with cutting-edge technology is creating a new paradigm of agriculture that is more efficient, more sustainable, and more resilient to the challenges of our changing world.

As we look to the future, we see a Glasgow where farms are not just producers of food but hubs of innovation, where the lines between agriculture and technology blur, creating new opportunities for growth, learning, and sustainability. The seeds of this future have been planted, and with tools like Farmonaut at our disposal, we’re well on our way to cultivating a thriving, tech-enabled agricultural sector that will feed Glasgow—and beyond—for generations to come.

So, whether you’re a farmer looking to take your first steps into precision agriculture, a tech enthusiast excited about the possibilities of agritech, or simply someone who cares about the future of food production, remember that the revolution is happening right here in our fields. The future of farming is now, and it’s growing stronger every day in the rich soil of Glasgow.

FAQ: Frequently Asked Questions

Q: What is precision agriculture, and how does it benefit Glasgow’s farmers?

A: Precision agriculture is a farming management concept that uses technology to observe, measure, and respond to variability in crops. For Glasgow’s farmers, it means more efficient use of resources, higher yields, and reduced environmental impact through targeted interventions.

Q: How does Farmonaut’s technology help in water conservation?

A: Farmonaut’s smart irrigation systems use satellite data and AI to monitor soil moisture levels and crop water needs in real-time. This allows for precise water application, reducing waste and ensuring crops receive exactly what they need.

Q: Can small-scale farmers in Glasgow benefit from this technology?

A: Absolutely! Farmonaut’s solutions are scalable and designed to be accessible to farms of all sizes. The potential for increased efficiency and yield improvements can be particularly impactful for smaller operations.

Q: How does weather data integration improve farming practices?

A: By integrating hyper-local weather data, farmers can make more informed decisions about planting, harvesting, and crop protection. This leads to better risk management and optimized crop cycles.

Q: Is there a learning curve for adopting these new technologies?

A: While there is a learning curve, Farmonaut provides comprehensive support and training to help farmers transition smoothly. The user-friendly interfaces of their apps and software are designed with farmers in mind.

Q: How does Farmonaut’s technology contribute to sustainable farming?

A: By optimizing resource use, reducing chemical inputs, and improving soil health management, Farmonaut’s solutions help farmers adopt more sustainable practices that are better for the environment and meet growing consumer demand for responsibly produced food.