Revolutionizing Agriculture: Inside Iowa’s State-of-the-Art Venlo Greenhouse for Year-Round Sustainable Crop Production

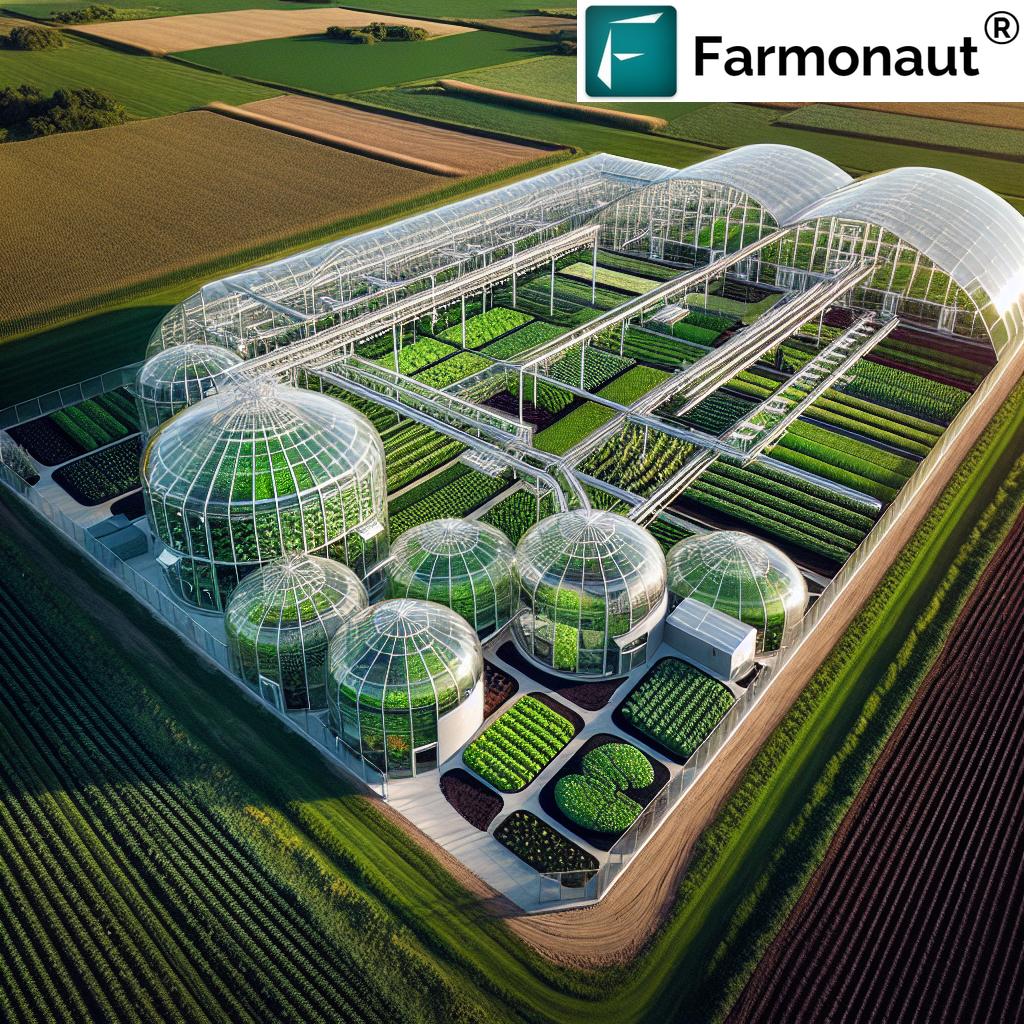

“Iowa’s new Venlo greenhouse spans nearly an acre, featuring 25,000 square feet of growing space divided into three distinct cultivation zones.”

Welcome to the future of agriculture! We’re excited to take you on a journey through Iowa’s cutting-edge Venlo greenhouse, a marvel of modern agricultural innovation that’s set to transform the way we grow crops year-round. This state-of-the-art facility, located in Dyersville, Iowa, is pushing the boundaries of controlled environment agriculture and setting new standards for sustainable greenhouse technology.

As we delve into the intricacies of this revolutionary glass greenhouse structure, we’ll explore how it’s changing the game for commercial greenhouse systems and paving the way for a more sustainable and productive future in agriculture.

The Dawn of a New Era in Greenhouse Technology

GrowSpan Greenhouse Structures has taken a giant leap forward with the unveiling of their new Venlo greenhouse at their Dyersville, Iowa campus. This groundbreaking project represents years of intensive research and development, coupled with substantial investments in manufacturing facilities and infrastructure.

The Iowa campus, now spanning over 60 acres, has undergone significant upgrades, including a $13 million investment in their production line. This expansion solidifies GrowSpan’s position as a leader in the greenhouse industry and demonstrates their commitment to innovation and quality.

The Venlo greenhouse project is a testament to GrowSpan’s manufacturing prowess and their ability to execute complex construction projects. As the only U.S. manufacturer of the Venlo, GrowSpan is uniquely positioned to provide innovative solutions to both existing and new customers in the agricultural sector.

A Closer Look at the Venlo Greenhouse Structure

The Venlo greenhouse is a marvel of modern engineering, designed to maximize efficiency and productivity. Let’s break down the key features that make this structure stand out:

- Size and Space: Spanning nearly an acre, the facility boasts approximately 25,000 square feet of dedicated growing space.

- Frame Construction: The frame is built using hot-dipped galvanized steel, ensuring durability and longevity.

- Glass Cladding: The structure is clad with 4 mm glass on all sides, allowing for maximum light penetration.

- Climate Control: Motorized, cable-driven climate screens provide total control over light diffusion and restriction.

- Growing Zones: The space is divided into three distinct zones, each tailored to specific crop types.

“The state-of-the-art greenhouse utilizes 4 mm glass cladding to maximize natural light penetration while ensuring structural durability.”

Advanced Growing Systems and Technology

The Venlo greenhouse incorporates cutting-edge hydroponic growing systems and greenhouse climate control technology to optimize crop production. Here’s a glimpse into the innovative systems at work:

- Deep Water Cultivation: The first zone features a deep water system with above-ground ponds and polystyrene rafts for lettuce production.

- Suspended Gutter Systems: The second and third zones utilize suspended gutter cultivation systems with drip irrigation and leachate collection for tomatoes and strawberries.

- Climate Control Equipment: State-of-the-art equipment including HAF and AHU fans, vertical sliding windows, hydronic heating systems, LED lighting, and high-pressure foggers ensure precise environmental control.

These advanced systems work in harmony to create the ideal growing conditions for a variety of crops, showcasing the versatility and efficiency of modern greenhouse technology.

Energy-Efficient Crop Production

One of the standout features of this Venlo greenhouse is its focus on energy-efficient crop production. The structure’s design and advanced technology work together to minimize energy consumption while maximizing yield. Here’s how:

- Natural Light Utilization: The glass structure allows for about 90% of natural sunlight to penetrate, reducing the need for artificial lighting.

- Climate Screens: The motorized climate screens help regulate temperature and light, reducing heating and cooling costs.

- Efficient Heating Systems: The hydronic heating system provides targeted warmth where it’s needed most, minimizing energy waste.

- LED Lighting: When supplemental lighting is required, energy-efficient LED lights are used to promote plant growth without excessive power consumption.

These energy-saving features not only reduce operational costs but also contribute to the overall sustainability of the greenhouse operation.

Year-Round Greenhouse Cultivation

One of the most significant advantages of this Venlo greenhouse construction is its ability to support year-round greenhouse cultivation. This capability is crucial for meeting the growing demand for fresh, locally grown produce throughout the year, regardless of external weather conditions.

The precise climate control systems allow growers to create ideal conditions for each crop type, ensuring optimal growth and yield even during the harsh Iowa winters or scorching summers. This level of control also enables the cultivation of crops that might not typically thrive in Iowa’s natural climate, expanding the range of produce available to local consumers.

Sustainable Greenhouse Solutions

Sustainability is at the heart of this Venlo greenhouse project. The structure incorporates several sustainable greenhouse solutions that reduce its environmental impact while enhancing productivity:

- Water Conservation: The hydroponic systems and drip irrigation with leachate collection significantly reduce water usage compared to traditional farming methods.

- Pesticide Reduction: The controlled environment reduces the need for pesticides, promoting healthier crops and minimizing environmental impact.

- Local Food Production: By enabling year-round cultivation, the greenhouse reduces the need for long-distance transportation of produce, lowering carbon emissions associated with food distribution.

- Resource Optimization: Advanced monitoring and control systems ensure that resources like water, nutrients, and energy are used efficiently, minimizing waste.

These sustainable practices not only benefit the environment but also contribute to the production of high-quality, fresh produce for local communities.

Impact on Local Agriculture and Economy

The introduction of this state-of-the-art Venlo greenhouse in Iowa is set to have a significant impact on the local agricultural landscape and economy:

- Job Creation: The greenhouse operation will create new employment opportunities in the area, from skilled growers to technicians and management positions.

- Educational Opportunities: GrowSpan plans to host tours for local schools and universities, providing valuable learning experiences in modern agriculture.

- Local Food Supply: The greenhouse will supply large quantities of fresh produce to surrounding communities, enhancing food security and reducing dependence on imports.

- Agricultural Innovation Hub: The facility will serve as a showcase for mid to large-scale growers, potentially attracting more agricultural innovation to the region.

These benefits highlight the broader impact of investing in advanced agricultural technologies and infrastructure.

Comparison: Venlo Greenhouse vs. Traditional Greenhouse

| Feature | Iowa Venlo Greenhouse | Traditional Greenhouse |

|---|---|---|

| Growing Space (sq ft) | 25,000 | Varies, typically smaller |

| Number of Cultivation Zones | 3 | Usually 1 |

| Frame Material | Hot-dipped galvanized steel | Varies (wood, aluminum, steel) |

| Glass Thickness (mm) | 4 | Varies, often thinner |

| Climate Control Technology | Advanced (HAF fans, AHU, hydronic heating, LED lighting) | Basic to moderate |

| Growing Systems | Deep water cultivation, suspended gutters | Often soil-based or basic hydroponics |

| Energy Efficiency Rating | High | Moderate |

| Year-Round Production Capacity | Full | Limited |

| Light Penetration (%) | ~90% | Varies, often lower |

| Crop Varieties | Multiple (lettuce, tomatoes, strawberries) | Often limited to fewer varieties |

The Role of Technology in Modern Agriculture

The Venlo greenhouse in Iowa is a prime example of how technology is revolutionizing agriculture. From advanced climate control systems to innovative growing techniques, technology plays a crucial role in enhancing productivity, sustainability, and food security.

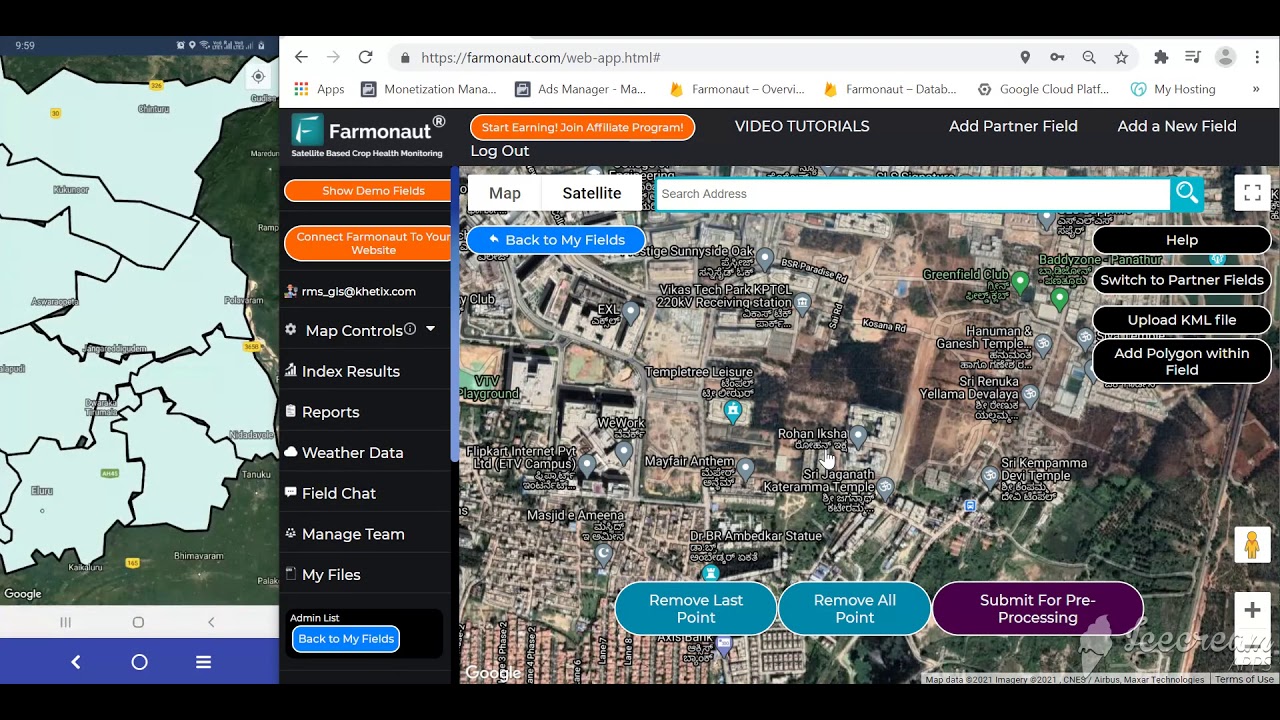

One company at the forefront of this agricultural technology revolution is Farmonaut. While not directly involved in the Venlo greenhouse project, Farmonaut’s innovative solutions complement and enhance modern agricultural practices.

Farmonaut offers advanced, satellite-based farm management solutions that can be accessed via Android, iOS, web browsers, and API. Their platform provides valuable services such as real-time crop health monitoring, AI-based advisory systems, and resource management tools.

For farmers and greenhouse operators looking to enhance their operations with cutting-edge technology, Farmonaut’s solutions can provide valuable insights and improve decision-making processes.

The Future of Large-Scale Greenhouse Solutions

As we look to the future, large-scale greenhouse solutions like the Venlo greenhouse in Iowa are likely to become increasingly important in global agriculture. These advanced structures offer several advantages that make them crucial for future food production:

- Climate Resilience: With the ability to control the growing environment, these greenhouses can protect crops from extreme weather events and climate change impacts.

- Land Use Efficiency: By maximizing vertical space and optimizing growing conditions, these greenhouses can produce more food per square foot than traditional farming methods.

- Water Conservation: Advanced irrigation systems and water recycling techniques significantly reduce water usage compared to open-field agriculture.

- Reduced Chemical Use: The controlled environment minimizes pest and disease pressures, reducing the need for chemical pesticides and herbicides.

- Urban Agriculture: Large-scale greenhouses can be built closer to urban centers, reducing transportation costs and providing fresher produce to cities.

As these technologies continue to evolve and become more accessible, we can expect to see more commercial greenhouse systems like the Venlo greenhouse being adopted worldwide.

Integrating Advanced Agricultural Technologies

While the Venlo greenhouse itself is a marvel of agricultural engineering, its effectiveness can be further enhanced by integrating other advanced agricultural technologies. This is where solutions like those offered by Farmonaut come into play.

Farmonaut’s satellite-based crop monitoring and AI-driven advisory systems can provide valuable data and insights to greenhouse operators, helping them make more informed decisions about crop management, resource allocation, and harvest timing.

By combining the controlled environment of the Venlo greenhouse with the data-driven insights provided by platforms like Farmonaut, growers can push the boundaries of productivity and sustainability even further.

The Economic Impact of Advanced Greenhouse Technology

The adoption of advanced greenhouse technologies like the Venlo structure in Iowa has significant economic implications:

- Increased Productivity: These greenhouses can produce higher yields per square foot, potentially increasing revenue for growers.

- Extended Growing Seasons: Year-round production capabilities can provide a steady income stream and help stabilize produce prices throughout the year.

- Job Creation: Advanced greenhouses require skilled workers, creating new employment opportunities in rural areas.

- Reduced Import Dependence: By enabling local production of a wider variety of crops, these greenhouses can reduce a region’s dependence on imported produce.

- Technology Sector Growth: The demand for advanced greenhouse technologies can spur growth in related technology sectors, from sensor manufacturing to software development.

These economic benefits highlight the potential of advanced greenhouse technologies to transform not just agriculture, but entire regional economies.

Challenges and Considerations

While the benefits of advanced greenhouse technologies are clear, there are also challenges and considerations to keep in mind:

- Initial Investment: The upfront costs of building and equipping a state-of-the-art greenhouse can be substantial.

- Energy Requirements: Despite energy-efficient designs, large-scale greenhouses still require significant energy inputs, particularly in colder climates.

- Skill Requirements: Operating advanced greenhouse systems requires specialized knowledge and skills, which may necessitate significant training investments.

- Market Dynamics: Increased local production could potentially impact market prices for certain crops.

- Technology Dependence: Reliance on complex systems means that technical failures could have significant impacts on crop production.

Addressing these challenges will be crucial for the widespread adoption and success of advanced greenhouse technologies.

FAQs

- Q: How does the Venlo greenhouse compare to traditional greenhouses in terms of energy efficiency?

A: The Venlo greenhouse is significantly more energy-efficient due to its advanced climate control systems, superior insulation, and optimized use of natural light. - Q: Can the Venlo greenhouse produce crops year-round in Iowa’s climate?

A: Yes, the greenhouse’s climate control systems allow for year-round cultivation, regardless of external weather conditions. - Q: What types of crops can be grown in the Venlo greenhouse?

A: The greenhouse is designed to support a variety of crops, including lettuce, tomatoes, and strawberries, with different zones optimized for specific crop types. - Q: How does the Venlo greenhouse contribute to sustainable agriculture?

A: It uses water and energy more efficiently, reduces the need for pesticides, and enables local food production, reducing transportation-related emissions. - Q: Are there plans to build more Venlo greenhouses in other parts of the United States?

A: While specific plans haven’t been announced, the success of this project could lead to similar installations in other regions.

Conclusion

The state-of-the-art Venlo greenhouse in Iowa represents a significant leap forward in controlled environment agriculture. By combining advanced structural design with cutting-edge growing systems and climate control technology, it showcases the potential of modern greenhouse agriculture to enhance productivity, sustainability, and food security.

As we face growing challenges in global food production, from climate change to resource scarcity, innovations like the Venlo greenhouse offer promising solutions. By enabling year-round, efficient, and sustainable crop production, these advanced structures could play a crucial role in shaping the future of agriculture.

The integration of complementary technologies, such as Farmonaut’s satellite-based crop monitoring and AI advisory systems, further enhances the potential of these advanced greenhouses. Together, these innovations are paving the way for a more resilient, productive, and sustainable agricultural future.

As we continue to push the boundaries of agricultural technology, projects like the Iowa Venlo greenhouse serve as beacons of innovation, inspiring further advancements and adaptations across the global agricultural landscape. The future of farming is here, and it’s growing strong in the heartland of America.

Earn With Farmonaut: Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!