Revolutionizing Juneau’s Water Infrastructure: Acoustic Velocity Testing for Smart Urban Management

“Acoustic velocity testing can assess up to 3 miles of water pipes per day without excavation.”

“Acoustic velocity testing can assess up to 3 miles of water pipes per day without excavation.”

In the realm of urban water management, we are witnessing a revolutionary transformation in how cities assess and maintain their vital water infrastructure. At the forefront of this change is the innovative technology of acoustic velocity testing, a non-invasive method that is reshaping the landscape of pipe condition monitoring and water distribution system maintenance. Today, we’ll dive deep into how this cutting-edge approach is being implemented in Juneau, Alaska, and explore its far-reaching implications for smart urban management across the globe.

The Water Infrastructure Challenge in Juneau

The City and Borough of Juneau faces a significant challenge common to many urban areas: maintaining an aging water infrastructure while ensuring reliable service to its residents. With an annual production and distribution of 1.2 billion gallons of water, Juneau’s water system is a complex network that demands constant attention and strategic planning.

- Over 180 miles of pipe

- 50 pump stations

- Multiple reservoirs

- Thousands of hydrants and terminal water distribution connections

This extensive system draws from both ground and surface water sources, including the Last Chance Basin aquifer for downtown and Douglas Island, and the Salmon Creek Water Filtration Plant for areas north of the hospital.

As part of the broader U.S. water infrastructure, Juneau’s system is one of over 153,000 public drinking water systems nationwide. The challenges it faces are emblematic of a larger issue:

- A pipe break occurs every two minutes in the U.S.

- 2.1 trillion gallons of water are lost annually due to these breaks

- Much of the nation’s infrastructure dates back to 1890-1940

In Juneau specifically, the city experiences 1-2 pipe breaks per year, with repair costs ranging from $200 to $1,000 per foot. These statistics underscore the critical need for innovative solutions in water infrastructure assessment and maintenance.

Enter Acoustic Velocity Testing: A Game-Changer for Pipe Inspection

To address these challenges, Juneau has turned to a groundbreaking technology: ePulse, an acoustic velocity (AV) testing technology developed by Echologics. This innovative approach to non-invasive pipe inspection is revolutionizing how cities assess and maintain their water infrastructure.

Key features of acoustic velocity testing:

- Non-invasive and non-destructive

- No need to interrupt water service

- Minimal traffic disruption

- Provides critical condition assessment information

- Simultaneously checks for leaks

Abner Miller, Project Manager for the City of Juneau, emphasizes the effectiveness of this technology: “We first used ePulse in 2022 and found the results to be very good. It is a non-invasive, non-destructive method of data collection for pipes in the ground and there is no need to stop the water service or alter traffic.”

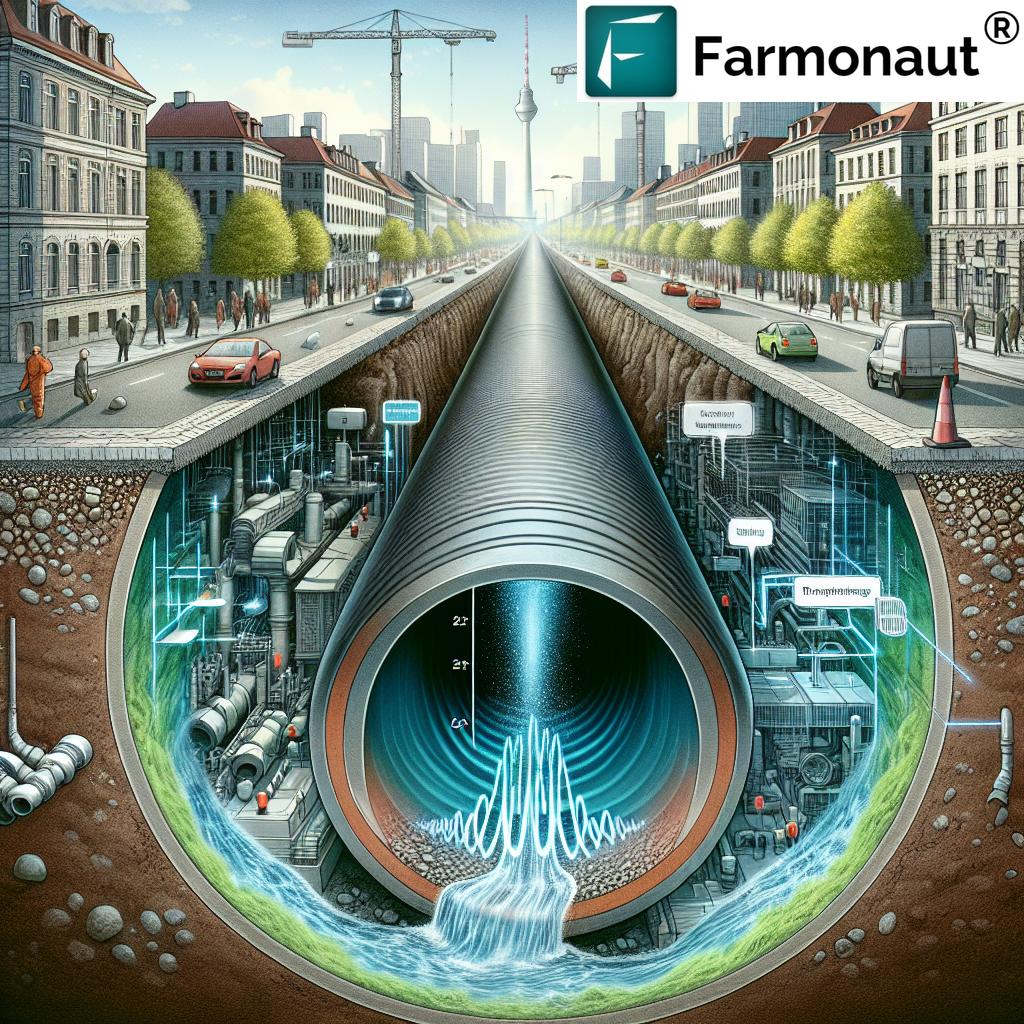

How Acoustic Velocity Testing Works

The process of acoustic velocity testing is both sophisticated and straightforward:

- Acoustic sensors are attached to existing appurtenances like valves or hydrant isolation valves.

- An acoustic wave is induced in the pipe by gently tapping on a fire hydrant.

- The velocity of the acoustic wave is measured as it travels through the pipe segment.

- The acoustic velocity is calculated based on sensor spacing and time delay between measured signals.

- Average structural wall thickness is derived from a theoretical model considering acoustic velocity, pipe diameter, and material properties.

This method provides invaluable data on the condition of water mains, enabling cities to make informed decisions about maintenance and replacement priorities.

Implementing Acoustic Velocity Testing in Juneau

Juneau’s adoption of acoustic velocity testing marks a significant step forward in their water main replacement program. In 2022, the city tested over a mile (5,800ft) of water distribution pipe in the South Douglas area, a region known for its challenging environmental conditions that accelerate pipe corrosion.

Nick Druyvestein, Engineering Associate at the City of Juneau, explains the strategic approach: “It’s only practical for us to replace ~1500ft of water pipe per year, so the goal was to identify the particularly bad segments so we could prioritize projects to replace those segments accordingly.”

The implementation process involved:

- Training city staff in the use of ePulse technology

- Conducting a three-week training program

- Enabling staff to collect field data independently

- Sending collected data to Mueller for analysis

This approach not only reduces costs but also empowers the city to manage its water infrastructure more effectively. Juneau is pioneering this model, being the first utility to license this technology for in-house data collection.

GIS Utility Mapping: Enhancing Infrastructure Management

Alongside acoustic velocity testing, Juneau has been advancing its GIS utility mapping capabilities. This integration of technologies is crucial for comprehensive water infrastructure assessment and management.

Key aspects of Juneau’s GIS implementation:

- Started GIS mapping about 10 years ago, initially for fire/public safety purposes

- Refined GIS of the water system to support condition assessment

- Developed maps to visually display assessment results

- Ramped up GIS utility work in 2023 to align with ePulse data collection

This enhanced GIS capability allows Juneau to visualize its water network more effectively, correlating acoustic velocity data with geographical and historical information. It’s a powerful tool for urban water management, enabling more informed decision-making and resource allocation.

“GIS utility mapping and leak detection technology can reduce water loss by up to 30% in urban distribution systems.”

Results and Impact of Acoustic Velocity Testing in Juneau

The implementation of acoustic velocity testing has yielded significant insights for Juneau’s water infrastructure management:

- Assessed varying lengths and sizes of pipe, from 6″ to 18″ ductile iron

- Conducted two condition assessment projects totaling about 6 miles of water main (3% of the network)

- Provided detailed reports on mean hoop thickness of each pipe segment

The results are visually represented using a color-coded system:

- Red: 1-9 years of remaining life (degradation > 30%)

- Yellow: 10-29 years of remaining life (degradation 10-30%)

- Green: 30+ years of remaining life (degradation 0-10%)

This data-driven approach allows Juneau to prioritize pipe replacement more effectively, focusing on areas with higher levels of degradation and optimizing their capital budget planning.

Future Plans and Long-Term Benefits

Looking ahead, Juneau has ambitious plans to expand its use of acoustic velocity testing:

- Aim to test 5-10 miles of pipe annually

- Goal to complete assessment of 100 miles of ductile iron pipe

- Utilize data for proper allocation of capital budgets

- Reduce risk by prioritizing replacement in high-degradation areas

The long-term benefits of this approach are substantial:

- More efficient use of resources

- Reduced water loss

- Lower repair costs

- Improved reliability of water service

- Enhanced urban water management

By embracing this innovative technology, Juneau is setting a benchmark for smart urban water management, potentially saving millions in unnecessary replacements and repairs.

Comparative Analysis of Water Infrastructure Assessment Methods

To fully appreciate the advantages of acoustic velocity testing, it’s essential to compare it with other methods of water infrastructure assessment. The following table provides a comprehensive overview of various techniques:

| Assessment Method | Technology Used | Pros | Cons | Estimated Cost Range |

|---|---|---|---|---|

| Acoustic Velocity Testing | Sound wave propagation |

– Non-invasive – Accurate wall thickness measurement – Simultaneous leak detection |

– Initial setup cost – Requires specialized training |

$2,000 – $5,000 per mile |

| Traditional Visual Inspection | Camera systems, physical examination |

– Direct visual evidence – Identifies surface-level issues |

– Invasive, requires excavation – Time-consuming – Limited to visible defects |

$5,000 – $10,000 per mile |

| Ground Penetrating Radar | Electromagnetic radiation |

– Non-invasive – Detects voids and soil issues |

– Less accurate for pipe wall thickness – Affected by soil conditions |

$3,000 – $7,000 per mile |

| Leak Detection Sensors | Acoustic sensors, pressure monitors |

– Identifies leaks quickly – Continuous monitoring possible |

– Limited to leak detection – Doesn’t assess overall pipe condition |

$1,500 – $4,000 per mile |

This comparison highlights the unique advantages of acoustic velocity testing, particularly its non-invasive nature and ability to provide comprehensive pipe condition data at a competitive cost.

Implications for Global Urban Water Management

The success of acoustic velocity testing in Juneau has significant implications for urban water management worldwide. As cities grapple with aging infrastructure and limited budgets, this technology offers a cost-effective and efficient solution for:

- Prioritizing pipe replacements

- Reducing water loss through early leak detection

- Optimizing capital expenditure on infrastructure

- Improving overall water system reliability

The potential for this technology to revolutionize urban water management is immense, offering a pathway to more sustainable and efficient water systems globally.

Challenges and Considerations

While acoustic velocity testing offers numerous benefits, it’s important to consider potential challenges:

- Initial investment in technology and training

- Need for accurate GIS data to maximize effectiveness

- Interpretation of results requires expertise

- May not be suitable for all pipe materials or conditions

Cities considering this technology should carefully evaluate their specific needs and infrastructure conditions to determine the best approach.

Integrating Technology for Comprehensive Water Management

The success of Juneau’s water infrastructure assessment program highlights the importance of integrating various technologies for comprehensive urban water management. While acoustic velocity testing forms the cornerstone of their approach, it’s complemented by other innovative solutions:

- GIS Utility Mapping: Enhances spatial understanding and visualization of the water network.

- Leak Detection Technology: Works in tandem with acoustic testing to identify and locate leaks quickly.

- Data Analytics: Helps in interpreting the vast amount of data collected, enabling predictive maintenance.

This integrated approach allows for a more holistic view of the water infrastructure, enabling better decision-making and resource allocation.

The Role of Technology in Sustainable Urban Development

The adoption of advanced technologies like acoustic velocity testing in water infrastructure management is part of a broader trend towards smart, sustainable urban development. These innovations contribute to:

- Reduced water waste

- Lower energy consumption in water distribution

- More efficient use of public funds

- Improved public health through better water quality management

As cities worldwide face challenges related to urbanization, climate change, and aging infrastructure, technologies that enable more efficient resource management become increasingly crucial.

Looking to the Future: Emerging Trends in Water Infrastructure Management

As we look to the future of urban water management, several emerging trends are worth noting:

- AI and Machine Learning: These technologies are increasingly being used to analyze data from acoustic testing and other sources, providing more accurate predictions of pipe failures and maintenance needs.

- Internet of Things (IoT): Smart sensors and connected devices are enabling real-time monitoring of water infrastructure, allowing for quicker responses to issues.

- Blockchain Technology: This could be used to enhance the security and transparency of water quality data and infrastructure management records.

- 3D Printing: Advancements in 3D printing technology may soon allow for on-site manufacturing of replacement parts, reducing repair times and costs.

These innovations, combined with acoustic velocity testing and other current technologies, promise to further revolutionize how we manage and maintain our vital water infrastructure.

Conclusion: A New Era in Urban Water Management

The implementation of acoustic velocity testing in Juneau marks a significant milestone in the evolution of urban water management. By embracing this innovative technology, cities can:

- Assess water infrastructure more accurately and efficiently

- Prioritize maintenance and replacement efforts based on data-driven insights

- Reduce water loss and associated costs

- Improve overall system reliability and sustainability

As more cities adopt these advanced technologies, we can look forward to a future where water infrastructure management is smarter, more efficient, and more sustainable. The success story of Juneau serves as an inspiration and a blueprint for urban areas worldwide, demonstrating how innovative approaches can address long-standing challenges in water infrastructure management.

In this new era of smart urban management, the integration of acoustic velocity testing, GIS mapping, and other cutting-edge technologies is not just an option—it’s a necessity for creating resilient, efficient, and sustainable water systems that will serve communities for generations to come.

FAQs

- What is acoustic velocity testing?

Acoustic velocity testing is a non-invasive method of assessing water pipe conditions by measuring the speed of sound waves through the pipe material. - How does acoustic velocity testing benefit cities?

It allows for accurate assessment of pipe conditions without excavation, reducing costs and disruption while providing valuable data for maintenance planning. - Is acoustic velocity testing suitable for all types of pipes?

While effective for many pipe materials, its efficiency may vary depending on pipe material, size, and surrounding soil conditions. - How often should acoustic velocity testing be conducted?

The frequency depends on the age and condition of the infrastructure, but many cities aim for annual or biennial assessments of critical segments. - Can acoustic velocity testing detect leaks?

Yes, it can simultaneously assess pipe condition and detect leaks, making it a versatile tool for water infrastructure management.

Earn With Farmonaut: Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!