Revolutionizing US Agtech: How Modern Biomanufacturing Facilities Are Shaping the Future of Precision Fermentation

“Precision fermentation in modern biomanufacturing facilities can produce high-value food ingredients at up to 20 times lower cost than traditional methods.”

In the rapidly evolving landscape of US agtech, modern biomanufacturing facilities are emerging as game-changers, revolutionizing the way we approach precision fermentation and shaping the future of sustainable food production. As we delve into this transformative trend, we’ll explore how these cutting-edge facilities are addressing the urgent need for updated infrastructure to meet the demands of next-generation bioproducts, including innovative food ingredients and agricultural biologics.

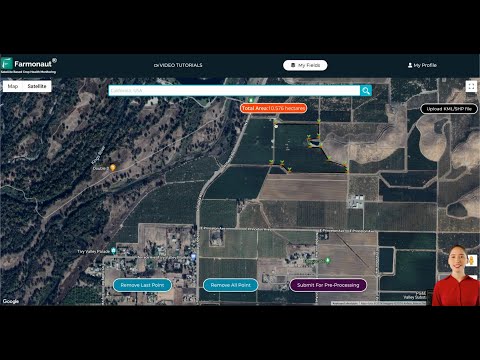

At Farmonaut, we’re committed to keeping you informed about the latest developments in agritech and precision cultivation techniques that are transforming the agricultural sector. While our focus is on satellite-based farm management solutions, we recognize the importance of staying abreast of all technological advancements that impact the industry.

The Rise of Modern Biomanufacturing Facilities

The US agtech industry is witnessing a paradigm shift with the advent of state-of-the-art biomanufacturing facilities. These modern marvels are not just production plants; they’re hubs of innovation that are redefining the possibilities of precision fermentation in food production and beyond. Let’s explore the key aspects driving this revolution:

- Advanced technologies enabling unprecedented efficiency

- Sustainable protein alternatives becoming economically viable

- Fermentation-based ingredients offering new possibilities for foodtech

- Next-generation bioproducts reshaping the agricultural landscape

The Urgent Need for Updated Infrastructure

The legacy US biomanufacturing network is struggling to keep pace with the demands of the burgeoning bioeconomy. Traditional facilities, designed for conventional fermentation processes, are ill-equipped to handle the complexities of precision fermentation and the production of novel bioproducts. This gap has created an urgent need for updated infrastructure that can support the next wave of innovation in agtech and foodtech.

Innovative Startups Leading the Charge

In response to these challenges, a new wave of innovative startups is emerging, focused on constructing state-of-the-art biomanufacturing facilities. These companies are not just building production plants; they’re creating ecosystems that foster innovation and drive the bioeconomy forward. Key features of these modern facilities include:

- Modular and flexible design to adapt to various fermentation processes

- Advanced automation and AI-driven control systems

- Integrated sustainability features for reduced environmental impact

- Scalable production capabilities to meet growing market demands

At Farmonaut, while we specialize in satellite-based farm management solutions, we recognize the importance of these advancements in biomanufacturing for the broader agricultural ecosystem. Our API and API Developer Docs provide complementary tools for those looking to integrate precision agriculture data into their biomanufacturing processes.

The Economics of Sustainable Protein Alternatives

One of the most exciting developments in modern biomanufacturing is the production of sustainable protein alternatives. These facilities are making it economically viable to produce plant-based and fermentation-derived proteins at scale, potentially revolutionizing the food industry. The economics of this shift are compelling:

- Reduced land and water usage compared to traditional animal agriculture

- Lower carbon footprint and environmental impact

- Scalable production that can meet growing global protein demands

- Potential for cost parity or even cost advantages over conventional proteins

“The global bioeconomy, driven by agtech innovations like biomanufacturing, is projected to reach a market value of $2 trillion by 2030.”

Fermentation-Based Ingredients: A New Frontier in Foodtech

Modern biomanufacturing facilities are not just producing alternative proteins; they’re opening up a whole new world of fermentation-based ingredients. These ingredients have the potential to revolutionize the food industry by offering:

- Novel flavors and textures previously unattainable

- Functional ingredients with enhanced nutritional profiles

- Natural preservatives and color additives

- Customizable ingredients tailored to specific dietary needs

Funding Strategies and Profitability Projections

The development of modern biomanufacturing facilities requires significant investment, but the potential returns are substantial. Innovative funding strategies are emerging to support these capital-intensive projects:

- Venture capital and private equity investments in agtech and foodtech startups

- Government grants and subsidies for sustainable manufacturing initiatives

- Strategic partnerships between established food companies and biotech innovators

- Crowdfunding and community investment models for local biomanufacturing projects

Profitability projections for these facilities are promising, driven by:

- High-value, specialized products commanding premium prices

- Economies of scale as production volumes increase

- Reduced input costs through efficient fermentation processes

- Growing consumer demand for sustainable and novel food products

Complexities of Producing Traditional Food Commodities

While modern biomanufacturing facilities offer exciting possibilities, it’s important to understand the complexities they face when producing traditional food commodities. These challenges include:

- Replicating the taste and texture of conventional products

- Achieving cost competitiveness with established supply chains

- Navigating regulatory frameworks for novel food ingredients

- Overcoming consumer hesitation towards fermentation-derived foods

At Farmonaut, we understand the importance of precision in agriculture, whether it’s in traditional farming or modern biomanufacturing. Our satellite-based crop health monitoring and AI advisory systems can provide valuable insights for both conventional and innovative agricultural practices. Explore our solutions through our Android App and iOS App.

The Future of Biomanufacturing: Advancements on the Horizon

As we look to the future, several exciting advancements are poised to further revolutionize biomanufacturing:

- Development of super-efficient microbe strains for enhanced production

- Implementation of continuous processing methods for increased output

- Integration of synthetic biology techniques for novel product creation

- Advanced bioinformatics and machine learning for process optimization

These developments are not only shaping the global bioeconomy but are also driving innovation in food production and agricultural practices. At Farmonaut, we’re excited to see how these advancements will complement our satellite-based precision agriculture solutions.

Global Implications: Beyond US Agtech

The revolution in biomanufacturing is not limited to the United States. Its impact is being felt globally, with significant developments in regions like:

- Europe: Leading in sustainable biomanufacturing practices

- Asia: Rapid adoption of fermentation technologies for traditional foods

- Australia: Pioneering research in novel fermentation-based ingredients

- Middle East: Investing in biomanufacturing to enhance food security

- Africa: Exploring biomanufacturing as a solution to protein deficiency

This global network of innovation is creating new opportunities for collaboration and knowledge exchange, driving the bioeconomy forward on a worldwide scale.

Precision Fermentation Facility Comparison

| Facility Type | Production Capacity (tons/year) | Primary Products | Key Technologies | Estimated Investment ($ millions) | Sustainability Features | Projected ROI (%) |

|---|---|---|---|---|---|---|

| Large-scale Industrial Biorefinery | 50,000+ | Bulk proteins, enzymes, biofuels | Advanced fermentation, continuous processing | 500+ | Closed-loop water systems, renewable energy integration | 15-20 |

| Mid-size Foodtech Facility | 5,000-20,000 | Alternative proteins, specialty ingredients | Precision fermentation, AI-driven process control | 100-300 | Waste upcycling, energy-efficient equipment | 20-25 |

| Specialized Agtech Biologics Plant | 1,000-5,000 | Biopesticides, biofertilizers | Sterile fermentation, advanced recovery systems | 50-150 | Biodegradable packaging, green chemistry principles | 18-22 |

| Multi-purpose Fermentation Hub | 10,000-30,000 | Diverse range of fermentation products | Flexible fermentation platforms, rapid changeover systems | 200-400 | Smart grid integration, carbon capture technology | 17-23 |

| Pilot-scale Research Facility | 100-1,000 | Novel ingredients, process development | High-throughput screening, small-batch fermentation | 20-50 | Life cycle assessment tools, sustainable lab practices | 10-15 (long-term potential) |

The Role of Agricultural Biologics in Modern Farming

Modern biomanufacturing facilities are not just revolutionizing food production; they’re also transforming the way we approach crop protection and soil health through the production of agricultural biologics. These natural, fermentation-derived products offer several advantages:

- Environmentally friendly alternatives to chemical pesticides and fertilizers

- Enhanced crop resilience and yield potential

- Reduced risk of pest resistance development

- Improved soil microbiome health for long-term sustainability

The production of agricultural biologics in modern facilities allows for:

- Precise control over microbial strains and fermentation conditions

- Scalable production to meet growing farmer demand

- Consistent product quality and efficacy

- Rapid development and testing of new biological formulations

At Farmonaut, we recognize the potential of agricultural biologics to complement our satellite-based crop monitoring solutions. While we don’t produce these products, our technology can help farmers optimize their application and assess their effectiveness through real-time crop health data.

Challenges and Opportunities in Scaling Biomanufacturing

As the biomanufacturing sector grows, it faces several challenges in scaling up production to meet global demands:

- Securing a stable supply of feedstocks for fermentation processes

- Optimizing downstream processing and product recovery

- Ensuring consistent product quality across large-scale batches

- Managing the energy and water requirements of large facilities

However, these challenges also present opportunities for innovation:

- Development of novel feedstock sources, including agricultural waste products

- Advancements in separation and purification technologies

- Implementation of real-time quality control and process analytical technologies

- Integration of renewable energy sources and water recycling systems

The Intersection of Biomanufacturing and Digital Agriculture

The future of agtech lies in the convergence of biomanufacturing and digital agriculture technologies. This intersection creates exciting possibilities:

- Data-driven optimization of biomanufacturing processes

- Precision application of biologically derived agricultural inputs

- Integration of satellite data for crop response monitoring

- AI-powered predictive models for bioproduct efficacy

At Farmonaut, we’re at the forefront of digital agriculture with our satellite-based solutions. While we don’t directly engage in biomanufacturing, our technology can provide valuable insights for the development and application of biologically derived products in agriculture.

The Future of Food: From Lab to Table

Modern biomanufacturing facilities are not just changing how we produce food; they’re redefining what food can be. As we look to the future, we can expect to see:

- Customized nutrition tailored to individual genetic profiles

- Novel food experiences with textures and flavors beyond traditional cuisine

- Significant reductions in the environmental footprint of food production

- Increased food security through localized, efficient production methods

While these advancements are exciting, it’s important to note that traditional agriculture will continue to play a crucial role in feeding the world. At Farmonaut, we’re committed to supporting both innovative and traditional farming methods through our precision agriculture solutions.

Regulatory Landscape and Consumer Acceptance

As biomanufacturing continues to evolve, navigating the regulatory landscape and ensuring consumer acceptance are critical challenges:

- Developing appropriate regulatory frameworks for novel food ingredients

- Ensuring transparency in labeling and product information

- Addressing consumer concerns about food safety and “naturalness”

- Educating the public about the benefits of biomanufactured products

The industry must work closely with regulators, consumers, and advocacy groups to build trust and establish clear guidelines for the future of food production.

Conclusion: A New Era in US Agtech

The rise of modern biomanufacturing facilities marks a new era in US agtech, one that promises to revolutionize food production, agricultural practices, and environmental sustainability. As these facilities continue to evolve and scale, they will play a crucial role in addressing global challenges such as food security, climate change, and resource scarcity.

At Farmonaut, we’re excited to be part of this agricultural revolution, providing cutting-edge satellite-based solutions that complement the advancements in biomanufacturing. While our focus remains on precision agriculture through remote sensing and data analytics, we recognize the immense potential of these new technologies to shape the future of farming.

As we move forward, the integration of digital agriculture, biomanufacturing, and traditional farming practices will be key to creating a more sustainable and resilient food system. By embracing innovation and fostering collaboration across sectors, we can build a future where technology and nature work hand in hand to feed the world.

FAQ Section

Q: What is precision fermentation in food production?

A: Precision fermentation is an advanced biotechnology process that uses genetically engineered microorganisms to produce specific proteins, fats, or other compounds. In food production, it’s used to create ingredients that are identical to or functionally similar to those found in nature, but with greater efficiency and sustainability.

Q: How do modern biomanufacturing facilities differ from traditional fermentation plants?

A: Modern biomanufacturing facilities are equipped with advanced technologies like AI-driven process control, continuous fermentation systems, and precision monitoring tools. They’re designed for flexibility, allowing for the production of a wide range of products, and often incorporate sustainable practices like closed-loop systems and renewable energy use.

Q: What types of products can be made in these new facilities?

A: These facilities can produce a diverse range of products, including alternative proteins, specialized enzymes, novel food ingredients, biofuels, agricultural biologics, and even pharmaceutical precursors. The versatility of modern biomanufacturing allows for the creation of both traditional fermentation products and entirely new biomolecules.

Q: How do biomanufacturing facilities contribute to sustainability in agriculture?

A: Biomanufacturing facilities contribute to sustainability by producing agricultural inputs like biopesticides and biofertilizers more efficiently, reducing the need for chemical alternatives. They also enable the production of alternative proteins with a lower environmental footprint compared to traditional animal agriculture.

Q: What role does Farmonaut play in the biomanufacturing revolution?

A: While Farmonaut doesn’t directly engage in biomanufacturing, our satellite-based precision agriculture solutions complement these advancements. Our technology can help optimize the application of biologically derived agricultural inputs and monitor their effectiveness through real-time crop health data.