Managing Dust Disasters in Seed Handling: Top Safety Tips

“Over 50% of grain facility explosions are linked to poor dust management, highlighting the need for strict safety protocols.”

Table of Contents

- Summary: Managing Dust Disasters in Seed Handling

- Understanding Dust Explosions in Seed Handling

- Historical Dust Explosion Incidents and Impact

- Recent Trends and Data in Grain Handling Safety

- Top Causes and Risks of Dust Explosion in Seed Processing

- Best Preventive Measures for Dust Explosion Prevention

- Comparative Safety Measures vs. Risk Reduction Table

- Regulatory Compliance: OSHA and NFPA Combustible Dust Standards

- Farmonaut: Tech-Forward Solutions for Safer Agriculture

- Frequently Asked Questions on Dust Disaster Management

- Conclusion: Building a Safer Seed Handling Environment

Summary: Managing Dust Disasters in Seed Handling—A Comprehensive Guide

Dust explosions remain a grave threat in seed handling facilities, often resulting in devastating injuries, fatalities, and property damage. To confront this challenge head-on, we must understand the underlying risks, adhere to safety protocols, and consistently implement comprehensive preventive strategies. This guide explores dust explosion prevention, the importance of grain handling safety, and guides us through the critical role of NFPA combustible dust standards in curbing hazards within seed processing facilities.

From the causes and history to the latest trends, we examine why and how dust disasters occur, and what actionable measures can drastically reduce risks to our operations, personnel, and infrastructure. Discover how a strong commitment to dust control systems for grain, robust housekeeping protocols for dust mitigation, and relentless employee training for dust hazards are transforming the safety landscape in today’s ever-evolving agriculture sector.

Understanding Dust Explosions in Seed Handling

What Are Dust Explosions?

To mitigate combustible dust hazards, it is crucial we begin with a firm grasp of what a dust explosion actually is. A dust explosion occurs when fine particles—such as those generated and suspended in the air from seeds like corn, wheat, and soybeans—accumulate to dangerous concentration levels. If these airborne particles come into contact with an ignition source such as a spark, hot surface, or static discharge, rapid combustion can ensue, leading to an extremely violent explosive event.

The five critical components, often referred to as the “Dust Explosion Pentagon,” are:

- Fuel (Combustible Dust): Fine, dry seed, grain, or flour particles.

- Oxygen: Present in ambient air.

- Dispersion: Dust particles suspended and distributed in the air.

- Confinement: Enclosed spaces like processing equipment, bins, or elevators.

- Ignition Source: Heat, spark, friction, or electrical discharge.

When all these elements converge, an explosion can be triggered—resulting in severe injuries, potentially fatalities, and catastrophic property damage.

Why Dust Explosions Occur in Grain and Seed Handling Facilities

Seed handling operations—from storage silos to mills, elevators, and processing plants—generate large volumes of fine dust. These environments provide the fuel, the air, the potential for dispersion, the confinement, and frequently, numerous unexpected ignition sources. The risk is ever-present, underscoring the need for constant vigilance and robust preventive systems.

Historical Dust Explosion Incidents and Their Impact

Examining historical incidents reinforces the harsh lessons learned and the ongoing global concerns regarding grain handling safety.

-

DeBruce Grain Elevator Explosion, 1998 (Wichita, Kansas):

- A series of powerful explosions at a major grain elevator in Wichita, Kansas, tragically resulted in seven fatalities and ten serious injuries.

- This incident catalyzed reforms in safety practices and influenced the rigorous standards now required in the U.S. agriculture sector.

-

Tradeston Flour Mills Explosion, 1872 (Glasgow, Scotland):

- Grain dust buildup led to an explosion at the Tradeston Flour Mills, causing eighteen deaths and more than sixteen injuries.

- The devastation highlighted the global scale of the dust explosion problem in seed and grain processing facilities.

These historical cases remind us that, despite modern advances, the potential for disaster remains unless we rigorously apply contemporary safety protocols and technologies.

Recent Trends: Grain Handling Safety Data and Statistics

Recent data continues to reveal the persistent risk landscape faced by grain and seed handling operations across the nation.

-

2024 U.S. Dust Explosion Statistics:

- Nine grain dust explosions were reported in the U.S., resulting in two injuries and thankfully, no fatalities.

- This aligns closely with the national average of 8.6 explosions per year over the past decade.

- The incidents occurred in a variety of settings including feed mills, grain elevators, and processing plants.

Despite improved awareness, combustible dust hazards remain a pressing threat. The challenge lies in converting knowledge and compliance into consistent, actionable best practices in our daily operations.

“NFPA standards have reduced combustible dust incidents in seed processing by up to 40% over the past decade.”

Top Causes and Risks of Dust Explosion in Seed Processing

Primary Hazards and Sources in Seed Handling Facilities

As we explore the risks in seed handling, it’s vital to identify the key causes of dust explosions:

- Poor Dust Control: Ineffective or absent dust collection systems allow accumulations on surfaces and in the air.

- Inadequate Housekeeping: Failure to enforce housekeeping protocols for dust mitigation increases the likelihood of airborne dust clouds.

- Equipment Malfunction: Overheated bearings, friction, misaligned belts, or worn parts can become ignition sources due to excess heat and sparks.

- Electrostatic Discharge: Static build-up from moving particles can suddenly ignite a dust cloud.

- Confinement in Enclosed Equipment: Dust accumulates in bin legs, elevators, hoppers, and mills, creating potential explosion zones.

- Lack of Staff Training: Inconsistent adherence to preventive protocols and improper emergency response increase the chance of major incidents.

The Role of Ignition Sources in Triggering Explosions

Common ignition sources in seed handling include electrical failures, hot equipment, welding, grinding, open flames, and even friction from rapidly advancing mechanical components. Ignition source control is vital for disaster prevention. An accumulation of dust can sit dormant for weeks, only to be explosively unleashed by a single, seemingly minor disturbance or spark. Therefore, maintaining robust control systems is non-negotiable for dust explosion prevention.

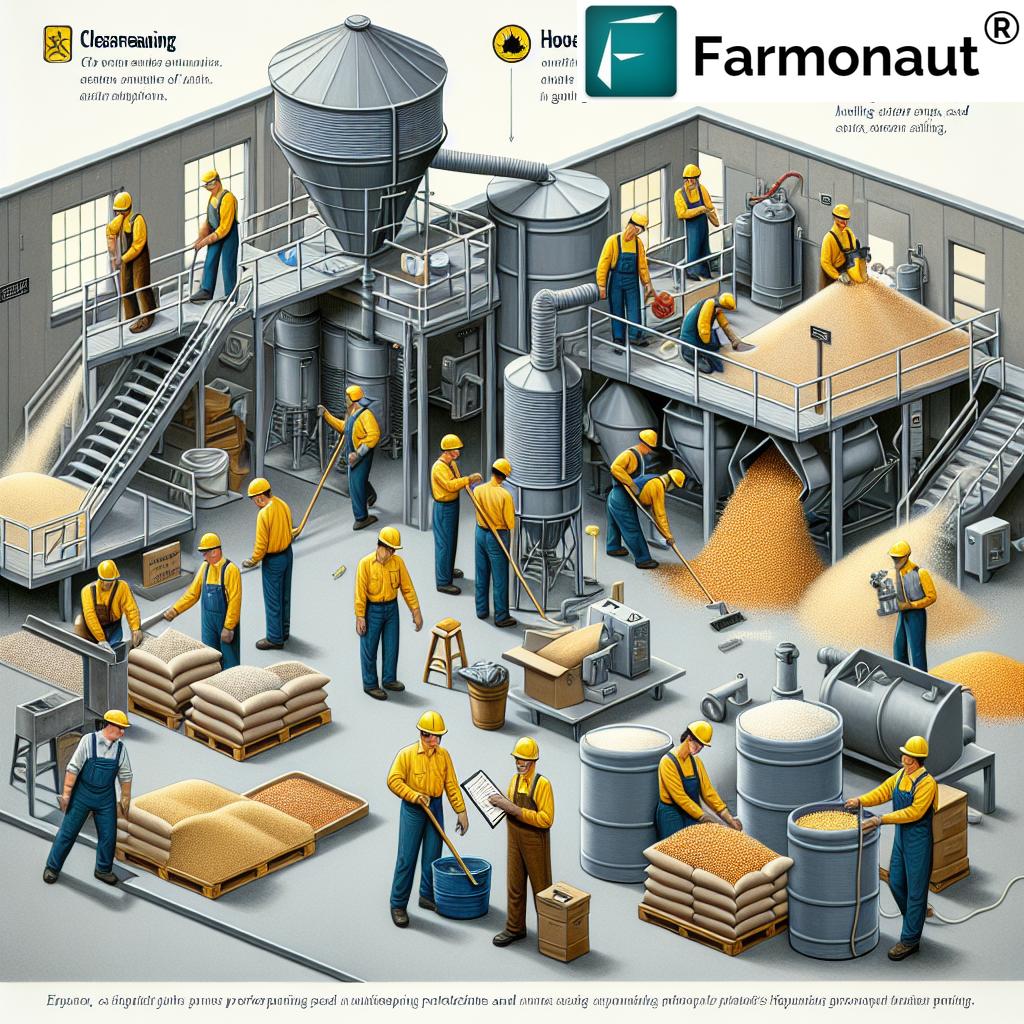

Best Preventive Measures: Dust Explosion Prevention Strategies

Robust Approaches to Reduce Seed Processing Facilities Risk

The cornerstone of seed processing facilities risk reduction lies in a multi-layered set of preventive measures. We must recognize that a single solution is insufficient—a holistic mix of technology, culture, and compliance is required to truly mitigate disaster risks.

-

Dust Control Systems for Grain

- Implementing high-efficiency dust collection systems with primary and secondary filters prevents fine dust particles from becoming airborne.

- These systems must be designed for the specific particle sizes and dust loads encountered in seed, grain, and flour handling.

- Proper venting ensures captured dust does not redeposit onto facility surfaces or into the air, achieving true mitigation.

-

Housekeeping Protocols for Dust Mitigation

- Developing and enforcing frequent and thorough housekeeping schedules (daily, weekly, and during shift changes).

- Pay special attention to inaccessible areas (rafters, beams, tops of machinery, bin legs) where dust accumulates.

- Routine vacuuming (using explosion-proof vacuums), mopping, and surface wiping reduce layered dust that fuels explosions.

- Staff must be trained to recognize and immediately address dust hazards—making cleanliness part of the organizational culture.

-

Equipment Maintenance and Inspection

- Regular maintenance and timely repair of conveying, milling, and handling equipment are fundamental to disaster prevention.

- Faulty motors, heated bearings, misalignments, or worn belts should never be overlooked, as these are major ignition source triggers.

- Scheduled inspections—using checklists aligned with national safety standards—should be the norm.

- Incorporate predictive maintenance using IoT sensors for monitoring heat, vibration, and dust emissions where possible.

-

Explosion Protection Systems in Agriculture

- Venting, suppression, and isolation systems are vital safeguards in mill, grain elevator, and processing environments.

- Explosion vents allow controlled pressure release, reducing structural damage.

- Suppression systems deploy extinguishing agents at the sign of an explosion, while isolation valves prevent explosion propagation.

- Periodic testing and certification ensure these systems remain effective.

-

Ignition Source Control

- Strict protocols to identify, eliminate, and control all forms of spark, heat, and static discharge.

- Only use explosion-proof electricals, minimize open flames and hot work, and ensure all static-charged machinery is grounded.

- Easing belt friction, cleaning bearings, and keeping equipment lubricated reduce unexpected ignition risks.

-

Employee Training for Dust Hazards

- Comprehensive staff education on combustible dust hazards and explosion mitigation is non-negotiable.

- Training includes identifying dust-prone areas, safe cleaning techniques, emergency response drills, hazard reporting, and PPE usage.

- Ongoing refresher courses maintain a proactive safety culture.

By weaving these risk mitigation strategies into our daily protocols and operational blueprint, we dramatically reduce the likelihood of disaster while enhancing safety, productivity, and regulatory compliance.

Use Case Highlight—Fleet and Resource Management:

For large-scale facilities managing numerous vehicles and equipment, Farmonaut’s Fleet Management Tools

enable efficient tracking and deployment, reducing downtime, aiding rapid response during emergencies, and enhancing equipment maintenance scheduling for dust hazard control.

Carbon Footprinting Integration:

Monitor and reduce your facility’s environmental impact with Farmonaut’s Carbon Footprinting Tool.

Track emissions from grain handling and processing, identify high-risk operations, and meet regulatory compliance efficiently.

Comparative Safety Measures vs. Risk Reduction Table

To help us evaluate which preventive methods are most effective for dust explosion prevention, the following table offers a comparative analysis of key safety measures with their impact estimates, regulatory compliance (NFPA), and practical implementation levels.

| Safety Measure | Description | Estimated Risk Reduction (%) | Compliance with NFPA Standard | Implementation Difficulty |

|---|---|---|---|---|

| Dust Ventilation & Collection Systems | High-efficiency dust collectors and ventilation systems remove airborne dust at the source. | 65% | Yes (NFPA 61/652) | Medium |

| Housekeeping Protocols | Routine cleaning and monitoring to prevent dust accumulation on all surfaces. | 45% | Yes (NFPA 61/652) | Low |

| Explosion-Proof Equipment | Electrical and mechanical devices designed to prevent ignition in dusty atmospheres. | 30% | Yes (NFPA 61/70) | Medium |

| Staff Training | Ongoing employee education regarding dust hazards, protocols, and emergency response. | 35% | Yes (NFPA 61/652) | Low |

| Regular Safety Audits | Frequent audits and inspections to detect and correct hazards. | 25% | Yes (NFPA 61/652) | Medium |

| Explosion Protection and Suppression Systems | Explosion venting panels, suppression agents, and isolation valves. | 60% | Yes (NFPA 61/68) | High |

| Ignition Source Control | Minimizing or eliminating sources like sparks, static, and friction. | 40% | Yes (NFPA 61/652/77) | Medium |

Tip: For easier integration of risk monitoring and compliance management, utilize Farmonaut’s Large Scale Farm Management Dashboard—enabling real-time data monitoring for hazards, crop health, and more, accessible on web and mobile.

Blockchain-Based Traceability for Supply Chain Safety:

Want to enhance transparency in seed processing and ensure every batch is monitored from field to silo? Consider Farmonaut’s Traceability Solutions. It leverages blockchain to secure and record every stage of your product’s journey, improving quality assurance and fostering stakeholder trust.

Regulatory Compliance: OSHA and NFPA Combustible Dust Standards

Adhering to Regulations for Safer Facilities

Compliance isn’t just a legal formality—it’s the backbone of workplace safety and risk mitigation in our sector.

- OSHA Standards: Mandate safe grain handling practices, establish regulations for dust control, explosion-proof equipment, and required training protocols to minimize workplace injuries and fatalities.

-

NFPA Combustible Dust Standards: Specifically NFPA 61 (for agricultural dusts) and NFPA 652 (fundamental combustible dust standard), provide a rigorous framework for best practices in:

- Engineering controls (ventilation, suppression).

- Administrative controls (maintenance schedules, audits, recordkeeping).

- Process safety (hazard analysis, incident investigation).

- Personnel training and emergency preparedness.

- Global Regulations: Many countries have adopted best practices based on U.S. OSHA/NFPA guidelines due to their proven effectiveness in reducing disaster rates.

Following these standards is essential not just for compliance, but for maintaining an ethical, sustainable, and resilient agricultural business.

Explore public API access for facility management with Farmonaut here:

Farmonaut Satellite-Weather Public API—easy for integrating hazard alerts, maintenance scheduling, and compliance monitoring.

Need development support? Visit our API Developer Documentation.

Farmonaut: Tech-Forward Solutions for Safer Agriculture

Farmonaut empowers the agricultural sector to strengthen disaster management and risk mitigation through advanced, precision agriculture technology, offering support across varied facets of farm management.

- Satellite-Based Crop Health Monitoring: Farmonaut delivers regular, objective insights—helping identify stressed fields, pest problems, or abnormal crop conditions at a glance. This can reveal operational issues (e.g. excessive dust production areas) that need urgent safety interventions.

- Jeevn AI Advisory System: This AI-driven personalized advisory is a game-changer—alerting managers to hazards, weather changes, or irrigation patterns that may affect dust risks and compliance.

- Blockchain-Backed Traceability: By tracing products from seed to shelf, Farmonaut strengthens transparency and builds trust with both end-consumers and regulatory agencies, essential in an era of heightened supply chain scrutiny.

- Fleet and Resource Management: Manage logistical flow, optimize routes, and reduce downtime—ensuring staff and vehicles respond rapidly in emergencies and facilitating scheduling for routine maintenance that reduces dust build-up.

- Carbon Footprinting: Monitor process emissions continually, revealing which operations or equipment yield the most airborne dust and combustibles, and track improvements as mitigation strategies are adopted.

Access all these tools easily via Android, iOS, web, or API—making grain handling safety and dust disaster management more proactive, cost-effective, and accessible than ever before.

Interested in broad-scale resource optimization or advisory for specialty crops? Farmonaut’s Crop Plantation, Forest & Management Advisory tailors insights to facility-specific conditions.

FAQ: Frequently Asked Questions on Managing Dust Disasters in Seed Handling

Q1: What is the most important factor in preventing dust explosions in seed handling?

The most critical factor is effective dust control. Without systematic dust collection and thorough housekeeping, airborne particles accumulate rapidly, amplifying explosion risks. Pair this with ignition source control for comprehensive safety.

Q2: Do NFPA standards apply globally or just in the United States?

While NFPA combustible dust standards originate in the U.S., many countries and international organizations adopt or adapt these protocols due to their effectiveness. Always consult local regulations, but NFPA remains a global benchmark.

Q3: How often should facility equipment be inspected to prevent dust explosions?

All equipment should undergo routine inspection at intervals defined by OSHA and NFPA standards—typically weekly or monthly, with increased frequency during high-intensity operations. Predictive digital tools can send automatic alerts for heat, vibration, or dust anomalies.

Q4: What employee training for dust hazards is required in seed processing?

Employee training for dust hazards must cover the properties of combustible dusts, safe cleaning practices, identifying hazards, emergency response, use of PPE, and must be refreshed regularly as per OSHA and NFPA requirements.

Q5: Can digital monitoring tools help with dust explosion prevention?

Absolutely. Digital platforms like Farmonaut offer real-time monitoring, alerting, and recordkeeping—key for early warning, compliance, and targeted preventive measures.

Q6: How are Farmonaut solutions different from traditional grain safety systems?

Traditional systems focus on reactive safety. Farmonaut’s solutions are data-driven and proactive—integrating satellite, blockchain, and AI insights for continuous, facility-wide risk reduction, not just compliance.

Q7: What role does traceability play in managing dust disasters?

Blockchain-based traceability ensures every batch is accounted for, all the way from the farm to the bin. This reduces human error, supports auditing, and fosters a transparent, accountable safety culture.

Q8: Are there financial benefits to implementing explosion control systems in agriculture?

Certainly. Reducing downtime, minimizing property damage, lowering insurance premiums, and avoiding costly regulatory fines all offer immediate and long-term ROI beyond the safety benefits.

Conclusion: Building a Safer Seed Handling Environment

In summary, managing dust disasters in seed handling is a holistic mission. We must be relentless about dust explosion prevention, invest in top-tier grain handling safety systems, and ensure every aspect—from equipment to culture—aligns with both OSHA and NFPA combustible dust standards. Whether through advanced dust collection systems for grain, digital resource management, or comprehensive employee training for dust hazards, embracing a zero-compromise attitude toward risk is non-negotiable.

Through a combination of technology, strong protocols, and unwavering vigilance, we not only mitigate disaster, but set our facilities apart as safe, efficient, and sustainable leaders in the global agriculture sector.

Ready to implement the future of seed and grain safety? Explore Farmonaut’s Apps for real-time monitoring and compliance-ready operations today.