Ultimate Guide: Mastering Farm Equipment Maintenance for Peak Performance with Farmonaut’s Precision Agriculture Technology

“Regular maintenance can extend farm equipment lifespan by up to 25%, saving farmers thousands in replacement costs.”

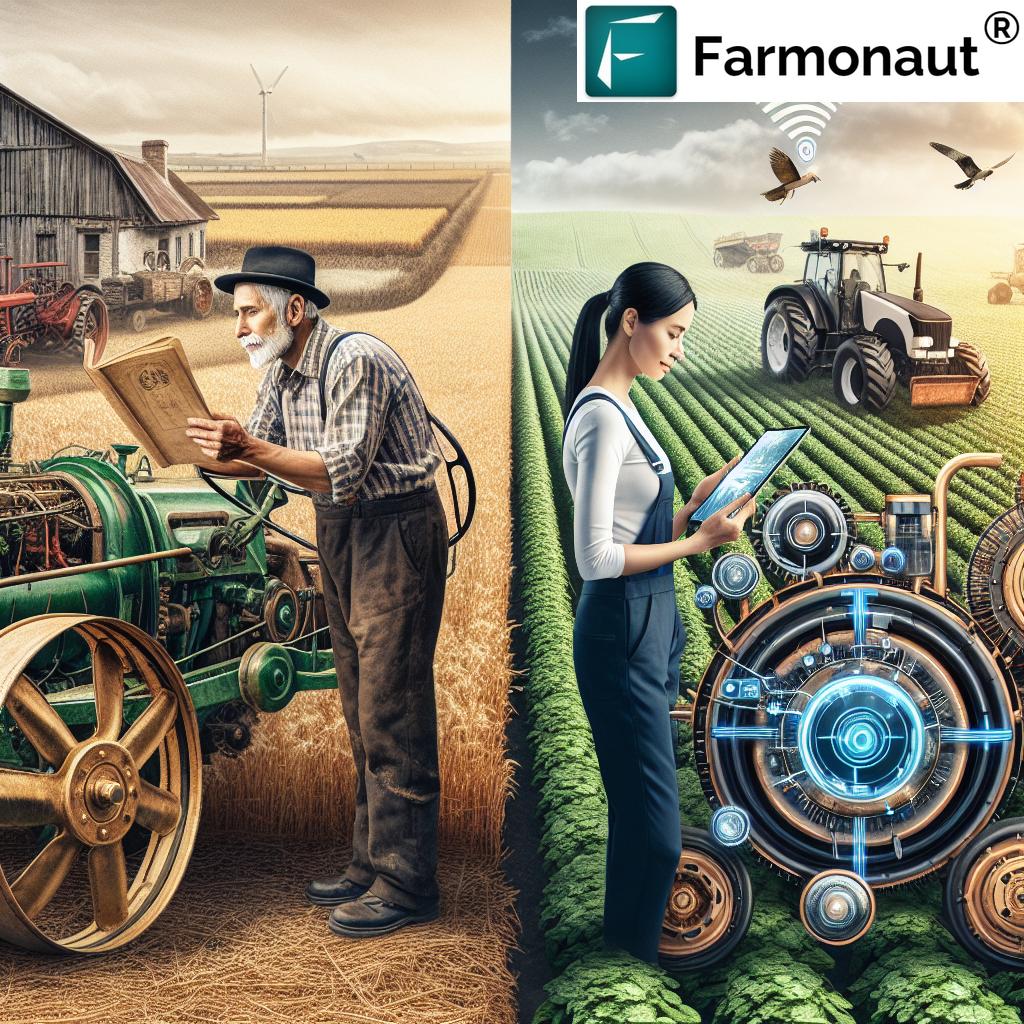

Welcome to our comprehensive guide on mastering farm equipment maintenance and harnessing the power of precision agriculture technology with Farmonaut. In this ultimate resource, we’ll explore essential strategies for keeping your agricultural machinery in peak condition while leveraging cutting-edge solutions to optimize your farming operations.

At Farmonaut, we understand the crucial role that well-maintained equipment plays in modern agriculture. That’s why we’ve combined our expertise in satellite-based farm management with practical insights on equipment care to bring you this invaluable guide. Whether you’re a small-scale farmer or managing a large agricultural enterprise, this blog post will equip you with the knowledge and tools to maximize the performance and longevity of your farm machinery.

The Importance of Farm Equipment Maintenance

Proper maintenance of farm equipment is not just about keeping machines running; it’s about ensuring the efficiency, safety, and profitability of your entire agricultural operation. Here’s why it matters:

- Extended Equipment Lifespan: Regular maintenance can significantly prolong the life of your machinery, reducing the need for costly replacements.

- Improved Performance: Well-maintained equipment operates at peak efficiency, leading to better crop yields and reduced resource waste.

- Enhanced Safety: Properly serviced machinery is less likely to malfunction, creating a safer working environment for farm operators.

- Cost Savings: While maintenance requires an investment, it’s far less expensive than major repairs or premature equipment replacement.

- Environmental Benefits: Efficient equipment consumes less fuel and produces fewer emissions, contributing to sustainable farming practices.

Now, let’s dive into the essential maintenance practices for various types of farm equipment, integrated with Farmonaut’s precision agriculture technology.

Tractor Maintenance: The Heart of Your Farm Operations

Tractors are the workhorses of any farm, and their proper maintenance is crucial for smooth operations. Here’s a comprehensive guide to keeping your tractors in top shape:

Daily Tractor Checks

- Fluid Levels: Check engine oil, coolant, and hydraulic fluid levels daily.

- Tire Pressure: Ensure proper inflation for optimal performance and fuel efficiency.

- Visual Inspection: Look for any signs of damage, leaks, or loose parts.

Weekly Tractor Maintenance

- Grease Points: Lubricate all grease fittings to prevent wear and tear.

- Air Filter: Clean or replace air filters to maintain engine efficiency.

- Battery: Check battery connections and clean any corrosion.

Monthly Tractor Service

- Belt Tension: Inspect and adjust all belts for proper tension.

- Fuel System: Check fuel lines and replace fuel filters as needed.

- Electrical System: Inspect wiring and connections for any signs of wear.

By integrating Farmonaut’s precision agriculture technology with your tractor maintenance routine, you can take your equipment care to the next level. Our satellite-based monitoring system can help you track tractor usage patterns, allowing for more precise scheduling of maintenance tasks based on actual usage rather than just calendar dates.

Harvesting Equipment: Ensuring a Smooth and Efficient Harvest

Harvesting equipment, such as combines and harvesters, plays a critical role in bringing in your crops. Proper maintenance of these machines is essential for maximizing yield and minimizing post-harvest losses. Here’s how to keep your harvesting equipment in prime condition:

Pre-Season Harvester Maintenance

- Thorough Cleaning: Remove any debris or residue from the previous season.

- Cutting Components: Sharpen or replace blades, knives, and other cutting parts.

- Belt and Chain Inspection: Check for wear and proper tension, replacing as necessary.

- Lubrication: Grease all moving parts according to the manufacturer’s specifications.

During Harvest Season

- Daily Inspections: Conduct visual checks before each use, looking for any signs of damage or wear.

- Auger and Conveyor Maintenance: Ensure these components are clean and functioning correctly to prevent blockages.

- Sensor Calibration: Regularly calibrate yield monitors and other sensors for accurate data collection.

Post-Harvest Care

- Thorough Cleaning: Remove all crop residue to prevent rust and pest infestations.

- Storage Preparation: Apply rust preventative to exposed metal surfaces and store equipment in a dry location.

- Off-Season Repairs: Address any issues noticed during the harvest season to ensure readiness for the next year.

Farmonaut’s precision agriculture technology can significantly enhance your harvesting equipment maintenance strategy. Our satellite imagery and AI-driven insights can help you predict optimal harvest times, allowing you to prepare your equipment just when it’s needed, reducing unnecessary wear and tear.

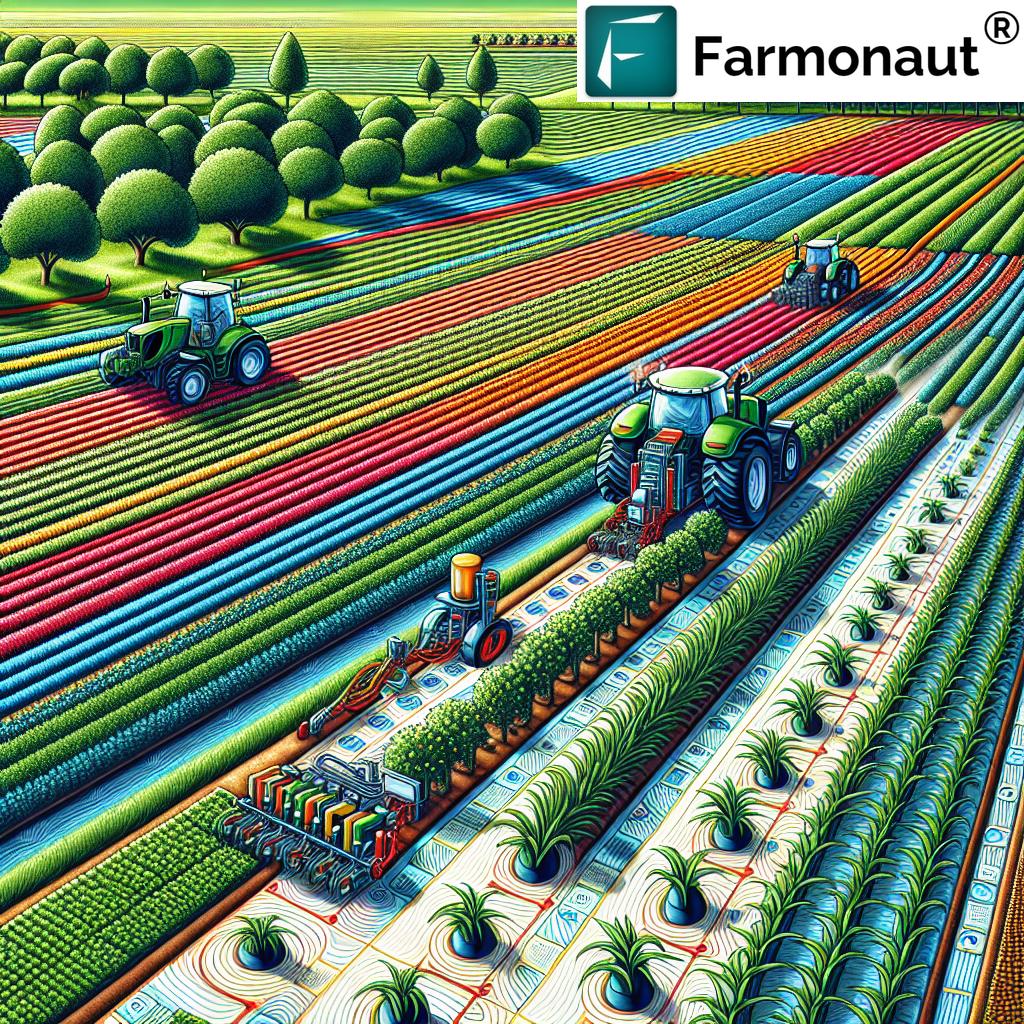

Planting and Seeding Equipment: Laying the Foundation for a Successful Crop

Proper maintenance of planting and seeding equipment is crucial for ensuring accurate seed placement, consistent depth, and optimal germination rates. Here’s how to keep these vital machines in top condition:

Pre-Season Planter Maintenance

- Seed Metering System: Clean, inspect, and calibrate for accurate seed distribution.

- Furrow Openers: Check for wear and proper alignment, replacing parts as needed.

- Depth Control: Verify and adjust depth-control mechanisms for consistent seed placement.

- Tire Pressure: Ensure proper inflation for even planting depth across the field.

In-Season Planter Care

- Daily Inspections: Check seed tubes, sensors, and moving parts for any obstructions or damage.

- Seed Monitoring: Regularly verify the accuracy of seed placement and adjust as necessary.

- Lubrication: Grease all moving parts according to the manufacturer’s recommendations.

Post-Season Maintenance

- Thorough Cleaning: Remove all seed and chemical residues to prevent corrosion.

- Component Inspection: Examine all parts for wear and create a list of needed repairs or replacements.

- Storage Preparation: Apply rust preventative and store in a dry location to protect from the elements.

Integrating Farmonaut’s precision agriculture technology with your planting equipment maintenance can lead to significant improvements in efficiency and accuracy. Our satellite-based soil moisture monitoring can help you determine the optimal time for planting, ensuring your equipment is ready when conditions are ideal.

Explore Farmonaut’s API for advanced soil moisture data integration

Irrigation Systems: Ensuring Efficient Water Management

Proper maintenance of irrigation systems is essential for water conservation, crop health, and overall farm productivity. Here’s how to keep your irrigation equipment in peak condition:

Pre-Season Irrigation System Checks

- Pump Inspection: Check and service irrigation pumps, ensuring proper pressure and flow rates.

- Pipe and Hose Examination: Inspect for leaks, cracks, or blockages in all water delivery components.

- Sprinkler and Nozzle Assessment: Clean and replace worn sprinkler heads and nozzles for even water distribution.

- Control System Verification: Test and calibrate automated control systems and timers.

In-Season Irrigation Maintenance

- Regular System Monitoring: Conduct weekly checks for any signs of malfunction or inefficiency.

- Filter Cleaning: Clean or replace filters to prevent clogging and ensure proper water flow.

- Pressure Gauge Readings: Monitor pressure levels regularly to detect any system issues early.

End-of-Season Care

- System Drainage: Properly drain all pipes and components to prevent freezing damage.

- Winterization: For cold climates, follow manufacturer guidelines for winterizing the system.

- Component Storage: Remove and safely store any removable parts to protect from off-season damage.

Farmonaut’s precision agriculture technology can revolutionize your irrigation management. Our satellite-based crop health monitoring and AI-driven advisory system can help you optimize irrigation schedules, ensuring your system operates only when necessary, thus reducing wear and tear while conserving water resources.

“Precision agriculture technology can increase crop yields by 10-15% while reducing water usage by up to 30%.”

Check out our API Developer Docs for integrating advanced irrigation management features

Tillage Equipment: Preparing the Perfect Seedbed

Proper maintenance of tillage equipment is crucial for creating optimal soil conditions for planting. Here’s how to keep your tillage tools in top shape:

Pre-Season Tillage Tool Maintenance

- Blade and Disc Inspection: Check for wear and replace or sharpen as needed.

- Frame and Hitch Check: Inspect for any cracks or damage, repairing as necessary.

- Bearing Examination: Grease all bearings and replace any that show signs of wear.

- Hydraulic System Service: Check hydraulic hoses and cylinders for leaks or damage.

In-Season Care

- Daily Inspections: Look for any bent or broken components before each use.

- Soil Buildup Removal: Clean off any soil accumulation to maintain proper operation.

- Bolt Tightening: Regularly check and tighten all bolts to prevent equipment failure.

Post-Season Maintenance

- Thorough Cleaning: Remove all soil and debris to prevent rust and corrosion.

- Rust Prevention: Apply a coat of oil or rust inhibitor to metal surfaces.

- Storage Preparation: Store in a dry location, preferably indoors or under a cover.

Farmonaut’s precision agriculture technology can enhance your tillage operations by providing detailed soil moisture and composition data. This information allows you to optimize your tillage practices, reducing unnecessary wear on your equipment while improving soil health.

Sprayers and Chemical Applicators: Ensuring Precise and Safe Application

Proper maintenance of sprayers and chemical applicators is essential for accurate and safe application of fertilizers and pesticides. Here’s how to keep these crucial tools in optimal condition:

Pre-Season Sprayer Maintenance

- Tank Inspection: Check for cracks, leaks, or damage to the main tank and rinse tank.

- Pump Service: Inspect and service the pump, replacing seals and diaphragms if necessary.

- Nozzle Check: Clean or replace all nozzles to ensure proper spray patterns and flow rates.

- Calibration: Thoroughly calibrate the sprayer for accurate application rates.

In-Season Sprayer Care

- Daily Cleaning: Rinse the system thoroughly after each use to prevent chemical buildup.

- Filter Maintenance: Regularly clean or replace filters to maintain proper flow.

- Pressure Check: Monitor system pressure regularly for consistent application.

Post-Season Maintenance

- Deep Cleaning: Perform a thorough cleaning of the entire system, including all hoses and nozzles.

- Winterization: In cold climates, add antifreeze to prevent damage from freezing.

- Component Inspection: Check all parts for wear and create a repair or replacement plan for the next season.

Farmonaut’s precision agriculture technology can significantly enhance your spraying operations. Our satellite-based crop health monitoring can help you identify areas that need treatment, allowing for targeted application and reducing overall chemical usage. This not only saves on input costs but also minimizes unnecessary wear on your spraying equipment.

Precision Agriculture Technology Integration

Integrating Farmonaut’s precision agriculture technology with your equipment maintenance routine can lead to significant improvements in efficiency and productivity. Here’s how our solutions can enhance your maintenance practices:

- Satellite-Based Monitoring: Our advanced satellite imagery provides real-time data on crop health, allowing you to optimize equipment usage and maintenance schedules.

- AI-Driven Advisory System: Our Jeevn AI system offers personalized recommendations for equipment maintenance based on your specific farm conditions and usage patterns.

- Resource Management Tools: Our platform helps you track equipment usage, schedule maintenance tasks, and manage your fleet more efficiently.

- Weather Forecasting: Accurate weather predictions allow you to plan equipment usage and maintenance activities around optimal conditions.

By leveraging these technologies, you can transition from reactive to proactive maintenance, reducing downtime and extending the lifespan of your valuable farm equipment.

DIY Equipment Maintenance Tips

While some maintenance tasks require professional service, there are many aspects of equipment care that farmers can handle themselves. Here are some DIY maintenance tips to keep your machinery running smoothly:

- Regular Cleaning: Keep your equipment clean to prevent buildup of dirt and debris that can cause wear.

- Proper Storage: Store equipment in dry, covered areas when not in use to protect from the elements.

- Lubrication Schedule: Develop and stick to a regular lubrication schedule for all moving parts.

- Tire Maintenance: Regularly check tire pressure and condition across all equipment.

- Fluid Checks: Routinely inspect and top off all fluids, including oil, coolant, and hydraulic fluid.

- Belt Inspections: Check belt tension and condition regularly, adjusting or replacing as needed.

- Bolt Tightening: Periodically check and tighten all bolts to prevent equipment failure.

Remember, while DIY maintenance can save costs, always consult your equipment’s owner’s manual and don’t hesitate to seek professional help for complex issues.

Farm Equipment Warranty and Financing Considerations

Understanding your equipment warranty and financing options is crucial for effective long-term management of your farm machinery. Here are some key points to consider:

Equipment Warranty

- Warranty Coverage: Familiarize yourself with what’s covered under your equipment’s warranty.

- Maintenance Requirements: Adhere to manufacturer-specified maintenance to keep your warranty valid.

- Documentation: Keep detailed records of all maintenance and repairs for warranty claims.

- Extended Warranties: Consider the cost-benefit of extended warranty options for critical equipment.

Equipment Financing

- Loan vs. Lease: Evaluate whether buying or leasing equipment is more beneficial for your operation.

- Interest Rates: Shop around for the best interest rates on equipment loans.

- Tax Implications: Consult with a tax professional about potential deductions for equipment purchases.

- Resale Value: Consider the long-term resale value when making equipment investments.

Farmonaut’s technology can play a role in your equipment financial planning by providing data-driven insights into equipment usage and efficiency, helping you make informed decisions about purchases, upgrades, and replacements.

Finding Reliable Agricultural Machinery Dealers

Choosing the right dealer for your farm equipment is crucial for ensuring quality machinery and ongoing support. Here are some tips for finding reliable agricultural machinery dealers:

- Reputation: Research the dealer’s reputation through online reviews and word-of-mouth from other farmers.

- Service Quality: Evaluate the dealer’s service department capabilities and responsiveness.

- Parts Availability: Ensure the dealer maintains a good inventory of parts for timely repairs.

- Equipment Range: Look for dealers that offer a wide range of equipment to meet various farming needs.

- Financing Options: Consider dealers that provide flexible financing solutions.

- Training and Support: Choose dealers that offer training on new equipment and ongoing technical support.

- Warranty Handling: Assess how efficiently the dealer processes warranty claims and repairs.

While Farmonaut doesn’t sell equipment directly, our platform can help you track the performance and efficiency of machinery from different dealers, aiding in future purchasing decisions.

Leveraging Technology for Equipment Maintenance

In today’s digital age, technology plays a crucial role in streamlining equipment maintenance processes. Here’s how you can leverage various tech solutions:

- Maintenance Tracking Software: Use digital tools to schedule and track maintenance tasks across your equipment fleet.

- IoT Sensors: Implement Internet of Things (IoT) sensors on key equipment to monitor performance and predict maintenance needs.

- Mobile Apps: Utilize mobile applications for quick access to equipment manuals, troubleshooting guides, and maintenance logs.

- Telematics: Employ telematics systems to track equipment usage, location, and performance metrics.

- Augmented Reality (AR): Explore AR tools for visual guides during complex maintenance procedures.

Farmonaut’s platform integrates seamlessly with many of these technologies, providing a comprehensive solution for equipment management and maintenance optimization.

Environmental Considerations in Equipment Maintenance

Sustainable farming practices extend to equipment maintenance. Here are some eco-friendly considerations:

- Efficient Resource Use: Properly maintained equipment uses less fuel and reduces emissions.

- Responsible Waste Disposal: Dispose of used oils, filters, and other maintenance waste in an environmentally friendly manner.

- Water Conservation: Use water-efficient cleaning methods when washing equipment.

- Biodegradable Products: Opt for biodegradable lubricants and cleaning products when possible.

- Energy-Efficient Upgrades: Consider energy-efficient options when replacing or upgrading equipment.

Farmonaut’s commitment to sustainability aligns with these practices, offering tools to help you monitor and reduce your farm’s environmental impact through efficient equipment use and maintenance.

Farm Equipment Maintenance Checklist

| Equipment Type | Maintenance Task | Frequency | Farmonaut Technology Integration |

|---|---|---|---|

| Tractors | Oil and filter change | Every 100-150 hours | Usage tracking for optimal scheduling |

| Harvesters | Blade sharpening | Pre-season and mid-season | Crop health monitoring for timing |

| Irrigation Systems | Nozzle cleaning and calibration | Monthly | Soil moisture analysis for efficiency |

| Planters | Seed meter calibration | Pre-season | Field readiness assessment |

| Sprayers | Tank and line cleaning | After each use | Precision application planning |

Conclusion

Mastering farm equipment maintenance is crucial for maximizing productivity, reducing costs, and ensuring the longevity of your valuable machinery. By integrating Farmonaut’s precision agriculture technology with your maintenance routines, you can take your farm operations to the next level of efficiency and sustainability.

Remember, proper equipment care is an investment in your farm’s future. It not only saves money in the long run but also contributes to safer operations and better environmental stewardship. As you implement these maintenance strategies, leverage the power of Farmonaut’s satellite-based monitoring and AI-driven insights to make data-informed decisions about your equipment usage and care.

Stay proactive, keep detailed records, and don’t hesitate to seek professional help when needed. With the right approach to equipment maintenance and the support of advanced agricultural technology, you’re well-equipped to face the challenges of modern farming and achieve sustainable success in your agricultural endeavors.

FAQ Section

Q: How often should I perform maintenance on my farm equipment?

A: The frequency of maintenance depends on the type of equipment and its usage. Generally, daily visual inspections, weekly lubrication, and monthly more thorough checks are recommended. Always refer to your equipment’s owner’s manual for specific guidelines.

Q: Can Farmonaut’s technology help me schedule equipment maintenance?

A: Yes, Farmonaut’s platform can track equipment usage patterns and provide data-driven insights to optimize your maintenance schedules, ensuring timely upkeep based on actual use rather than just calendar dates.

Q: How can I reduce equipment maintenance costs?

A: Regular preventive maintenance, proper storage, timely repairs, and using quality parts can significantly reduce long-term maintenance costs. Additionally, leveraging precision agriculture technology like Farmonaut can help optimize equipment usage, further reducing wear and tear.

Q: Is it worth investing in high-tech farm equipment?

A: High-tech farm equipment can offer significant benefits in terms of efficiency and precision. However, the decision should be based on your specific farm needs, budget, and potential return on investment. Farmonaut’s technology can help you analyze the effectiveness of your current equipment and make informed decisions about upgrades.

Q: How does proper equipment maintenance contribute to sustainable farming?

A: Well-maintained equipment operates more efficiently, consuming less fuel and reducing emissions. It also helps in precise application of inputs, minimizing waste and environmental impact. Farmonaut’s precision agriculture solutions complement these efforts by providing data for optimized resource use.