3 Key Agricultural Plastic Recycling Solutions for Cleaner Canadian Farms

“Over 40,000 tonnes of agricultural plastic waste are generated annually in Canada, highlighting the urgent need for recycling solutions.”

Table of Contents

- Introduction: Agricultural Plastic Recycling in Canada

- The Problem: Agricultural Plastic Waste and Its Challenges

- 1. Chemical Recycling Technologies: Transforming Farm Plastics

- 2. National Collection & Recovery Programs: Cleanfarms and Extended Producer Responsibility

- 3. Building a Circular Economy in Agriculture

- Farmonaut: Supporting Data-Driven Clean Technology for Agriculture

- Comparative Solutions Table

- The Future of Agricultural Waste Solutions in Canada

- Frequently Asked Questions (FAQ)

- Conclusion

Introduction: Agricultural Plastic Recycling in Canada

As Canada’s agricultural sector modernizes, the integration of plastic products—like silage film, bale wrap, grain bags, netting, and twine—has become indispensable. However, this progress brings forth significant agricultural plastic recycling challenges. Canadian farms collectively generate over 62,000 tonnes of plastic annually, underscoring a mounting waste crisis that threatens both Ontario and Quebec’s natural landscapes and our national environmental legacy.

At the heart of sustainable agriculture is a responsibility to innovate, minimize waste, and embrace cleaner, scalable solutions. This commitment is steering the Canadian sector toward advanced chemical recycling technologies, robust farm plastic waste management programs via Producer Responsibility Organizations (PROs), and a renewed focus on building a circular economy in agriculture.

“Advanced recycling technologies can reduce farm plastic landfill rates by up to 60%, supporting a circular economy in Canadian agriculture.”

The Problem: Agricultural Plastic Waste and Its Challenges

We recognize that agricultural plastics—while essential for crop and animal production—have created environmental and logistical obstacles at a national scale. Let’s explore the depth of these challenges, setting the stage for targeted agricultural waste solutions Canada urgently needs.

Types of Agricultural Plastics Ubiquitous in Canadian Farming

- Silage Film & Bale Wrap: Used extensively to preserve fodder, but become contaminated with soil and moisture, making traditional recycling difficult.

- Grain Bags: Employed for temporary grain storage—large volume, single-use, and often contaminated with crop residues.

- Netting & Twine: Essential for baling hay and straw, but pose challenges due to mixed polymers and high contamination levels.

Why is Farm Plastic Waste Management Problematic?

- Contamination: Plastics collected from the field frequently contain high levels of soil, organic matter, and moisture, complicating conventional recycling and raising costs.

- Collection & Logistics: Plastic films are lightweight and bulky, making storage, transport, and collection logistically demanding—especially in a landscape as vast as Canada’s.

- Lack of Viable End-of-Life Options: Historically, the most common options included landfilling, burning, or on-farm stockpiling, limiting recovery and increasing environmental impact.

- Economic Barriers: Low commodity prices for recycled farm plastics reduce economic incentives for conventional recycling initiatives beyond programs managed by organizations like Cleanfarms.

The Canadian agricultural sector urgently requires sustainable farming plastic solutions that move beyond landfilling and support clean farms across all provinces, including Ontario and Quebec. Our next sections spotlight three transformative solutions.

1. Chemical Recycling Technologies: Transforming Farm Plastics

Advanced chemical recycling technologies are redefining how we address agricultural plastic recycling—specifically for waste streams previously considered too challenging to process. This approach is not just a technical innovation; it’s an opportunity to create a national shift toward genuine resource recovery and circularity in farming.

What is Chemical Recycling?

Unlike mechanical recycling (which typically grinds, washes, and melts clean, single-polymer plastics), chemical recycling—particularly hydrochemolytic processing—breaks down mixed and contaminated feedstocks into their molecular building blocks. This allows us to convert even dirty, heterogeneous waste into marketable, high-value products.

- Hydrochemolytic Technology for Plastics: A standout innovation, this technology leverages water-based chemical reactions at lower temperatures. It efficiently transforms agricultural plastics—dirty silage film, bale wrap, and mixed bags—into usable hydrocarbon products.

- Contaminant Tolerance: These new technologies handle high contamination levels (soil, organics, and moisture) that previously rendered plastics “unrecyclable.”

- Resource Circularity: Recovery of hydrocarbons creates new value streams and aligns with the principles of a circular economy in agriculture.

Key Phases in Chemical Recycling: From Laboratory to Demonstration

Successful deployment of chemical recycling technologies for recycling contaminated agricultural plastics follows a rigorous, multi-phase evaluation:

- Laboratory Feasibility Trials: Testing representative samples—including real-world, contaminated mixes of silage film, netting, and twine. This assesses tolerance to contamination and conversion efficiency.

- Pilot and Next-Gen Processing: Scaling up to continuous system flow, where larger volumes are processed in a pilot facility. This tests stability, yields, and the technical and economic feasibility in a real-world setting.

- Demonstration Plant Integration: If laboratory and pilot results are successful, integration into a demonstration facility will validate operational models and support development of scalable deployment strategies.

These rigorous phases ensure each proposed solution is viable, scalable, and ready for commercial deployment.

Benefits of Chemical Recycling in Agriculture

- Reduces Landfilling: Diverts plastics away from landfill, proportional to commercial adoption and collection system effectiveness.

- Supports Clean Technology for Agriculture: Elevates Canadian farms as global leaders in sustainable agriculture innovation.

- Enables Resource Recovery: Converts waste into marketable products supporting future economic growth and environmental stewardship.

Real-World Example: Pilot Testing on Canadian Farm Plastics

For illustration, let’s consider a typical laboratory trial. Plastics gathered from Ontario farms—dirty silage wrap and grain bags—are tested for preprocessing requirements. Batch processing using hydrochemolytic methods measures contaminant tolerance and conversion efficiency. These results then define which feedstock types are best suited for scale-up and what marketable hydrocarbons can be expected.

Key Technologies Driving Success

- Advanced Sorting & Preprocessing: Automated and semi-automated approaches to assess and prepare contaminated streams for recycling.

- Continuous Flow Processing: Pilot plants in Ontario and Quebec demonstrate stability in system operation and deliver actionable techno-economic models.

- Life Cycle Analysis (LCA): Comprehensive modeling of environmental benefits, circularity, and market impacts.

2. National Collection & Recovery Programs: Cleanfarms and Extended Producer Responsibility

While new technology enables cleaner agricultural plastic recycling, its effectiveness depends on robust collection and recovery infrastructure. This is where national programs like Cleanfarms, operating under extended producer responsibility agriculture frameworks, become transformative.

Cleanfarms: Closing the Loop on Agricultural Plastics

Cleanfarms (AgriRÉCUP in Quebec) operates as an industry stewardship and Producer Responsibility Organization (PRO). Its mission: support clean farms by recovering and recycling materials across Canada.

- National Reach: Over 2,000 collection sites serve members in British Columbia, Alberta, Saskatchewan, Manitoba, Ontario, Quebec, and the Maritimes.

- Integrated Programs: Cleanfarms’ network collects agricultural plastics, including pesticide and fertilizer containers under 23 litres, and achieved an impressive 87% recovery rate in 2023.

- Member-Driven Commitment: Serves over 200 member companies in crop protection, seed, fertilizer, animal health, packaging, and beyond.

How Extended Producer Responsibility (EPR) Frameworks Work

Extended producer responsibility mandates that companies producing agricultural inputs also support the responsible end-of-life management of the products and packaging they introduce into the market. This policy-driven model creates accountability and incentivizes innovation in waste management.

- Centralized Agricultural Waste Collection Sites: Provincial regulations require producers to fund or operate plastic take-back programs.

- Data-Driven Tracking: Robust reporting and verification of total volumes recovered support continuous improvement and transparency.

- Link to Clean Technology: National programs are now collaborating with technology developers to test and deploy new recycling solutions for hard-to-recycle streams.

Benefits of Producer Responsibility and National Programs

- Scalable Logistics: National network ensures collection from diverse geographies—enabling true scalability and consistent supply of feedstock for recycling technology.

- Increased Recovery Rates: Data from Ontario, Quebec, and the Maritimes show how comprehensive EPR frameworks directly improve plastic recovery and reduce on-farm stockpiles.

- Environmental Stewardship: These programs support our goal of cleaner environments and demonstrate the commitment of Canadian farmers.

3. Building a Circular Economy in Agriculture

Embracing a circular economy in agriculture means reimagining farming from a linear ‘use-and-dispose’ model to one of responsible consumption, recovery, and reuse. This shift requires the integration of clean technology for agriculture, inclusive waste management programs, and supportive policy frameworks.

What is a Circular Economy?

A circular economy is an economic system aimed at eliminating waste and continually using resources through recycling, remanufacturing, and regeneration. For Canadian agriculture, this translates to:

- Designing Out Waste: Choosing products and materials that have viable recovery options—and encouraging manufacturing innovations that allow for easier recycling.

- Renewable Resource Utilization: Prioritizing renewable inputs and optimizing resource management (irrigation, fertilizer) using tools like carbon footprinting to track environmental performance.

- Enabling Product Traceability: Leveraging platforms like Farmonaut’s blockchain-based traceability solutions to bolster transparency from farm to consumer.

Farm Plastics in the Circular Economy: Pathways to Resource Recovery

- Closing Material Loops: By chemically recycling mixed and contaminated plastics, new hydrocarbon products can be returned to the agricultural value chain as essential inputs or fuels.

- Integrated Resource Management: Optimized logistics and fleet management systems—such as those provided by Farmonaut Fleet Management—streamline collection, reduce costs, and improve environmental outcomes.

- Transparent Data Streams: Comprehensive data analytics from digital platforms enable better policy, improved stakeholder engagement, and continuous system improvement.

The Role of Policy and Stakeholder Engagement

- Government Incentives: Provincial and federal funding can accelerate adoption of new recycling solutions and demonstration projects.

- Stakeholder Collaboration: Collaboration across supply chain members—from manufacturers and waste managers to farmers and transporters—builds resilient, scalable deployment strategies.

- Monitoring & Verification: Precision monitoring tools, like Farmonaut’s carbon footprinting platform, enable consistent tracking of environmental performance at both the farm and national levels.

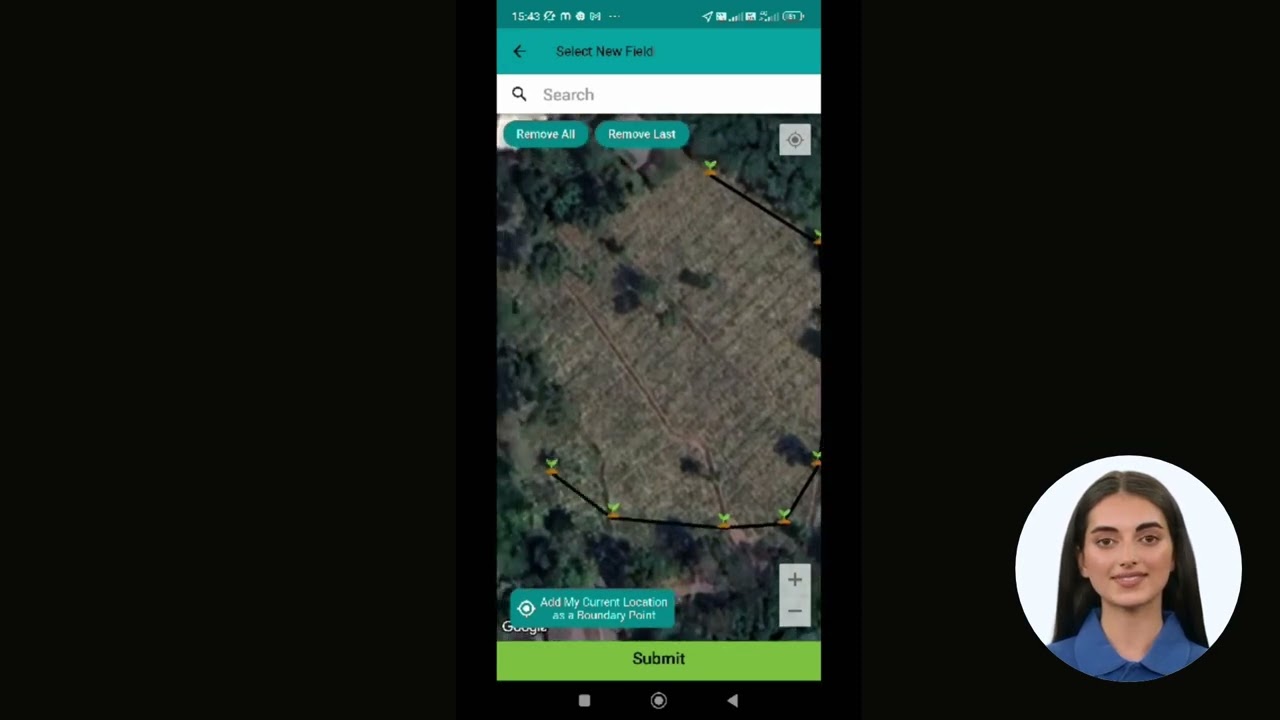

Farmonaut: Supporting Data-Driven Clean Technology for Agriculture

Adopting clean technology for agriculture is essential for achieving a sustainable, circular farming sector in Canada. We at Farmonaut are committed to supporting this transformation by delivering advanced, satellite-based tools that empower farmers to improve efficiency, minimize waste, and confidently participate in the new green economy.

Farmonaut’s Solutions & Value Proposition

- Satellite Crop Health Monitoring: Our platform uses multispectral satellite imagery to monitor NDVI, soil moisture, and crop health, helping Canadian farmers optimize input use and maximize yields.

- AI-Based Advisory Systems (Jeevn AI): Real-time, customized farming advice supports timely decisions, reducing unnecessary resource application and supporting sustainable outcomes.

- Blockchain-based Product Traceability: Ensures transparency and trust throughout the supply chain—an essential enabler for extended producer responsibility agriculture and circular economy integration.

- Fleet and Resource Management: Our Fleet Management Tools help farm operators and logistics providers lower costs, optimize equipment use, and streamline recycling collection efforts.

- Carbon Footprinting: Through our carbon footprinting modules, farmers and agribusinesses can track emissions, demonstrate compliance, and target sustainability improvements relevant to their operations and the environment.

For those interested in integrating satellite weather and field data into their own platforms or research initiatives, explore our robust API system here. Developer resources and comprehensive documentation are available at Farmonaut API Developer Docs.

Unlocking New Value Streams with Data and Traceability

Digital traceability is the backbone of the circular economy in agriculture. Our product traceability tools empower companies and farmers to verify every stage of their supply chain—a vital capability for recycling contaminated agricultural plastics and adopting new recycling technologies.

Supporting Scalable Waste Management

- Large Scale Farm Management: Our modular large-scale farm management platform is designed to scale with your operations, integrating multiple features to streamline resource use and support compliance with new environmental programs.

Comparative Solutions Table: Agricultural Plastic Recycling in Canada

For sustainability leaders, farm managers, and agri-policy stakeholders, clear decision-making requires side-by-side data. The table below compares critical attributes of each agricultural plastic recycling solution—supporting your broader strategy for cleaner, more resilient Canadian farms.

| Solution Name | Description | Estimated Waste Reduction (%) | Estimated Cost Savings (%) | Implementation Complexity | Environmental Impact | Circular Economy Contribution |

|---|---|---|---|---|---|---|

| Chemical Recycling Technologies | Water-based hydrochemolytic processing of contaminated/mixed plastics into usable hydrocarbons | Up to 60% | 35–50% | High (pilot to commercial scale) | High (reduces landfilling, supports resource recovery) | Closes material loops, turns waste into valuable feedstock |

| National Collection & Recovery Programs | Industry-funded programs (e.g., Cleanfarms) with >2,000 collection points nationwide | 30–40% | 15–25% | Medium (requires coordinated logistics) | Medium to High (direct recovery, less open burning/stockpiling) | Supports feedstock consolidation for advanced recycling solutions |

| Circular Economy Integration | Holistic approach using policy, technology, and traceability to keep materials in use | 50–70% | 20–40% | Medium to High (multi-stakeholder, policy-driven) | High (regeneration, net positive resource impact) | Maximizes value retention, redesigns recovery and reuse systems |

Farmonaut Subscriptions: Affordable & Scalable Solutions

We believe scalable clean technology for agriculture must be accessible. Review our flexible Farmonaut subscription packages—including solutions for individual farmers, cooperatives, and agribusinesses—below:

The Future of Agricultural Waste Solutions in Canada

Our roadmap for agricultural waste solutions Canada centers on continuous improvement. We anticipate several clear trends and strategies emerging in the coming years:

- Advanced Technology Integration: Data-driven platforms, like those offered by Farmonaut, will enable stakeholders to monitor in real time, optimize logistics, and target highest-value recycling streams.

- Wider Adoption of Hydrochemolytic Technology for Plastics: Pilot and demonstration plants in Ontario and Quebec will pave the way for provincial and national rollout, contingent on proven technical and economic feasibility.

- Policy Evolution: Policymakers are likely to increase support for extended producer responsibility agriculture and offer incentives for technology adoption and commercial deployment.

- Stakeholder Collaboration: Effective deployment strategies will require ongoing dialogue and knowledge sharing between farmers, processors, technology companies, and policymakers.

- Continuous Environmental Performance Tracking: Solutions like Farmonaut’s Carbon Footprinting module will allow all players in the agricultural ecosystem to measure, benchmark, and communicate their progress in reducing the sector’s waste and emissions footprint.

- Broader Market Transformation: As recycling contaminated agricultural plastics becomes mainstream, expect Canadian agriculture to be recognized globally as a leader in sustainable, circular value chains.

Frequently Asked Questions (FAQ)

How much agricultural plastic waste is produced in Canada each year?

Over 62,000 tonnes of agricultural plastic waste is generated annually in Canada, much of which is currently landfilled, burned, or stockpiled due to the lack of viable recycling options.

What are the main challenges in recycling contaminated agricultural plastics?

The biggest challenges relate to high contamination levels (soil, organics, moisture), the logistical difficulty of collecting bulky plastic streams, and the economic limitations of conventional recycling due to market price fluctuations and processing costs.

What is chemical recycling and how does it help clean farms?

Chemical recycling—especially via hydrochemolytic technology—breaks down mixed and dirty farm plastics into their molecular components, creating usable products and reducing landfill dependency. This process supports clean farms by recovering value from previously unrecyclable plastics.

Why are national recovery programs like Cleanfarms important?

Cleanfarms and similar national programs create the infrastructure necessary to collect and consolidate waste, enabling scale and supporting the transition to advanced recycling technologies.

How does a circular economy benefit Canadian agriculture?

A circular economy in agriculture keeps resources in use for as long as possible, reduces waste, creates new economic streams, and enhances environmental sustainability at the field, provincial, and national levels.

How can Farmonaut’s technology support farm plastic waste management?

Farmonaut’s precision platforms deliver real-time monitoring, logistics tracking, and traceability—empowering farmers, cooperatives, and policy leaders to make informed decisions that reduce waste and support the integration of advanced recycling solutions.

Where can I access Farmonaut’s digital tools and subscription plans?

Explore our web and mobile platforms for affordable, modular farm management and analytics. You can also find subscription options in the section above and by clicking here for large-scale farm management details.

Conclusion: Advancing Sustainability & Resource Recovery in Canadian Agriculture

As we face rising agricultural plastic waste volumes, the call for cleaner, more sustainable farming practices across Ontario, Quebec, and all Canadian provinces grows ever more urgent. Leading solutions—chemical recycling technologies, robust national recovery programs, and the shift to a circular economy in agriculture—hold the key to transforming waste into valuable resources.

By integrating real-time digital tools from Farmonaut alongside advanced recycling, Canadian farms can achieve measurable progress to reduce landfilling, recover resources, and build resilient food systems. Our collective goal should be the creation of clean farms—where every product, bale wrap, and grain bag is viewed not as waste, but as a future resource.

Let’s lead the world in farm plastic waste management—by supporting innovation, embracing data, and building a circular future for all.