The Ultimate Guide to Farm Equipment Maintenance: Boost Efficiency and Reduce Downtime Costs

“Regular maintenance can reduce farm equipment downtime by up to 25%, significantly boosting operational efficiency.”

Welcome to our comprehensive guide on farm equipment maintenance, where we’ll explore how to maximize efficiency and minimize downtime costs in modern agriculture. As the agricultural landscape evolves with precision agriculture technology, understanding the nuances of equipment care becomes increasingly crucial for farmers worldwide.

In this blog post, we’ll delve into essential aspects of agricultural machinery repair, preventative maintenance for farm equipment, and strategies to optimize hay and forage equipment performance. We’ll also explore how innovative solutions, like those offered by Farmonaut, can revolutionize your approach to farm management and equipment maintenance.

The Importance of Farm Equipment Maintenance

Proper maintenance of farm equipment is the cornerstone of efficient and profitable agricultural operations. Here’s why it’s so crucial:

- Reduces unexpected breakdowns and costly repairs

- Extends the lifespan of machinery

- Improves fuel efficiency and reduces emissions

- Ensures optimal performance during critical farming seasons

- Enhances safety for operators and workers

By implementing a robust maintenance routine, farmers can significantly reduce equipment downtime costs and boost overall productivity. Let’s explore some key strategies for effective farm equipment maintenance.

Preventative Maintenance: The Key to Longevity

Preventative maintenance is the practice of regularly inspecting, cleaning, and servicing farm equipment to prevent issues before they occur. Here are some essential preventative maintenance tasks for common farm machinery:

Tractors:

- Check and change engine oil and filters regularly

- Inspect and clean air filters

- Grease all fittings and moving parts

- Check tire pressure and condition

- Inspect and tighten belts

Sprayers:

- Clean nozzles and filters after each use

- Check for leaks in hoses and fittings

- Calibrate sprayer regularly for accurate application

- Flush the system with clean water after use

Harvesters:

- Sharpen or replace cutting components

- Inspect and adjust belts and chains

- Lubricate all moving parts

- Check and clean the grain tank and unloading auger

By following these preventative maintenance routines, farmers can significantly reduce the risk of unexpected breakdowns and extend the life of their equipment.

Seasonal Farm Equipment Preparation

Proper seasonal preparation is crucial for ensuring your farm equipment is ready when you need it most. Here’s a breakdown of key tasks for each season:

Spring Preparation:

- Inspect and repair any winter damage

- Change fluids and filters

- Check and adjust tire pressure

- Test batteries and electrical systems

- Calibrate planting equipment

Summer Maintenance:

- Keep cooling systems clean and functioning

- Monitor and maintain air conditioning systems

- Regularly clean and maintain harvesting equipment

- Check and adjust combine settings

Fall Checklist:

- Prepare tillage equipment for post-harvest work

- Clean and store sprayers properly

- Inspect and repair hay and forage equipment

- Begin winterization of irrigation systems

Winter Storage:

- Clean all equipment thoroughly

- Apply rust inhibitors to exposed metal surfaces

- Store batteries in a cool, dry place

- Drain fuel systems or add fuel stabilizer

- Cover equipment or store in a protected area

By following these seasonal maintenance routines, farmers can ensure their equipment is always ready for the tasks ahead, reducing downtime and improving efficiency.

“Proper storage and maintenance of farm equipment can extend its lifespan by 15-20%, saving farmers thousands in replacement costs.”

Optimizing Hay and Forage Equipment

Hay and forage equipment plays a crucial role in livestock operations and requires special attention to maintain peak performance. Here are some tips for optimizing your hay and forage machinery:

- Mowers and Conditioners: Keep blades sharp and properly aligned. Replace worn tines or rollers to ensure even conditioning.

- Balers: Regularly inspect and replace belts, chains, and bearings. Keep knotters clean and properly adjusted for consistent bale formation.

- Rakes and Tedders: Check tine condition and replace as needed. Ensure proper ground clearance to avoid soil contamination in hay.

- Forage Harvesters: Sharpen or replace knives regularly. Adjust the shear bar for optimal cutting performance.

Proper maintenance of hay and forage equipment not only improves efficiency but also ensures high-quality feed for livestock, ultimately contributing to better farm profitability.

Leveraging Technology for Equipment Management

In today’s digital age, farmers can leverage precision agriculture technology to enhance their equipment maintenance routines. Here’s how technology is revolutionizing farm equipment management:

- Telematics Systems: These systems provide real-time data on equipment performance, fuel usage, and maintenance needs.

- Predictive Maintenance Software: Advanced algorithms can predict potential equipment failures before they occur, allowing for proactive maintenance.

- Remote Diagnostics: Many modern machines can be diagnosed remotely, reducing the need for on-site technician visits.

- Mobile Apps: Farmers can access maintenance schedules, order parts, and log repairs using smartphone applications.

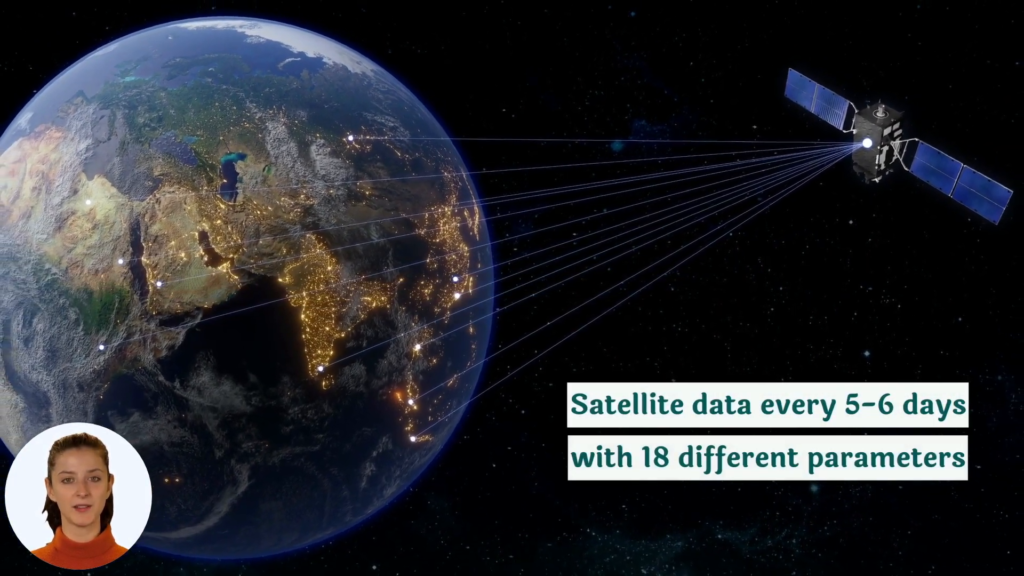

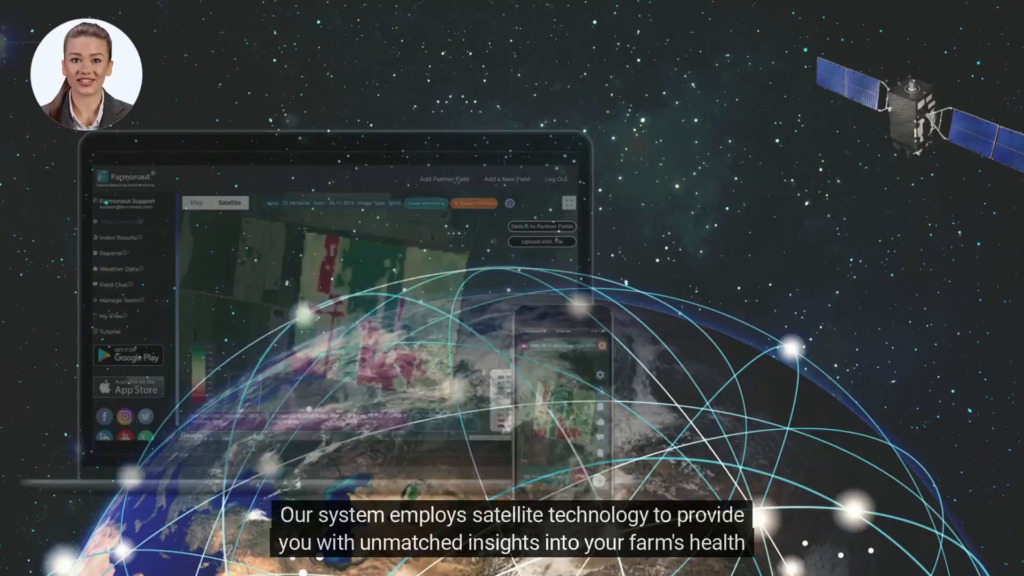

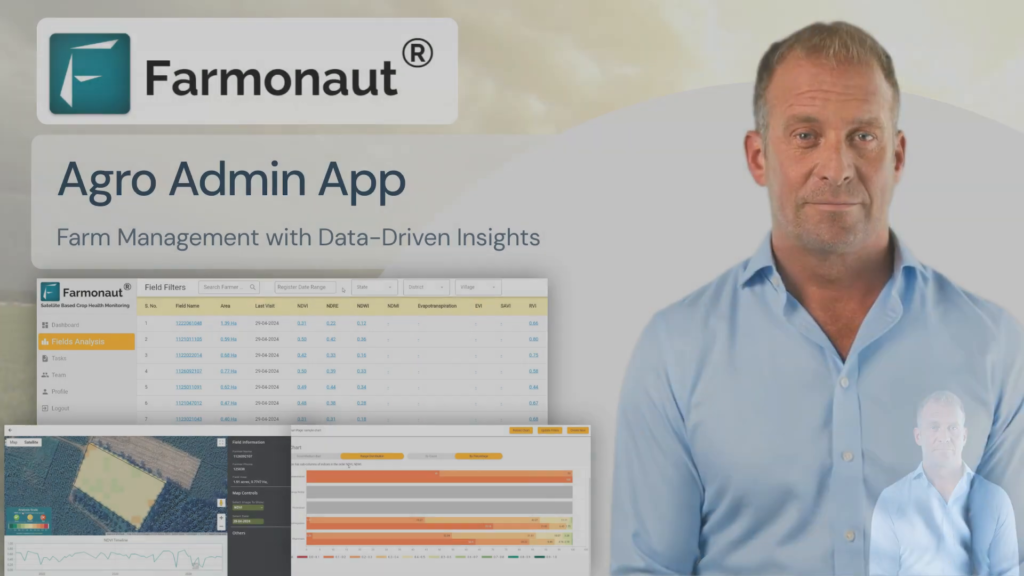

One such innovative solution is offered by Farmonaut, a company that provides advanced, satellite-based farm management solutions. While not directly related to equipment maintenance, Farmonaut’s technology can help farmers optimize their operations, indirectly benefiting equipment management through improved resource allocation and decision-making.

Explore Farmonaut’s solutions:

Minimizing Equipment Downtime Costs

Equipment downtime can be incredibly costly for farmers, especially during critical planting or harvesting periods. Here are strategies to minimize downtime and its associated costs:

- Implement a Proactive Maintenance Schedule: Regular check-ups and servicing can prevent many common breakdowns.

- Stock Essential Spare Parts: Keep commonly needed parts on hand to reduce repair time.

- Train Operators Properly: Well-trained operators can identify potential issues early and operate equipment more efficiently.

- Utilize Equipment Monitoring Systems: These can alert you to potential problems before they cause breakdowns.

- Establish Relationships with Local Dealers and Mechanics: This can lead to faster service when you need repairs.

By implementing these strategies, farmers can significantly reduce the frequency and duration of equipment downtime, leading to improved productivity and profitability.

Farm Equipment Storage Tips

Proper storage of farm equipment is crucial for protecting your investment and ensuring machinery is ready for use when needed. Here are some essential storage tips:

- Clean Equipment Thoroughly: Remove all dirt, debris, and crop residue before storage.

- Protect from the Elements: Store equipment in a covered area or use weatherproof tarps.

- Elevate Equipment: Use blocks to keep machinery off the ground, preventing moisture damage.

- Protect Electronic Components: Remove or cover any exposed electronic displays or controls.

- Lubricate Moving Parts: Apply grease or lubricant to prevent rust and seizure.

- Prepare Fuel Systems: Either drain fuel systems or add fuel stabilizer to prevent degradation.

Proper storage not only protects your equipment but also ensures it’s ready for immediate use when the farming season begins, reducing startup delays and maintenance issues.

Safety Considerations in Equipment Maintenance

Safety should always be the top priority when performing farm equipment maintenance. Here are some crucial safety tips to keep in mind:

- Always Read the Manual: Familiarize yourself with the manufacturer’s safety guidelines and maintenance procedures.

- Use Proper Personal Protective Equipment (PPE): Wear safety glasses, gloves, and appropriate clothing when working on equipment.

- Implement Lockout/Tagout Procedures: Ensure equipment is fully powered down and cannot be accidentally started during maintenance.

- Use Proper Tools: Always use the correct tools for the job to prevent injury and equipment damage.

- Be Aware of Hydraulic Systems: Never work under raised hydraulic components without proper supports in place.

- Handle Chemicals Safely: Follow proper procedures when handling fuels, oils, and other chemicals.

By prioritizing safety in your maintenance routines, you protect not only your workers but also your equipment and overall farm operations.

Agritech Solutions for Enhanced Farm Management

While not directly related to equipment maintenance, agritech solutions can significantly improve overall farm management, indirectly benefiting equipment use and maintenance. Farmonaut offers innovative tools that can help farmers optimize their operations:

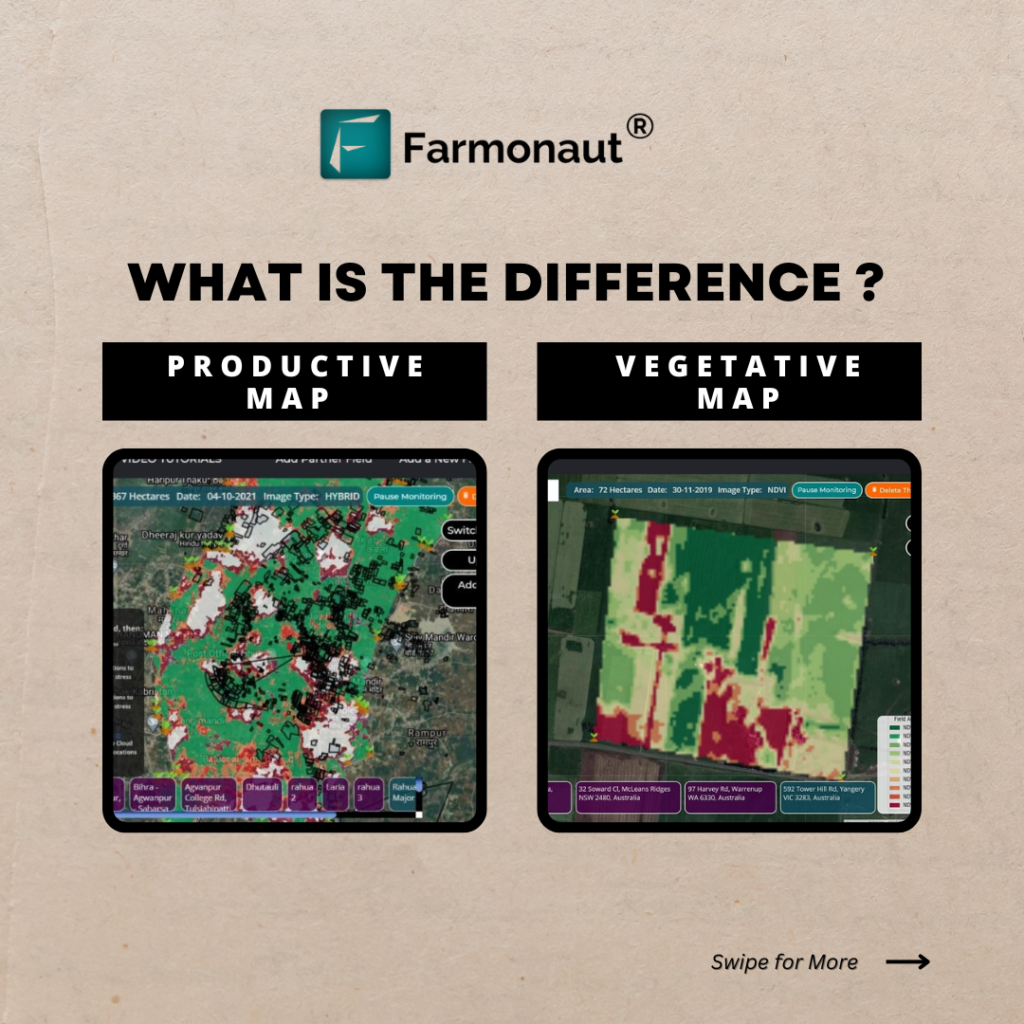

- Satellite-Based Crop Monitoring: Real-time insights into crop health can help farmers make informed decisions about equipment deployment and resource allocation.

- AI-Driven Advisory Systems: Personalized recommendations can help farmers optimize their farming practices, potentially reducing wear and tear on equipment.

- Weather Forecasting: Accurate weather predictions can assist in planning equipment use and maintenance schedules more effectively.

To learn more about how Farmonaut’s solutions can enhance your farm management practices, visit their web application or explore their API services.

Farm Equipment Maintenance Checklist

To help you stay on top of your equipment maintenance, we’ve created a comprehensive checklist. This table outlines key maintenance tasks for various types of farm equipment, along with recommended frequencies and potential cost savings:

| Equipment Type | Maintenance Task | Frequency | Estimated Time Required | Potential Cost Savings |

|---|---|---|---|---|

| Tractor | Oil and Filter Change | Every 100-150 hours | 1-2 hours | $500-$1000 annually |

| Harvester | Belt and Chain Inspection | Daily during harvest | 30 minutes | $2000-$3000 per season |

| Sprayer | Nozzle Cleaning and Calibration | Before each use | 1 hour | $1000-$1500 in chemical savings |

| Irrigation System | Pump and Filter Check | Monthly | 2-3 hours | $3000-$5000 in water and energy savings |

| Baler | Knotter Adjustment and Lubrication | Weekly during use | 1 hour | $1000-$2000 in reduced downtime |

By following this checklist, you can ensure that your equipment remains in top condition, reducing the likelihood of costly breakdowns and improving overall farm efficiency.

Cost-Effective Strategies for Equipment Management

Managing farm equipment effectively involves balancing maintenance costs with productivity. Here are some cost-effective strategies to consider:

- Prioritize Preventative Maintenance: Investing in regular maintenance can prevent costly breakdowns.

- Keep Detailed Maintenance Records: This helps identify recurring issues and plan for replacements.

- Consider Leasing vs. Buying: For some equipment, leasing might be more cost-effective than ownership.

- Invest in Quality Parts: Higher quality parts may cost more upfront but can lead to longer-lasting repairs.

- Utilize Off-Season for Major Repairs: Conducting major overhauls during slower periods can minimize disruption to operations.

By implementing these strategies, farmers can optimize their equipment management, balancing costs with operational needs and long-term productivity.

The Role of Precision Agriculture in Equipment Management

Precision agriculture technology plays a significant role in modern farm equipment management. Here’s how it contributes to improved efficiency and reduced maintenance costs:

- GPS Guidance Systems: Reduce overlap and improve efficiency, leading to less wear on equipment.

- Variable Rate Technology: Optimizes input application, reducing stress on sprayers and spreaders.

- Telemetry Systems: Provide real-time data on equipment performance, allowing for timely maintenance.

- Automated Record Keeping: Helps track equipment usage and maintenance history accurately.

While Farmonaut doesn’t directly offer equipment management solutions, their satellite-based crop monitoring and AI advisory systems can indirectly contribute to more efficient equipment use by optimizing overall farm operations.

For more information on Farmonaut’s precision agriculture solutions, check out their API Developer Docs.

Frequently Asked Questions

Q: How often should I service my tractor?

A: Tractors should typically be serviced every 100-150 hours of operation or at least annually. However, always refer to your specific model’s manual for manufacturer recommendations.

Q: What’s the best way to store farm equipment during the off-season?

A: Clean the equipment thoroughly, apply rust inhibitors, store in a dry, covered area, and elevate off the ground. Also, consider adding fuel stabilizer or draining fuel systems for long-term storage.

Q: How can I reduce fuel costs for my farm equipment?

A: Regular maintenance, proper tire inflation, optimizing equipment settings, and using GPS guidance systems can all contribute to improved fuel efficiency.

Q: When should I consider replacing farm equipment instead of repairing it?

A: Consider replacement when repair costs exceed 30-50% of the equipment’s value, or when newer models offer significant improvements in efficiency or technology that could justify the investment.

Q: How can precision agriculture technology help with equipment maintenance?

A: Precision ag tech can provide detailed usage data, performance metrics, and predictive maintenance alerts, helping farmers schedule maintenance more effectively and identify potential issues before they lead to breakdowns.

Conclusion

Effective farm equipment maintenance is crucial for maximizing efficiency and reducing downtime costs in modern agriculture. By implementing preventative maintenance routines, leveraging technology, and following best practices for equipment care and storage, farmers can significantly extend the lifespan of their machinery and improve overall farm productivity.

While companies like Farmonaut don’t directly offer equipment maintenance solutions, their innovative agritech tools can contribute to more efficient farm management, indirectly benefiting equipment use and maintenance. By combining traditional maintenance practices with modern precision agriculture technology, farmers can optimize their operations and stay competitive in today’s agricultural landscape.

Remember, investing time and resources in proper equipment maintenance is not just about preserving machinery; it’s about ensuring the long-term success and sustainability of your farming operation.