Drinking Water Tank Construction: Logan City 10 MG Project Update

“Logan City’s new water tank project adds 10 million gallons of storage, supporting rapid urban growth and infrastructure resilience.”

Project Update: Logan City’s 10 MG Drinking Water Tank Construction

As urban growth surges across Utah, the demand for resilient infrastructure and reliable water supply rises sharply. Logan City, located in Cache County, has taken a proactive stance with drinking water storage tank construction and a booster pump station project—the First Dam 10 Million Gallon (MG) Tank and Booster Pump Station Project.

This comprehensive update explores construction methods, industry trends, and contractor prequalification proposals behind one of Utah’s most significant water infrastructure investments. If your firm seeks to bid, understanding the details—requirements, timelines, and key construction technologies—is critical. Only pre-qualified contractors will be eligible to participate, setting a new benchmark for quality in municipal projects.

As we examine the design and work scope at 1600 East Canyon Road, Logan City, we also incorporate the latest trends in water tank excavation and installation, emergency overflow systems for tanks, vertical turbine pump installation, and the integration of advanced piping solutions. Our review is tailored for industry professionals, contractors, engineers, municipal planners, and all stakeholders invested in sustainable water management.

Site & Scope: Description of Work

The First Dam 10 MG Tank and Booster Pump Station Project is strategically located at 1600 East Canyon Road, Logan City, Utah. The project’s significance extends beyond sheer storage capacity, combining advanced construction techniques, robust backup systems, and seamless pipeline integration. Let us break down the full description of work for industry clarity:

- Storage: Construction of a post-tensioned concrete drinking water storage tank, divided into two 5 MG cells for optimized compartmentalization and maintenance flexibility.

- Pumping Facilities: Construction of a valve vault and booster pump station structure—including two high-capacity (150 HP) vertical turbine pumps, pump cans, and associated piping.

- Excavation & Foundations: Large-scale water tank excavation and installation with site grading, soil nail wall stabilization, and structural fill for robust support.

- Hydraulic Connections: Carefully executed connection to Dewitt Springs Meter Vault and adjacent Dewitt Springs Pipeline (pipeline by Whitaker Construction).

- Overflow & Emergency: Dual emergency overflow system for tanks using twin overflow boxes to mitigate flooding risks.

- Piping Systems: Full installation of fabricated steel piping (42-inch and 36-inch diameter, provided and fabricated steel piping installation by Whitaker Construction), HDPE drain pipe connection, and connection to the Cliffside Pipeline.

- Facility Construction: CMU (Concrete Masonry Unit) valve vault/pump station structure with standing seam metal roofing, roof access hatches, geofoam blocks, and secure fencing.

- Mechanical & Electrical: Electrical controls, backup diesel generator for pump stations, HVAC, security cameras, and site-fencing.

- Finishing & Restoration: Complete site grading and paving for water projects, final backfill, landscaping, and overall site restoration.

The broad, multi-trade aspects—from fabricated steel piping installation to climate control—require a tightly coordinated effort among qualified contractors. For project manuals, prequalification documents, and access, interested parties must download documents starting April 17, 2025, via the official web address: https://www.virtual-bid.com (search for “First Dam 10 MG Tank and Booster Pump Station Project”).

“Over 70% of large-scale water tank projects now require contractor prequalification, ensuring higher construction standards and safety compliance.”

Industry Trends: Drinking Water Storage Tank & Pump Station Projects

In recent years, infrastructure spending in U.S. cities like Logan has shifted decisively towards higher standards and technology integration. The drinking water storage tank construction sector is influenced by several key trends:

- Contractor Prequalification Requirements: Comprehensive prequalification ensures that only the most capable and safety-conscious contractors participate in bidding, setting higher benchmarks for public safety and project durability.

- Post-Tensioned Concrete Tanks: Preference for post-tensioned solutions offers enhanced seismic performance, reduced leakage, and long-term structural integrity—a vital factor in Utah’s varied geology.

- Advanced Pump Technology: Integration of high-efficiency vertical turbine pump installation reduces operational costs and energy use while ensuring reliable supply across topographic gradients.

- Redundant & Resilient Systems: Inclusion of emergency overflow system for tanks, backup diesel generators, and dual-celled tank configurations delivers contingency and ease of maintenance.

- Smart Controls & Security: State-of-the-art electrical controls, SCADA, and site security cameras protect municipal assets and enable remote operations.

- Sustainable Site Management: Prioritization of site grading and paving for water projects and environmentally responsible restoration preserves natural habitats post-construction.

We are witnessing a new standard where HDPE drain pipe connection and fabricated steel piping installation (especially for large-diameter connections) have become integral, ensuring both structural robustness and flow efficiency. Projects like the 10 MG First Dam Tank set the pace for quality and future-readiness in the industry.

Contractor Prequalification: Insights & Processes

Given the scope and criticality of the Logan City 10 MG Drinking Water Tank and Booster Pump Station Project, the City, as the Owner, strictly manages contractor prequalification proposals. Bids will only be accepted from those contractors that are pre-qualified, highlighting a fast-growing industry trend focused on risk mitigation.

Prequalification Timeline & Proposal Submittal

- Prequalification proposals must be received by 2:00 pm Mountain Daylight Time on May 8, 2025, exclusively via Virtual-Bid (www.virtual-bid.com).

- Late submittals will not be accepted; on-time, compliant packages are mandatory for eligibility.

- Documents titled “General Contractor Prequalification Documents for Construction of the First Dam 10 MG Tank and Booster Pump Station Project” may be downloaded starting April 17, 2025.

- Search for “First Dam 10 MG Tank and Booster Pump Station Project” in the Virtual-Bid search box to locate all required documents.

Key Elements of Prequalification Proposals

- Proof of Experience: Documentation of large-diameter water tank, pump station, vault, and pipeline construction.

- Compliance History: Safety records, quality management, and regulatory compliance.

- Project Staff: Qualified personnel with expertise in water tank excavation and installation, booster pump projects, emergency overflow system for tanks, and advanced controls.

- Financial Capacity: Evidence of financial resilience to manage complex, high-value projects.

- Specialized Equipment: Having resources for large-scale excavation, HDPE drain pipe connection, fabricated steel piping installation, site grading and paving.

- Subcontractor Identification: List of major subcontractors and suppliers (including those for structural fill, standing seam metal roofing, and electrical controls).

This rigorous selection ensures eligible contractors understand both project scale and regulatory requirements, fortifying public trust and project outcomes.

Key Project Components & Advanced Construction Methods

To appreciate what sets the First Dam 10 MG Drinking Water Tank and Booster Pump Station Project apart, a detailed understanding of each component is essential. Let’s review the primary work packages and highlight innovative approaches critical for success:

- Tank Construction: Two-compartment post-tensioned tank (10 MG total, divided into 5 MG cells) for operational flexibility and redundancy in drinking water storage tank construction.

- Pump Station: Advanced booster pump station project with robust vault structure, HVAC, standing seam metal roofing, and vertical turbine pump installation for top-tier efficiency.

- Pipeline Integration: Simultaneous connection to the Dewitt Springs, Cliffside Pipeline, and integrated HDPE drain pipe connection for high-flow and drainage capacity.

- Valve Vaults: Purpose-built valve vault and pump station piping management, plunger valves, roof access hatches, and security measures—key to safe, easy maintenance.

- Electrical & Controls: Modern electrical design with full automation, backup diesel generator for pump stations, HVAC, and on-site security cameras.

- Supporting Structures: CMU construction, geofoam block insulation, and efficient backfill for structural and hydrological resilience.

- Site Works: Extensive site grading and paving for water projects, security fencing, and final restoration to protect community and environment.

Technical Highlights: Excavation, Tank, Valve Vaults, and Piping

1. Water Tank Excavation and Installation

The project’s excavation phase is foundational, requiring expertise in large-volume earthworks for tanks. Soil nail wall stabilization, precise structural fill, and environmental mitigation measures are integrated from the ground up.

2. Valve Vault and Pump Station Structure

Constructed of durable CMU, the valve vault and pump station structure incorporates standing seam metal roofing and roof access hatches for safe maintenance. All operations are controlled through advanced electrical and controls systems, meeting the latest instrumentation standards.

3. Advanced Piping Solutions

- Fabricated Steel Piping Installation: Key for high-pressure mains, the provided and installed 42 & 36-inch diameter fabricated steel pipes enable robust water transmission upgrades.

- HDPE Drain Pipe Connection: 42-inch HDPE outlets offer superior flow for emergency overflows and routine tank drainage—installed by the tank contractor per owner specification.

- Pipeline Integration: Flanged connections to existing Dewitt Springs and Cliffside pipelines ensure seamless hydraulic transitions.

4. Vertical Turbine Pump Installation

Installation of dual 150 HP vertical turbine pumps (with pump cans) adds high-lift, energy-efficient capacity to the station. Emergency systems include dual overflow boxes and a plunger valve for surge or bypass scenarios.

5. Mechanical, Electrical, and Security Systems

- Backup Diesel Generator for Pump Stations: Guarantees supply continuity during grid outages—a critical requirement for urban scale water delivery.

- HVAC & Controls: Integrated mechanical ventilation and automated facility monitoring for reliability and safety compliance.

- Security & Fencing: Camera systems and perimeter fencing protect against unauthorized site access.

6. Site Grading, Access Roads, and Paving

Precision site and access road grading and paving underpin tank and pump station accessibility, long-term maintenance ease, and water management throughout construction and operational phases.

Video Insights: Technology and Construction Best Practices

To deepen our understanding of technological advancements in modern infrastructure and project management, we recommend these video insights:

Benefits for Logan City: Water Security & Urban Resilience

The completion of the 10 MG Tank and Booster Pump Station confers crucial advantages on Logan City and the surrounding Cache Valley area:

- Urban Growth Support: New storage capacity aligns with city expansion and population growth projections.

- Redundancy & Emergency Protection: Divided cells, dual overflows, and backup power ensure continuity even during maintenance or outages.

- Enhanced Fire Protection: Larger volumes and hydraulic connectivity enable rapid response in emergencies.

- Operational Flexibility: Segmented tank operation allows for partial draining, cleaning, or repair without affecting supply.

- Compliance & Sustainability: Meeting or exceeding regulatory standards for drinking water safety, efficiency, and long-term infrastructure performance.

By adhering to rigorous contractor prequalification proposals and specifying high standards—from drinking water storage tank construction to site restoration—the City ensures dependable investment and operational confidence for years to come.

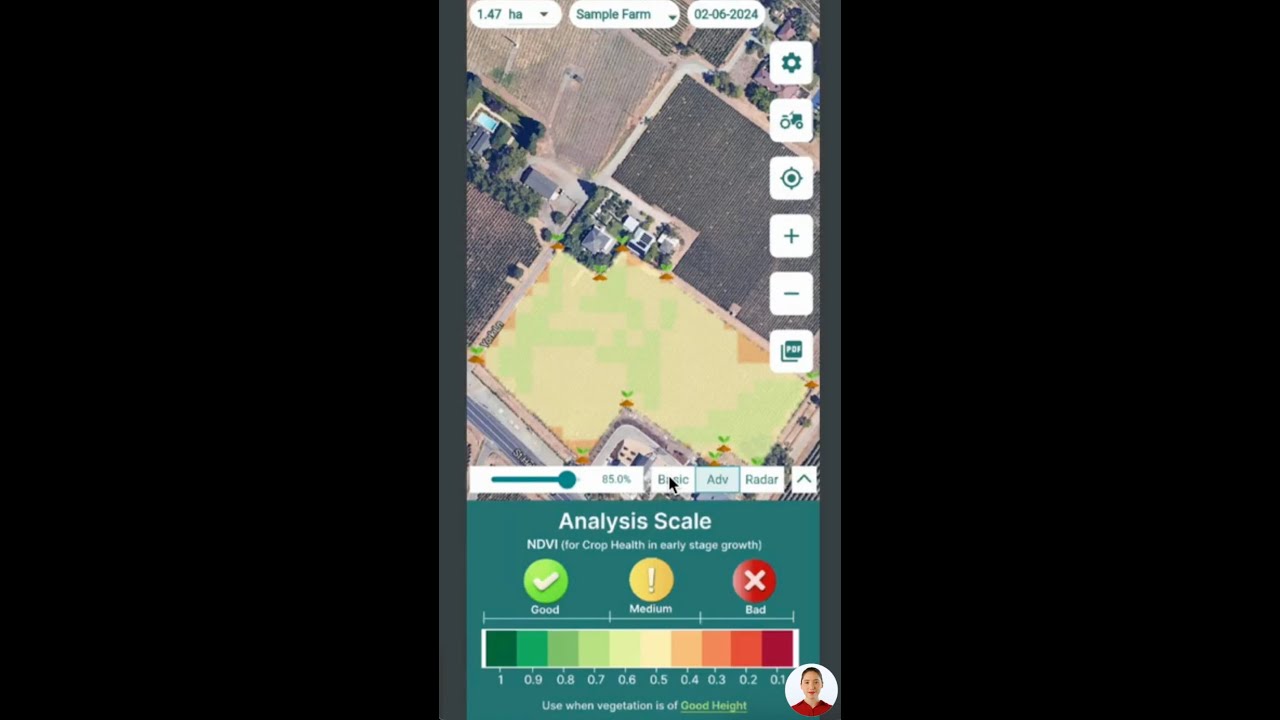

Farmonaut Solutions for Modern Infrastructure Projects

As water infrastructure becomes smarter and more connected, leveraging data-driven platforms for resource monitoring, compliance, and operational transparency is vital. This is where sophisticated technology solutions such as Farmonaut can dramatically increase efficiency and sustainability.

Farmonaut Platform: Transforming Resource Management

- Satellite-Based Crop Health Monitoring: Enables utility owners and contractors to monitor adjacent green spaces and prevent erosion or post-project soil degradation. Large-Scale Farm Management Tools from Farmonaut can be used to track vegetation around water facilities and integrate these insights with ongoing site restoration.

- Jeevn AI Advisory System: Provides real-time advisories based on current satellite and weather data—supporting project teams by alerting them to ground risks, severe weather warnings, and optimal maintenance windows.

- Blockchain-Based Product Traceability: For contractors and city asset managers, the product traceability feature ensures every supply chain component (pipes, valves, structural steel) is verifiable and tamper-proof.

- Fleet and Resource Management: Farmonaut’s fleet management solution helps contractors coordinate logistics, improve fuel efficiency, and streamline construction equipment deployment at tank or pipeline sites.

- Carbon Footprinting: For sustainability-driven cities, carbon footprinting modules monitor emissions and guide cleaner construction practices, supporting Logan City’s green infrastructure vision.

- API and Integrations: The Farmonaut API and Developer Docs allow utility companies and municipalities to integrate farm, ecosystem, or construction site data directly into custom dashboards or asset management tools.

These smart technologies provide better compliance, transparency, and efficiency—paving the way for resilient infrastructure and sustainable growth in places like Logan City, Utah and beyond.

Project Highlights & Contractor Prequalification Table

The following table offers a structured comparison of project milestones, phases, and prequalification criteria crucial for contractors and municipal stakeholders involved in drinking water storage tank construction, booster pump station project management, and bid planning in Logan City and similar regions.

| Project Phase | Estimated Completion Date | Storage Capacity (MG) | Key Contractor | Prequalification Status | Estimated Cost (USD Million) | Current Progress (%) |

|---|---|---|---|---|---|---|

| Design | Q1 2025 | 10 | To be selected | Prequalification In Progress | 22 | 100 |

| Construction Start | Q3 2025 | 10 | To be announced | From Prequalified List | 33 | 0 |

| Structural Installation | Q2 2026 | 10 | Awarded Contractor | Must Be Prequalified | 18 | — |

| Testing & Commissioning | Q4 2026 | 10 | Head Contractor | Qualified Only | 3 | — |

| Comparable Project: Logan City Reservoir Upgrade | 2023 | 6 | Whitaker Construction | Prequalified | 11 | 100 |

Frequently Asked Questions

The project centers on drinking water storage tank construction and a state-of-the-art booster pump station, significantly increasing Logan City’s capacity and resilience for drinking water storage and distribution.

Contractors must submit prequalification proposals via Virtual-Bid by the specified deadline. Only pre-qualified contractors will be eligible to submit bids—no exceptions.

Key components include a 10 MG post-tensioned tank (split into two cells), valve vault/pump station, vertical turbine pumps, emergency overflow boxes, large-diameter steel and HDPE pipeline connections, a robust electrical and controls setup, backup diesel generator, HVAC, site security systems, grading, paving, and restoration works.

All prequalification and project documents can be downloaded starting April 17, 2025, from the web address https://www.virtual-bid.com (search for First Dam 10 MG Tank and Booster Pump Station Project).

Over 70% of large-scale water projects now require contractor prequalification. This step ensures higher standards, contractor capability, public safety, and long-term project integrity.

Farmonaut offers satellite-based monitoring, traceable supply chain solutions, carbon emission tracking, advanced fleet management, and affordable, scalable data APIs for real-time farm, site, and environmental management.

Farmonaut Subscriptions

For enhanced monitoring, sustainability, and traceability across your projects, choose a Farmonaut subscription plan to match your operations—from single fields to multi-site construction, project management, or government-scale monitoring.

Conclusion: Best Practices for Water Infrastructure Projects

The Drinking Water Tank Construction: Logan City 10 MG Project Update demonstrates the higher standards and technological advancements now demanded in municipal infrastructure. From compliant contractor prequalification proposals to post-tensioned tanks and energy-efficient booster stations, every stage reinforces resilience and reliability.

For contractors, the opportunity lies in meticulous readiness—downloading and studying all prequalification documents, ensuring experience aligns with Logan City’s specifications, and assembling a bid team skilled in the latest site, tank, station, and pipeline construction techniques. For public sector leaders, investments in both physical infrastructure and digital platforms such as Farmonaut support oversight, transparency, and sustainability for generations.

As water resource challenges intensify, drinking water storage tank construction projects like Logan City’s 10 MG First Dam Tank are essential blueprints for the future—built on expertise, innovation, and an unwavering commitment to public safety and urban vitality.