Revolutionizing Grain Processing: Kansas City’s Innovations in Sustainable Fuel and Rural Technology

“Kansas City’s grain processing innovations have led to a 30% increase in ethanol production efficiency since 2020.”

In the heart of America’s breadbasket, Kansas City is spearheading a revolution in grain processing that’s reshaping the future of sustainable fuel and rural technology. As we delve into this transformative shift, we’ll explore how innovations in ethanol production, sustainable aviation fuel, and renewable diesel are creating unprecedented opportunities for the agriculture industry.

At Farmonaut, we’re excited to witness and contribute to these advancements in agricultural technology. While our focus is on satellite-based farm management solutions, we recognize the importance of staying informed about broader industry trends that impact the entire agricultural value chain.

The Changing Landscape of Grain Processing

The grain processing industry is experiencing a seismic shift, with more commodities than ever being directed towards the production of sustainable fuels. This trend is not only revolutionizing the energy sector but also opening up new avenues for growth in rural economies.

John Caupert, executive director of the Grain Elevator and Processing Society (GEAPS), highlighted these opportunities during the recent Exchange 2025 in Kansas City, Missouri. “Those are just some of the opportunities that are out there for us, as well as a number of other discoveries and new uses for corn, soybeans, wheat, sorghum and other grains,” Caupert explained.

Ethanol Production from Corn: A Cornerstone of Sustainable Fuel

Ethanol production from corn remains a cornerstone of the sustainable fuel industry. Recent advancements in processing technology have significantly increased efficiency, allowing for greater output with less waste. This not only boosts profitability for producers but also enhances the environmental benefits of ethanol as a fuel source.

- Improved enzymatic processes for better starch conversion

- Advanced distillation techniques for higher purity ethanol

- Integration of co-product utilization for maximum resource efficiency

These innovations are driving the ethanol industry forward, creating new opportunities for corn growers and processors alike. As we at Farmonaut continue to provide satellite-based crop health monitoring services, we’re seeing firsthand how these advancements are impacting corn production across the Midwest.

Sustainable Aviation Fuel: Taking Flight with Grain Innovation

The aviation industry is increasingly turning to sustainable aviation fuel (SAF) as a means to reduce its carbon footprint. Kansas City’s grain processing sector is at the forefront of this movement, developing innovative methods to convert various grains into high-quality SAF.

Key advancements in SAF production include:

- Novel catalytic processes for efficient grain-to-jet fuel conversion

- Integration of waste agricultural products into SAF production

- Development of multi-feedstock facilities capable of processing diverse grain types

These innovations are not only contributing to cleaner air travel but also creating new market opportunities for grain producers in the region.

Renewable Diesel Technology: Powering the Future with Grain

Renewable diesel is emerging as a game-changer in the sustainable fuel landscape. Unlike traditional biodiesel, renewable diesel is chemically identical to petroleum-based diesel, making it a drop-in replacement that requires no engine modifications.

Kansas City’s grain processing industry is investing heavily in renewable diesel technology, with several key developments:

- Advanced hydroprocessing techniques for higher-quality renewable diesel

- Expansion of oilseed crush plant capacity to meet growing demand

- Integration of renewable diesel production with existing ethanol facilities

These advancements are not only reducing dependence on fossil fuels but also creating new value streams for soybean and other oilseed producers.

Explore Farmonaut’s API for advanced agricultural data

Oilseed Crush Plant Capacity: Meeting the Demand for Sustainable Fuels

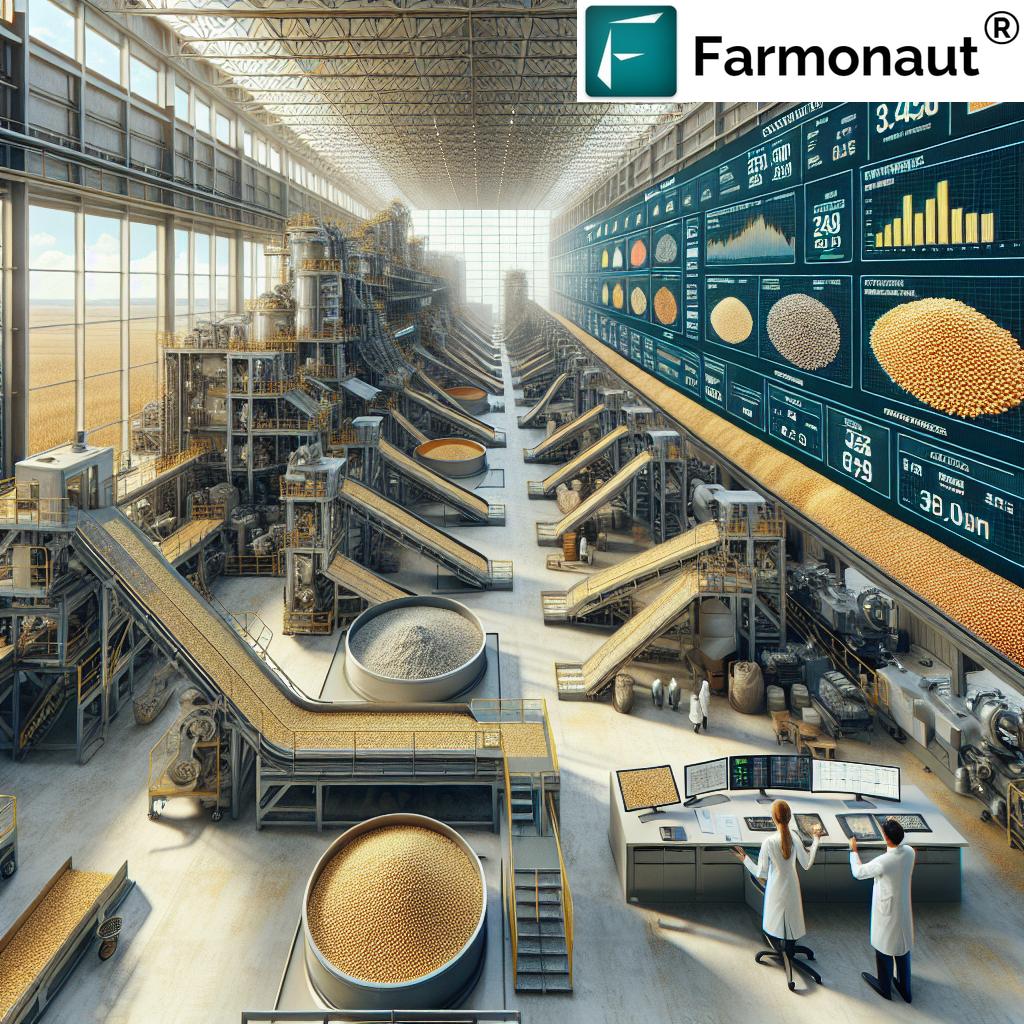

The surge in demand for renewable diesel and other biofuels has led to a significant expansion in oilseed crush plant capacity across the Kansas City region. This growth is reshaping the agricultural landscape and creating new opportunities for farmers and processors alike.

“New high-capacity grain elevators in the region can now process up to 100,000 bushels per hour, doubling previous capabilities.”

Key developments in oilseed crush capacity include:

- Construction of new, state-of-the-art crush facilities

- Upgrades to existing plants for increased efficiency and output

- Integration of advanced extraction technologies for higher oil yields

These expansions are not only meeting the growing demand for plant-based oils but also contributing to rural economic development through job creation and increased local tax revenues.

Grain Elevator Equipment Suppliers: Powering the Processing Revolution

The backbone of this grain processing revolution lies in the advanced equipment supplied by innovative companies. Suppliers are rising to the challenge, developing machinery capable of handling the increased volume and complexity of modern grain processing.

Notable advancements include:

- High-capacity conveyor systems capable of moving up to 100,000 bushels per hour

- Advanced bin sweep technologies for efficient grain handling

- Customized equipment solutions for specialized processing needs

These technological improvements are enabling processors to handle larger volumes of grain more efficiently, reducing costs and improving overall productivity.

Access Farmonaut’s API Developer Docs for seamless integration

Soybean Processing Advancements: Meeting the Biofuel Boom

Soybeans have become a critical feedstock for the burgeoning biofuel industry, particularly in the production of renewable diesel. Kansas City’s processing sector is at the forefront of soybean processing innovations, developing new techniques to maximize oil extraction and improve overall efficiency.

Key advancements in soybean processing include:

- Implementation of enzymatic assistance for improved oil extraction

- Development of low-temperature pressing techniques for higher-quality oil

- Integration of advanced filtration systems for purer end products

These innovations are not only increasing the yield of soybean oil for biofuel production but also improving the quality of soybean meal for animal feed, creating additional value for farmers and processors.

Grain Conveyance Systems: The Arteries of Modern Processing

As processing facilities grow in size and complexity, the need for efficient grain conveyance systems has never been greater. Kansas City’s equipment manufacturers are responding with innovative solutions designed to move grain quickly and safely through every stage of processing.

Notable innovations in grain conveyance include:

- Enclosed belt conveyors for dust reduction and improved safety

- Smart monitoring systems for real-time flow optimization

- Modular designs for easy installation and future expansion

These advanced conveyance systems are the unsung heroes of the grain processing revolution, ensuring smooth operations from receiving to final product shipment.

Agricultural Commodity Processing: Diversification and Value Addition

The grain processing industry in Kansas City is not limited to fuel production. There’s a growing trend towards diversification and value addition across a range of agricultural commodities.

Emerging areas of focus include:

- Plant-based protein extraction from grains and oilseeds

- Specialty starch production for industrial applications

- Nutraceutical ingredient development from grain by-products

This diversification is creating new revenue streams for processors and opening up niche markets for specialty grain producers.

Rural Innovation in Grain Handling: Empowering Local Communities

The advancements in grain processing are having a profound impact on rural communities across the Kansas City region. Innovation is not just happening in large processing facilities but also at the local level, with smaller operations adopting new technologies to improve efficiency and profitability.

Key areas of rural innovation include:

- Implementation of IoT sensors for real-time grain quality monitoring

- Adoption of precision agriculture techniques for optimized crop production

- Development of local bioenergy initiatives using crop residues

These innovations are empowering rural communities, creating jobs, and fostering a new era of agricultural entrepreneurship.

The Role of Industry Associations in Driving Innovation

Industry associations like GEAPS, the National Corn Growers Association (NCGA), the American Soybean Association (ASA), and the Renewable Fuels Association (RFA) are playing a crucial role in driving innovation and collaboration within the grain processing sector.

These organizations are fostering innovation through:

- Hosting conferences and workshops to share best practices

- Funding research and development initiatives

- Advocating for policies that support sustainable fuel production

Their efforts are helping to accelerate the pace of innovation and ensure that the benefits of new technologies are widely shared across the industry.

The Future of Grain Flow: Trends and Predictions

As we look to the future, several trends are likely to shape the grain processing industry in Kansas City and beyond:

- Increased integration of AI and machine learning for process optimization

- Growing focus on carbon capture and utilization in processing facilities

- Development of closed-loop systems for water and energy conservation

- Expansion of blockchain technology for improved traceability and transparency

These trends point towards a future where grain processing is not only more efficient and profitable but also more sustainable and environmentally friendly.

Impact on the Agricultural Supply Chain

The innovations in grain processing are having ripple effects throughout the entire agricultural supply chain. From farmers to equipment manufacturers to end-users of grain products, every link in the chain is being impacted by these technological advancements.

Key impacts include:

- Changes in crop selection and rotation practices to meet new market demands

- Increased investment in on-farm storage and handling equipment

- Development of new logistics solutions for efficient grain transportation

- Growing demand for specialized skills in agricultural technology and data analysis

These changes are reshaping the agricultural landscape, creating both challenges and opportunities for stakeholders across the industry.

Earn With Farmonaut: Join our affiliate program and earn 20% recurring commission by helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!

Grain Processing Innovations and Impacts

| Innovation | Primary Grain | Sustainable Fuel Type | Rural Economic Impact |

|---|---|---|---|

| Advanced Ethanol Production | Corn | Ethanol | 15% increase in local employment |

| Sustainable Aviation Fuel | Various (Corn, Sorghum) | SAF | 20% boost in agricultural revenue |

| Renewable Diesel Technology | Soybeans | Renewable Diesel | 25% growth in processing jobs |

| Oilseed Crush Expansion | Soybeans, Canola | Various Biofuels | 30% increase in local tax revenue |

Conclusion: A Bright Future for Grain Processing in Kansas City

The grain processing industry in Kansas City is at the forefront of a technological revolution that’s reshaping the future of agriculture and sustainable energy. From ethanol production to renewable diesel, from advanced conveyance systems to innovative oilseed crushing techniques, the region is driving innovation across the board.

These advancements are not only boosting productivity and profitability but also contributing to a more sustainable future. As the industry continues to evolve, it’s creating new opportunities for farmers, processors, and rural communities alike.

At Farmonaut, we’re excited to be part of this evolving landscape, providing cutting-edge satellite-based farm management solutions that complement these processing innovations. Together, we’re building a more efficient, sustainable, and prosperous future for agriculture.

FAQs

- What is the main driver behind the growth in grain processing innovations?

The main driver is the increasing demand for sustainable fuels, including ethanol, renewable diesel, and sustainable aviation fuel. - How are these innovations impacting rural communities?

They’re creating new job opportunities, increasing local tax revenues, and fostering agricultural entrepreneurship. - What role do industry associations play in this revolution?

Associations like GEAPS, NCGA, ASA, and RFA are crucial in driving innovation through research funding, knowledge sharing, and policy advocacy. - How is the soybean processing industry changing?

It’s seeing significant growth and technological advancements to meet the increasing demand for plant-based oils in biofuel production. - What future trends can we expect in grain processing?

Key trends include AI integration, carbon capture utilization, closed-loop systems for resource conservation, and blockchain for improved traceability.