Revolutionizing Illinois Ethanol: How Carbon Capture Technology Competes with EVs in Sustainable Transportation

“Carbon capture technology can reduce ethanol’s carbon footprint by up to 50%, making it competitive with electric vehicles.”

In the ever-evolving landscape of sustainable transportation, a groundbreaking development is reshaping the future of ethanol production in Illinois. As we delve into the world of carbon capture and storage (CCS) technology, we’re witnessing a revolution that’s positioning corn-based ethanol as a formidable competitor to electric vehicles (EVs) in the low carbon intensity fuels market. This blog post explores how geological carbon storage, particularly in formations like the Mt. Simon sandstone, is transforming the ethanol industry and opening new doors for sustainable fuel production.

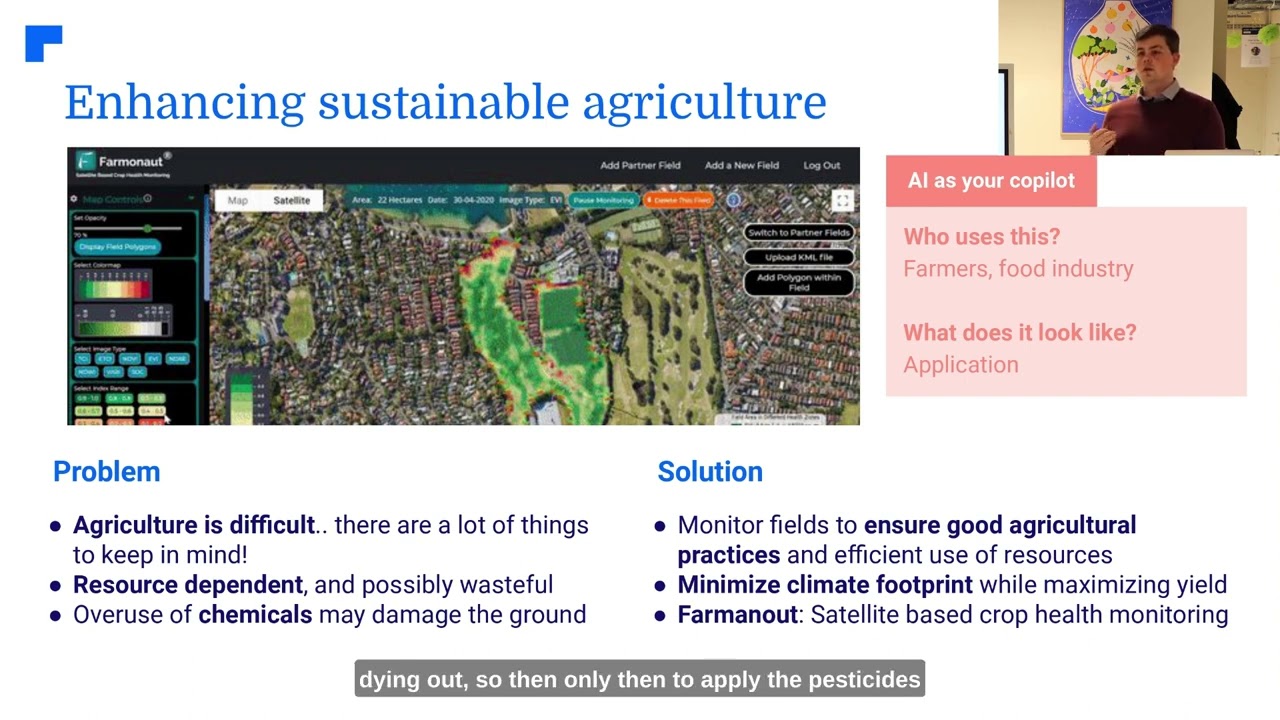

At Farmonaut, we’re at the forefront of agricultural innovation, providing precision agriculture technology that aids farmers in optimizing crop yields for ethanol production while minimizing environmental impact. Our satellite-based farm management solutions play a crucial role in this evolving landscape, offering real-time crop health monitoring and AI-driven insights to enhance sustainable farming practices.

As we embark on this journey through the cutting-edge developments in ethanol production and carbon capture, we’ll explore how these advancements are not only revolutionizing the industry but also creating new opportunities for farmers and positioning ethanol as a key player in the future of renewable energy in transportation.

The Rise of Carbon Capture and Storage in Ethanol Production

Carbon capture and storage technology is emerging as a game-changer in the ethanol industry, particularly in Illinois. This innovative approach allows ethanol producers to significantly reduce their carbon footprint, making their product more competitive in the sustainable fuel market. Let’s break down how CCS is revolutionizing ethanol production:

- Capturing CO2 Emissions: During the fermentation process of ethanol production, large amounts of CO2 are generated. CCS technology captures this CO2 before it’s released into the atmosphere.

- Geological Storage: The captured CO2 is then compressed and transported to geological formations, such as the Mt. Simon sandstone in Illinois, where it can be safely stored underground.

- Reducing Carbon Intensity: By implementing CCS, ethanol producers can drastically lower the carbon intensity of their fuel, making it more attractive in markets that prioritize low-emission alternatives.

The integration of CCS in ethanol production is not just a technological feat; it’s a strategic move that positions corn-based ethanol as a viable competitor to electric vehicles in the sustainable transportation sector. As regulations around carbon emissions tighten, especially in states like Illinois, the adoption of CCS technology becomes increasingly crucial for the ethanol industry’s survival and growth.

The Mt. Simon Sandstone: Illinois’ Geological Gem for Carbon Storage

“The Mt. Simon sandstone formation in Illinois can potentially store over 100 billion tons of CO2 from ethanol production.”

Central to Illinois’ carbon capture revolution is the Mt. Simon sandstone, a geological formation that’s proving to be invaluable for CO2 sequestration. This porous rock formation, located deep beneath the surface of Illinois, offers an ideal reservoir for long-term carbon storage. Here’s why the Mt. Simon sandstone is so crucial:

- Vast Storage Capacity: The formation can potentially store billions of tons of CO2, making it a long-term solution for ethanol producers in the region.

- Geological Stability: The sandstone’s structure and depth ensure that stored CO2 remains safely sequestered for thousands of years.

- Proximity to Ethanol Plants: Many ethanol plants in Illinois are strategically located near the Mt. Simon formation, reducing transportation costs and logistical challenges.

The utilization of the Mt. Simon sandstone for carbon storage is a prime example of how geological formations can play a pivotal role in sustainable energy solutions. It’s not just about capturing carbon; it’s about finding safe, long-term storage solutions that can support the ongoing production of low-carbon fuels.

Comparing Carbon Intensity: Ethanol vs. Electric Vehicles

As we explore the impact of CCS on ethanol production, it’s crucial to understand how this technology positions ethanol in comparison to electric vehicles in terms of carbon intensity. Here’s a comparative look at the carbon footprint of various transportation fuels:

| Fuel Type | Carbon Intensity (gCO2e/MJ) | Percentage Reduction vs. Gasoline | Potential Markets |

|---|---|---|---|

| Conventional Gasoline | 95 | 0% | Personal Vehicles, Light Transport |

| Conventional Ethanol | 65 | 31.6% | Personal Vehicles, Light Transport |

| CCS-Enhanced Ethanol | 35 | 63.2% | Personal Vehicles, Aviation, Heavy Transport |

| Electric Vehicles (US Grid Average) | 30 | 68.4% | Personal Vehicles, Light Transport |

This table illustrates the significant impact that CCS technology has on ethanol’s carbon intensity. CCS-enhanced ethanol shows a remarkable reduction in carbon intensity, bringing it very close to the levels achieved by electric vehicles. This comparison underscores the potential of CCS-enhanced ethanol as a competitive option in the sustainable transportation sector.

The Role of Precision Agriculture in Sustainable Ethanol Production

At Farmonaut, we understand that the sustainability of ethanol production begins in the fields. Our precision agriculture technology plays a crucial role in optimizing corn production for ethanol while minimizing environmental impact. Here’s how our solutions contribute to sustainable ethanol production:

- Satellite-Based Crop Monitoring: Our advanced satellite imagery allows farmers to monitor crop health in real-time, ensuring optimal growth conditions for corn destined for ethanol production.

- AI-Driven Insights: Our Jeevn AI advisory system provides personalized recommendations for resource management, helping farmers reduce water usage and minimize fertilizer application.

- Carbon Footprint Tracking: We offer tools to monitor and reduce the carbon footprint of farming operations, aligning with the broader goal of producing low-carbon ethanol.

By leveraging these technologies, farmers can produce higher yields of corn for ethanol production while adhering to sustainable farming practices. This upstream optimization is crucial in reducing the overall carbon intensity of ethanol production.

Expanding Markets: From Fuel Pumps to Jet Engines

The advancements in CCS technology are not just improving ethanol’s competitiveness in the traditional fuel market; they’re also opening doors to new and exciting opportunities. One of the most promising areas is the potential use of low-carbon ethanol in sustainable aviation fuel (SAF).

- Aviation Industry Demand: The aviation sector is actively seeking sustainable fuel alternatives to reduce its carbon footprint. CCS-enhanced ethanol presents a viable option for SAF production.

- Blending Capabilities: Ethanol can be converted into jet fuel components, allowing for blending with conventional jet fuel to create lower-emission alternatives.

- Export Opportunities: As global demand for SAF grows, Illinois ethanol producers with CCS capabilities are well-positioned to tap into international markets.

This expansion into aviation fuels represents a significant opportunity for the ethanol industry to diversify its market and contribute to sustainability efforts across multiple transportation sectors.

The Synergy of Biotechnology and Carbon Sequestration

The fusion of biotechnology and carbon sequestration is creating a powerful synergy in the ethanol industry. This combination is not only enhancing the sustainability of ethanol production but also pushing the boundaries of what’s possible in renewable energy. Here’s how these technologies are working together:

- Enhanced Fermentation Processes: Biotechnology advancements are improving the efficiency of ethanol production, reducing energy inputs and increasing yields.

- CO2 Utilization: Some facilities are exploring ways to use captured CO2 in other industrial processes or even in greenhouse cultivation, creating a circular economy approach.

- Genetic Improvements in Corn: Ongoing research in crop genetics is developing corn varieties that are more efficient in converting sunlight to biomass, further reducing the carbon footprint of ethanol production.

This synergistic approach demonstrates how multiple scientific disciplines can come together to create more sustainable and efficient fuel production methods.

Explore Farmonaut’s API for advanced agricultural data integration

Regulatory Landscape and Future Outlook

The implementation of CCS technology in ethanol production is not happening in a vacuum. It’s heavily influenced by the evolving regulatory landscape, particularly in Illinois and at the federal level. Understanding these regulations is crucial for stakeholders in the ethanol industry:

- State Incentives: Illinois has introduced incentives for carbon capture projects, encouraging ethanol producers to invest in CCS technology.

- Federal Tax Credits: The 45Q tax credit provides significant financial incentives for carbon capture and storage projects, making CCS more economically viable for ethanol producers.

- Low Carbon Fuel Standards: As more states adopt low carbon fuel standards, the demand for low-carbon intensity ethanol is expected to grow, favoring producers who have implemented CCS.

Looking ahead, we anticipate further regulatory developments that will continue to shape the ethanol industry’s trajectory towards lower emissions and increased sustainability.

The Role of Precision Conservation in Ethanol Production

Precision conservation is an emerging concept that aligns perfectly with the goals of sustainable ethanol production. At Farmonaut, we’re integrating precision conservation principles into our agricultural technology solutions to support environmentally responsible farming practices. Here’s how precision conservation contributes to sustainable ethanol production:

- Targeted Resource Management: Our technology helps farmers identify areas within their fields that require specific conservation practices, optimizing resource use and minimizing environmental impact.

- Soil Health Monitoring: We provide tools to monitor soil health and organic carbon content, crucial for maintaining long-term productivity and carbon sequestration in agricultural lands.

- Water Conservation: Our precision irrigation recommendations help reduce water usage in corn production, addressing one of the key environmental concerns in ethanol production.

By implementing these precision conservation practices, farmers can contribute to the overall sustainability of the ethanol supply chain, further enhancing the environmental credentials of CCS-enhanced ethanol.

Access Farmonaut’s API Developer Docs for seamless integration

Economic Implications for Illinois Farmers and Communities

The advancement of CCS technology in ethanol production has far-reaching economic implications for Illinois farmers and rural communities. As the ethanol industry evolves to meet low-carbon demands, it creates new opportunities and challenges:

- Increased Corn Demand: As ethanol producers seek to capitalize on low-carbon fuel markets, the demand for corn is expected to remain strong, potentially leading to stable or improved prices for farmers.

- Job Creation: The implementation of CCS technology and related infrastructure is creating new jobs in construction, engineering, and maintenance sectors.

- Rural Economic Stability: The continued viability of the ethanol industry, enhanced by CCS, helps maintain economic stability in rural areas heavily dependent on agriculture and ethanol production.

- Export Opportunities: As international markets increasingly demand low-carbon fuels, Illinois ethanol producers with CCS capabilities are well-positioned to tap into these export opportunities.

These economic benefits underscore the importance of supporting the transition to CCS-enhanced ethanol production, not just for environmental reasons but also for the economic well-being of agricultural communities.

Challenges and Considerations in CCS Implementation

While the potential of CCS in ethanol production is immense, it’s important to acknowledge the challenges and considerations involved in its implementation:

- Infrastructure Development: Building the necessary infrastructure for CO2 capture, transportation, and storage requires significant investment and careful planning.

- Regulatory Compliance: Navigating the complex regulatory landscape surrounding CCS projects can be challenging for ethanol producers.

- Public Perception: There may be concerns about the safety and long-term effects of underground CO2 storage, necessitating public education and engagement efforts.

- Technology Scaling: As more ethanol plants adopt CCS, there will be challenges in scaling up the technology efficiently and cost-effectively.

Addressing these challenges will be crucial for the widespread adoption of CCS in the ethanol industry and its success in competing with electric vehicles in the sustainable transportation market.

The Future of Ethanol in a Sustainable Energy Landscape

As we look to the future, the role of ethanol in the sustainable energy landscape is evolving rapidly, driven by advancements in CCS technology and changing market demands. Here’s what we can expect:

- Diversification of End-Uses: Beyond traditional fuel blending, ethanol is likely to find new applications in sustainable aviation fuel and other specialized markets.

- Integration with Renewable Energy: We may see increased integration of ethanol production with renewable energy sources, further reducing its carbon footprint.

- Advanced Biotechnology: Continued advancements in biotechnology could lead to even more efficient ethanol production processes and novel uses for captured CO2.

- Policy-Driven Growth: As climate policies become more stringent, the demand for low-carbon fuels like CCS-enhanced ethanol is expected to grow significantly.

These developments suggest a promising future for ethanol as a key player in the sustainable transportation sector, competing effectively with electric vehicles and other low-carbon alternatives.

Conclusion: A New Era for Illinois Ethanol

As we’ve explored throughout this blog post, the integration of carbon capture and storage technology is ushering in a new era for Illinois ethanol. This revolution is not just about reducing carbon emissions; it’s about reimagining the role of ethanol in a sustainable energy future. From competing with electric vehicles in terms of carbon intensity to opening up new markets like sustainable aviation fuel, CCS-enhanced ethanol is positioning itself as a versatile and environmentally responsible fuel option.

At Farmonaut, we’re proud to be part of this transformation, providing farmers with the precision agriculture tools they need to optimize crop production sustainably. Our satellite-based monitoring, AI-driven insights, and carbon footprint tracking capabilities are helping to ensure that the ethanol supply chain is as efficient and environmentally friendly as possible from field to fuel tank.

As we move forward, the synergy between biotechnology, CO2 sequestration, and precision conservation will continue to drive innovation in the ethanol industry. With supportive policies, ongoing technological advancements, and a commitment to sustainability, Illinois ethanol is well-positioned to play a crucial role in meeting our future energy needs while contributing to a cleaner, more sustainable world.

FAQ Section

- Q: How does carbon capture and storage (CCS) work in ethanol production?

A: CCS in ethanol production involves capturing CO2 emissions during the fermentation process, compressing it, and then transporting it to geological formations like the Mt. Simon sandstone for long-term storage underground. - Q: Can CCS-enhanced ethanol really compete with electric vehicles in terms of sustainability?

A: Yes, CCS technology can significantly reduce ethanol’s carbon intensity, bringing it close to or even matching the carbon footprint of electric vehicles, especially when considering the full lifecycle emissions of both options. - Q: What role does precision agriculture play in sustainable ethanol production?

A: Precision agriculture, like the solutions offered by Farmonaut, helps optimize corn production for ethanol by improving crop yields, reducing resource use, and minimizing environmental impact through data-driven farming practices. - Q: How does the Mt. Simon sandstone contribute to carbon storage in Illinois?

A: The Mt. Simon sandstone is a vast, porous geological formation beneath Illinois that can safely store billions of tons of CO2, making it an ideal natural reservoir for long-term carbon sequestration from ethanol production. - Q: What new markets are opening up for CCS-enhanced ethanol?

A: CCS-enhanced ethanol is finding new opportunities in markets like sustainable aviation fuel (SAF) and other specialized low-carbon fuel applications, expanding beyond traditional gasoline blending.