Revolutionizing Iowa Dairy: How Shredlage and Inoculants Boost Corn Silage Quality for Optimal Feed Technology

“Innovative inoculants in shredlage processing can increase acetate levels by up to 15% in corn silage fermentation.”

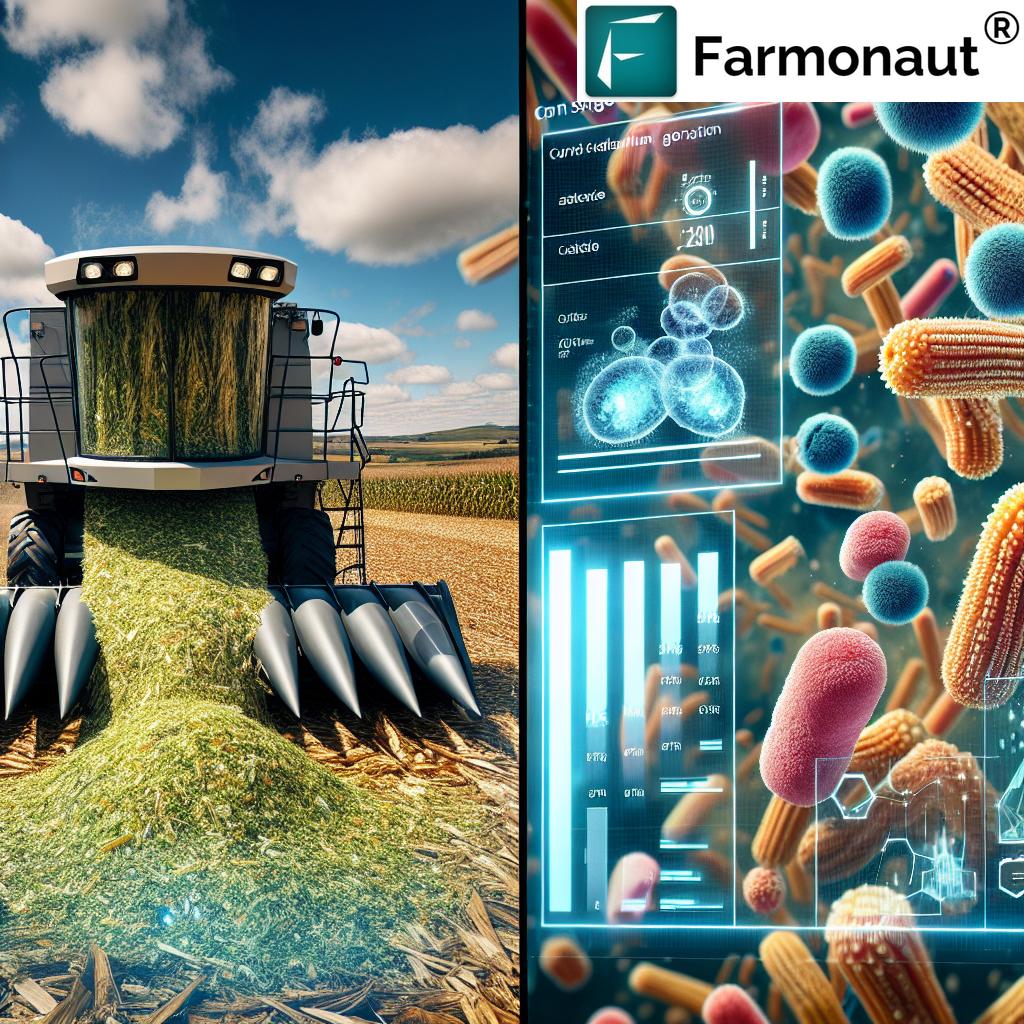

In the heart of America’s Heartland, Iowa’s dairy industry is undergoing a remarkable transformation. As we delve into the world of advanced corn silage fermentation and cutting-edge feed technology, we’re witnessing a revolution that’s set to redefine the standards of dairy production. Our journey through this groundbreaking research will unveil how innovative techniques in shredlage processing and the application of specialized inoculants are elevating the quality of corn silage to unprecedented levels.

The Dawn of a New Era in Corn Silage Production

Iowa, known for its vast cornfields and thriving dairy farms, is at the forefront of adopting new technologies to enhance feed quality. The integration of shredlage processing benefits with advanced inoculants is proving to be a game-changer in the realm of dairy feed technology. This synergy is not just improving silage quality; it’s revolutionizing the entire approach to dairy nutrition and herd management.

As we explore the intricacies of this innovative approach, it’s crucial to understand the fundamental components that make this revolution possible. From the fields where corn is grown to the advanced processing techniques and the microscopic world of beneficial bacteria, every element plays a vital role in enhancing the nutritional value of silage.

Understanding Shredlage: A Leap Forward in Corn Processing

Shredlage represents a significant advancement in corn silage harvesting techniques. Unlike traditional chopping methods, shredlage involves a specialized processor that shreds and crushes corn stalks and kernels more intensively. This process results in longer particles with frayed edges, increasing the surface area exposed to rumen microbes.

- Enhanced fiber digestibility

- Improved starch utilization

- Better rumen mat formation

- Reduced sorting by cows

The benefits of shredlage extend beyond mere physical characteristics. By optimizing particle size and texture, we’re setting the stage for more efficient fermentation and improved digestibility, which are crucial factors in maximizing the nutritional value of silage for dairy cows.

The Role of Inoculants in Silage Fermentation

Complementing the physical improvements brought by shredlage, the use of specialized inoculants marks another leap in silage inoculant effects. These carefully selected bacterial strains are designed to guide the fermentation process, ensuring optimal pH levels and the production of beneficial organic acids.

- Rapid pH drop for improved preservation

- Increased production of lactic and acetic acids

- Inhibition of harmful bacteria and yeasts

- Enhanced aerobic stability during feed-out

The synergy between shredlage and inoculants creates an environment where beneficial bacteria thrive, leading to a more stable and nutritious end product. This combination is key to unlocking the full potential of corn silage as a high-quality feed for dairy cows.

The Science Behind Improved Silage Quality

To truly appreciate the impact of these innovations, we need to delve into the science of silage fermentation parameters. The process involves a complex interplay of microorganisms, enzymes, and chemical reactions, all working together to transform freshly harvested corn into a stable, nutritious feed.

| Parameters | Traditional Silage | Shredlage with Inoculants |

|---|---|---|

| pH Levels | 4.0 – 4.5 | 3.8 – 4.2 |

| Acetate Concentration | 1-2% | 2-3% |

| Lactic Acid Content | 4-6% | 6-8% |

| Fiber Digestibility | 45-50% | 55-60% |

| Microbial Biomass | Moderate | High |

| Estimated Milk Production Increase | Baseline | 5-10% |

This comparative analysis clearly illustrates the significant improvements achieved through the combination of shredlage processing and innovative inoculants. The lower pH, higher acetate and lactic acid concentrations, and improved fiber digestibility all contribute to a superior feed product that can significantly enhance dairy cow performance.

Optimizing Rumen Health and Function

One of the most significant benefits of this advanced silage technology is its positive impact on rumen microbial biomass. The rumen, often described as the engine of the dairy cow, relies on a diverse and thriving microbial population to break down feed and convert it into nutrients that the cow can use.

- Increased surface area for microbial attachment

- Enhanced fiber digestion

- Improved volatile fatty acid production

- Better overall rumen function

By providing a more digestible substrate and promoting beneficial bacterial growth, shredlage and inoculants work together to create an optimal environment for rumen microbes. This, in turn, leads to improved feed efficiency and increased milk production.

The Impact on Dairy Nutrition and Performance

“Advanced silage management techniques can potentially boost milk production by 5-10% in dairy herds.”

The ultimate goal of any feed technology advancement is to improve dairy cow performance. With the implementation of shredlage and inoculants, we’re seeing remarkable improvements in several key areas:

- Increased dry matter intake

- Higher milk yield

- Improved milk components (fat and protein)

- Better overall cow health and longevity

These improvements are not just theoretical; they’re being observed in real-world applications across Iowa’s dairy farms. Farmers who have adopted these technologies are reporting significant increases in milk production and improved herd health metrics.

Corn Hybrid Selection: The Foundation of Quality Silage

While processing and fermentation are crucial, the journey to superior silage begins with corn hybrid selection for silage. Choosing the right hybrid is a critical decision that can significantly impact the final feed quality.

- Yield potential

- Fiber digestibility

- Starch content

- Plant structure and standability

Modern hybrids developed specifically for silage production offer a balance of high yield and superior nutritional characteristics. When combined with advanced processing techniques and inoculants, these hybrids provide the foundation for exceptional silage quality.

Harvesting Techniques: Timing is Everything

The success of shredlage and inoculants relies heavily on proper harvesting techniques. Timing is critical, as the moisture content and maturity of the corn at harvest significantly impact the fermentation process and final silage quality.

- Optimal whole plant moisture: 65-70%

- Kernel milk line: 1/2 to 2/3

- Proper chop length: 26-30 mm for shredlage

- Processor gap setting: 1-3 mm

By adhering to these guidelines, farmers can ensure that their corn crop is in the ideal condition for shredlage processing and inoculation, setting the stage for optimal fermentation and preservation.

The Economics of Advanced Silage Technology

Implementing shredlage and inoculant technology does require an initial investment, but the returns can be substantial. Let’s break down the economic benefits:

- Increased milk production per cow

- Improved feed efficiency

- Reduced need for supplemental feeds

- Lower feed waste

- Potential for reduced veterinary costs due to improved herd health

When considering these factors, many Iowa dairy farmers are finding that the investment in advanced silage technology pays for itself quickly through improved production and efficiency.

Environmental Considerations

In addition to economic benefits, advanced silage technology also contributes to environmental sustainability. By improving feed efficiency, we’re reducing the overall environmental footprint of dairy production:

- Lower methane emissions per unit of milk produced

- Reduced land requirements for feed production

- Improved nutrient utilization, leading to less nutrient runoff

- Potential for reduced water usage in feed crop production

These environmental benefits align with the growing consumer demand for sustainably produced dairy products, providing an additional marketing advantage for farms adopting these technologies.

Implementing Advanced Silage Technology on Your Farm

For Iowa dairy farmers looking to implement shredlage and inoculant technology, here are some key steps to consider:

- Assess your current silage production system

- Consult with agricultural extension services or silage specialists

- Invest in appropriate equipment or custom harvesting services

- Choose high-quality inoculants designed for your specific needs

- Train staff on new procedures and best practices

- Monitor and evaluate results regularly

By taking a systematic approach to implementation, farmers can maximize the benefits of these advanced technologies and set their operations up for long-term success.

The Future of Dairy Feed Technology

As we look to the future, the advancements in silage production are just the beginning. Ongoing research in areas such as precision fermentation, microbial genomics, and advanced sensor technologies promise to further revolutionize dairy feed technology.

- Real-time fermentation monitoring systems

- Customized inoculant blends based on specific farm conditions

- Integration with precision dairy farming technologies

- Advanced predictive modeling for silage quality and cow performance

These innovations will continue to push the boundaries of what’s possible in dairy nutrition, driving further improvements in efficiency, sustainability, and profitability.

Conclusion: Embracing Innovation for a Thriving Dairy Industry

The revolution in corn silage production through shredlage processing and innovative inoculants represents a significant leap forward for Iowa’s dairy industry. By embracing these technologies, farmers are not only improving their feed quality and cow performance but also positioning themselves at the forefront of sustainable and efficient dairy production.

As we continue to push the boundaries of what’s possible in dairy feed technology, it’s clear that the future of the industry is bright. With ongoing research and development, we can look forward to even more exciting innovations that will continue to revolutionize dairy farming in Iowa and beyond.

For those looking to stay ahead in this rapidly evolving field, continuous education and openness to new technologies will be key. The dairy farms that thrive in the coming years will be those that successfully integrate these advanced silage production methods into their operations, reaping the benefits of improved efficiency, sustainability, and profitability.

FAQ Section

Q: What is shredlage, and how does it differ from traditional corn silage?

A: Shredlage is an advanced corn silage processing technique that uses a specialized processor to shred and crush corn stalks and kernels more intensively than traditional methods. This results in longer particles with frayed edges, increasing the surface area exposed to rumen microbes and improving digestibility.

Q: How do inoculants improve silage quality?

A: Inoculants contain specialized bacterial strains that guide the fermentation process. They help achieve a rapid pH drop, increase the production of beneficial acids like lactic and acetic acids, inhibit harmful bacteria and yeasts, and enhance aerobic stability during feed-out.

Q: What are the main benefits of using shredlage and inoculants in corn silage production?

A: The main benefits include improved fiber digestibility, better starch utilization, enhanced rumen health, increased milk production, and improved overall feed efficiency. Additionally, this technology can lead to reduced feed waste and potentially lower veterinary costs due to improved herd health.

Q: How does advanced silage technology impact the environment?

A: Advanced silage technology contributes to environmental sustainability by improving feed efficiency, which leads to lower methane emissions per unit of milk produced, reduced land requirements for feed production, improved nutrient utilization, and potentially reduced water usage in feed crop production.

Q: Is implementing shredlage and inoculant technology cost-effective for dairy farmers?

A: While there is an initial investment required, many farmers find that the technology pays for itself quickly through improved milk production, better feed efficiency, and reduced need for supplemental feeds. The economic benefits often outweigh the initial costs, making it a cost-effective solution for many dairy operations.

As we conclude our exploration of this revolutionary approach to corn silage production, it’s clear that the combination of shredlage processing and innovative inoculants is set to transform Iowa’s dairy industry. By embracing these advanced technologies, farmers can look forward to improved feed quality, enhanced cow performance, and a more sustainable future for dairy production.

For those interested in leveraging technology to enhance their agricultural operations, Farmonaut offers advanced satellite-based farm management solutions. While not directly related to silage production, Farmonaut’s tools can help farmers optimize various aspects of their operations, complementing the benefits of advanced silage technology.

For developers interested in integrating agricultural data into their own systems, Farmonaut also offers an API with comprehensive developer documentation.

Farmonaut’s solutions are also available on mobile platforms:

By combining advanced silage production techniques with cutting-edge farm management tools, Iowa’s dairy farmers can position themselves at the forefront of agricultural innovation, ensuring a prosperous and sustainable future for the industry.