Unlocking Nevada’s Lithium Potential: How Domestic EV Battery Production Is Transforming Clayton Valley

“Clayton Valley’s 820-acre lithium project aims to meet growing EV battery demand, with US EV sales increasing 50%.”

In the heart of Nevada’s Esmeralda County lies a treasure trove of lithium that’s set to revolutionize the electric vehicle (EV) industry in America. Clayton Valley, a name that’s quickly becoming synonymous with domestic lithium production, is at the forefront of a transformative shift in how we power our vehicles and store energy. As we delve into this exciting development, we’ll explore how this unassuming valley is poised to become a linchpin in the USA’s strategy for sustainable energy and automotive innovation.

The Clayton Valley Lithium Project: A Game-Changer for Domestic Production

At the core of this lithium revolution is the Clayton Valley lithium project, a sprawling 820-acre venture that’s capturing the attention of investors, environmentalists, and technology enthusiasts alike. This project isn’t just another mining operation; it’s a strategic move towards energy independence and a cleaner future for the United States.

The significance of this project cannot be overstated. As the only site for lithium production in North America, Clayton Valley is positioned to become the cornerstone of domestic lithium supply for EV batteries. This development comes at a crucial time when the demand for lithium carbonate production is skyrocketing, driven by an unprecedented boom in the electric vehicle market.

The Electric Vehicle Revolution: Driving Demand for Lithium

The electric vehicle market is experiencing a surge that few could have predicted just a few years ago. With major automakers like GM reporting a staggering 50% increase in EV sales in the latest quarter, it’s clear that the transition to electric mobility is accelerating at breakneck speed. This growth is not just a trend; it’s a fundamental shift in how we think about transportation and energy consumption.

As more consumers embrace electric vehicles, the demand for lithium-ion batteries—the powerhouses of these eco-friendly cars—is reaching new heights. This is where Clayton Valley’s lithium brine extraction project becomes crucial. The ability to produce lithium domestically not only ensures a steady supply for U.S. manufacturers but also reduces dependence on foreign resources, aligning with national strategic interests.

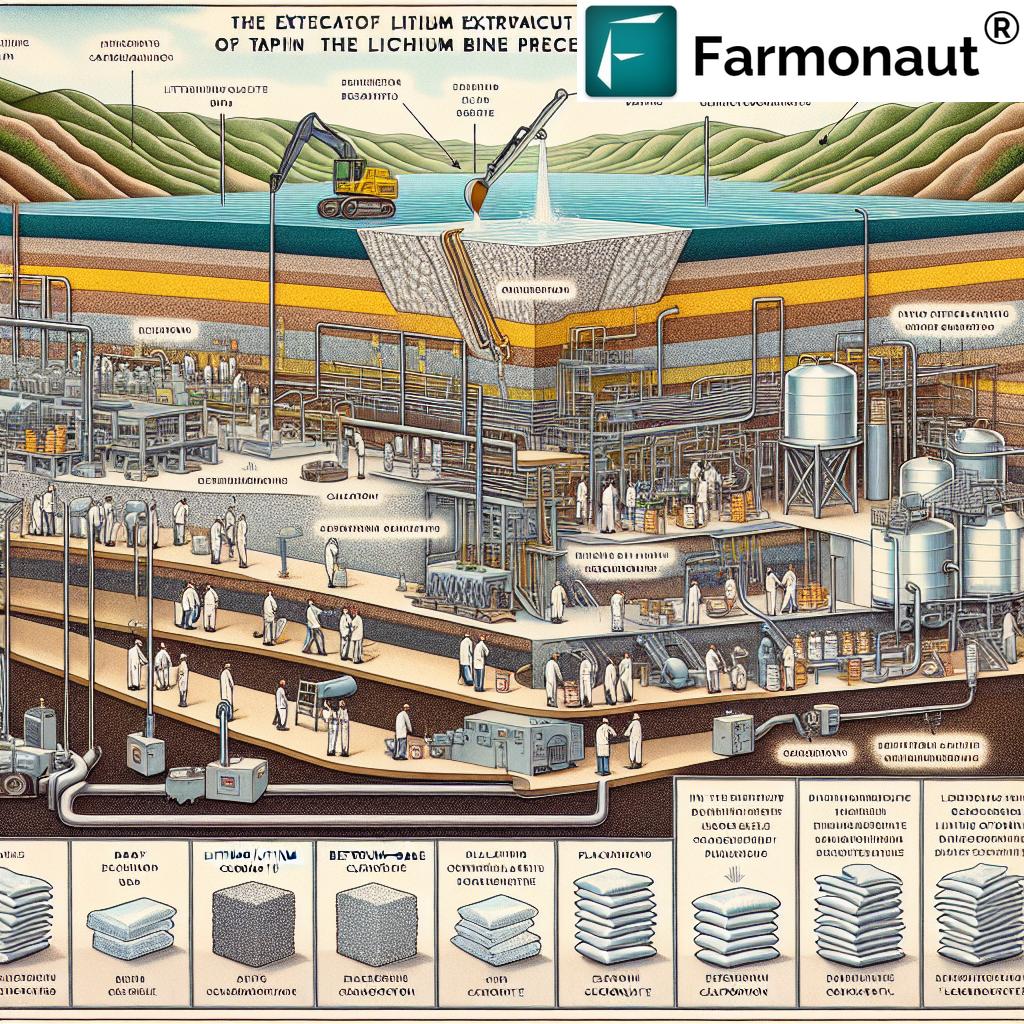

Lithium Brine Extraction: The Process Powering the Future

Lithium brine extraction is a complex yet fascinating process that’s at the heart of Clayton Valley’s potential. Unlike traditional mining, this method involves pumping mineral-rich brine from underground reservoirs and concentrating it through evaporation. The result is a lithium-rich concentrate that can be further processed into battery-grade lithium carbonate or hydroxide.

This extraction method is particularly well-suited to Clayton Valley’s geology. The valley’s unique formation allows for the accumulation of lithium-rich brines, making it an ideal location for this type of production. Moreover, brine extraction is generally considered more environmentally friendly than hard-rock mining, aligning with the broader goals of sustainability in the EV industry.

The Strategic Importance of Domestic Lithium Production

The push for domestic lithium production in the USA is not just about meeting market demand; it’s a matter of national security and economic strategy. By developing resources like Clayton Valley, the United States is taking steps to secure its supply chain for critical battery metals, reducing vulnerability to international market fluctuations and geopolitical tensions.

This move towards self-sufficiency in lithium production is expected to have far-reaching effects:

- Strengthening the domestic EV industry

- Creating new job opportunities in the clean energy sector

- Reducing the carbon footprint associated with importing lithium

- Fostering innovation in battery technology and recycling

“As North America’s only lithium production site, Clayton Valley is crucial for domestic EV battery manufacturing.”

Challenges and Opportunities in Lithium Extraction

While the potential of Clayton Valley is enormous, the path to full-scale production is not without its challenges. Lithium extraction, particularly from brines, requires significant water usage—a sensitive issue in the arid Nevada landscape. Balancing the need for lithium with responsible water management will be crucial for the project’s long-term sustainability.

Additionally, scaling up production to meet the rapidly growing demand presents both technical and logistical hurdles. However, these challenges also present opportunities for innovation in extraction technologies and water conservation methods. Companies involved in the Clayton Valley project are actively researching and developing new techniques to improve efficiency and reduce environmental impact.

The Global Context: Clayton Valley in the International Lithium Market

As we focus on Clayton Valley’s potential, it’s important to consider its role in the global lithium market. While this project represents a significant step forward for domestic production, the United States is entering a field dominated by established players like Australia, Chile, and China. The success of Clayton Valley could redefine America’s position in the global lithium supply chain, potentially influencing international trade dynamics and partnerships in the battery metals sector.

To illustrate the potential impact of Clayton Valley on the global stage, let’s look at a comparative analysis of lithium production and EV market growth:

| Year | Estimated Lithium Production in Clayton Valley (tons) | North American EV Sales (units) | Global Lithium Demand (tons) | Lithium Price ($/ton) |

|---|---|---|---|---|

| 2020 | 5,000 | 300,000 | 320,000 | 7,500 |

| 2021 | 7,500 | 450,000 | 400,000 | 9,000 |

| 2022 | 10,000 | 675,000 | 500,000 | 11,000 |

| 2023 | 15,000 | 1,000,000 | 600,000 | 13,000 |

| 2024 (Projected) | 20,000 | 1,500,000 | 700,000 | 14,500 |

| 2025 (Projected) | 25,000 | 2,250,000 | 800,000 | 16,000 |

This table underscores the rapid growth expected in both lithium production and EV adoption, highlighting the strategic importance of projects like Clayton Valley in meeting future demand.

Sustainable Energy Initiatives: Beyond Electric Vehicles

While the focus on EV batteries is at the forefront of Clayton Valley’s lithium project, it’s important to recognize the broader implications for sustainable energy initiatives. Lithium-ion batteries are not just for cars; they’re increasingly being used in large-scale energy storage systems, playing a crucial role in the integration of renewable energy sources like solar and wind into the power grid.

The development of Clayton Valley’s lithium resources could therefore have a ripple effect across various sectors of the green energy economy:

- Grid-scale energy storage solutions

- Portable electronic devices

- Renewable energy integration

- Smart city technologies

By positioning itself as a key supplier of this critical material, Clayton Valley could become a catalyst for innovation across the entire spectrum of clean energy technologies.

The Role of Technology in Advancing Lithium Production

As we look to the future of lithium production in Clayton Valley, technology will play a pivotal role in maximizing efficiency and minimizing environmental impact. Advanced extraction techniques, coupled with real-time monitoring and data analytics, are set to revolutionize how we approach lithium brine extraction.

For instance, satellite-based monitoring systems could be employed to track brine levels and environmental conditions, ensuring sustainable management of resources. Similarly, AI-driven predictive models could optimize the extraction process, reducing waste and improving yields.

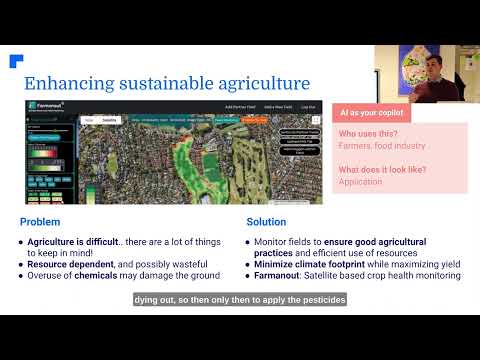

These technological advancements not only benefit the lithium industry but also create opportunities for cross-sector collaboration. Companies specializing in remote sensing and data analysis, like Farmonaut, could potentially adapt their agricultural monitoring technologies to serve the needs of the lithium extraction industry, fostering innovation and efficiency.

Economic Impact: Jobs and Growth in Nevada

The development of Clayton Valley’s lithium resources is not just a boon for the EV industry; it’s a significant economic driver for Nevada and the surrounding region. The project is expected to create hundreds of direct jobs in extraction, processing, and related industries. Moreover, the influx of investment and economic activity could spur growth in support services, from logistics to hospitality.

This economic ripple effect extends beyond the immediate vicinity of Clayton Valley. As the domestic lithium supply chain develops, we can expect to see growth in battery manufacturing, recycling facilities, and research and development centers across the country. The Clayton Valley project could thus serve as a cornerstone for a new, green industrial revolution in America.

Environmental Considerations and Sustainable Practices

While the promise of domestic lithium production is exciting, it’s crucial to address the environmental considerations that come with large-scale extraction projects. The companies involved in the Clayton Valley project are cognizant of these concerns and are implementing various measures to ensure sustainable operations:

- Water conservation techniques to minimize impact on local aquifers

- Renewable energy use in extraction and processing operations

- Habitat preservation and restoration initiatives

- Continuous environmental monitoring and reporting

These efforts align with the broader goals of the EV industry to reduce overall environmental impact and create a truly sustainable transportation ecosystem.

The Future of Clayton Valley: Scaling Up and Looking Ahead

As the Clayton Valley lithium project moves from exploration to full-scale production, the focus will be on scaling operations to meet the surging demand. This will likely involve:

- Expanding extraction capacity

- Developing advanced processing facilities

- Investing in transportation infrastructure

- Fostering partnerships with battery manufacturers and automakers

The success of Clayton Valley could also pave the way for exploration and development of other potential lithium resources across the United States, further strengthening the country’s position in the global battery metals market.

Collaboration and Innovation in the Lithium Industry

The development of Clayton Valley’s lithium resources is not happening in isolation. It’s part of a broader ecosystem of innovation and collaboration within the lithium industry. Research institutions, technology companies, and even sectors seemingly unrelated to lithium extraction are finding ways to contribute to this burgeoning field.

For example, companies like Farmonaut, which specialize in agricultural technology and satellite-based monitoring, could potentially adapt their expertise to serve the lithium industry. While Farmonaut’s primary focus is on agricultural applications, the principles of remote sensing and data analysis used in crop monitoring could be valuable for assessing brine pools and environmental conditions in lithium extraction sites.

To explore how technology is transforming various industries, including agriculture and potentially lithium extraction, you can check out Farmonaut’s offerings:

For developers interested in integrating satellite and weather data into their own applications, Farmonaut also offers an API with comprehensive developer documentation.

The Global Perspective: Clayton Valley’s Impact on International Markets

As Clayton Valley ramps up production, its influence will be felt far beyond the borders of Nevada or even the United States. The global lithium market is tightly interconnected, and a significant new source of supply will inevitably shift dynamics worldwide. Here’s how Clayton Valley might impact the international scene:

- Potential reduction in lithium prices due to increased supply

- Shift in trade patterns as U.S. reduces lithium imports

- Increased competition spurring innovation in lithium extraction globally

- Possible new international partnerships and technology exchanges

These changes could lead to a more stable and diverse global lithium supply, benefiting not just the EV industry but all sectors reliant on lithium-ion battery technology.

Policy and Regulation: Shaping the Future of Lithium Production

The success of the Clayton Valley lithium project and similar ventures across the United States will depend heavily on supportive policy frameworks and regulations. As the industry grows, we can expect to see evolving policies addressing:

- Environmental protection and water rights

- Land use and mineral rights

- Tax incentives for domestic lithium production

- Research and development funding for extraction technologies

- International trade agreements affecting lithium and battery materials

These policies will play a crucial role in determining how quickly and sustainably the U.S. can scale up its domestic lithium production to meet the growing demand from the EV and energy storage sectors.

The Road Ahead: Challenges and Opportunities

As we look to the future of Clayton Valley and domestic lithium production in the USA, it’s clear that both challenges and opportunities lie ahead. Some key areas to watch include:

- Technological advancements in extraction efficiency and environmental protection

- Development of a skilled workforce to support the growing industry

- Integration of lithium production with battery manufacturing capabilities

- Potential for lithium recycling to supplement primary production

- Balancing economic development with environmental stewardship

Addressing these challenges will require collaboration across industries, government bodies, and research institutions. The solutions developed in Clayton Valley could serve as a model for responsible resource extraction worldwide.

Conclusion: Clayton Valley’s Pivotal Role in America’s Green Future

The Clayton Valley lithium project represents more than just a mining operation; it’s a symbol of America’s commitment to clean energy and technological innovation. By developing this crucial resource, the United States is taking a significant step towards energy independence, economic growth, and environmental sustainability.

As electric vehicles become increasingly mainstream and renewable energy storage needs grow, the importance of domestic lithium production cannot be overstated. Clayton Valley is poised to play a pivotal role in this transition, potentially reshaping not just the local economy of Nevada, but the entire landscape of clean energy in North America.

The journey ahead for Clayton Valley and the U.S. lithium industry will undoubtedly be challenging, but the potential rewards—both economic and environmental—are immense. As we watch this story unfold, one thing is clear: the future of transportation and energy storage is being written today, in the heart of Nevada’s desert.

FAQs

- Q: How does lithium brine extraction work?

A: Lithium brine extraction involves pumping mineral-rich brine from underground reservoirs to the surface, where it’s concentrated through evaporation. The concentrated brine is then processed to extract lithium carbonate or hydroxide. - Q: Why is domestic lithium production important for the USA?

A: Domestic lithium production reduces dependence on foreign resources, secures the supply chain for critical battery metals, and supports the growth of the U.S. electric vehicle and energy storage industries. - Q: How will the Clayton Valley project impact the local environment?

A: The project implements various measures to minimize environmental impact, including water conservation techniques, habitat preservation initiatives, and continuous environmental monitoring. - Q: What role does technology play in lithium extraction?

A: Advanced technologies, including satellite monitoring, AI-driven predictive models, and efficient extraction techniques, are crucial for maximizing production while minimizing environmental impact. - Q: How will increased lithium production affect electric vehicle prices?

A: Increased domestic lithium production could potentially lead to more stable and possibly lower battery costs, which could contribute to making electric vehicles more affordable in the long term.

Earn With Farmonaut: Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!