Farm Machinery Management: 10 Key Maintenance Tips

“Regular maintenance can reduce farm machinery breakdowns by up to 25%, significantly improving operational efficiency.”

Introduction: Why Farm Machinery Management Matters

Ensuring farm machinery maintenance and effective equipment management are crucial components of modern agriculture. As farms become more technology-driven and operations expand, the demands on our agricultural machinery grow more intense. Routine machinery maintenance is not just about keeping tractors moving or implements working; it impacts everything from productivity and safety to long-term cost savings.

According to recent studies, regular maintenance can reduce farm machinery breakdowns by up to 25%, significantly improving operational efficiency. Similarly, “Proper tire pressure management can extend farm equipment tire life by nearly 30%, lowering replacement costs.” These statistics demonstrate how maintenance practices directly affect our bottom line and the sustainability of our operations.

In this comprehensive guide, we will explore the ten essential maintenance tips for optimizing agricultural equipment management. From routine checks to leveraging emerging technology such as satellite farm management apps and data-driven insights, we will help you prevent damage, reduce costly repairs, and extend your machinery’s lifespan.

1. Routine Maintenance: The Cornerstone of Reliability

Routine machinery maintenance is the foundation of reliable and efficient farm operations. By establishing consistent maintenance schedules and strictly following the manufacturer’s recommendations, we sharply reduce the risk of unexpected breakdowns and extend our machinery’s lifespan.

Key Elements of Routine Farm Machinery Maintenance

- Lubrication: We must regularly lubricate moving parts to reduce friction, wear, and possible overheating. Following the recommended intervals and types of lubricants for our machines ensures optimal performance and prevents early component failure. Learn more

- Tire Maintenance: It’s essential to inspect tires for proper inflation, tread depth, and any visible signs of damage. Properly inflated tires enhance fuel efficiency, ensure equipment safety, and can extend tire life by up to 30%. Read further

- Fluid Checks: Our equipment relies heavily on quality engine oil, hydraulic fluids, and clean filters. We should monitor and replace these fluids according to the manufacturer’s guidelines to maintain operational efficiency and prevent engine damage. See tips

- Electrical System Inspection: We must inspect batteries, wiring, and electrical connections. Checking for corrosion or wear is crucial for maintaining reliable operation and avoiding unexpected downtime. More details

Practical Example: Lubrication and Fluid Checks

Putting off oil changes or forgetting to grease joints can quickly escalate into serious, costly breakdowns. A simple habit—like checking fluids and lubricating grease points every week—helps prevent damage to essential components and keeps machinery running smoothly during the busiest seasons.

2. Seasonal Farm Machinery Preparation

Our farm machinery maintenance routines should adapt as our operational demands fluctuate throughout the year. Seasonal farm machinery preparation ensures our equipment is ready for peak workloads and protected during off-seasons.

Pre-Harvest Preparation

- Thorough Cleaning: We must clean equipment thoroughly before harvest, ensuring all dirt and debris are removed. Built-up debris can become a fire hazard or cause equipment damage, especially around heat-producing components like exhaust systems.

- Component Inspections: It is wise to inspect belts, filters, and hoses, replacing any worn components before they fail at critical times. Preventive maintenance for farm equipment at this stage is key to avoiding costly breakdowns. Explore more

Off-Season Machinery Storage

- Dry, Sheltered Storage: We should store machinery in dry, sheltered locations to protect it from the elements, minimizing rust and weather-related damage.

- Fuel Stabilizers: For longer storage periods, we recommend using fuel stabilizers to prevent fuel degradation and protect engines.

- Pre-Storage Checks: All equipment should be cleaned and checked for damage before it’s put away. This includes removing batteries if appropriate, to prevent electrical issues during long-term storage.

By using Farmonaut’s fleet management tools, we can schedule maintenance reminders and document our storage locations to track all seasonal maintenance and storage activities digitally.

“Proper tire pressure management can extend farm equipment tire life by nearly 30%, lowering replacement costs.”

3. Technological Integration in Machinery Management

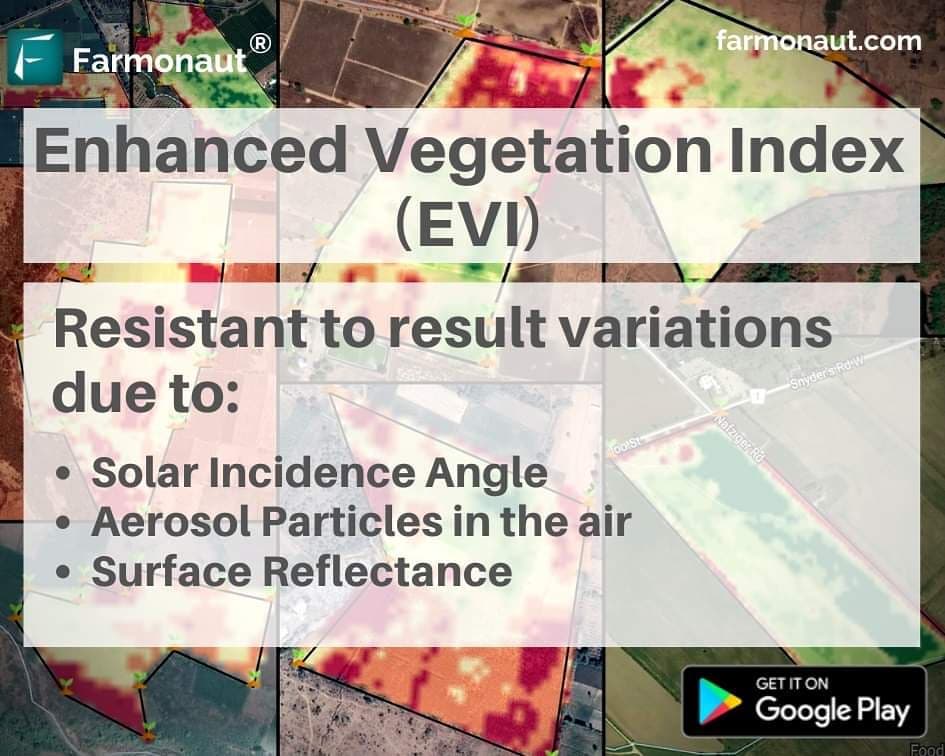

Our approach to agricultural equipment management is transformed by embracing emerging technology. The integration of sensors, telematics, and digital planning tools takes preventive maintenance for farm equipment to the next level.

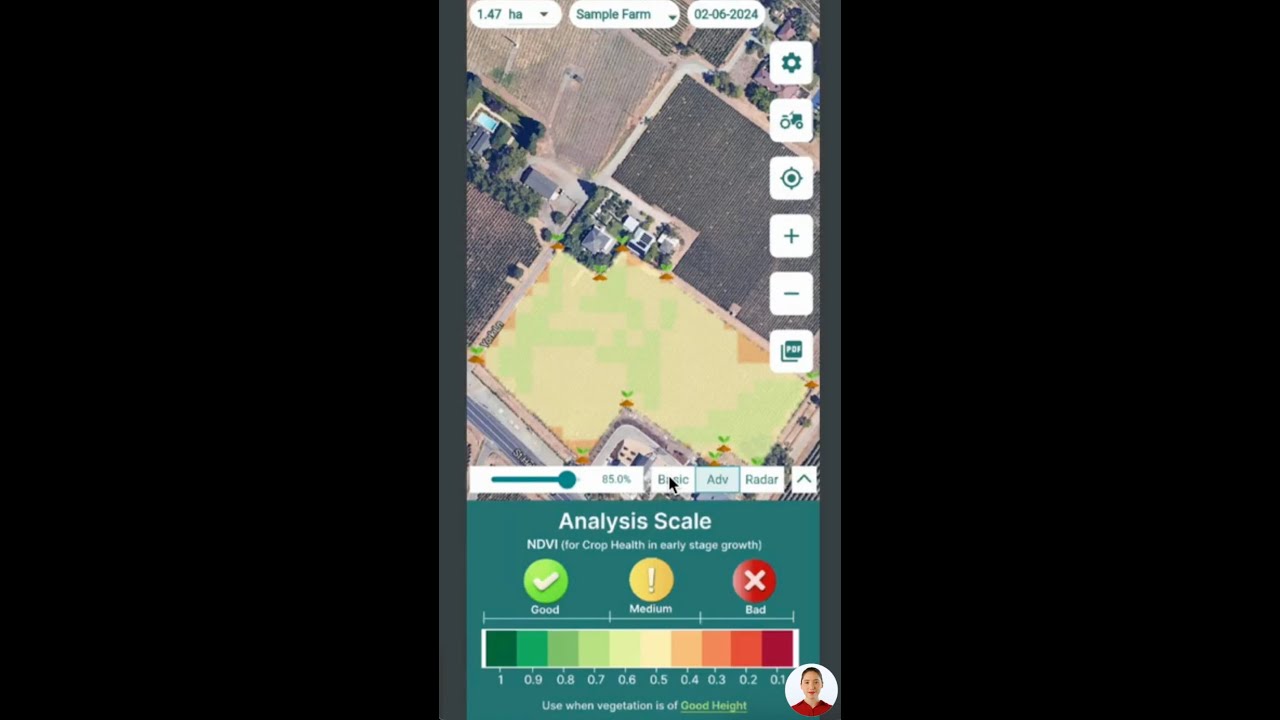

Farmonaut’s platform is a leader in this sphere, offering advanced, satellite-based crop and fleet management tools that bring unprecedented transparency and efficiency.

Telematics and Sensors

- Real-time Monitoring: We equip machinery with IoT-enabled sensors and telematics for real-time performance monitoring. These solutions alert us to maintenance needs and provide instant data on equipment use, location, and operational efficiency (more info).

- Predictive Maintenance: Analyzing data from sensors allows us to spot trends, anomalies, or early warning signs before breakdowns occur. This proactive approach significantly helps prevent damage and unexpected downtime.

Diagnostic Tools

- Advanced Diagnostics: With today’s technology, we can use digital diagnostics to detect issues early—from minor sensor malfunctions to potential engine failures.

- Smart Scheduling: Our Farmonaut fleet management module allows us to schedule and automate routine maintenance tasks, improving coordination between operators and mechanics.

To leverage the power of modern agricultural technology, learn how Farmonaut’s carbon footprinting system helps track emissions and optimize fuel consumption for your machinery fleet.

4. Machinery Operator Training and Documentation

Skilled operators and thorough documentation practices are vital to effective farm machinery maintenance. Machinery operator training not only boosts safety but also reduces avoidable wear and breakdowns.

Operator Training: Safe, Skilled, Prepared

- Comprehensive Training: All operators must receive training to understand the machinery’s functions, limitations, and safety protocols.

- Recognizing Warning Signs: Operators should learn to quickly spot unusual noises, vibrations, warning lights, or operational changes—often early signs of a developing problem.

- Emergency Procedures: Regular practice and reinforcement of emergency protocols lead to prompt, coordinated responses to breakdowns or accidents (more).

Meticulous Maintenance Records

- Document Everything: Maintain clear records of all maintenance services, dates, components replaced, and repairs. This documentation is invaluable for troubleshooting, warranty claims, and year-to-year planning.

- Digital Solutions: Our Farmonaut large scale farm management app tracks equipment usage and maintenance logs across all operations—making audits simple and transparent.

5. Preventive Maintenance for Farm Equipment: Replacement & Spare Parts

Preventive maintenance for farm equipment means not waiting for failure—replace worn or aging parts before they risk causing costly damage. Effective spare parts management ensures repairs are quick and downtime is minimal.

Planned Replacement of Worn Components

-

Critical Part Replacement: We should proactively replace parts like filters, belts, hoses, seals, and bearings as they approach end of life.

Consult the manufacturer’s service schedule and replace at recommended intervals. - Minimize Downtime: Avoid last-minute parts orders; proactive replacement prevents unexpected breakdowns during critical periods like planting or harvest.

Effective Spare Parts Inventory

- Stock Essential Parts: We always keep key spare parts (filters, belts, fuses, fluids) on hand for each equipment type. Quick access means we can reduce farm equipment downtime substantially.

- Inventory System: A digital inventory system, like one tracked in Farmonaut’s resource management tools, prevents under- or over-stocking and drastically improves parts availability.

6. Proper Machinery Cleaning and Storage Practices

A consistent cleaning and storage regimen is vital for maintaining equipment’s value, reliability, and performance over time. Machinery cleaning prevents buildup of abrasive dirt and corrosive residues, while proper machinery storage wards off weather-related damage.

Regular Cleaning—Essential & Easy

- Wash After Each Use: Aim to clean equipment after every operation, focusing on hidden accumulations, undercarriage, and moving parts. Use brushes, air compressors, or power washers as appropriate. See details

- Remove Debris and Dirt: Caked-on dirt, crop residues, and mud can hold moisture, cause corrosion, and accelerate wear.

Best Practices for Machinery Storage

- Indoor Storage: Whenever possible, store equipment indoors in a dry, well-ventilated, sheltered location.

- Weatherproof Covers: If indoor storage isn’t feasible, use fitted, heavy-duty tarps or covers to shield equipment from direct sun, rain, and snow. The goal is to protect valuable machinery year-round.

Make use of Farmonaut crop, plantation, and forest advisory tools for weather alerts and recommendations on best storage timings and practices according to local forecasts.

7. Emergency Preparedness: Stay Ready for the Unexpected

Despite meticulous planning, failures can occur. Being prepared with emergency protocols ensures we can respond quickly, prevent injuries, and get machinery back in operation with minimal delay.

Develop and Communicate Emergency Procedures

- Clear Protocols: Develop concise written procedures for common emergencies—such as hydraulic line failures, engine fires, or tire blowouts.

- Contact and First Aid: Ensure all operators know how to reach emergency mechanical services and access first aid supplies.

- Drill and Train: Regular reviews and practice drills prepare everyone to stay calm and respond effectively.

Leverage Digital Communication

- Centralized Information: Use shared digital platforms, such as Farmonaut’s web and mobile apps, to share locations, contact information, and reference guides across our team.

Maintenance Tip Checklist Table

For practical planning and easy reference, see our Maintenance Tip Checklist Table below. This table is an actionable guide to the best practices for farm machinery and equipment management.

| Tip Number | Maintenance Action | Estimated Time Required (hours) | Estimated Cost Range (USD) | Frequency (per year) |

|---|---|---|---|---|

| 1 | Lubricate moving parts | 0.5–1 | $10–$50 | 12 |

| 2 | Check & inflate tires | 0.5 | $0–$20 | 12+ |

| 3 | Monitor and replace engine oil, hydraulic fluid, and filters | 1–2 | $30–$120 | 4–8 |

| 4 | Inspect batteries and electrical system | 0.5–1 | $0–$75 | 2–4 |

| 5 | Clean machinery after use | 1 | $0–$15 | 10–30 (post-use) |

| 6 | Inspect & replace worn belts, hoses, filters | 1–1.5 | $20–$100 | 2–4 |

| 7 | Store equipment under shelter or protective cover | 0.5–2 | $0–$300 (cover cost) | 2 |

| 8 | Operator training and emergency protocols | 2–6 | $0–$200 | 1–2 |

| 9 | Update maintenance records/logs | 0.25–0.5 | $0 (digital or manual) | 12+ |

| 10 | Review spare parts inventory | 0.5 | $0–$500+ | 4 |

Farmonaut Solutions for Agricultural Equipment Management

As we strive to optimize machinery management and streamline our operations, embracing advanced solutions like those offered by Farmonaut can yield significant benefits:

-

Satellite-Driven Fleet Management:

Use Farmonaut’s fleet tracking and resource management tools to monitor real-time location, performance, and schedules of all agricultural equipment across your farm or plantation. -

Precision Agriculture Integration:

Integrate data from satellite-based crop health monitoring with machinery usage for a holistic picture—maximize yield and minimize unnecessary work or wear. -

Blockchain Traceability:

Use Farmonaut’s blockchain traceability solutions to verify and track the journey of agricultural products, enhancing supply chain transparency and safety. -

Data-Driven Emission Tracking:

Monitor the carbon footprint of your machinery fleet and take actionable steps toward sustainability using Farmonaut’s carbon footprinting module. -

Access to Satellite & Weather API:

For third-party system integration or data enrichment, use Farmonaut’s Agricultural API (Developer Docs) to seamlessly embed farm and equipment monitoring data into your existing solutions.

We are committed to making precision agriculture affordable and accessible to every farmer and agribusiness. Explore flexible subscription options below to start optimizing your machinery management today:

Frequently Asked Questions (FAQ) – Farm Machinery Management

What is the most important rule in farm machinery maintenance?

The most fundamental rule is consistency. Performing routine machinery maintenance at regular, scheduled intervals, as outlined by the manufacturer, prevents unexpected breakdowns and extends equipment lifespan.

How often should I check and change fluids in farm equipment?

We recommend following the manufacturer’s recommended intervals for checking and changing engine oil, hydraulic fluid, and filters. Typically, engine oil and filters should be checked every 50–100 hours of operation or at least every season.

Why is spare parts management so important?

Having the right spare parts on hand minimizes downtime. Proactive spare parts management ensures that in the event of failure, essential repairs can be performed immediately, avoiding operational losses during peak periods.

How can technology improve my farm machinery maintenance?

With telematics, sensors, and data-driven scheduling (as provided by Farmonaut’s Fleet Management), you can monitor machinery health in real-time, receive predictive maintenance alerts, and maintain efficient maintenance records—all leading to cost savings and enhanced performance.

What steps should be taken for off-season farm machinery storage?

- Thoroughly clean equipment to remove all dirt and debris.

- Store machinery in a dry, sheltered location or under a high-quality cover.

- Add fuel stabilizer, disconnect batteries if needed, and lubricate moving parts before storage.

Where can I get more resources and digital support for managing my farm?

Visit the Farmonaut App & Web Platform for advanced digital solutions in precision agriculture, resource management, and satellite-supported crop and equipment monitoring.

Conclusion: Best Practices for Farm Machinery

Farm machinery management is a comprehensive discipline that blends routine maintenance, seasonal preparations, technological integration, operator training, and robust spare parts management. By implementing these best practices for farm machinery, we can ensure efficiency, reduce damage, and extend the operational life of all agricultural equipment.

By utilizing digital farm management tools—like Farmonaut’s Agro Admin App—we can further optimize our workflows, improve sustainability, and prepare for the agricultural challenges of tomorrow.

Remember, maintaining a safe, reliable, and efficient agricultural operation is a team effort. Let’s work together to create a future of smart, sustainable farming.