Revolutionizing Sustainable Packaging: Málaga’s Eco-Friendly Innovation Reducing CO2 Emissions in Manufacturing

“The sustainable packaging market is projected to reach a staggering $800 billion by 2032.”

In the ever-evolving landscape of sustainable packaging solutions, we are witnessing a remarkable transformation that is reshaping the biodegradable packaging industry. As we delve into this exciting realm, we’ll explore how innovative technologies are driving significant reductions in CO2 emissions and environmental impact, particularly in the manufacturing sector. Join us on this journey as we uncover the revolution taking place in Málaga, Spain, and its implications for the global packaging market.

The Evolution of Eco-Friendly Packaging Innovations

To truly appreciate the magnitude of the current innovations, we must first look back at the history of packaging materials. The story begins with polystyrene, a material that has dominated the packaging industry for nearly two centuries.

- Polystyrene’s Legacy: Invented in 1839, polystyrene has been a staple in packaging for decades. However, its environmental impact has become increasingly problematic.

- Environmental Concerns: With a recycling rate of less than 1% and significant contributions to CO2 emissions, polystyrene has fallen out of favor in the push for sustainability.

- Market Shift: The biodegradable packaging market, valued at $473.74 billion in 2023, is projected to surpass $800 billion by 2032, signaling a dramatic shift in consumer and industry preferences.

This shift has paved the way for companies like Tetra Pak, which has shown remarkable leadership in climate impact reduction within the food packaging industry. Their success in reducing climate impact while maintaining growth in package sales demonstrates the viability and necessity of sustainable alternatives.

Málaga’s Eco-Friendly Revolution: S.Lab’s Innovative Approach

At the forefront of this packaging revolution is S.Lab, a Ukrainian startup that has found a new home in Málaga, Spain. Their relocation to this region is no coincidence; it’s a strategic move that capitalizes on Málaga’s commitment to sustainability and its abundant agricultural resources.

Julia Bialetska, CEO and co-founder of S.Lab, articulates a vision that resonates with the growing demand for sustainable packaging solutions:

“Our goal is to create scalable biodegradable packaging that doesn’t compromise on functionality or environmental safety. We’re not just replacing plastic; we’re reimagining packaging from the ground up.”

Mycelium: Nature’s Answer to Packaging

S.Lab’s innovative process centers around the use of mycelium—the root structure of mushrooms—combined with agricultural waste. This approach represents a return to nature-inspired manufacturing, offering a sustainable alternative to traditional packaging materials.

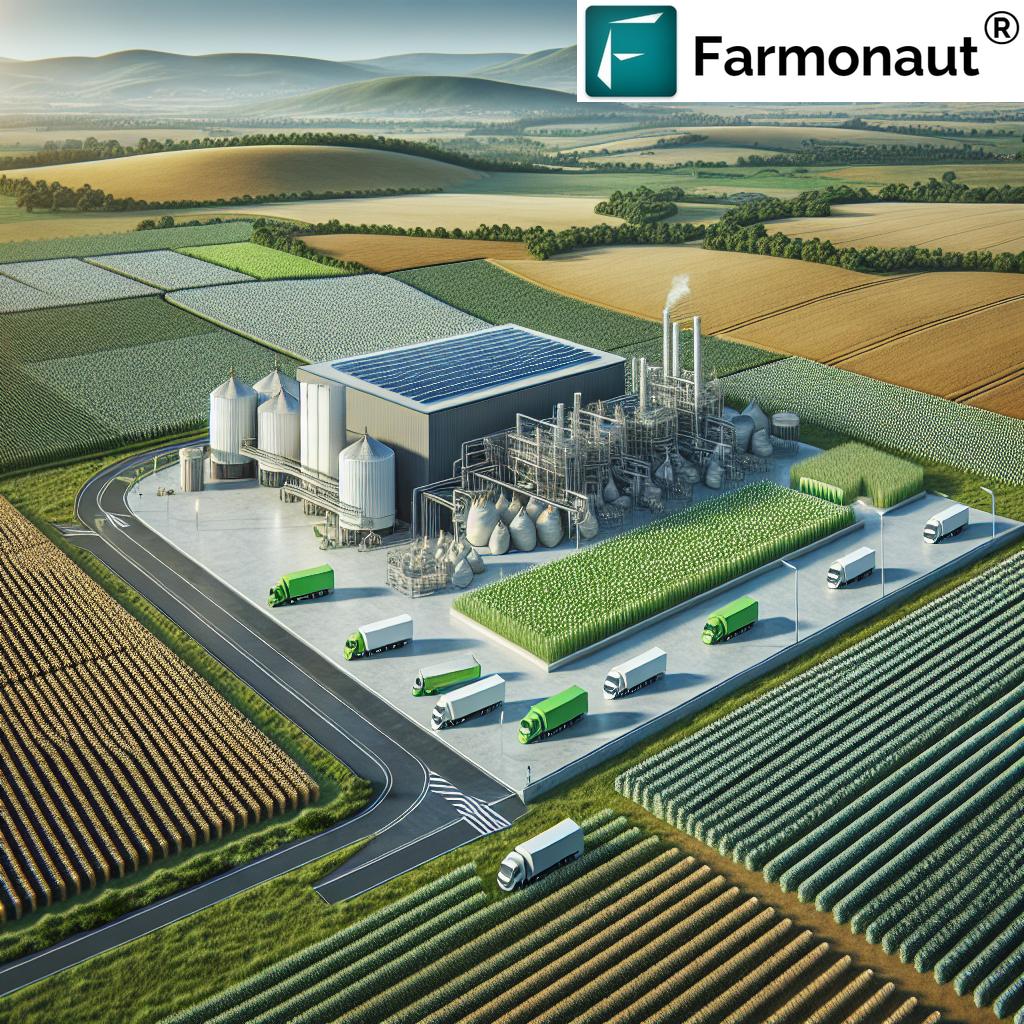

- Agricultural Waste Recycling: Utilizing hemp and linen waste from local farms, S.Lab transforms what would be discarded into valuable packaging material.

- Biodegradable Solution: The resulting packaging biodegrades within 30 days, drastically reducing environmental impact compared to traditional plastics.

- Scalability Challenge: Bialetska emphasizes the company’s focus on developing this process for large-scale production, a key factor in making sustainable packaging viable for widespread adoption.

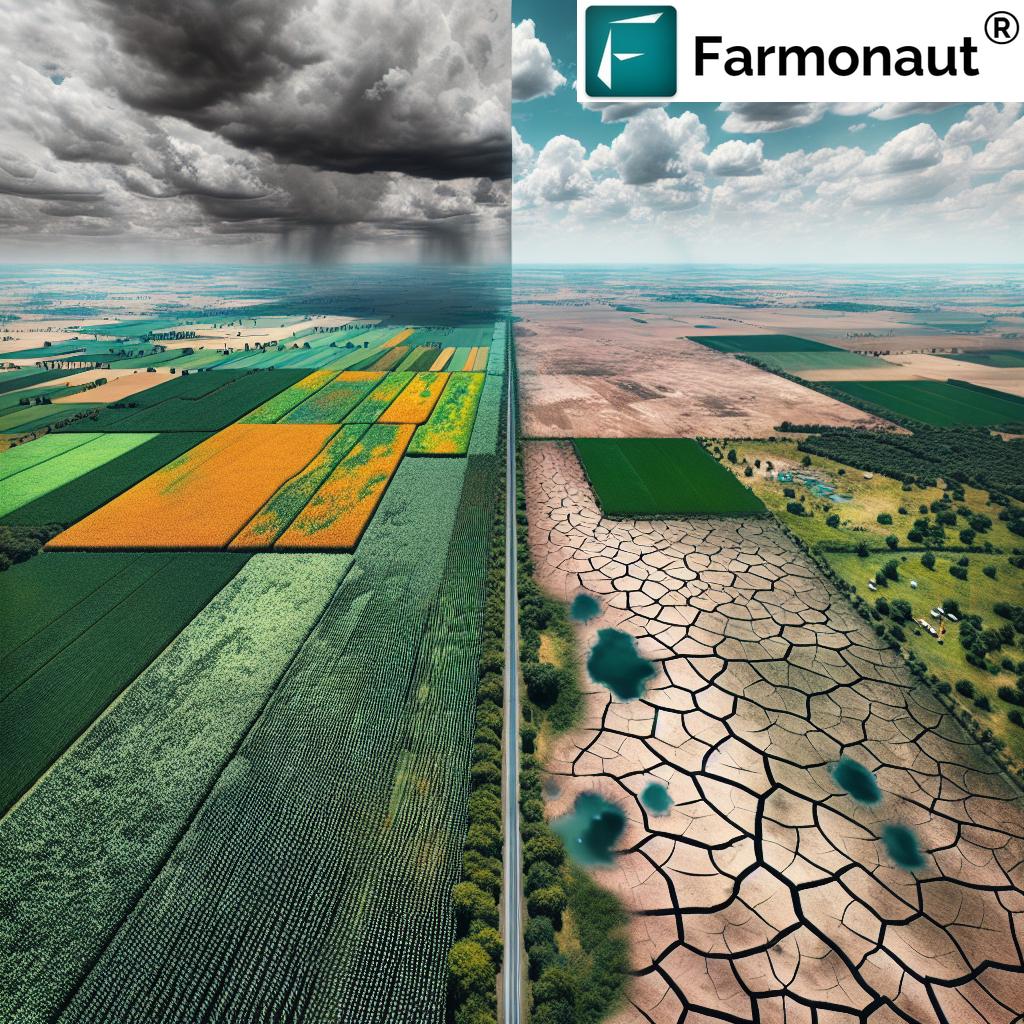

As we consider the potential of mycelium-based packaging, it’s worth noting how technologies like those developed by Farmonaut could complement these sustainable initiatives. Farmonaut’s satellite-based farm management solutions could provide valuable data on agricultural waste availability, helping to optimize the supply chain for eco-friendly packaging production.

Automated Packaging Production: Scaling Up Sustainability

“Málaga’s eco-friendly packaging innovation significantly reduces CO2 emissions in manufacturing processes.”

S.Lab’s commitment to innovation extends beyond material science to the production process itself. In 2024, they launched a fully automated production line capable of producing up to 30,000 units monthly. This achievement marks a significant milestone in the journey towards scalable, sustainable packaging solutions.

Key Features of S.Lab’s Automated Production:

- Efficiency: The automated line ensures precision and consistency in packaging production.

- Reduced Environmental Impact: Compared to conventional polystyrene production, S.Lab’s process reduces CO2 emissions and water usage by up to 90%.

- Integration: The system is designed to seamlessly integrate into existing manufacturing processes, making adoption easier for companies looking to transition to sustainable packaging.

This level of automation and efficiency in sustainable packaging production aligns well with the principles of precision agriculture promoted by companies like Farmonaut. Just as Farmonaut uses advanced technology to optimize farming practices, S.Lab is applying cutting-edge automation to revolutionize packaging manufacturing.

Explore Farmonaut’s API for agricultural insights

The Market Potential of Sustainable Packaging Solutions

The growing market for sustainable packaging solutions is a testament to the changing priorities of consumers and businesses alike. With projections indicating a market value of $800 billion by 2032, it’s clear that eco-friendly packaging is not just a trend but a fundamental shift in the industry.

| Packaging Type | Material Source | CO2 Emissions Reduction (Estimated) | Market Potential (Estimated) |

|---|---|---|---|

| Traditional Polystyrene | Petroleum-based | Baseline | Declining |

| Mycelium-based Packaging | Fungal growth + Agricultural waste | 70% | High growth potential |

| Agricultural Waste Recycling | Crop residues | 50% | Moderate growth |

| Hemp/Linen Waste Utilization | Industrial hemp and linen byproducts | 60% | Rapid growth expected |

This table illustrates the significant advantages of newer sustainable packaging solutions over traditional materials like polystyrene. The estimated CO2 emissions reductions and market potential highlight why companies are increasingly investing in these innovative technologies.

Local Initiatives and Government Support

The success of companies like S.Lab in Málaga is not isolated. It’s part of a broader movement supported by local initiatives and government policies aimed at fostering green innovation. Spain, and particularly the Andalusia region, has been proactive in supporting sustainable industries.

- Government Incentives: Tax breaks and grants for companies developing eco-friendly technologies.

- Research Collaboration: Partnerships between universities and private companies to advance sustainable packaging research.

- Circular Economy Initiatives: Local programs promoting the use of agricultural waste in various industries, including packaging.

These supportive measures create an ecosystem where innovations in sustainable packaging can thrive, attracting more companies and talent to the region.

The Role of Technology in Sustainable Food Packaging

While S.Lab focuses on general packaging solutions, the food industry presents unique challenges and opportunities for sustainable packaging. Advancements in sterilization and manufacturing processes are paving the way for eco-friendly food packaging that meets strict safety and preservation standards.

Key Technological Advancements:

- Biodegradable Barrier Coatings: New coatings that provide the same protective properties as plastic but are fully biodegradable.

- Smart Packaging: Incorporating sensors to monitor food freshness and reduce waste.

- Energy-Efficient Sterilization: Developing methods that ensure food safety while minimizing energy consumption in the packaging process.

These advancements in sustainable food packaging technology complement the broader efforts in the packaging industry, creating a more comprehensive approach to sustainability across various sectors.

Check out Farmonaut’s API Developer Docs for agricultural insights

The Future of Packaging: Reshaping Logistics and Consumer Behavior

As we look to the future, it’s clear that sustainable packaging solutions will have far-reaching effects beyond just reducing environmental impact. They are set to reshape logistics and consumer behavior in profound ways.

Impacts on Logistics:

- Lighter Materials: Reducing transportation costs and emissions.

- Compact Design: Optimizing storage and shipping space.

- Local Production: Shortening supply chains with on-site packaging manufacturing.

Changes in Consumer Behavior:

- Increased Awareness: Consumers becoming more conscious of packaging materials and their environmental impact.

- Preference for Sustainable Brands: Growing market share for companies using eco-friendly packaging.

- Circular Economy Participation: Consumers more likely to engage in recycling and composting practices.

These changes align well with the growing trend of sustainable agriculture practices supported by technologies like those offered by Farmonaut. As consumers become more environmentally conscious, they’re likely to seek out products that are sustainable from farm to packaging.

Challenges and Opportunities in Scaling Sustainable Packaging

While the potential of sustainable packaging solutions is immense, scaling these innovations presents both challenges and opportunities.

Challenges:

- Cost Competitiveness: Initially higher production costs compared to traditional packaging.

- Performance Consistency: Ensuring biodegradable materials meet the same standards as conventional packaging across various applications.

- Infrastructure Adaptation: Modifying existing manufacturing and distribution systems to accommodate new materials.

Opportunities:

- Technological Innovation: Continuous improvement in material science and production processes.

- Market Differentiation: Companies adopting sustainable packaging can stand out in a crowded market.

- Regulatory Compliance: Getting ahead of potential future regulations on packaging materials.

Addressing these challenges and capitalizing on the opportunities will be crucial for the widespread adoption of sustainable packaging solutions. Companies that can navigate these waters effectively will be well-positioned to lead in the evolving packaging industry.

The Role of Consumer Education in Sustainable Packaging Adoption

As we progress towards a more sustainable future in packaging, consumer education plays a pivotal role. Informed consumers are more likely to support and drive the adoption of eco-friendly packaging solutions.

Key Areas of Consumer Education:

- Material Understanding: Educating consumers about different sustainable materials and their benefits.

- Disposal Practices: Teaching proper disposal methods for various types of biodegradable packaging.

- Environmental Impact: Raising awareness about the long-term effects of packaging choices on the environment.

By fostering a more informed consumer base, we can create a market-driven demand for sustainable packaging solutions, further accelerating their development and adoption.

Conclusion: A Sustainable Future in Packaging

The innovations emerging from Málaga, spearheaded by companies like S.Lab, represent a significant leap forward in sustainable packaging solutions. By leveraging nature-inspired materials like mycelium and agricultural waste, and employing advanced manufacturing techniques, these innovations are setting new standards for eco-friendly packaging.

As we look to the future, it’s clear that the packaging industry is on the cusp of a green revolution. With projections pointing to an $800 billion market by 2032, sustainable packaging is not just an environmental imperative but a major economic opportunity. The success of these initiatives will depend on continued technological innovation, supportive government policies, and growing consumer awareness.

In this evolving landscape, the synergy between sustainable packaging and other eco-friendly initiatives, such as precision agriculture supported by companies like Farmonaut, will be crucial. As we move towards a more sustainable future, these interconnected innovations will play a vital role in reducing our environmental footprint across multiple industries.

The journey towards fully sustainable packaging is ongoing, but the progress made in places like Málaga offers a glimpse of a future where packaging not only protects products but also preserves our planet. It’s a future we can all look forward to and contribute to, one package at a time.

FAQs

- What makes mycelium-based packaging sustainable?

Mycelium-based packaging is sustainable because it uses natural, biodegradable materials that break down quickly without harming the environment. It also utilizes agricultural waste, reducing overall waste and carbon footprint. - How does S.Lab’s packaging compare to traditional polystyrene in terms of CO2 emissions?

S.Lab’s packaging production process reduces CO2 emissions by up to 90% compared to conventional polystyrene production methods. - Can sustainable packaging materials match the performance of traditional plastics?

Many sustainable packaging materials are being developed to match or exceed the performance of traditional plastics in terms of durability, protection, and shelf life. - What role does government support play in the development of sustainable packaging?

Government support through incentives, grants, and supportive policies plays a crucial role in fostering innovation and adoption of sustainable packaging solutions. - How can consumers contribute to the adoption of sustainable packaging?

Consumers can contribute by choosing products with eco-friendly packaging, properly disposing of or recycling packaging materials, and supporting brands that prioritize sustainability.