Fertilizer Plant Explosion in West, TX: 7 Key Emergency Lessons

Table of Contents

- Introduction

- Context: The West, TX Fertilizer Plant Explosion 2013

- Tragedy Unfolds: Blast and Immediate Aftermath

- Comparative Incident Analysis Table: Ammonium Nitrate Disasters

- 7 Key Emergency Lessons from the West, TX Fertilizer Plant Explosion

- Lesson 1: Understanding the Danger of Ammonium Nitrate

- Lesson 2: First Responders’ Safety During Plant Explosions

- Lesson 3: Evacuation Procedures in Industrial Disasters

- Lesson 4: Search and Rescue Functions Post-Explosion

- Lesson 5: Community Emergency Mitigation and Preparedness

- Lesson 6: Fire Mitigation After Explosions

- Lesson 7: Building Back Better and Elevating Industrial Safety

- Farmonaut’s Role in Modern Emergency & Safety Monitoring

- Frequently Asked Questions (FAQ)

- Conclusion

Introduction

On April 17, 2013, the small city of West, TX was changed forever. That evening, an unexpected fire at the West Fertilizer Company escalated into a catastrophic fertilizer plant explosion. In just seconds, an ammonium nitrate blast with the force of 7.5 to 10 tons of TNT obliterated much of the northern part of the town, caused seismic stations to register what felt like a 2.1-magnitude earthquake, and tragically killed 15 people, including first responders, leaving over 260 people injured.

This modern industrial disaster remains a stark lesson. It compels us to rethink emergency preparedness, industrial safety, and our collective approach to high-risk chemical facilities. Fertilizer plant explosions have shaped regulatory and operational trends globally, and the West, Texas explosion 2013 stands as a pivotal case study.

In this exhaustive analysis, we explore exactly what happened in West, TX: the night of the blast, the valiant role and tragic loss suffered by first responders, how evacuation and rescue unfolded, and, ultimately, the 7 emergency lessons every industry, emergency planner, and municipal leader must internalize from this disaster. We further examine how advanced technologies like Farmonaut’s satellite crop and asset monitoring now support safer, more responsive industrial and agricultural operations.

Context: The West, TX Fertilizer Plant Explosion 2013

West, Texas is a close-knit rural community, home to less than 3,000 residents in 2013. Agriculture plays a central role in daily life, and facilities handling bulk fertilizer chemicals—like the West Fertilizer Company—are a vital part of the region’s infrastructure. Ammonium nitrate, while essential as a fertilizer, is also a powerful oxidizer, presenting the risk of rapid ignition and catastrophic explosion under the wrong circumstances.

On the evening of April 17th, a fire was reported inside the fertilizer plant’s storage structure. The plant at the time housed more than 30 tons of ammonium nitrate. As local fire departments responded, few realized the scale of latent danger. Within minutes, the heat from the fire set off a rapid, overwhelming chemical reaction: 30 tons of ammonium nitrate ignited in a single, devastating ammonium nitrate blast.

Explosion Details at a Glance

- Date: April 17, 2013

- Location: West, McLennan County, TX, USA

- Chemical Involved: Ammonium Nitrate (30 tons estimated)

- Force: 7.5–10 tons TNT equivalent

- Damage Radius: Several city blocks, with effects felt kilometers away

- Seismic Stations: Registered a 2.1-magnitude earthquake

- Casualties: 15 killed (includes first responders), over 260 injured

- Structures: Over 150 buildings damaged or destroyed

Tragedy Unfolds: Blast and Immediate Aftermath

The explosion struck approximately 20 minutes after first responders arrived to try to mitigate the plant fire. Many of the first fire crew found themselves directly in the blast radius. Former mayor Tommy Muska described witnessing the smoke, moving toward the plant, and then being rocked by the devastating explosion from only a block away:

“My experience was I saw the smoke and I went to the school and I started towards the fertilizer plant on foot and I got about halfway, about a block and a half away, and that’s when it blew up, and so it was a devastating, devastating memory.” – Tommy Muska, Former Mayor of West

The explosion left a massive crater, instantly flattened nearby structures, and sent debris raining down on adjacent buildings and homes. Across West, windows shattered, roofs caved in, and entire streets became nearly unrecognizable. The tragedy impacted virtually every member of the community, and the loss of first responders in the initial blast intensified the local grief.

Thousands were forced to evacuate, hospitals across Texas activated mass casualty protocols, and over 400 emergency crews from across the state joined local teams for the days-long search and rescue operations.

Comparative Incident Analysis Table: Ammonium Nitrate Disasters

| Incident Location | Year | Estimated Amount of Ammonium Nitrate Involved (tons) | Estimated Casualties (Deaths / Injuries) | Immediate Response Measures Taken | Evacuation Radius (km) | Lessons Learned |

|---|---|---|---|---|---|---|

| West, TX, USA | 2013 | ~30 | 15 / 260+ |

– Local/state search, rescue, fire mitigation – Multi-agency coordination – Town evacuation |

1.5 km (est.) |

– Need for chemical hazard awareness – First responder risk training – Improved community evacuation plans |

| Tianjin, China | 2015 | ~800 | 173 / 700+ |

– Large-scale military/civil response – Hospital mobilization – Extended zone evacuation |

2+ km |

– Chemical zoning laws – Emergency communications upgrades – Hazardous materials registry enforcement |

| Beirut, Lebanon | 2020 | ~2,750 | 200+ / 6,500+ |

– National/international aid – Port and city evacuation – Mass medical response |

Up to 8-10 km |

– Strict regulation/storage – Transparent reporting – National hazard mapping |

7 Key Emergency Lessons from the West, TX Fertilizer Plant Explosion

The West Texas explosion 2013 was not the first ammonium nitrate disaster, and it will not be the last unless we thoroughly absorb the hard-won lessons of that night. Let’s analyze the 7 essential emergency and safety takeaways that all hazardous industries, rural towns, regulators, and emergency services must heed:

Lesson 1: Understanding the Danger of Ammonium Nitrate

- Ammonium nitrate, when properly managed, remains invaluable as a fertilizer. But under fire or contamination, its potential to ignite and cause catastrophic blasts is extreme. The force released in West, TX equated to a small wartime bomb, and similar explosions have decimated entire port districts globally.

- Key Takeaway: Industry and emergency personnel must undergo regular training on chemical dynamics, the signs of impending chemical instability, and the correct response (including “downwind” evacuation zones and the warning signs before a blast).

- Policy Implication: AVV (Ammonium Nitrate Vulnerability and Volume) thresholds should drive local permitting, response protocols, and zoning regulations across the US and globally.

- For agricultural businesses managing fertilizer inventories, integrating real-time monitoring solutions can ensure early detection of high temperature, leaks, or risk of ignition. Innovative solutions like satellite-based environmental monitoring—such as Farmonaut offers for crop and land use—can provide similar advantages for industrial sites, alerting stakeholders before a disaster strikes.

Lesson 2: First Responders’ Safety During Plant Explosions

- The first responders in West, TX paid the ultimate price, as most casualties were among the initial fire crews on scene who did not anticipate the imminent enormity of the explosion.

- First responders explosion protocols now mandate detailed hazardous inventory documentation and remote consultation with chemical experts before direct fire mitigation inside a potentially unstable site.

- State and federal agencies have strengthened first responder training, emphasizing the unique risks of ammonium nitrate and other hazardous agricultural chemicals.

- Farmonaut Advisory: For agricultural and industrial sites, a comprehensive digital record of inventory, historical site usage, and environmental metrics is essential. Cloud-based asset management and fleet management solutions can help coordinate safer, real-time responder deployment in remote rural areas.

Lesson 3: Evacuation Procedures in Industrial Disasters

- Evacuation procedures during plant fire in West, TX relied on first responders’ quick decision-making amid uncertainty—highlighting the need for regular, community-wide evacuation drills specifically tailored to likely industrial hazards.

-

Lessons:

- Establish pre-determined evacuation zones and communication plans for neighborhoods near any chemical facility.

- Incorporate mobile alerts, community sirens, and social media channels into evacuation protocols.

- Provide first responders and local authorities with digital mapping tools and rapid deployment checklists.

- Modern platforms, such as those powered by real-time satellite data, can help track population dynamics and resource allocation during emergencies—reducing risks of anyone being left behind in rapidly evolving situations.

Lesson 4: Search and Rescue Functions Post-Explosion

- Critical search and rescue after disasters began within minutes of the blast. Emergency teams from across the state navigated collapsed buildings, fires, and hazardous chemical debris. Every building had to be combed for trapped or injured residents.

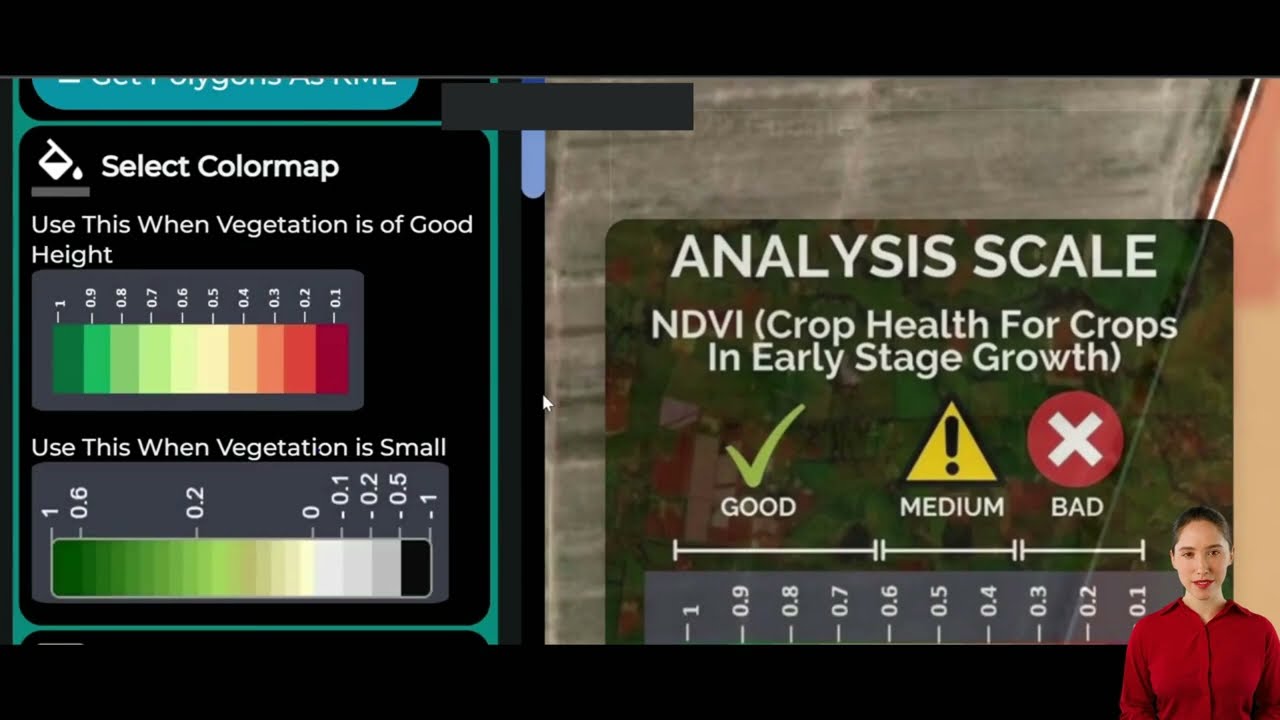

- Advanced safety mapping, drone or satellite imagery (like the NDVI crop health maps Farmonaut provides for large-scale agriculture), and shared digital blueprints can dramatically improve the speed, safety, and accuracy of post-blast search and rescue.

- Key Requirement: Cities and emergency planners must build robust, digital inventories and continuously updated building maps for all high-risk zones, with backups accessible offsite in crisis situations.

Lesson 5: Community Emergency Mitigation and Preparedness

- In West, immediate community mobilization—volunteers, churches, schools—was crucial in sheltering and feeding evacuees. But initial chaos illuminated gaps in readiness, inter-agency communication, and resource reallocation.

-

Best Practices:

- Local governments must maintain up-to-date emergency plans with regular audits and public training.

- Technology solutions (including blockchain-based traceability platforms) can assist in tracking everything from facility inventories to aid supply chains, improving transparency even during large disasters.

- Partner with agricultural technology providers to maintain actionable data on farms, chemicals, and infrastructure, leveraging multi-source information for wide-area preparedness.

Lesson 6: Fire Mitigation After Explosions

- Three distinct fires were actively burning in West, TX after the main explosion, further complicating search and rescue and hazard control. Firefighters had to adapt on the fly, redirecting resources and requesting state-wide mutual aid.

- Fire mitigation after explosions depends heavily on near-real-time situational awareness. Remote surveillance, infrared mapping (from drone, satellite, or elevated cameras), and rapid resource allocation build a smarter emergency response.

-

For Agribusiness:

Carbon footprinting and environmental monitoring tools are now essential components of responsible facility management. Monitoring environmental changes through space and ground sensors ensures earlier detection, safer emergency responses, and aids subsequent investigation.

Lesson 7: Building Back Better and Elevating Industrial Safety

- The recovery of West, TX became a model for resilience, but highlighted harsh truths: insurance gaps, absent documentation, and outdated safety protocols can prolong suffering and hinder rebuilding.

- To truly “build back better,” communities and companies must automate compliance tracking, share safety best practices, and deploy digital infrastructure to monitor critical assets year-round.

- Facilities with digital environmental and traceability audit trails (for example, blockchain-based traceability solutions) are less likely to overlook hazardous trends and more likely to recover efficiently post-disaster.

Farmonaut’s Role in Modern Emergency & Safety Monitoring

Advanced disaster response and site safety now demand not just readiness but precision. Technologies like those developed by Farmonaut enable a new paradigm—continuous, affordable, satellite-based monitoring for crops, environmental health, and large installations.

Key Technologies and Value Proposition:

- Satellite-Based Environmental Monitoring: Through multispectral satellites, Farmonaut can detect abnormal vegetation health, soil moisture changes, and potential patterns risky for both agricultural yield and chemical storage stability.

- AI Advisory Systems: Farmonaut’s Jeevn AI system delivers expert recommendations and early warnings for resource management, fire risk, and site conditions—helpful features whether you’re managing fields or hazardous storage yards.

- Blockchain Traceability: Facility managers can employ blockchain-based audit chains to document every input, transfer, and inspection, ensuring compliance is always visible and transparent.

- Fleet & Resource Management: Using efficient resource tracking tools, managers ensure all vehicles and machinery are accounted for and deployed optimally, critical in large-scale evacuation or response scenarios.

- Carbon Footprinting: Track emissions, chemical use, and environmental impact with Farmonaut’s sustainability suite. This data assists in compliance and proactively addressing regulatory mandates.

- API Integration: Bring real-time Farmonaut data and recommendations into custom emergency dashboards via the Farmonaut Satellite & Weather API and developer documentation at API developer docs.

Farmonaut democratizes precision agriculture and industrial safety by making high-tech monitoring accessible via Android, iOS, and web apps. Our aim is clear: empower users across the globe to anticipate risks before disaster strikes and recover more quickly should worst-case scenarios occur.

Farmonaut Subscriptions & Solutions: Affordable, Scalable, Transparent

Sign up for Farmonaut for easy, flexible access to advanced satellite monitoring, carbon tracking, advisory services, supply chain traceability, and more. Choose your plan below:

Frequently Asked Questions (FAQ)

-

What caused the fertilizer plant explosion in West, TX in 2013?

The explosion was triggered by a fire that ignited approximately 30 tons of ammonium nitrate stored at the West Fertilizer Company. The rapid reaction produced a blast equivalent to 7.5–10 tons of TNT. -

How many people died or were injured in the West, TX blast?

15 people died—including several first responders—and over 260 residents were injured. -

What seismic effects did the blast have?

Seismic monitoring stations registered a 2.1-magnitude earthquake as a result of the explosion. -

What emergency response challenges were revealed?

The tragedy exposed gaps in hazardous material awareness, first responder training, community evacuation plans, incident mapping, and fire mitigation strategies. -

How does Farmonaut improve safety and mitigation?

Farmonaut’s satellite and AI-driven technologies empower users to monitor environmental health, receive real-time alerts, and maintain transparent records for compliance and insurance—all critical for preventing and recovering from disaster. -

Is Farmonaut only for large companies?

No. Farmonaut’s scalable platform serves individuals, cooperatives, agribusinesses, and governments. It is practical and affordable even for small and medium operations.

Conclusion

The events of April 17, 2013, in West, TX, remain a pivotal chapter in the history of American industrial safety. The fertilizer plant explosion was catastrophic: a massive ammonium nitrate blast that echoed in seismic stations like an earthquake, leveled entire buildings and caused modern America’s worst loss of first responders to a chemical disaster. Our collective duty is to learn and evolve: industry, emergency personnel, municipal leaders, and technology partners.

Adoption of advanced monitoring, immediate data-driven response, comprehensive training, and digital traceability systems is not just best practice—it’s a moral imperative. We at Farmonaut are dedicated to supporting this new era of emergency preparedness and precision agriculture. By leveraging satellite imagery, AI-based advisory, route optimization, fleet management, and traceability technologies, we can help navigate, mitigate, and recover from crises—making towns and companies safer, more resilient, and future-ready.

Finally, if you’re responsible for the safety of a farm, facility, or community, act now: update your emergency plans, digitize your operations, and leverage world-class tools—because the next blast can be prevented.