Sustainable Forestry Revolution: Inside Jamestown’s Innovative Biomass Plant Transforming Forest Waste into Green Energy

“Jamestown’s biomass plant processes 30,000 tons of forest waste annually, creating valuable wood products and biochar.”

In the heart of Tuolumne County, California, a groundbreaking biomass plant is revolutionizing the way we approach sustainable forestry and renewable energy production. Since October, this innovative facility in Jamestown, CA has been transforming forest waste into valuable wood products, contributing significantly to forest fire prevention and eco-friendly wood processing. As we delve into the intricacies of this $14-million project, we’ll explore how it’s shaping the future of biomass to bioenergy conversion and supporting community development in the region.

The Genesis of Jamestown’s Biomass Plant

Located on O’Byrnes Ferry Road near the Sierra Conservation Center, the Tuolumne Biomass plant leases 17 acres from T-5 Ranches. This strategic location, surrounded by a solar farm and cattle grazing land, exemplifies the harmonious integration of sustainable energy practices with traditional land use.

Tuolumne Biomass, owned by Heartwood Biomass, has expanded its operations from its original base in Wallowa County, Oregon, to this new location in Tuolumne County. With 25 team members at the Oregon facility and 10 at the new Jamestown plant, the company is making significant strides in the biomass industry.

Innovative Technology and Processes

The Jamestown biomass plant utilizes cutting-edge technology to process forest waste efficiently. Here’s how the facility operates:

- Biomass Collection: The plant works closely with local loggers to remove biomass from forest floors. This includes smaller logs and other woody materials that larger wood products companies typically don’t utilize.

- Processing Capacity: The facility can process about 30,000 tons of biomass annually, a significant amount that contributes to forest resiliency and reduces the size of brush piles.

- Product Creation: The plant transforms forest waste into various valuable products, including:

- Bundled firewood

- Peeled agricultural poles

- Wood straw

- Biochar

- Wood chips

- Combined Heat and Power System: The plant incorporates an efficient combined heat and power system, enhancing its energy production capabilities.

This innovative approach not only helps in forest restoration but also creates a range of products that serve various industries and consumer needs.

Environmental Impact and Sustainability

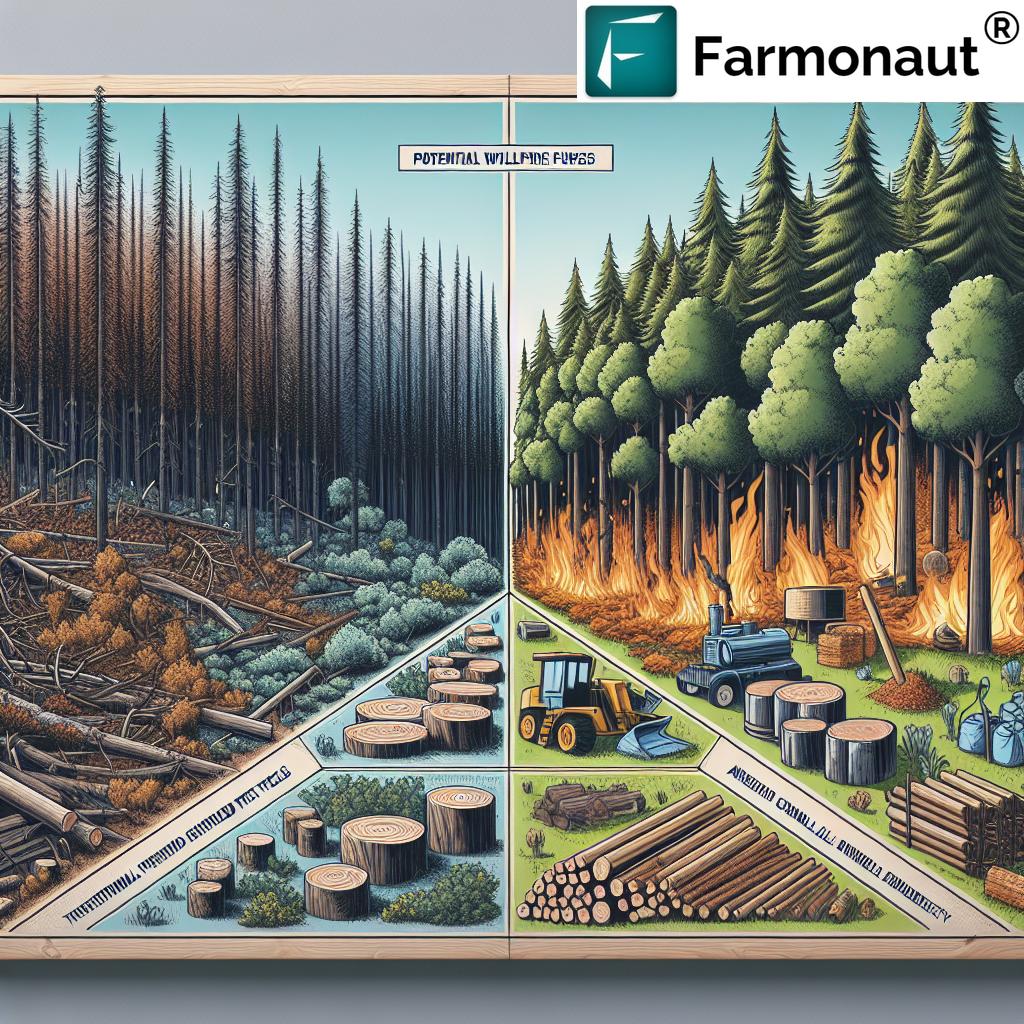

The Jamestown biomass plant is at the forefront of sustainable forestry practices and renewable energy production. Here’s how it’s making a positive impact:

- Forest Fire Prevention: By removing excess biomass from forest floors, the plant significantly reduces the risk of catastrophic wildfires.

- Eco-Friendly Wood Processing: The facility’s methods ensure that even small woody materials are put to good use, minimizing waste.

- Carbon Footprint Reduction: By converting forest waste into usable products, the plant helps sequester carbon and reduce greenhouse gas emissions.

- Promotion of Forest Resiliency: The removal of excess biomass promotes healthier forest growth and biodiversity.

Economic Benefits and Job Creation

The Jamestown biomass plant is not just an environmental success story; it’s also a significant contributor to the local economy:

- Green Jobs: The facility has created new employment opportunities in the forestry industry, with 10 team members currently working at the Jamestown location.

- Local Business Support: Products like firewood are being sold at local supermarkets, gas stations, and regional parks, boosting the local economy.

- Economic Development: The plant’s operations contribute to the overall economic growth of Tuolumne County, creating a ripple effect across various sectors.

“The $14-million Jamestown biomass facility contributes to California’s forest restoration efforts while generating green jobs in the forestry industry.”

Funding and Partnerships

The realization of this ambitious project was made possible through a combination of grants, loans, and private equity:

- $4.2 million grant from the HUD National Resilience Program

- $3.5 million grant from the same HUD program

- $2-million HUD Residual Receipts Loan

- $2 million CAL Fire Workforce Development Grant

- $800,000 US Forest Service Community Wood Grant

- $600,000 RCAC/EDA Revolving Small Business Loan

- $1.5 million in private equity

These funds have been crucial in establishing the plant and ensuring its successful operation.

Community Involvement and Workforce Development

The Jamestown biomass plant project has been a collaborative effort involving various community organizations:

- Mother Lode Job Training (MLJT): MLJT has been actively involved in workforce development and compliance documentation throughout the project.

- Central Sierra Economic Development District: This organization has played a crucial role in supporting the economic aspects of the project.

- Rural Community Assistance Corporation (RCAC): RCAC has overseen compliance documentation for Section 3 and Public Benefit requirements.

These partnerships have ensured that the project not only meets environmental goals but also contributes to community development and workforce training.

Impact on Forest Management and Restoration

The Jamestown biomass plant is playing a pivotal role in California’s forest restoration efforts:

- Sustainable Forest Management: By utilizing forest waste, the plant promotes more sustainable forestry practices.

- Wildfire Prevention: Removal of excess biomass significantly reduces the risk of devastating wildfires.

- Ecosystem Health: The plant’s operations contribute to overall forest health and biodiversity.

Explore Farmonaut’s API for advanced agricultural insights

Innovative Products and Their Applications

The Jamestown biomass plant produces a variety of products from forest waste:

- Bundled Firewood: Sold in local supermarkets and gas stations, providing a sustainable heating option for homes and campsites.

- Agricultural Poles: Used in various agricultural applications, supporting local farming practices.

- Wood Straw: An eco-friendly alternative to traditional straw, used for erosion control and landscaping.

- Biochar: A valuable soil amendment that improves soil health and sequesters carbon.

- Wood Chips: Used in landscaping, mulching, and as a renewable energy source.

These products demonstrate the versatility of biomass utilization and its potential to create value from what was once considered waste.

Technology and Innovation in Biomass Processing

The Jamestown plant incorporates several innovative technologies:

- Advanced Sorting Systems: To efficiently separate different types of biomass.

- Precision Cutting Equipment: For creating uniform wood products.

- Biochar Production Units: Specialized equipment for converting woody biomass into biochar.

- Combined Heat and Power System: Maximizing energy efficiency in the plant’s operations.

These technologies ensure that the plant operates at peak efficiency, maximizing the value extracted from forest waste.

Environmental Monitoring and Compliance

The Jamestown biomass plant operates under strict environmental guidelines:

- Air Quality Monitoring: Regular checks to ensure emissions are within acceptable limits.

- Water Conservation Practices: Implementing systems to minimize water usage and prevent pollution.

- Sustainable Sourcing: Ensuring that biomass is collected in an environmentally responsible manner.

- Regular Audits: Conducting frequent environmental impact assessments to maintain high standards of operation.

These measures ensure that the plant’s operations align with California’s stringent environmental regulations.

Access Farmonaut’s API Developer Docs for integration guidelines

Future Prospects and Expansion Plans

The success of the Jamestown biomass plant opens up exciting possibilities for the future:

- Potential Expansion: Plans to increase processing capacity and product range.

- Research and Development: Ongoing efforts to discover new applications for biomass products.

- Collaboration Opportunities: Potential partnerships with other industries to broaden the impact of biomass utilization.

- Educational Initiatives: Programs to educate the public and industry professionals about sustainable forestry practices.

These future prospects highlight the plant’s potential to continue driving innovation in sustainable forestry and renewable energy.

Comparative Analysis: Before and After Plant Implementation

| Metrics | Before Plant | After Plant Implementation |

|---|---|---|

| Annual forest waste processed (tons) | 0 | 30,000 |

| Wildfire risk reduction (%) | 0% | Estimated 20-30% |

| Green jobs created | 0 | 10+ |

| Renewable energy produced (MWh) | 0 | Estimated 10,000-15,000 |

| CO2 emissions avoided (tons) | 0 | Estimated 5,000-7,500 |

| Revenue from wood products ($) | 0 | Estimated $2-3 million |

| Forest area managed sustainably (acres) | 0 | Estimated 5,000-7,000 |

This table clearly illustrates the significant impact of the Jamestown biomass plant across various environmental and economic metrics.

Challenges and Solutions

While the Jamestown biomass plant has been largely successful, it has faced some challenges:

- Supply Chain Management: Ensuring a consistent supply of forest waste can be challenging. The plant has addressed this by building strong relationships with local loggers and forestry companies.

- Regulatory Compliance: Navigating complex environmental regulations requires ongoing effort. The plant maintains strict adherence to all guidelines and regularly updates its processes.

- Public Awareness: Educating the community about the benefits of biomass utilization is an ongoing process. The plant conducts regular tours and community outreach programs to address this.

- Technological Adaptation: Keeping up with the latest biomass processing technologies requires continuous investment. The plant is committed to regular upgrades and innovation in its processes.

By proactively addressing these challenges, the Jamestown biomass plant continues to improve its operations and impact.

Community Feedback and Engagement

The Jamestown biomass plant has been well-received by the local community:

- Positive Local Impact: Residents appreciate the plant’s contribution to wildfire prevention and job creation.

- Educational Opportunities: The plant offers tours and workshops, educating the public about sustainable forestry practices.

- Collaborative Approach: Regular meetings with community leaders ensure that the plant’s operations align with local needs and concerns.

- Support for Local Businesses: The plant’s products support various local industries, strengthening the regional economy.

This community engagement has been crucial in building support for the plant and its mission.

The Role of Technology in Modern Forestry

The Jamestown biomass plant exemplifies how technology is transforming the forestry industry:

- Satellite Imaging: Used for forest monitoring and planning biomass collection.

- Data Analytics: Helps in optimizing plant operations and predicting biomass availability.

- Automated Processing: Increases efficiency and safety in biomass handling.

- IoT Sensors: Monitor various aspects of plant operations in real-time.

These technological advancements are crucial in making biomass utilization more efficient and sustainable.

Policy Implications and Government Support

The success of the Jamestown biomass plant has significant policy implications:

- Renewable Energy Incentives: Demonstrates the effectiveness of government support for biomass projects.

- Forest Management Policies: Influences strategies for sustainable forest management and fire prevention.

- Job Creation Initiatives: Showcases the potential of green jobs in rural areas.

- Environmental Regulations: Helps shape policies on carbon emissions and waste management.

The plant serves as a model for future biomass projects and informs policy decisions at state and federal levels.

Economic Impact Analysis

The economic benefits of the Jamestown biomass plant extend beyond direct job creation:

- Local Supply Chain Boost: Increased business for local logging and transportation companies.

- Tourism Impact: The plant attracts visitors interested in sustainable forestry, benefiting local hospitality businesses.

- Property Value Stabilization: Reduced wildfire risk can positively impact local property values.

- Tax Revenue Generation: Contributes to the local tax base, supporting community services.

These wide-ranging economic impacts underscore the plant’s importance to the local economy.

FAQs About the Jamestown Biomass Plant

- Q: How does the biomass plant contribute to wildfire prevention?

A: By removing excess forest waste and reducing fuel loads in forests, the plant significantly decreases the risk of catastrophic wildfires. - Q: What types of products does the plant produce?

A: The plant produces bundled firewood, peeled agricultural poles, wood straw, biochar, and wood chips. - Q: How many jobs has the plant created?

A: The Jamestown facility currently employs 10 team members, with additional indirect jobs created in related industries. - Q: Is the plant’s operation environmentally friendly?

A: Yes, the plant operates under strict environmental guidelines, ensuring sustainable practices in biomass collection and processing. - Q: How does the plant benefit the local community?

A: The plant provides jobs, supports local businesses, reduces wildfire risk, and contributes to sustainable forest management in the region.

Conclusion: A Model for Sustainable Forestry and Renewable Energy

The Jamestown biomass plant stands as a shining example of how innovative technology and sustainable practices can transform forest waste into valuable resources. By processing 30,000 tons of biomass annually, this facility not only contributes to forest fire prevention and eco-friendly wood processing but also plays a crucial role in California’s forest restoration efforts.

The plant’s success in creating green jobs, supporting local economies, and promoting sustainable forestry practices makes it a model for future biomass to bioenergy conversion projects. As we continue to face environmental challenges, initiatives like the Jamestown biomass plant offer hope and practical solutions for a more sustainable future.

The journey of this $14-million project, from its inception to its current operations, demonstrates the power of collaboration between government agencies, private enterprises, and local communities. It serves as an inspiration for similar projects across the country and around the world, showing how we can effectively balance environmental stewardship with economic development.

As we look to the future, the Jamestown biomass plant will undoubtedly continue to play a pivotal role in shaping sustainable forestry practices and renewable energy production in California and beyond. Its success story is not just about transforming forest waste into energy; it’s about transforming our approach to forest management and community development in the face of environmental challenges.

Earn With Farmonaut: Affiliate Program

Earn 20% recurring commission with Farmonaut’s affiliate program by sharing your promo code and helping farmers save 10%. Onboard 10 Elite farmers monthly to earn a minimum of $148,000 annually—start now and grow your income!