Table of Contents

- Introduction: Maple Syrup Innovation in Wisconsin

- Industry Trivia

- Historical Innovations in Wisconsin Maple Syrup Equipment

- Technological Innovations: Comparison Table

- Advanced Sap Collection Systems

- Vacuum Pumps: Boosting Sap Flow and Syrup Yield

- Reverse Osmosis for Maple Syrup Production

- Maple Syrup Evaporator Innovations

- Density Measurement Devices for Syrup Quality

- Sustainable Maple Syrup Practices & Environmental Impact

- Local Innovations and Equipment Manufacturers

- Farmonaut: Supporting Sustainable Agriculture Innovation

- Frequently Asked Questions

- Conclusion: Wisconsin’s Continued Evolution in Maple Syrup Equipment

Wisconsin Maple Syrup Equipment Innovations: Top 7 Advances

Maple syrup production in Wisconsin has always reflected a deep-rooted connection to both the region’s heritage and a continuous spirit of innovation. From birch bark containers and hot stones to today’s complex reverse osmosis maple syrup systems, the evolution of equipment has transformed syrup quality, boosted production efficiency, and enhanced sustainability across the industry.

In this comprehensive guide, we explore the top seven technological advances and equipment innovations shaping the future of the Wisconsin maple syrup industry. Whether you’re intrigued by sustainable maple syrup practices, driven by improving syrup production efficiency, or fascinated by the environmental impact of maple syrup industry advancements, this article walks you through the latest methods, devices, and systems—from sap collection and evaporators to smart density measurement.

“Wisconsin producers using reverse osmosis can reduce sap boiling time by up to 75% compared to traditional methods.”

Historical Innovations in Wisconsin Maple Syrup Equipment

Wisconsin’s rich history of maple syrup production is a narrative of adaptation and innovation. In the early days, Native American and pioneer producers relied on birch bark containers and hot stones to process sap into syrup, marking the industry’s humble technological origins. With time, these methods evolved, stimulating generations of advancements and improvements.

The Central Evaporator Plant: A Groundbreaking Model

A pivotal moment arrived in the 1940s and 1950s with the introduction of Wisconsin’s Central Evaporator Plant system. This groundbreaking concept centralized sap collection and processing at a facility similar to a cheese factory. Here, sap from various producers in the region was transported, combined, and converted into syrup—with compensation based on the sugar content of each batch. This model was instrumental in:

- Streamlining production for efficiency and scale

- Improving quality control through standardized processing

- Encouraging collaborative growth among small and large maple syrup producers

- Shaping Wisconsin’s maple syrup industry as a leader in approached-based innovation

This willingness to centralize, modernize, and compensate fair value for producers’ efforts set the stage for decades of sustained equipment and method improvements in Wisconsin’s maple syrup sector.

Comparison Table: Top 7 Technological Innovations in Maple Syrup Equipment (Wisconsin)

| Innovation Name | Function/Description | Estimated Efficiency Improvement (%) | Sustainability Impact | Adoption Rate in Wisconsin (%) | Year Introduced |

|---|---|---|---|---|---|

| Vacuum-Assisted Sap Collection | Uses vacuum pumps to enhance sap flow through tubing systems from trees directly to storage tanks | 20–40 | Reduces labor, increases yield, minimal tree impact | 60+ | 1970s–1980s |

| Reverse Osmosis Filtration | Removes a significant portion of water before boiling; concentrates sap to save energy | 50–75 | Cuts fuel use by up to 66%, less steam/water output | 70 (large), 30 (small) | 1980s–1990s |

| Smart Monitoring Systems | Integrates digital sensors and real-time monitors for sap flow, temperature, and tank status | 10–20 | Reduces losses/spillage, improves syrup quality | 35+ | 2000s–Present |

| Energy-Efficient Evaporators | Modern evaporators with pre-heaters, economizers, and tight fireboxes | 25–40 | Lower wood/fuel consumption, reduced emissions | 50 | 1990s–Present |

| Sustainable Tubing Materials | Longer-lasting, food-safe, and recyclable plastic tubing for sap collection | 5–10 | Less plastic waste, safer syrup | 65 | 2000s–Present |

| Data Analytics Platforms | Analyses sap flow, weather, and production trends to optimize tapping and processing | 10–15 | Helps reduce waste, enhances yield predictability | 20+ | 2010s–Present |

| Automated Bottling/Packaging | Automates filling, capping, and labeling syrup | 15–25 | Less labor, consistent product quality | 35 | 2000s–Present |

Advanced Sap Collection Systems in Wisconsin

The transition from traditional sap collection methods—such as metal sap buckets and open-air pipelines—to today’s modern sap collection systems is at the core of technological progress in Wisconsin’s maple syrup industry. These innovations contribute directly to efficiency, yield, and quality, while upholding the sustainability of local woodlands.

Modern Tubing and Collection Systems

- Plastic Tubing Networks: The adoption of durable, food-grade plastic tubing has enabled sap to flow directly from maple trees to central collection tanks, minimizing exposure and contamination risks.

- Gravity-Powered vs. Vacuum-Assisted: While gravity has always been used to move sap, modern vacuum pumps (detailed below) now enhance flow and overall sap yield.

- Centralized Tanks: Saps are funneled toward large reservoir tanks, reducing the labor and repetitive strain once required to empty sap buckets on foot.

By replacing traditional buckets with advanced tubing systems, producers have markedly reduced labor, improved hygiene, and boosted their quantities per harvest—all key drivers of modern maple syrup production in Wisconsin.

How Modern Sap Collection Methods Improve Efficiency and Sustainability

- Reducing Sap Spoilage: Closed tubing prevents external contaminants—crucial for syrup quality and food safety

- Minimizing Tree Injury: Proper tubing setups reduce over-tapping, protecting maple trees and sustaining long-term production

- Streamlining Labor: Fewer hands in the woods means lower risk and higher efficiency, especially for larger Wisconsin maple farms

“Over 60% of Wisconsin maple farms now use advanced vacuum sap collection systems, boosting syrup yield per tree.”

Vacuum Pumps for Maple Sap: Increasing Efficiency and Yield

One of the most transformational advancements in Wisconsin’s maple syrup equipment heritage has been the adoption of vacuum pumps for maple sap collection. Vacuum-assisted operations apply gentle suction to the plastic tubing, increasing the flow of sap from trees—especially during marginal weather patterns or late-season runs.

Key Benefits of Vacuum Pump Systems:

- Enhanced Sap Flow: Vacuum pumps can increase sap yield per tree by 20-40% compared to gravity-only systems

- Improved System Efficiency: Larger and more predictable sap flows allow producers to plan boiling and processing more efficiently

- Reducing Labor & Fuel Usage: With more sap available per tap, overall resource consumption (fuel, water, labor) per finished gallon of syrup decreases

- Environmental Impact: By making each tree’s output more productive, there’s less forest disturbance for the same syrup output—a win for sustainability

The introduction and widespread adoption of vacuum-assisted sap collection represents a defining trend in the evolution of the Wisconsin maple syrup industry. Producers can now rely on high-yield systems that are both scalable and suited to modern environmental practices.

Reverse Osmosis Maple Syrup: The Energy-Saving Advancement

Perhaps no modern advance has done more to reduce fuel usage and improve syrup production efficiency than the reverse osmosis (RO) system. Now a mainstay in both small and large Wisconsin syrup operations, reverse osmosis maple syrup equipment removes up to two-thirds of water from fresh sap before it ever touches an evaporator pan.

Key Features and Benefits of RO Systems:

- Significant Energy Reduction: RO systems can cut boiling time by 50–75% and reduce fuel consumption by up to 66% compared to traditional boiling. This directly impacts cost, labor, and the environmental impact of maple syrup producers.

- Uniform Syrup Quality: By concentrating sap before boiling, RO systems facilitate consistent syrup density and taste, a crucial aspect of commercial-grade production.

- Flexible Scale: RO maple syrup systems are scalable for both small family-run sugarhouses and large commercial operations in Wisconsin.

- Environmental Sustainability: Less fuel burned means fewer carbon emissions and lower environmental impact of maple syrup industry activities statewide.

The adoption of reverse osmosis has made it feasible for the Wisconsin industry to keep growing while reducing its footprint—another shining example of balancing productivity with sustainability.

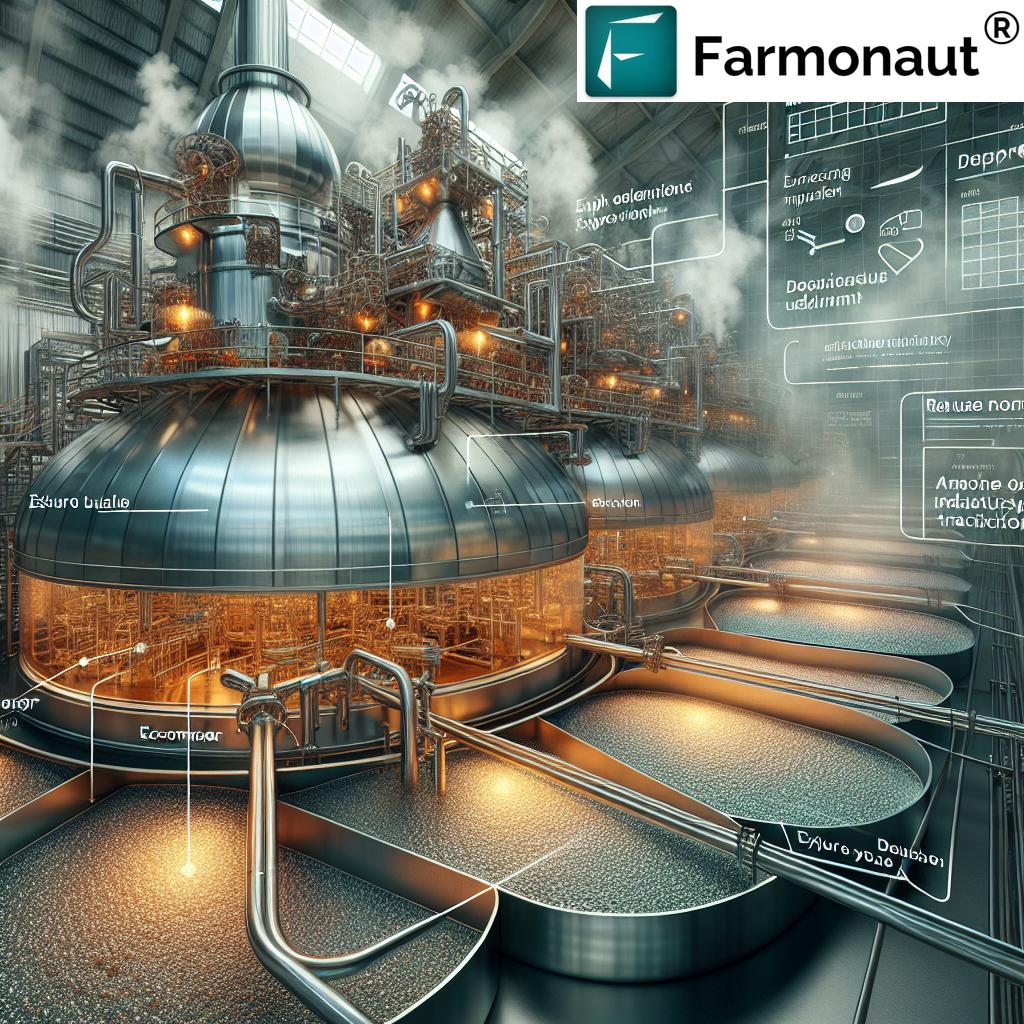

Maple Syrup Evaporator Innovations: Enhancing Efficiency and Quality

The maple syrup evaporator is at the very heart of the syrup-making process. As technology evolves, so too does the design and efficiency of evaporators. Modern systems incorporate features and materials that serve to:

- Pre-heat incoming sap: Using heat exchangers, steam from boiling syrup is recycled to preheat fresh sap, reducing overall energy usage by up to 40%.

- Economizer Units: Further recapture exhaust steam to push overall system efficiency even higher.

- Airtight Fireboxes: Especially with wood-fueled setups, airtight fireboxes can reduce cordwood usage by over 30%—helpful for both cost-cutting and carbon emission reduction.

- Innovative Accessories: Tools such as flue scrapers (developed by Wisconsin-based manufacturers) keep pans clean and heat transfer smooth, reducing fuel waste and improving syrup quality.

Impact on Production Efficiency

Increasingly, Wisconsin syrup producers are investing in these evaporator enhancements to lower running costs, improve consistent product quality, and support their broader goals for sustainable syrup production.

Density Measurement Devices for Syrup: Technology for Consistency and Quality

Consistent, high-quality maple syrup requires precise monitoring of syrup density during processing. In the past, crude thermometers and manual hydrometers were the norm—often leading to wide variability between batches. Today, innovative density measurement devices for syrup ensure state-regulated standards are met every time.

Groundbreaking Devices: The Murphy Compensation Cup

- Patented Innovation: Wisconsin’s own Smoky Lake Maple Products developed the Murphy Compensation Cup to provide fast, reliable hydrometer readings across a range of syrup temperatures.

- Key Benefits:

- Temperature-compensated measurement—no need for constant cooling or warming

- Rapid feedback for syrup makers, reducing guesswork and waste

- Consistent syrup density, supporting premium product quality

Thanks to these modern density measurement devices, Wisconsin producers now enjoy better quality control and less product loss—evidence of how technology improves classic traditions.

Sustainable Maple Syrup Practices: Reducing Environmental Impact

The drive toward sustainability shapes every facet of the Wisconsin maple syrup industry. Maple producers today are not simply focused on yield or profit—they also care deeply about the health of their trees, the longevity of their forests, and the environmental impact of maple syrup industry activities.

Key Sustainability Practices in Maple Syrup Production:

- Responsible Tapping: Sizing taps according to tree size and rotating which trees are tapped each season aids in forest health and maintains sap flow long-term.

- Energy Conservation: By embracing tools like reverse osmosis filtration and energy-efficient evaporators, many Wisconsin producers are actively reducing both operational costs and carbon footprint.

- Modern Sap Collection Systems: Closed, reusable plastic tubing systems mean far less waste, less risk of contamination, and minimal damage to maple trees.

From adopting resource-conserving equipment to implementing responsible forestry practices, Wisconsin’s maple community leads by example in balancing production growth with environmental stewardship.

Local Innovations and Equipment Manufacturers: Wisconsin’s Cutting Edge

A unique strength of the Wisconsin maple syrup sector is its ecosystem of local equipment manufacturers. By developing and refining specialized tools—often in direct collaboration with local producers—these manufacturers drive innovation while maintaining the character and quality for which Wisconsin syrup is known.

Spotlight: Smoky Lake Maple Products

- Based in Hilbert, Wisconsin, Smoky Lake Maple Products is famous for innovations like the Murphy Compensation Cup and Flue Scraper tool.

- Their dedication to quality, reliability, and cutting-edge solutions keeps Wisconsin at the forefront of technological advancement in maple syrup production.

- Other Local Manufacturers: Numerous family-run and regional companies supply everything from small-plot tubing setups to full-scale, energy-efficient evaporator systems, supporting all sizes of syrup operations across the state.

This ongoing spirit of innovation fosters collaboration, drives continuous improvement, and cements Wisconsin’s reputation as a leader in both traditional craftsmanship and modern technology in the syrup industry.

Farmonaut: Empowering Modern and Sustainable Agriculture

At Farmonaut, we are committed to making precision agriculture technologies both affordable and accessible for all types of farmers, including those producing specialty crops like maple syrup in Wisconsin. We believe that innovative solutions must work in harmony with tradition, local knowledge, and nature’s rhythm. Our mission aligns with the changing needs of agriculture worldwide by providing:

- Satellite-based crop health monitoring: Real-time NDVI imagery, soil moisture analysis, and pest risk alerts for optimal resource deployment and crop health.

- AI-based advisory: The Jeevn AI system helps farms adapt management strategies in real time with weather, disease, and growth forecasts—empowering smart decisions.

- Blockchain-enhanced traceability: Producers, including those in Wisconsin’s syrup sector, use blockchain to verify and showcase genuine, contamination-free syrup tracing from tree to local or gourmet market.

- Fleet and resource management tools: For Wisconsin’s large syrup producers, our fleet tools deliver efficient logistics, vehicle use optimization, and cost reductions.

- Carbon footprint tracking: With integrated carbon monitoring, syrup producers can track, benchmark, and reduce their environmental footprint, supporting both marketplace and regulatory demands for sustainability.

Our platform is available on Android, iOS, and Web, and can be integrated into existing farm management systems via API or via our developer docs here.

With real-time insights, actionable recommendations, and full transparency from field to consumer, Farmonaut is proud to support the next era of sustainable, tech-driven agriculture.

Frequently Asked Questions about Wisconsin Maple Syrup Equipment Innovations

What are the latest advances in sap collection systems for Wisconsin maple syrup producers?

Modern sap collection methods rely on food-grade plastic tubing networks and, increasingly, vacuum pumps. These systems enhance sap flow, minimize contamination risks, and streamline the collection process, especially for larger operations.

How does reverse osmosis maple syrup equipment improve energy efficiency?

Reverse osmosis maple syrup systems remove much of the water from sap before it reaches the evaporator, reducing boiling time by up to 75% and cutting fuel usage by up to two-thirds—a significant cost and environmental benefit.

What are the main advantages of modern evaporator innovations?

Modern evaporators now incorporate steam pre-heaters, economizers, and airtight fireboxes, leading to up to 40% reductions in fuel consumption and more consistent syrup density—key for high-quality, market-ready syrup.

Which devices ensure syrup quality and correct density?

Density measurement devices for syrup, such as the Murphy Compensation Cup, allow producers to quickly and accurately test syrup density across temperatures, assuring both regulatory compliance and optimal taste and texture.

How does the industry prioritize sustainable maple syrup practices?

Sustainability is achieved through practices like responsible tapping, tree rotation, carbon footprint tracking, closed tubing systems, and energy-efficient equipment. Wisconsin’s syrup producers lead US regions in merging productivity with environmental stewardship.

Why are local equipment manufacturers important for Wisconsin maple syrup innovation?

Local manufacturers quickly respond to producers’ needs with custom solutions—whether it’s new density measurement tools, flue scrapers, or energy-saving evaporators—ensuring that innovations are practical, region-specific, and highly effective.

How can Farmonaut help syrup producers and other agricultural businesses?

Our solutions—including satellite-based monitoring, resource and fleet management, AI advice, traceability, and carbon footprint tools—help optimize yield, sustainability, and transparency for farmers of all sizes. See our

large-scale farm management platform here.

Conclusion: The Continued Evolution of Maple Syrup Equipment in Wisconsin

The story of maple syrup production in Wisconsin is a testament to continuous improvement—where tradition and technology meet to create an ever-better future. The top seven equipment innovations discussed here—advanced sap collection systems, vacuum pumps, reverse osmosis, energy-efficient evaporators, density measurement devices, sustainable industry practices, and locally developed tools—form the backbone of a modern, resilient, and sustainable maple syrup industry.

With ongoing focus on efficiency, sustainability, and superior product quality, and with the support of technology partners like Farmonaut, Wisconsin’s syrup producers are well-positioned to lead the nation’s maple sector through the coming decades—including whatever challenges and opportunities may arise.

Whether you’re a hobbyist with a few taps or a multi-generation producer managing hundreds of acres, embracing technological innovation and data-driven management helps ensure that Wisconsin’s maple syrup legacy remains rich, sustainable, and world-renowned.