Agricultural Repairs & Maintenance: Boost Efficiency Now!

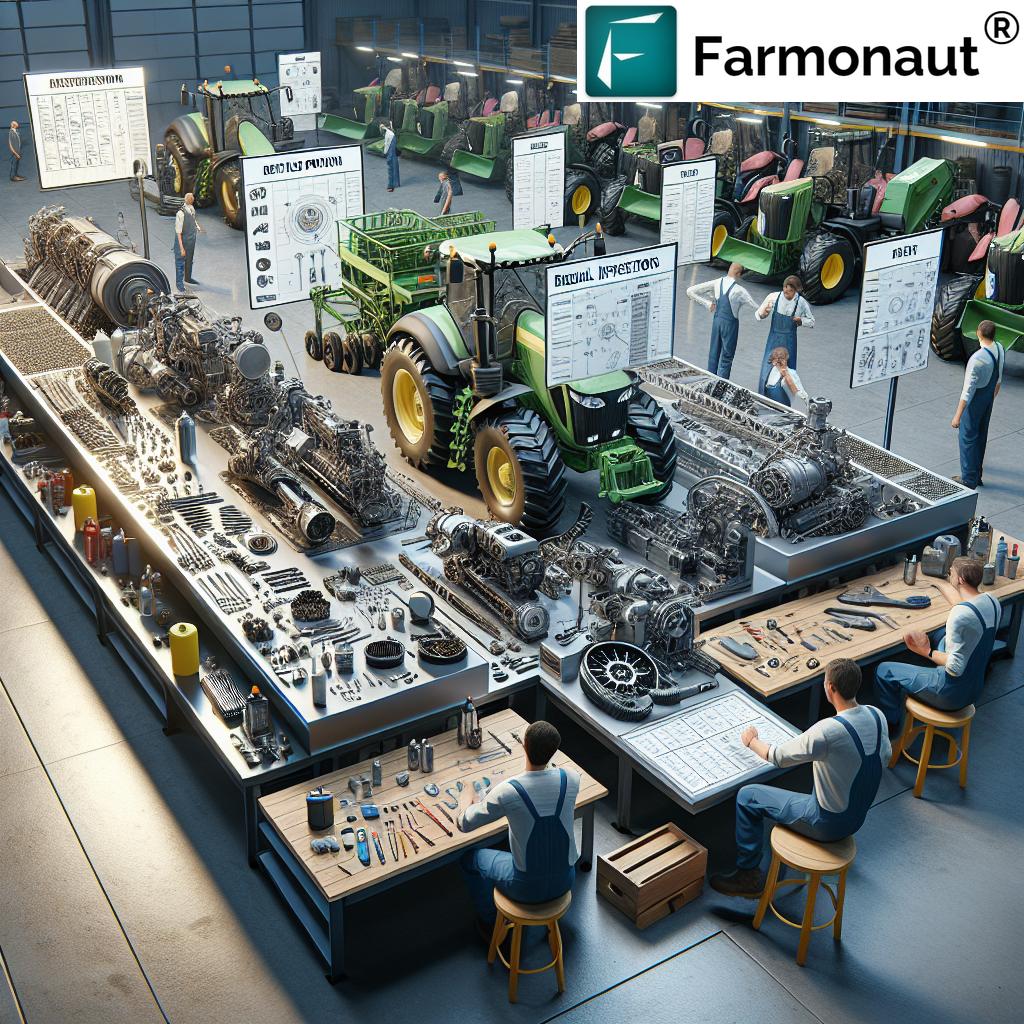

Understanding the Importance of Agricultural Equipment Maintenance

At Farmonaut, we understand the importance of proper agricultural equipment maintenance in achieving operational excellence and long-term success in both farming and forestry. Whether you operate a single tractor or run a large fleet of machinery, implementing the right practices ensures that your investment delivers maximum productivity and minimum downtime. Let’s explore why routine maintenance is vital and how best to optimize your efforts.

Key Reasons for Maintenance

- Enhanced Equipment Longevity: Conducting routine checks and servicing extends the lifespan of machinery, reducing the need for costly replacements and keeping your business sustainable.

- Improved Efficiency: When equipment is maintained regularly, it operates efficiently—providing better fuel economy, higher output, and optimized utilization of time and resources.

- Safety Assurance: Regular inspections help us identify potential hazards. Adhering to agricultural machinery safety protocols not only protects workers but also ensures smooth operation.

- Cost Savings: By prioritizing preventive maintenance, we minimize unexpected breakdowns, reducing repair expenses and operational disruptions.

- Reduced Downtime: Proper servicing reduces farm equipment downtime, thus maintaining smooth farming operations even during peak seasons.

The importance of regular equipment inspections cannot be overstated. Proactive measures prevent issues, optimize performance, and keep farms both safe and productive.

Best Practices for Equipment Upkeep and Preventive Maintenance

We advocate for a proactive approach using best practices for equipment upkeep. By building a culture of farm machinery preventive maintenance, our operations are streamlined, productivity is enhanced, and the overall health of our machinery is preserved. Let’s dive into the cornerstones of a strong maintenance program:

-

1. Familiarize Yourself with Equipment Manuals

Always begin by carefully studying the manufacturer manuals. They provide essential guidelines on maintenance schedules, lubrication points, operational procedures, and service intervals tailored to your model. A deep understanding of this information allows us to perform routine servicing correctly and mitigate risks.

-

2. Conduct Regular Inspections

Establishing a regular inspection schedule helps us identify issues early and resolve them before they escalate. Key areas to check:

- Fluid Levels: Inspect engine oil, coolant, and transmission fluid diligently.

- Hydraulic Systems: Check hydraulic lines and hoses for leaks or damage.

- Structural Components: Look for signs of rust, corrosion, or cracks in load-bearing components.

- Moving Parts: Assess bearings, belts, and chains for excessive wear and ensure optimal tension.

By adhering to a structured plan, preventive maintenance for farming operations becomes more efficient and predictable.

-

3. Prioritize Cleaning After Use

Frequent cleaning is essential to prevent debris accumulation and avoid corrosive damage. We pay special attention to undercarriages, engine compartments, and electronic components where dirt easily collects. Proper cleaning also reduces fire risks and ensures optimal visibility of warnings and indicators.

-

4. Implement Proper Lubrication for Farm Machinery

Application of the right lubricants and adhering to specified intervals reduce friction, wear, and overheating. Following the manufacturer’s recommendations for lubrication points helps us avoid breakdowns. Regular application protects all moving parts—including joints, bearings, and gears—ensuring smooth operation.

-

5. Monitor Tire Condition and Pressure

Maintaining the correct tire pressure according to the equipment manual preserves fuel efficiency and handling. We regularly inspect for punctures, cracks, bulges, and tread wear to ensure safety and stability during operation.

-

6. Store Equipment Properly and Protect from Elements

Whenever possible, we store machinery indoors away from harsh elements. If outside storage is necessary, robust covers or tarps help prevent rust and weather-related damage. This simple step is crucial to maintain equipment condition year-round.

-

7. Replace Worn or Damaged Parts Promptly

Immediate replacement of worn-out belts, blades, or hoses prevents larger failures and keeps our systems running efficiently. Keeping essential spare parts on hand allows us to react quickly, minimizing downtime and safeguarding productivity.

-

8. Calibrate Equipment Regularly

Sensors and control systems require calibration to ensure operational precision. We periodically calibrate seeders, sprayers, and harvesters to optimize their accuracy, thus enhancing both resource usage and yields.

-

9. Maintain Detailed Maintenance Records

Documenting every servicing activity, repairs, fluid changes, and part replacements lets us track trends, anticipate future needs, and comply with warranty or insurance requirements. Digitized or paper logs are both effective, but adopting a computerized maintenance management system for agriculture streamlines this further.

-

10. Invest in Operator Training

Trained operators are key to avoiding improper use that leads to premature wear and damage. We conduct regular training on correct operation, maintenance procedures, and safety protocols—all crucial to maximizing machinery lifespan and minimizing risks.

Agricultural Machinery Safety Protocols & Procedures

Ensuring safety is a shared responsibility and a non-negotiable cornerstone of equipment maintenance. Adhering to key safety protocols during agricultural repairs and upkeep protects both our teams and machinery. Consider these essential principles:

Core Safety Measures During Maintenance Activities

- Power Down Before Servicing: Never service a machine while it’s running. Always turn off the engine, engage safety locks, and allow any hot components to cool. This one step helps us prevent accidental injuries.

- Use Appropriate Tools and Protective Gear: Select the right equipment—including gloves, safety goggles, and steel-toed footwear—for every task. Using improper tools increases both the risk of damage and injury.

- Maintain a Clean Work Environment: Ensure that workspaces are free from spilled oil, grease, and clutter. Stable ladders and platforms are crucial. A tidy area prevents slips, trips, and falls, safeguarding both workers and machines.

- Proper Lighting and Ventilation: Good visibility helps us spot potential hazards quickly. Similarly, well-ventilated spaces reduce exposure to harmful fumes from lubricants or fuel.

- Lockout/Tagout Procedures: When performing major repairs or servicing electrical components, disconnect all power sources and apply visible tags to signal ongoing maintenance work.

- Follow Manufacturer’s Safety Guidelines: Only use recommended parts and follow specified torque or tension values to avoid introducing new risks. Deviations may void warranties and lead to dangerous failures.

Integrating these safety procedures into our maintenance routine protects the wellbeing of our operators and ensures our farming equipment remains in peak condition.

Leveraging Technology: Digital Tools & Farmonaut Solutions for Equipment Maintenance

The integration of modern technology into agricultural equipment maintenance transforms preventive care from a chore into a strategic advantage. Farmonaut’s satellite-based farm management platform empowers farmers, agribusinesses, and forestry teams to use data-driven insights for timely repairs, smarter resource usage, and advanced fleet management.

Key Digital Innovations in Maintenance

- Satellite Monitoring and AI Analytics: Farmonaut’s platform harnesses satellite imagery and artificial intelligence (AI) to track crop health, soil conditions, and environmental factors. This data can inform preventive maintenance schedules and highlight areas that risk equipment overuse or failure.

- Fleet and Resource Management: Our fleet management features help us monitor, optimize, and document the performance and location of all fleet assets. This assists in tracking service history, planning scheduled maintenance, and reducing bottlenecks.

- Digital Maintenance Logs (CMMS): By adopting a computerized maintenance management system for agriculture, we automate reminders, record detailed repair histories, and manage part inventories for consistent preventive maintenance.

- Real-Time Advisory Systems: With our AI-based advisory tools, we receive custom maintenance tips, weather alerts, and equipment status updates, helping to prevent failure before it happens.

- Blockchain Traceability: Secure, transparent record-keeping using blockchain traceability can validate service events and replacements—a benefit for warranty claims or supply chain verification.

The use of data analytics and digital tools strengthens our maintenance practices, helping us identify issues early, extend equipment lifespan, and optimize resource allocation. This technological edge means that we reduce farm equipment downtime and keep our operations resilient and future-ready.

Preventive Maintenance Schedule Table

Effective planning is essential for maximizing the lifespan and safety of agricultural machinery. Our comprehensive preventive maintenance schedule table offers actionable guidance on frequency, required tools, and safety tips for each equipment type. This resource makes it easy for farmers and managers to organize regular upkeep, ensure compliance with best practices, and reduce downtime.

| Equipment Type | Maintenance Task | Estimated Frequency | Required Tools/Parts | Estimated Time | Safety Precautions |

|---|---|---|---|---|---|

| Tractor | Check & replace engine oil | Every 100 hours / Monthly | Oil filter, engine oil, wrench | 30 minutes | Allow engine to cool, wear gloves |

| Combine Harvester | Lubrication of moving parts | Weekly/Before use | Grease gun, multi-purpose lubricant | 20 minutes | Disconnect power, avoid loose clothing |

| Sprayer | Inspect hoses and valves | Monthly | Replacement hoses, clamps, screwdriver | 15 minutes | Release pressure, wear goggles |

| Seeder/Planter | Calibrate seed distribution | Every season/startup | Calibration tools, manual | 1 hour | Read manual, ensure machine is off |

| Baler | Clean and check belts | After every use | Air compressor, replacement belts | 15 minutes | Disconnect power, wear dust mask |

| Utility Vehicle | Inspect tires & check pressure | Bi-weekly | Pressure gauge, replacement tire | 10 minutes | Chock wheels, wear safety shoes |

| Irrigation Pump | Clear debris and check fittings | Monthly | Wrench, cleaning cloth | 20 minutes | Cut off power, wear safety gloves |

For detailed record-keeping and reminders, we recommend adopting a computerized maintenance management system for agriculture, allowing you to track service intervals, store digital manuals, and even manage parts inventories centrally for your entire operation.

Farmonaut Apps, API, and Advanced Solutions for Smarter Maintenance

Digital tools help us manage maintenance more efficiently than ever. Farmonaut’s suite of apps and APIs provide essential solutions, whether you’re an individual farmer or a large agribusiness. Here’s how you can leverage their technology:

-

Farmonaut Web App: Enables advanced, satellite-based monitoring for all your fields, delivering real-time data crucial for equipment deployment, crop health surveys, and fleet tracking. This connectivity ensures faster response to maintenance needs. -

Android App: Take your farm machinery preventive maintenance planning on the go, set reminders for fluid checks, record breakdowns, or get real-time AI-based advisories wherever you work. -

iOS App: Manage equipment health and get satellite-based insights directly on your iPhone or iPad. - API Access: Integrate Farmonaut’s robust platform into your own management system using the API. Ideal for developers or large operations needing seamless satellite data, weather analytics, or automated equipment logs.

- API Developer Docs: Ready to integrate? Access the technical documentation at Farmonaut Satellite & Weather API Developer Docs for custom setups and advanced fleet tracking.

- Large Scale Farm Management: The Agro Admin App is designed for estates, plantations, and cooperatives—offering centralized control over equipment deployment, preventive servicing, and fleet management.

- Fleet Management: Efficient management starts with visibility. Farmonaut’s Fleet Management solutions help plan routine checks and track fluid level status, service intervals, and even vehicle location.

- Product Traceability: Protect quality and transparency from field to final customer by using Farmonaut’s Blockchain Traceability. Every maintenance, part replacement, and activity is securely logged—essential for certifications or premium markets.

- Carbon Footprinting: Farmonaut’s Carbon Footprinting tools assist in tracking your operation’s emissions. By optimizing machinery usage and reducing unnecessary running time via preventive maintenance, you actively lower your farm’s environmental impact.

Frequently Asked Questions (FAQ) about Agricultural Repairs & Maintenance

How often should I perform preventive maintenance on my agricultural machinery?

Maintenance frequency varies by equipment type, usage intensity, and manufacturer guidelines. However, most tractors and harvesters require oil changes every 100 hours, with inspections (fluid, belts, tires) performed weekly or before major operation cycles. Follow the provided preventive maintenance schedule table and consult your equipment manual for specific intervals.

What are the first signs of wear or potential failure in farming equipment?

Common early signs include unusual noises, decreased performance, oil leaks, vibration, visible rust, or excessive smoke. Regular inspections will help identify these signs early and prevent costly repairs or failures.

Why is computerized maintenance management important for modern agriculture?

Adopting a CMMS (computerized maintenance management system for agriculture) enables automated scheduling, digital record-keeping, and advanced analytics. This improves compliance, reduces downtime, and streamlines spare parts inventory. Farmonaut’s solutions readily integrate with existing operations for even greater efficiency.

How can I extend the lifespan of my farm equipment?

By performing regular inspections, prompt repairs, timely lubrication, proper cleaning, correct storage, and operator training, you dramatically increase the longevity of agricultural machinery, reduce breakdowns, and protect your investment.

Does Farmonaut offer direct equipment repairs or sell machinery?

No, Farmonaut is not a manufacturer, dealer, or repair service provider of farm equipment. Instead, we offer advanced satellite-driven technology solutions for real-time crop and fleet management, helping you optimize farm machinery preventive maintenance and digitalize your on-site practices.

What steps should be taken before seasonal equipment storage?

Clean equipment thoroughly, check and top up fluids, lubricate all moving parts, disconnect batteries, inflate tires to recommended pressure, and cover machines securely to protect from dust and moisture. Store indoors when possible for optimal protection.

How does preventive maintenance reduce operational costs?

Preventive maintenance helps identify and fix minor issues before they become major breakdowns. This leads to lower repair expenses, reduced downtime, less frequent equipment replacement, improved fuel efficiency, and higher overall productivity.

Conclusion: Boosting Efficiency and Longevity through Strategic Repairs & Maintenance

Regular, well-documented agricultural repairs and maintenance are the foundation of a resilient, efficient, and profitable farming operation. By following best practices for equipment upkeep, applying rigorous safety protocols, and capitalizing on the advantages of technology—like those from Farmonaut—we can extend equipment lifespan, reduce downtime, and safeguard both workers and assets.

Remember, commitment to preventive maintenance not only minimizes risks and costs, but it also fuels continuous improvement and sustainable agriculture for generations to come.