Forestry Harvesters: 7 Secret Features for Massive Gains

“Modern forestry harvesters can process up to 200 trees per day, doubling productivity compared to traditional methods.”

Table of Contents

- Forestry Harvesters: An Overview

- Types of Forestry Harvesters

- The 7 Secret Features of Modern Forestry Harvesters

- Technological Advancements in Logging Equipment

- Applications and Benefits: Efficiency, Safety & Sustainability

- Forestry Machine Maintenance and Serviceability

- Comparative Table: 7 Secret Features & Their Benefits

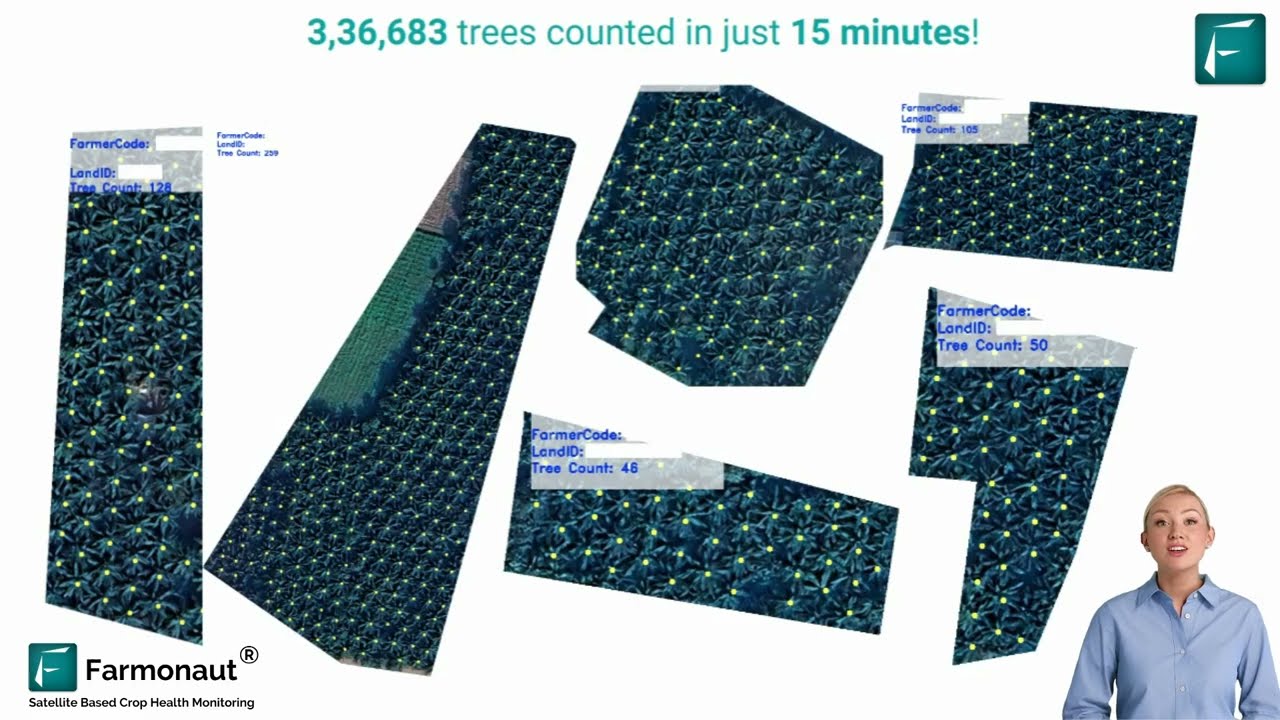

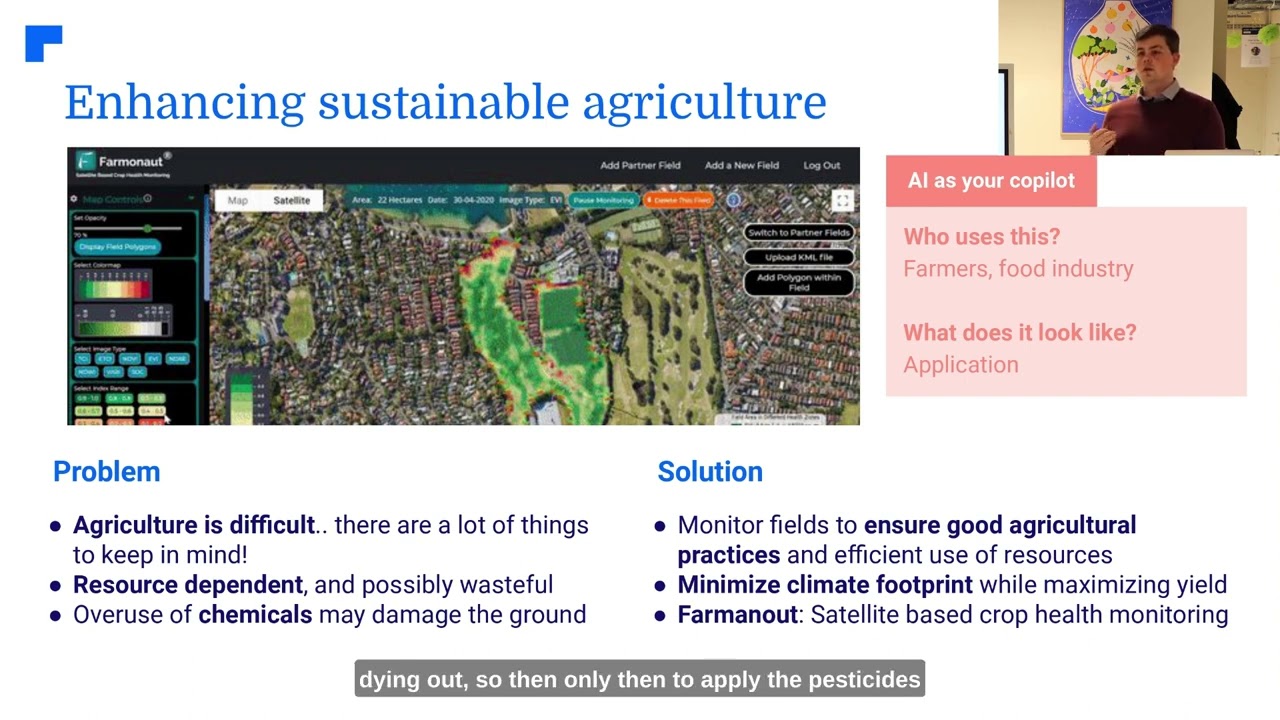

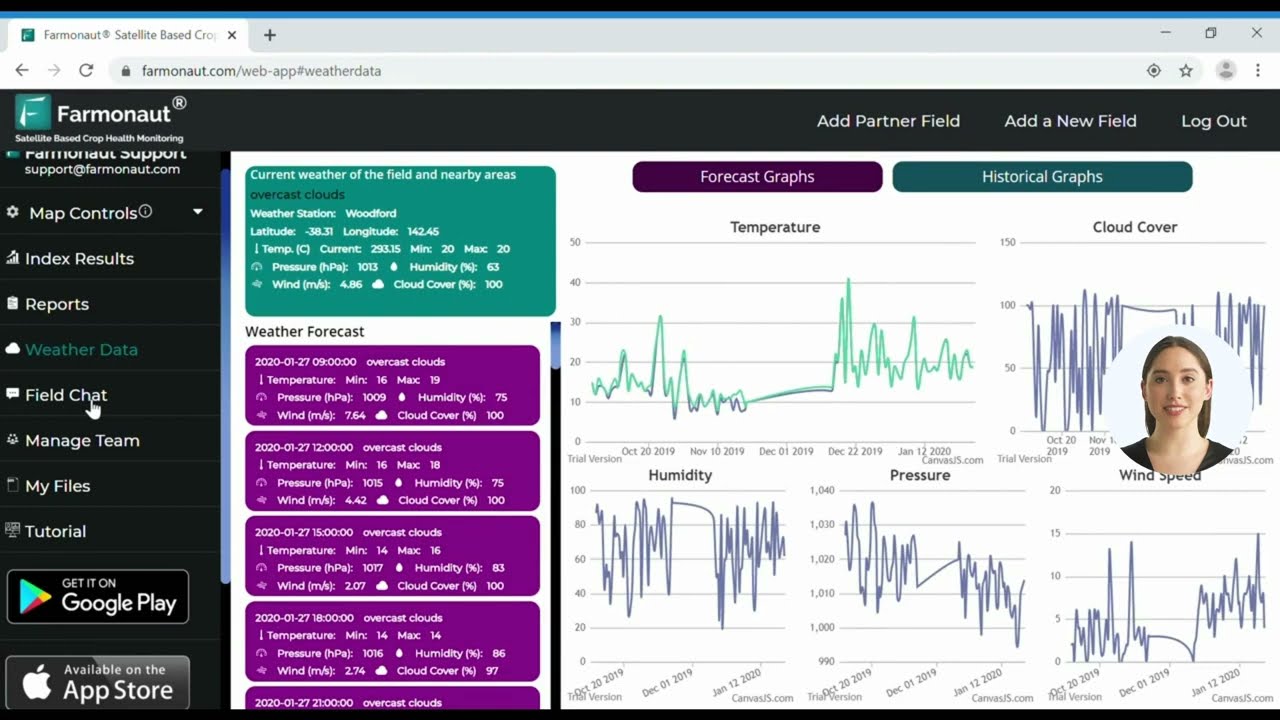

- Precision Forestry and Data Insights: The Farmonaut Edge

- FAQ: Forestry Harvesters, Logging Technology & More

- Conclusion

Forestry Harvesters: An Overview

In today’s forestry industry, forestry harvesters and feller bunchers have become the backbone of efficient logging operations worldwide. These specialized machines are engineered for felling, delimbing, bucking, and transporting trees with exceptional speed and safety. Advanced forestry machinery now drives productivity, facilitates sustainable logging practices, and ensures the safety and well-being of operators across diverse forest environments.

Harvesters have transformed traditional logging operations by integrating multiple processes into a single, sophisticated unit. Their continuous development—especially in tracked and wheeled configurations—help industry professionals maximize output while minimizing the environmental impact. At Farmonaut, we recognize the pivotal role forestry harvesters play in facilitating precision and sustainability in modern forest management, closely aligning with our mission to combine data-driven insights for enhanced agricultural and forestry outcomes.

In this in-depth blog, we explore the two main types of forestry harvesters, unlock 7 secret features turbo-charging efficiency, detail cutting-edge technologies like intelligent boom control (IBC) and telematics, and provide actionable insights for managing both operations and machine maintenance.

Types of Forestry Harvesters: Feller Bunchers & Cut-to-Length Harvesters

To understand the power and versatility of today’s logging equipment, we need to distinguish between their primary types and operational roles:

Feller Bunchers

- Definition: These are specialized machines capable of felling—i.e., cutting—multiple trees at once and gathering them into “bunches” before dropping, which makes them integral to large-scale forest operations.

-

Design Variants:

- Tracked Feller Bunchers: Engineered for rugged terrains such as steep slopes and swampy areas, with enhanced stability and traction.

- Wheeled Feller Bunchers: Suited to low-slope environments, these versions offer greater mobility and speed in less challenging terrains.

Cut-to-Length (CTL) Harvesters

- Definition: All-in-one forestry machines that fell, delimb, and buck (cut into logs of specific lengths) directly at the forest site. This minimizes tree handling and improves the efficiency of timber processing.

- Configurations: Available as tracked and wheeled machines, ensuring suitability for a wide array of operational conditions, from rocky highlands to soft, damp locations.

Both feller bunchers and cut-to-length harvesters come with specialized cutting heads, advanced controls, and multi-functional attachments. Their development embodies the industry’s evolutionary leap in maximizing productivity while keeping up with sustainability imperatives.

“Advanced feller bunchers reduce fuel consumption by 15%, thanks to precision cutting and automated control systems.”

7 Secret Features of Modern Forestry Harvesters for Massive Gains

What truly sets advanced forestry machinery apart are the integrated technologies and smart engineering features that drive operational excellence and cost savings. Let’s uncover the seven “secret” game-changers responsible for revolutionizing productivity, operator safety, and sustainability in forest resource management:

- 1. Intelligent Boom Control (IBC): This feature automates movement of the crane or boom, allowing operators to focus on precise positioning of the cutting head or attachment. The system automatically coordinates movements, drastically reducing operator fatigue and boosting both efficiency and accuracy.

- 2. Telematics & GPS Integration: Machines equipped with telematics systems provide real-time data on machine performance, fuel consumption, and maintenance alerts. GPS enables ultra-precise navigation, route mapping, and optimized harvesting, while minimizing environmental impact.

- 3. Advanced Hydraulic Systems with Load-Sensing Abilities: Modern harvesters use load-sensing hydraulics and multiple pump configurations to ensure optimal power distribution. This improves control, reduces fuel usage, and delivers consistent performance even in unpredictable field conditions.

- 4. Operator-Focused Cabin Design: Operator comfort in forestry equipment has reached new heights: 360-degree visibility, climate control, highly ergonomic seating, low-vibration environments, and intuitive interfaces—all reducing fatigue and facilitating safer, more productive long shifts.

- 5. Automated Diagnostics & Maintenance Support: Onboard sensors provide machine health data, issue maintenance alerts, and allow proactive servicing, reducing unscheduled downtime while extending machine life.

- 6. Low-Impact Tracked Configurations: Special tracked harvesters for steep slopes and soft terrain are engineered to distribute machine weight, reducing soil compaction and preserving forest floor integrity.

- 7. Programmable Cutting & Processing Heads: Automated heads can cut, delimb, and buck logs to precise customer-required lengths, optimizing both timber yield and uniformity—essential for commercial forestry operations.

Smart adoption of these features enables forestry professionals to both boost output and ensure that logging is conducted with maximum safety and environmental sustainability. Enhancements in operator comfort also mean fewer injuries, lower staff turnover, and higher morale.

Why Focus on “Secret Features”?

- Productivity: Combining multiple processes—felling, moving, processing—saves substantial time and wages.

- Cost Efficiency: Initial investment in advanced harvesters is offset by lower unit production costs, faster log throughput, and lower fuel consumption.

- Sustainability: By minimizing soil impact and optimizing tree yield, we protect both the forest ecosystem and long-term wood supply.

Technological Advancements in Logging Equipment & Forest Machine Technologies

The forestry industry is experiencing a digital and mechanical renaissance, with state-of-the-art logging equipment designed to meet both commercial and ecological goals.

1. Intelligent Boom Control (IBC): Redefining Precision and Ergonomics

- The IBC system intuitively guides the boom, joints, and cylinders, letting us focus on the target area rather than executing complex maneuvers.

- Benefits include increased precision, faster work cycles, significantly reduced operator fatigue, and minimized risk of accidentally damaging valuable standing trees.

- Read more about how IBC supports forestry operations efficiency and control.

2. Telematics & GPS for Real-Time Insights and Smart Navigation

- Telematics systems provide live performance data about machine health, fuel consumption, productivity rates, and scheduled service alerts.

- GPS mapping optimizes harvesting routes, prevents overlap, and improves timber tracking (enabling full traceability across the supply chain).

- This integration is essential for reducing resource waste and ensuring compliance with best-practice sustainable logging practices.

3. Advanced Hydraulic Systems: Power, Control, and Fuel Savings

- Adaptive hydraulic settings and load-sensing pumps ensure each system receives only the needed power, improving fuel economy and fine movement control.

- Multi-functionality allows us to simultaneously perform different processes (e.g., cutting, moving booms, processing logs), enhancing operational efficiency.

- More about how hydraulic advancements drive performance in wheeled harvesters.

4. Operator Comfort in Forestry Equipment: Modern Cabins

- Enhanced cabins offer full panoramic visibility and climate control, reducing eye strain and fatigue in all operational conditions.

- Features like ergonomic seating and interface design prioritize health and productivity for the operator.

- Designed to meet the needs of prolonged, intense forestry campaigns, as explored in advanced harvester cabin innovation.

5. Proactive Maintenance and Onboard Diagnostics

- Embedded sensors and diagnostics software help predict part wear, issue maintenance alerts, and reduce unplanned downtime.

- This increases equipment reliability and reduces lifetime operational costs—a core focus of fleet management for large-scale operators.

6. Low-Impact Track Designs

- Wide, continuous tracked harvesters for steep slopes minimize ground pressure (reducing soil compaction) and are essential for delicate, erosion-prone environments.

- By preserving soil integrity, we protect the forest floor for future regeneration, directly addressing concerns over sustainability.

- Learn more about precision logging with tracked harvester technologies.

7. Automated Processing Heads for Precision Bucking

- Program lengths and cut patterns into the processor; logs are cut, delimbed, and sorted to order in the field.

- This reduces handling labor, transportation costs, and material waste—key for both sustainability and contractual fulfilment in timber operations.

Applications & Benefits of Forestry Harvesters: Efficiency, Safety and Sustainability

A. Increased Productivity

- Modern harvesters combine multiple operations—felling, delimbing, bucking, transporting—into one seamless workflow. This can double timber output compared to manual or outdated mechanical methods.

- Automation in process control reduces time on site, improves log uniformity, and facilitates logistics coordination.

B. Enhanced Operator Safety

- By mechanizing hazardous tasks (felling, sawing, and log movement), advanced harvesters reduce physical risk for workers.

- Enclosed, climate-controlled cabins, with full vision and protection, further reduce operator injury rates in active logging sites.

C. Environmental Sustainability

- Technologies like tracked harvester designs distribute weight, minimizing soil disruption and preserving forest regeneration potential.

- Automation also ensures efficient resource utilization, reducing waste per harvested tree.

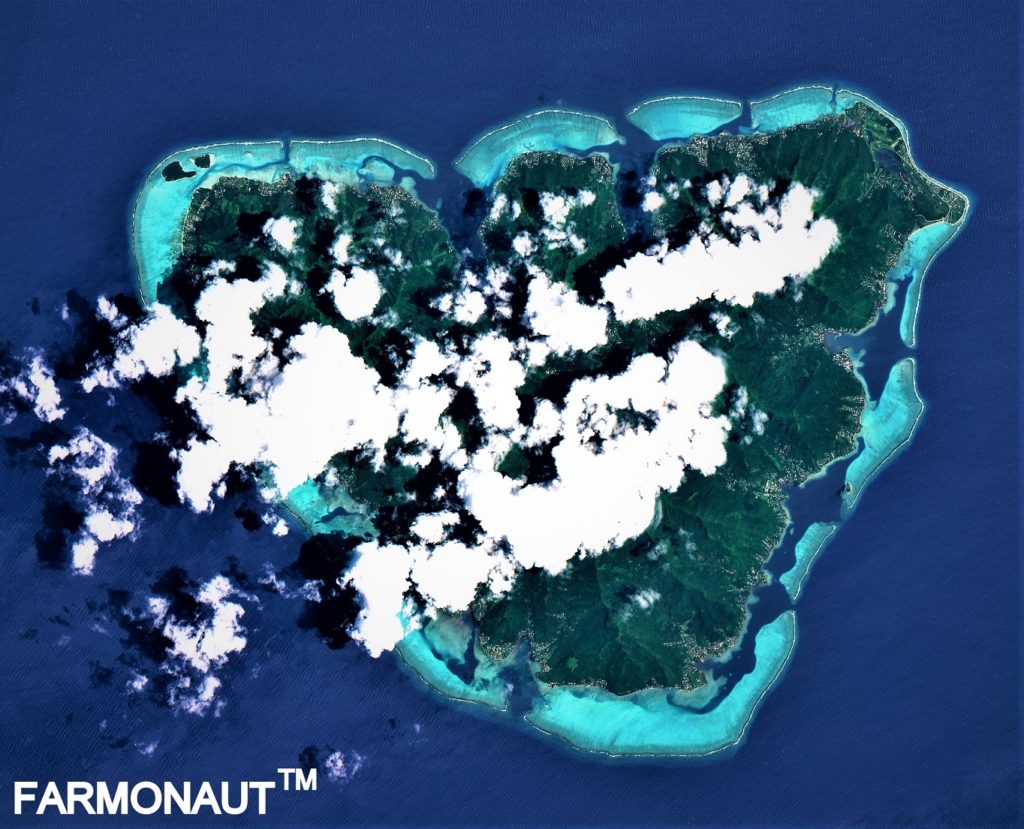

- Telematics and GPS help us optimize harvesting routes, avoid ecologically sensitive areas, and collect data for carbon footprinting, a core service area for Farmonaut’s sustainability-minded fleet partners.

D. Cost Efficiency

- Unit production cost with a feller buncher can be lower than with any other system, especially in large-scale commercial operations (feller buncher on Wikipedia).

- Reduced downtime, fewer manual laborers, less frequent maintenance (thanks to predictive diagnostics), and lower fuel consumption translate to dramatic lifetime savings.

E. Precision Forestry & Data-Based Decisions

- Satellite monitoring and analytics—such as those provided by Farmonaut—enable ongoing precision management of forest resources.

- This includes crop plantation and forest advisory insights for optimal yield and ecological compliance.

Forestry Machine Maintenance & Serviceability: Ensuring Longevity and Peak Performance

To keep forestry operations running smoothly, daily attention and strategic servicing of our advanced machines is essential.

A. Daily Forestry Machine Maintenance

- Visual Inspections: Check booms, cylinders, hoses, cutting heads, and undercarriage for visible damage, leaks, or blockages.

- Lubrication: Regularly lubricate moving parts to reduce wear and tear on all key machine pivots.

- Hydraulic Systems: Monitor levels and inspect for pressure loss, contamination, or abnormal temperature spikes.

- Cabin Hygiene: Keep interior controls clean, and windows unobstructed for safety and operator comfort.

B. Scheduled Servicing

- Follow manufacturer recommendations for oil/filter changes, component replacement, and interval-based system checks.

- Detailed data from telematics can help inform when preventive service is due, reducing risk of costly unplanned downtime.

C. Proactive Maintenance with Smart Diagnostics

- Modern onboard telematics and diagnostics continuously scan for anomalies and provide maintenance alerts both in-cab and remotely via the management dashboard.

- This supports advanced fleet and resource management, including for large-scale logging contractors and government forestry agencies.

D. Farmonaut’s Role in Maintenance Analytics

-

For organizations seeking deeper insights into machine health and operational efficiency, Farmonaut enables API-driven integration of satellite-based fleet monitoring, helping

to schedule, track, and optimize servicing across diverse forestry operations. - Find developer documentation for integration: Farmonaut API Developer Docs

Comparative Table: The 7 Secret Features of Forestry Harvesters

| Feature Name | How It Works | Estimated Efficiency Gain (%) | Safety Benefit | Sustainability Impact |

|---|---|---|---|---|

| Intelligent Boom Control (IBC) | Automates boom/joint motion for operator. System adjusts movements based on attachment position. | +15–25% | Yes | Medium |

| Telematics & GPS Integration | Real-time data, route mapping for harvesting and real-time performance monitoring. | +10–30% | Yes | High |

| Advanced Hydraulic Systems | Load-sensing hydraulics, multiple pumps to allocate power optimally and enhance control. | +12–20% | Yes | Medium |

| Operator-Focused Cabin Design | 360° visibility, comfort seating, climate control, ergonomic controls to reduce fatigue. | +10–18% | Yes | Low |

| Automated Diagnostics | Sensors track machine health, prompt alerts reduce unplanned downtime. | +12–20% | Yes | Medium |

| Low-Impact Tracked Configuration | Track designs spread machine weight, preserve soil, ideal for delicate environments. | +5–15% | Yes | High |

| Programmable Processing Heads | Automated heads for precision log cutting and bucking, consistent timber sizing. | +10–25% | Yes | Medium |

Precision Forestry & Data Insights: The Farmonaut Edge

While advanced forest machines propel efficiency, the future of sustainable forestry relies on high-accuracy monitoring and insight-driven decision making. Farmonaut addresses these needs via a suite of technologies, putting real-time analytics in the hands of operations managers:

- Satellite-Based Monitoring: Track forest machine technologies, tree health, regrowth, and soil moisture on-demand from mobile, desktop, and API solutions.

- AI-Driven Analytics: Use the Jeevn AI advisory system for tailor-made, in-season recommendations—whether for timber stand health or regeneration planning.

- Fleet & Resource Optimization: Farmonaut’s platform is purpose-built for fleet management, enabling managers to efficiently coordinate logging equipment and minimize unnecessary fuel expenditure.

- Traceability: Leverage blockchain-based traceability to ensure that each log’s journey—from forest harvest to processing—remains transparent and secure. This is especially valuable for corporate forestry operators and those aiming for international green certifications.

- Environmental Impact Monitoring: With carbon footprinting analysis, forest managers can log and verify emissions, plan reforestation, and pursue credits under global carbon trading schemes.

Subscription Options: Access Farmonaut’s full-featured platform through flexible web or mobile app packages—ideal for scaling operations from individual foresters to government or enterprise-level managers.

FAQ: Forestry Harvesters, Logging Technology & Data-Driven Operations

Q1. What is a forestry harvester’s main advantage over traditional chainsaw logging?

Forestry harvesters integrate felling, delimbing, and bucking in one machine. This streamlines the process, doubles productivity (up to 200 trees per day), and reduces physical hazards for workers by keeping them inside protected cabins.

Q2. Are tracked harvesters for steep slopes always better than wheeled versions?

Each configuration suits specific conditions: Tracked harvesters excel in steep, uneven, or soft terrain while providing maximum stability and soil protection. Wheeled harvesters offer greater speed and mobility on flat or gently sloping ground.

Q3. How do telematics and GPS improve harvesting?

Integrated telematics and GPS provide real-time performance data and enable optimized route planning, machine monitoring, and proactive maintenance. This helps us reduce resource consumption and environmental impact.

Q4. What safety features do modern harvesters offer?

Today’s machines include enclosed, climate-controlled cabins, panoramic visibility, intuitive controls, and automated diagnostic systems. All these features work together to reduce operator fatigue and risk of injury.

Q5. How does Farmonaut support forestry machine operations?

Farmonaut empowers managers with satellite-based crop and forest monitoring, AI-driven advisory, carbon footprinting, and blockchain traceability. These digital tools enable better decision making and operational oversight in forestry.

Q6. Where can I access API-based forestry & farm management services?

Farmonaut provides a comprehensive API for real-time data and offers full integration documentation for developers at Farmonaut API Documentation.

Q7. How do advanced harvester heads improve timber yield?

Programmable heads cut, delimb, and buck logs to custom lengths at the site, increasing usable timber and uniformity—optimizing value across the log supply chain.

Conclusion: Transforming Forestry with Innovation and Insight

In summary, forestry harvesters—driven by breakthrough features like intelligent boom control (IBC), real-time telematics, advanced hydraulics, and ultra-ergonomic cabins—are rewriting the rules of forest resource management. Whether using tracked harvesters for steep slopes or modular wheeled machines on flatter terrain, we can now achieve unprecedented levels of productivity while safeguarding both our teams and the natural environment.

The future of forestry lies in integrating advanced logging equipment with satellite-based analytics, traceability, carbon tracking, and sustainable plantation advisory—all available through Farmonaut’s accessible, app-based solutions. By investing in both hardware innovation and actionable data, today’s managers ensure the forests of tomorrow remain healthy, productive, and resilient.

Ready to modernize your forestry operations with precision insights and robust, efficient machines? Explore Farmonaut’s specialist forestry solutions for advisory, management, and real-time remote monitoring—empowering the next leap in sustainable, high-performance logging!