Maintenance of Agricultural Machinery: 15 Essential Tips to Boost Equipment Performance

“Regular cleaning can extend agricultural machinery lifespan by up to 30%.”

Table of Contents

- Introduction

- Why Agricultural Machinery Maintenance Matters

- 15 Essential Tips for Maintaining Agricultural Machinery

- Maintenance Task Checklist Table

- Farmonaut: Precision Tools for Smarter Maintenance

- Frequently Asked Questions (FAQ)

- Conclusion

Introduction

Maintaining agricultural machinery is not just about preventing breakdowns—it’s a fundamental practice that ensures optimal performance, extends equipment lifespan, and maximizes farm productivity. With machines playing a vital role in modern agriculture, neglecting farm equipment upkeep can lead to unexpected downtime, costly repairs, and compromised safety. Our comprehensive guide covers maintenance of agricultural machinery, offering practical, step-by-step tips for cleaning, lubrication, calibration, tire checks, and more—empowering farmers everywhere to get the most out of their investments.

As an expert in both agricultural technology and machinery maintenance, we understand the challenges farmers face in keeping their machines running smoothly. With structured preventative maintenance for tractors, combines, and implements, as well as guidance on how to maintain farm machinery in all seasons, we aim to make your daily operations safer and more efficient. Whether you operate a family farm or manage large-scale agribusiness, this guide is tailored for you.

Why Agricultural Machinery Maintenance Matters

Regular and proper agricultural machinery maintenance is essential. Let’s highlight why:

- Extends Equipment Lifespan: Just as a well-oiled engine runs longer, regular cleaning and lubrication prevent wear and corrosion, extending farm machinery lifespan.

- Prevents Downtime: Proactive upkeep and inspections help us catch issues early, minimizing the risk of unexpected breakdowns during peak seasons.

- Boosts Efficiency: Well-maintained machines operate at optimal efficiency, reducing fuel consumption and maximizing productivity.

- Enhances Safety: Operating safe equipment with fully functional brakes, lighting, and systems protects us, our teams, and our communities.

- Protects Investments: Tractors and implements are substantial investments; upholding their value through proper maintenance protects our long-term profitability.

- Supports Sustainability: Efficient machinery reduces resource wastage and environmental impact—a key pillar for modern, sustainable farming.

With this in mind, let’s explore 15 essential maintenance tips that every farmer should follow.

“Proper tire pressure maintenance reduces fuel consumption in tractors by approximately 10%.”

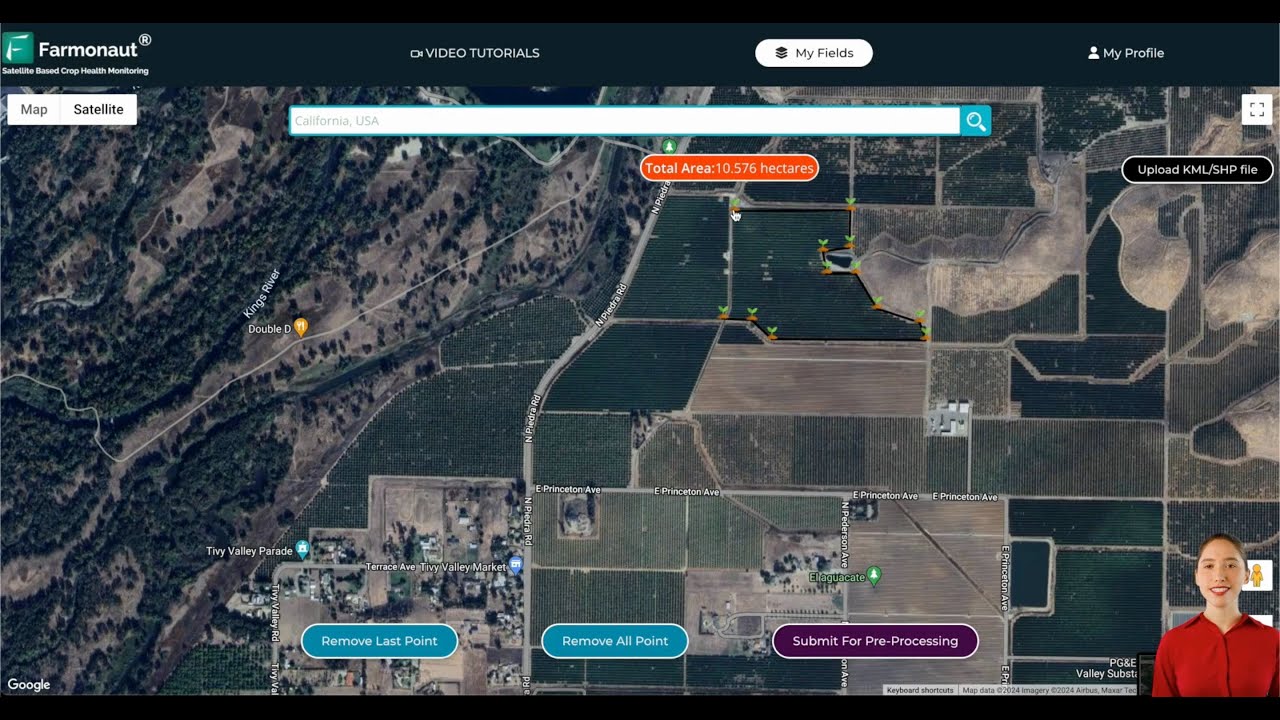

Farmonaut App Tutorial: How to Add & Map Fields Easily

Farmonaut Agro Admin App: Revolutionizing Large-Scale Farm Management

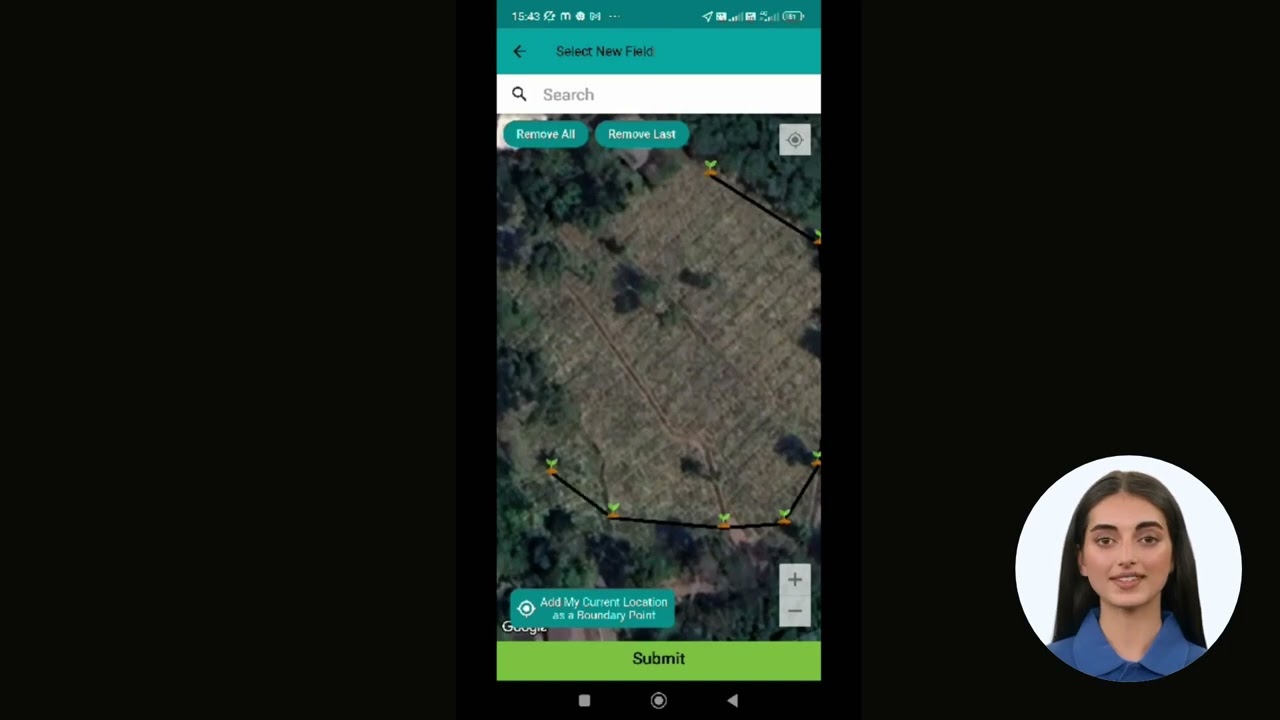

Farmonaut Farm Mapping Tutorial – Mobile App

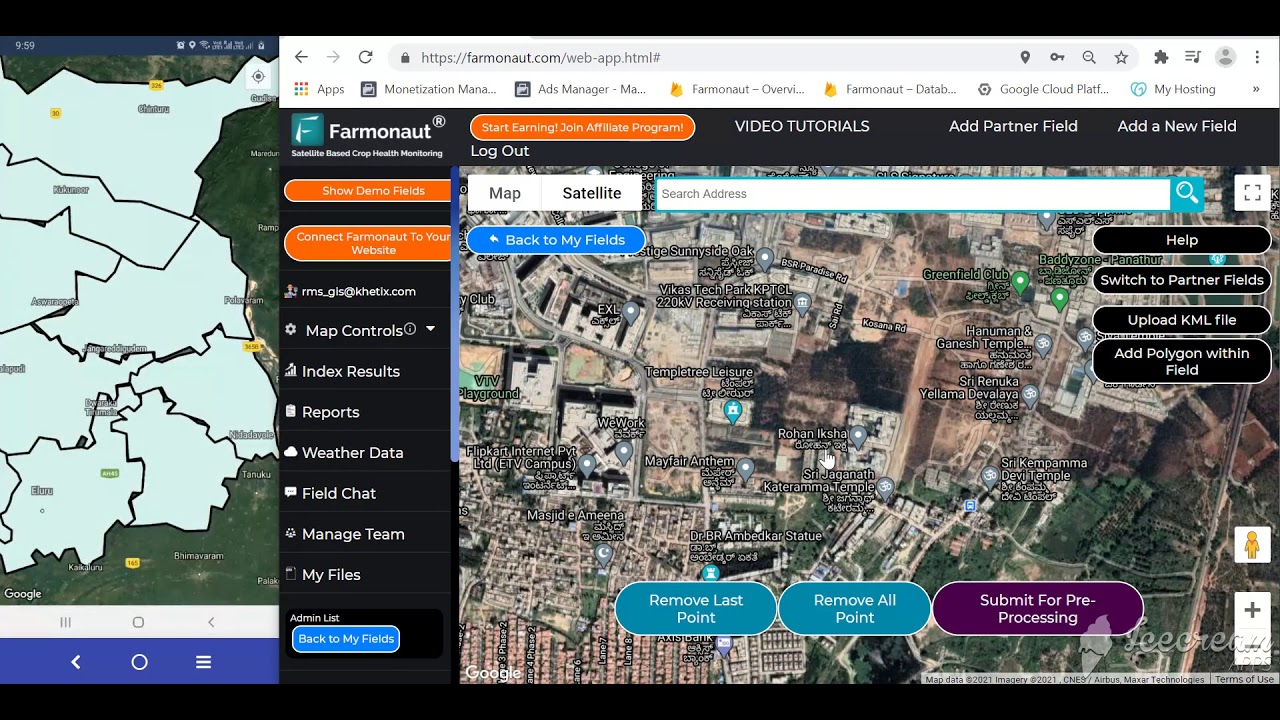

Farmonaut Large Scale Field Mapping & Satellite Based Farm Monitoring | How To Get Started

15 Essential Tips for Maintaining Agricultural Machinery

Let’s break down each key aspect of agricultural machinery maintenance—from the basics like regular cleaning and lubrication, to advanced seasonal maintenance tips and professional servicing. Each recommendation is grounded in expert best practices and is crucial for efficient, safe, and sustainable farm operations.

1. Regular Cleaning of Farm Equipment

We start every successful maintenance routine with thorough, regular cleaning of our agricultural machinery. After each use—especially at the end of a season—carefully clean your machines to remove dirt, dust, mud, salt, crop residue, and debris. Pay special attention to the undercarriage and less visible parts, as these areas can accumulate material that leads to corrosion and rust. Keeping lighting elements and road-safety features clean ensures visibility for other users and compliance with regulations.

- Use water or an air compressor to clear out debris, but avoid direct high-pressure sprays on electronics.

- Consider cleaning the engine bay, but only when the engine is cool and electrical systems are protected.

- Inspect for and remove salt buildup in winter, especially in regions using road salt.

“Regular cleaning can extend agricultural machinery lifespan by up to 30%.“

This preventative maintenance for tractors and implements is one of the least expensive yet most impactful measures we can take.

2. Lubrication and Fluid Checks for Optimal Performance

Following tractor lubrication guidelines and checking all major fluids is non-negotiable.

Make it a habit to regularly check and, as necessary, change oil, hydraulic and transmission fluids as specified by the manufacturer. Using the recommended lubricants at proper intervals reduces friction, wear, and premature damage to internal components.

- Check the oil level before each use and change oil as per the equipment manual.

- Top up and, if needed, replace hydraulic fluids—especially after long work periods or signs of contamination.

- Thoroughly lubricate all moving parts to prevent wear and keep your system operating smoothly.

Not only does proper lubrication keep equipment running, but it also helps in extending farm machinery lifespan significantly.

3. Tire Maintenance for Agricultural Machines

Tires are crucial for the safe and efficient operation of all agricultural equipment. Always inspect tires for cuts, punctures, wear, and signs of damage. Proper tire pressure maintenance reduces fuel consumption in tractors by approximately 10%.

- Check tire pressure before each use; use the manufacturer’s recommended settings for each machine.

- Watch for underinflated tires, which cause increased fuel consumption, reduced traction, and potential damage to the tire structure.

- Avoid overinflated tires—they lead to uneven wear and a rough ride.

- Rotate tires periodically to promote even wear and maximize lifespan.

With tire maintenance for agricultural machines as a regular task, we can ensure safer, more efficient operation and avoid costly downtime due to flats or blowouts.

4. Battery and Electrical System Maintenance

Modern machines rely on sensors, control systems, and electronic displays—making electrical health as essential as mechanical upkeep.

- Check battery charge levels before winter and after extended non-use; cold weather can reduce battery efficiency dramatically.

- Clean corrosion from battery terminals and cables to prevent poor connections and electrical faults.

- Monitor for warning lights and error codes from the onboard computer system.

- Check for frayed wires, damaged connectors, or exposed metal which may lead to shorts or failures.

A reliable battery and electrical system keep the farm running with minimal interruptions.

5. Inspect and Replace Filters for Clean Operation

Filters play a critical role in protecting your machine from dirt and contaminants. Regularly inspect and replace:

- Air filters—to ensure clean air intake for the engine.

- Fuel filters—to keep impurities out of sensitive components such as injectors.

- Oil filters—to maintain healthy lubrication cycles.

Replace filters according to the manufacturer’s guidelines, or even more often in dusty or harsh conditions, to ensure optimal performance and prevent internal wear.

6. Brake System Functionality—For Safety

A fully functioning brake system is crucial for safety. Regularly inspect brake pads, discs, fluid reservoirs, and linkages:

- Look for excessive wear, strange noises, or delayed response—these are clear signs of issues.

- Check brake fluid levels and top up or replace if contaminated.

- Don’t risk it: replace worn parts immediately to avoid accidents and downtime.

Safe operation isn’t just about protecting equipment—it’s about our lives and those around us.

7. Cooling System Maintenance: Preventing Overheating

Overheating can lead to catastrophic damage and expensive repairs. Here’s how we prevent it:

- Check coolant levels regularly; top up with the proper antifreeze or coolant mixture as needed.

- Inspect radiator, hoses, and all cooling system parts for leaks, damage, or blockages.

- Remove debris, dirt, or crop residue from the radiator and fans after each use.

A healthy cooling system means longer intervals between major services and a lower risk of sudden breakdowns.

8. Tire Pressure and Condition Checks

Check tire pressure before operations and regularly throughout the season. Excessively worn or damaged tires should be replaced immediately:

- Keep pressure within the manufacturer’s recommended range for peak efficiency and traction.

- Inspect sidewalls for cracks, bulges, or exposed cords—which signal imminent failure.

- Replace any damaged tire to help prevent accidents and field delays.

Combined, tire checks and proper inflation are among the fastest ways to boost equipment lifespan and lower running costs.

9. Calibration of Specialized Agricultural Machinery

Farm equipment today—especially for seeding, fertilizing, irrigation, and crop protection—often includes embedded electronics, precision GPS, and advanced sensors. Regularly calibrate this equipment to ensure:

- Accurate material and input applications for optimal resource efficiency.

- Consistent operation across different fields or tasks.

- Cost savings by avoiding input overuse or underuse.

For example, calibrating a GPS-driven spreader before the season controls input costs, maximizes yields, and protects the environment.

10. Proper Storage for Off-Season Protection

When the season ends, proper equipment storage prevents damage and maintains value:

- Clean equipment thoroughly and address any corrosion or paint chips.

- Drain, use stabilizer, or top up fuel if machines will remain unused for an extended period.

- Store machinery in a dry, covered place to reduce exposure to moisture and prevent rust.

- Disconnect the battery to avoid discharge and electrical issues.

This step is also an ideal time to update your maintenance log and create a to-do list for pre-season inspections.

11. Record Maintenance Activities in a Log

Tracking all maintenance activities in a detailed log ensures we never miss a service interval. It’s also a valuable asset for resale or warranty claims.

- Log every oil change, filter replacement, calibration, storage, and seasonal check.

- Include date, machine hours, and name of the person performing the task.

Digital tools, such as a mobile app, can make maintenance tracking simple and accessible for farm teams—explore solutions that offer powerful data logging.

Farmonaut offers easy digital management of farm resources and activity logs through its web, Android, and iOS apps, making farm equipment upkeep and tracking seamless.

12. Operator Training for Equipment Longevity & Safety

Well-trained operators prevent accidents, reduce costly errors, and enjoy better machine performance:

- Provide comprehensive instructions on safe operation and routine inspections.

- Review procedures for starting, stopping, emergency shutdown, and safe navigation.

- Highlight the dangers of overloading, incorrect attachments, and unauthorized operation.

Operator discipline and knowledge are often the difference between a well-loved machine with decades of service and one plagued by constant breakdowns.

13. Avoid Unauthorized Modifications

As tempting as it may be to modify machinery for “better” performance:

- Unauthorized modifications can void warranties and cause issues with manufacturer insurance and liability.

- Modifications to fuel systems, electronics, or safety systems often cause more harm than good.

- Any change should be approved by the equipment’s manufacturer or a recognized dealership.

Maintaining machinery according to manufacturer guidelines ensures safety, compliance, and longevity.

14. Seasonal Maintenance Tips for Farm Equipment

Before peak tasks such as planting or the irrigation season, conduct targeted inspections:

- Inspect and lubricate pumps, check for leaks, and clean irrigation or hydraulic lines before use.

- Flush old fluids and replace them before extended usage periods.

- Check tire condition and pressure as machines return to daily operation.

- Calibrate specialized equipment in line with seasonal jobs (like planters or spreaders).

Seasonal checks are a major pillar of preventative maintenance for tractors and other equipment—helping avoid mid-season breakdowns and peak-time delays.

15. Professional Servicing—Maximize Lifespan

While daily and weekly checks are handled on-farm, invest in periodic professional servicing:

- Have certified technicians conduct deep system diagnostics, advanced repairs, and full inspections annually or at manufacturer-recommended intervals.

- Professional servicing identifies less visible issues—such as internal hydraulic leaks, electrical problems, or excessive component wear.

- Stay current with all scheduled interventions to maximize uptime and protect equipment value.

Great machinery deserves expert care—prioritize professional maintenance as part of your farm management plan.

Maintenance Task Checklist for Agricultural Machinery

| Maintenance Task | Estimated Frequency | Purpose/Benefit | Estimated Time Required |

|---|---|---|---|

| 1. Regular Cleaning | After every use & end of season | Remove dirt/mud; prevent corrosion; maintain visibility and compliance | 30–60 min |

| 2. Lubrication & Fluid Checks | Weekly or as per guidelines | Reduce friction; prevent wear; protect internal parts | 20–30 min |

| 3. Tire Maintenance | Weekly / Pre-season | Prevent accidents; maintain traction and fuel efficiency | 15–30 min |

| 4. Battery & Electrical System Checks | Monthly / pre-storage | Keep electronics/sensors functional; avoid electrical failures | 15–20 min |

| 5. Inspect/Replace Filters | Monthly or as per guidelines | Protect machine from contaminants; maintain efficiency | 30 min |

| 6. Brake System Functionality | Monthly | Operator/road safety; prevent accidents | 20–30 min |

| 7. Cooling System Maintenance | Monthly & pre-season | Avoid overheating; reduce risk of breakdown | 15–20 min |

| 8. Tire Pressure & Condition Check | Before each use | Ensure safety, efficiency, and performance | 10 min |

| 9. Calibration of Specialized Equipment | Pre-season / before key tasks | Precision application; cost control | 30–45 min |

| 10. Proper Storage | Post-season | Protect from weather/rust; maintain value | 60–90 min |

| 11. Maintenance Activity Record | Every time a task is completed | Track schedules; plan future work; support warranty | 5–10 min |

| 12. Operator Training | Annual / new staff | Safe/proper use; reduce wear and risk | 60 min minimum |

| 13. Avoid Modifications | Ongoing | Maintain warranty/safety; reduce liability | N/A |

| 14. Seasonal Maintenance | Pre- & post-season | Maximize uptime; prevent breakdowns | 45–90 min |

| 15. Professional Servicing | Annual or as advised | Deep inspection; extend equipment life | 2–4 hours |

Farmonaut: Precision Tools for Smarter Maintenance & Farm Management

With the advancement of digital agriculture, integrating smart technology in our operations ensures that we stay ahead. Farmonaut is a pioneering technology platform built for modern agriculture. Let’s see how Farmonaut can support agricultural machinery maintenance and overall farm equipment upkeep:

- Satellite-Based Crop Health Monitoring: Farmonaut provides real-time NDVI, soil moisture, and vegetation health insights. By using their Android/iOS/web app, we can better schedule preventative maintenance for tractors and irrigation equipment—addressing issues before they lead to breakdowns.

- AI Advisory Systems: Receive weather forecasts and adaptive recommendations to time equipment calibration and storage, ensuring optimal performance all year.

- Fleet and Resource Management: Through Farmonaut’s Fleet Management, we track machinery, manage periodical servicing, and reduce costs by optimizing usage patterns.

- Blockchain-Based Traceability: With traceability tools, we add trust and transparency to our crop and machinery records, supporting compliance and reducing disputes.

- Carbon Footprinting: Monitor the environmental impact of your equipment and field activities. With Farmonaut’s Carbon Footprinting tools, adopt sustainability practices while optimizing maintenance tasks.

- Large-Scale Farm Management: The Farmonaut Agro Admin App is perfect for large farming enterprises, enabling field mapping, machinery scheduling, and efficient resource allocation.

- API & Integration: For developers or agri-businesses, get seamless access to remote farm data and weather integrations with the Farmonaut API and developer docs here.

Farmonaut’s mission is to make precision agriculture affordable and accessible globally—empowering us to maximize productivity, minimize costs, and promote sustainable practices.

Upgrade Your Farm Management with Farmonaut Subscriptions

Choose from flexible packages to monitor crops, machinery, and environmental factors on your terms. Experience precision agriculture in action—real-time data transforms everyday maintenance and productivity for farms large and small.

Frequently Asked Questions (FAQ) – Agricultural Machinery Maintenance

1. What is the most essential maintenance task for agricultural equipment?

Regular cleaning and lubrication top the list for essential agricultural machinery maintenance. These simple tasks prevent corrosion, reduce wear, and maintain both safety and value.

2. How often should I check or change oil in my tractor or combine?

Always follow the manufacturer’s guidelines, but a general rule is to check oil before each use and change it after every 100–200 hours of operation or at the specified interval for your engine model.

3. What happens if I neglect tire pressure and condition?

Improper tire inflation can cause increased fuel consumption, reduced traction, uneven wear, and the risk of accidents or sudden blowouts.

4. Can digital tools help with my maintenance schedule?

Yes! Platforms like Farmonaut help farmers log activities, track machine health, and receive advisories based on real-time data.

5. When should I call for professional servicing?

At least once a year, or whenever you suspect deep system issues. Complex problems involving hydraulic systems, electrical faults, or advanced diagnostics require certified technicians.

6. How do I prevent machine breakdowns during peak season?

Adhere to all seasonal maintenance tips for farm equipment: clean, calibrate, and inspect every major system before the season begins. Keep spare parts handy, and maintain a log of all completed maintenance.

7. Is there a way to monitor my carbon footprint with my maintenance routine?

Absolutely! Use Farmonaut’s Carbon Footprinting feature to track and optimize emissions from machinery, improving both efficiency and sustainability.

8. Should I modify my tractor for more power?

We do not recommend unauthorized modifications—they can void warranties, increase wear, and put safety at risk. Always consult your manufacturer first.

Conclusion: Invest in Maintenance, Reap the Rewards

In our journey toward productive, profitable, and sustainable farming, maintenance of agricultural machinery is the cornerstone. Adopting these 15 essential tips—spanning cleaning, lubrication, tire checks, seasonal upkeep, and digital record-keeping—empowers us to maximize equipment lifespan, minimize costs, and protect our investments. Coupled with smart technology from Farmonaut, we take farm equipment upkeep to new heights—ensuring each machine delivers optimal performance, field after field and season after season.

Ready to level up your farm’s maintenance regimen? Explore Farmonaut’s suite of powerful solutions for crop health monitoring, AI advisories, fleet management, traceability, and more. It’s time to make every season your most productive yet.