Table of Contents

- Introduction: Revolutionizing Canadian Construction with Graphene Concrete Solutions

- Trivia: CO2 Reduction Power

- Why Canada Needs Sustainable Construction Innovation

- How Graphene Reinvents Eco-Friendly Building Materials

- Graphene Concrete Solutions: 5 Powerful Ways Canada Cuts CO2

- Comparative Benefits Table: Traditional vs. Graphene Concrete

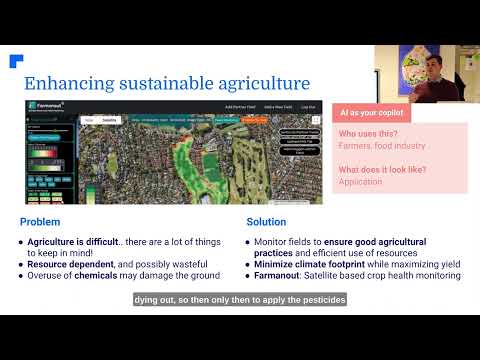

- Technological Synergy: Farmonaut for Modern Soil & Carbon Management

- Nanomaterials in the Canadian Construction Industry: From Lab to Infrastructure

- FAQ: Sustainable Construction & Graphene Innovations

- Summary & Next Steps

- Farmonaut Subscriptions

Graphene Concrete Solutions: 5 Powerful Ways Canada Cuts CO2

Focus Keyword: Graphene Concrete Solutions

Meta Description: Graphene concrete solutions are transforming the Canadian construction industry by leveraging cutting-edge nanomaterials to boost durability, reduce CO2, and drive sustainable, eco-friendly building material trends.

As industrial materials evolve, so do the ways we construct the infrastructure of tomorrow. In Canada, and particularly in dynamic hubs like Vancouver, British Columbia, the drive to reduce CO2 emissions in concrete propels the industry toward embracing advanced nanomaterials. Our focus: graphene concrete solutions, which dramatically boost durability, lower climate impact, conserve water, and deliver resilient, sustainable construction materials for the modern world.

“Graphene concrete can cut CO2 emissions by up to 30% compared to traditional concrete in Canadian construction projects.”

Why Canada Needs Sustainable Construction Innovation

Canada is rapidly moving toward eco-friendly infrastructure to meet the needs of a changing planet. With the North American ready-mix concrete market valued at USD 250 billion in 2024—and an annual growth rate of 4.5% projected through 2030—demand for sustainable construction materials is at an all-time high. Our country’s ever-increasing focus on green infrastructure trends in Canada is driven by both climate concerns and ambitious government mandates.

Yet, the construction industry faces a stark challenge: Concrete production remains one of the world’s largest industrial sources of CO2 emissions, accounting for approximately 8% of global emissions. Canadian stakeholders are searching for solutions that can reduce this impact while delivering the performance modern infrastructure demands.

Emerging Challenges Facing the Canadian Construction Sector:

- High volume of CO2 emissions from cement production

- Growing demand for infrastructure in rapidly urbanizing areas, especially British Columbia and North American urban centers

- A need to develop durable ready-mix concrete to withstand harsh Canadian weather cycles (freeze-thaw, high moisture)

- Increasing regulations and incentives for sustainable construction materials

- Pressure to adopt organic and bio-based technologies to improve soil and material performance

The answer is convergence: blending scientific breakthroughs in nanomaterials—like graphene—and novel materials science with robust eco-friendly building materials.

How Graphene Reinvents Eco-Friendly Building Materials

What if we could make concrete that is simultaneously stronger, more durable, longer lasting, and less polluting? Graphene concrete solutions do just that. Through the use of graphene nanoplatelets (GNPs) and other carbon nanomaterials, we can fundamentally transform one of construction’s oldest materials into a next-generation green product. Here’s why this is game-changing:

- Industrial materials upgraded: Adding graphene enhances microstructure, increases performance, and reduces the resources needed for effective production.

- Global impact: The technology offers scalable CO2 emission reduction—essential in Canada and worldwide.

- Increased durability: Graphene’s structure forms a tighter, more resilient matrix in concrete, boosting material durability and resisting water penetration, frost, and cracking.

- Water-Efficient Construction Technology: Graphene-integrated concrete requires less water during mixing and curing, conserving a precious resource and reducing energy requirements.

Graphene is not merely an additive—it reshapes the very performance limits of sustainable construction materials.

“Nanomaterial-enhanced concrete increases durability by 25%, revolutionizing sustainable building technology in Canada.”

Graphene Concrete Solutions: 5 Powerful Ways Canada Cuts CO2

Let’s dive into five essential ways graphene concrete solutions drive sustainability, reduce CO2 emissions in concrete, and put Canada at the forefront of eco-friendly construction:

1. Enhanced Strength for Material Efficiency

Research and industry studies indicate that by incorporating graphene, concrete’s compressive and tensile strength can be increased by up to 30%. This means Canadian companies are able to use less material for the same—or even improved—results, thereby reducing the total CO2 emissions associated with each structure. Fewer tons of cement are required for the same job, directly lowering associated emissions.

- Allows thinner, lighter structures without sacrificing safety

- Reduces raw material extraction and transportation needs

- Supports sustainable growth rate in urban centers without expanding environmental impact

2. Superior Durability for Long-Lasting Infrastructure

Concrete structures in British Columbia, other Canadian provinces, and worldwide face environmental stressors—frost, deicing salts, and more. Graphene’s unique nano-scale network forms a denser, crack-resistant matrix. The benefits:

- Extended lifespan for bridges, roads, and buildings (in some cases from 40 to 60+ years!)

- Fewer repairs and maintenance cycles—saving materials, water, and energy

- Enhances the integrity of new and existing infrastructure

- Addresses the specific durability needs of north american climates

3. Material Resource Conservation & CO2 Reduction

The production of cement—the key ingredient in traditional concrete—is a top global source of industrial CO2 emissions. By strengthening concrete via graphene, significantly less cement is needed per cubic meter (up to 20% reduction). This cascades into enormous CO2 savings at scale across national infrastructure projects.

- Efficient sourcing: Less reliance on global quarrying and mining

- Lowered downstream emissions: Transport, processing, and installation become greener

- Strategic alignment: Meets Canada‘s commitment to sustainable development and climate action targets

4. Water-Efficient Construction Technology

Conserving fresh water is paramount in Canadian and global construction practices. Graphene-enhanced materials require less water in the concrete mixing process and result in denser, less water-permeable cured structures.

- Contributes to responsible water stewardship in both urban and rural projects

- Minimizes water loss through evaporation during curing

- Aligns with the targeting trend of minimizing all resource inputs in the industry

5. Driving New Standards in Organic & Eco-Friendly Infrastructure

Canada’s new market for graphene concrete is targeting a merger of organic technologies with next-gen nanomaterials. Many firms also integrate organic soil amendments for onsite vegetation and land restoration, showcasing circular, carbon-smart systems. These intersecting solutions:

- Offer eco-friendly building materials that perform at the highest levels

- Promote bio-based soil and construction cycles alongside industrial innovation

- Support the sustainable construction materials movement not just in Canada, but worldwide

Current Market Snapshot

- Annual growth rate of Canadian construction: 4.5% CAGR through 2030

- Graphene nano-additives quickly moving from research lab into mainstream materials supply chain

- Canadian cities like Vancouver are on the leading edge of deploying nanomaterials in construction industry applications

- Policymakers and industry players focus on both durability and radical CO2 impact reductions

Comparative Benefits Table: Traditional vs. Graphene Concrete

This table compares traditional concrete with advanced graphene concrete solutions across key sustainability and performance metrics relevant to Canadian infrastructure:

| Feature/Metric | Traditional Concrete | Graphene Concrete | CO2 Reduction (%) |

|---|---|---|---|

| Carbon Emissions (kg CO2/ton) | 900 | 630-720 | 20-30% |

| Compressive Strength (MPa) | 25-40 | 32-52 | Up to 30% higher strength |

| Durability (years) | 40-50 | 50-65 | 20-30% improvement |

| Water Usage (liters/ton) | 180 | 150 | ~15% |

| Estimated Cost ($/m3) | $120-140 | $135-155 (balanced by lifecycle savings) | Cost benefit over time |

The above figures are industry ranges—Canada’s trend is towards further sustainability and innovation benefits as technology evolves.

Optimizing Carbon: Track, Analyze, and Reduce with Modern Tools

- To ensure your construction or land development project is truly sustainable, consider using Farmonaut’s Carbon Footprinting feature. This tool lets companies and land managers monitor and actively reduce their environmental impact with real-time emissions data—essential for compliance and eco-certification.

- For those seeking full supply chain transparency—particularly in tracking organic materials and eco-friendly building materials—blockchain-based traceability ensures every material’s journey, from soil or source to finished structure, is authentic and tamper-proof.

Technological Synergy: Farmonaut for Modern Soil & Carbon Management

At Farmonaut, our commitment to sustainability isn’t restricted to agriculture—it’s about optimizing resources at the intersection of organic soil amendments, carbon management, and data-driven construction materials stewardship.

- Satellite-Based Monitoring for Construction & Soil Health: Leverage our platform to monitor soil conditions on construction sites, enable reclamation, and maximize the benefits of organic soil amendments. This ensures every project leaves a positive impact.

- Resource Management: Our advanced management tools support optimized allocation and tracking of water, raw materials, and emission-intensive sources.

Learn more about our Fleet & Resource Management solutions to streamline logistics and cut operational emissions in both farming and construction supply chains.

For those managing plantation, forest, or diversified cropping projects alongside construction, our Plantation and Advisory App delivers actionable insights, ensuring healthy vegetation and soil on and around new infrastructure.

Nanomaterials in the Canadian Construction Industry: From Lab to Infrastructure

Let’s explore how nanomaterials in construction industry like graphene have moved from advanced research to the heart of modern industrial production:

- What are nanomaterials? – Particles or structures at the nanometer scale (one-billionth of a meter) that exhibit remarkable properties.

- Why is graphene special? – It’s composed of a single atomic layer of carbon arranged in a honeycomb lattice. In concrete, it delivers ultra-high strength and conductivity while remaining exceedingly lightweight.

- How is graphene concrete made? – By dispersing graphene nanoplatelets (GNPs) throughout the cement and water mix using specialized additive formulations, then batching as usual.

Case Applications in Canada

- Municipal projects—including road, bridge, and green infrastructure initiatives in British Columbia and across Canada—are pilot testing GNP technologies.

- Independent testing labs and university research affirm that graphene-enhanced concrete delivers the performance and CO2 reductions demanded by next-gen development.

- Companies are using bio-graphene technology—derived from renewable sources—to further bridge the gap between industrial scale and organic sustainability.

Industry trend: Within the next decade, expect graphene-based materials to transition from pilot project to market standard in Canadian and North American construction.

- Integrate climate and resource management into your systems with Farmonaut API Access for satellite and weather data.

- Explore API Documentation now to start building smarter, greener solutions.

FAQ: Sustainable Construction & Graphene Innovations

What are graphene concrete solutions?

Graphene concrete solutions refer to the integration of graphene or graphene nanoplatelets into concrete mixtures. This enhances the material’s performance, increases durability, and significantly reduces the carbon footprint of concrete used in the construction industry, especially within Canada’s rapidly growing markets.

How do graphene additives reduce CO2 emissions in concrete?

Graphene increases the strength and utility of concrete, enabling less cement to be used for every cubic meter produced. Since cement production is a major source of industrial CO2 worldwide, this reduction delivers significant emission cuts.

Is graphene concrete more expensive?

Upfront costs per cubic meter are slightly higher due to the addition of graphene. However, lifecycle assessments show lower repair, maintenance, material, and energy costs, making graphene concrete competitive or more affordable long term—particularly when considering CO2 savings and improved durability.

How does graphene-enhanced concrete help meet regulations?

Canadian and international regulators are tightening standards for CO2 emissions and sustainability. By using graphene concrete solutions, projects can meet or exceed these standards and support green infrastructure trends in Canada.

Can graphene technology be combined with other eco-friendly trends?

Absolutely. Many projects combine graphene concrete with organic soil amendments, sustainable sourcing, and advanced monitoring tools—such as those offered by Farmonaut—to ensure holistic climate and resource stewardship from ground to structure.

What makes Canada a leader in sustainable construction materials?

Canada’s focus on climate action, resource efficiency, and technological innovation, particularly in areas like British Columbia, positions it as a trendsetter for eco-friendly building materials worldwide.

Summary & Next Steps

The future of construction in Canada and North America is undeniably green. With the advent of graphene concrete solutions, we see a pivotal shift: strength, durability, and CO2-cutting all achieved in tandem. This evolution not only meets the demands of modern infrastructure but also aligns with wider global mandates for sustainability, making Canada a beacon for industrial eco-innovation.

Nanomaterials, especially graphene, are now central to the transition toward climate-smart construction. When combined with digital and organic approaches to soil and land stewardship—such as those enabled by Farmonaut’s cutting-edge satellite and AI-based solutions—Canada’s construction industry is fully equipped to meet the needs of tomorrow’s cities and ecosystems.

For construction professionals, civil engineers, architects, policymakers, and environmental thinkers: the journey to a net-zero construction landscape begins with embracing advanced materials and world-class digital tools for monitoring and resource management.

Start building smarter, greener, and stronger—right from the ground up.

Farmonaut Subscriptions

Farmonaut offers a range of subscription plans to support sustainable construction, eco-friendly agriculture, and resource-efficient projects across Canada and the globe. Our platform’s flexible pricing and comprehensive technology suite make it easy to scale precision monitoring and management for any operation.