Mining Dust Suppressant Market: Supply Chain & Exports

“Global mining dust suppressant exports are projected to grow by 8% annually, driven by advanced chemical formulations and supply chain innovations.”

Mining Dust Suppressant Market 2025: Overview & Outlook

The mining dust suppressant market,mining supply chain,mining exports, as we head into 2025, is evolving rapidly in response to the ongoing rise in demand for minerals and metals. As global mining activity continues to rise, the industry faces mounting pressure to optimize operational efficiency, maintain supply chains, and adhere to stringent environmental and health regulations.

One critical aspect that is often overlooked is dust suppression and management. Effective dust control has a direct impact not just on health and safety at mining sites, but also on equipment longevity, compliance, and ultimately the quality and reliability of mining exports.

In this comprehensive blog, we’ll explore:

- The significance of dust generation as an inherent byproduct of mining operations

- Upcoming market trends, technologies, and innovations revolutionizing dust suppression in 2025

- How effective suppression techniques critically improve the mining supply chain and facilitate export growth

- The impact of sustainability in gaining access to international trade markets

- The continuous role of companies like Farmonaut, providing satellite-based compliance and monitoring solutions for mining

Let’s delve deeper into the evolving landscape of the mining dust suppressant market, mining supply chain, and mining exports – and see how innovation, technology, and sustainability converge for a smarter, safer mining future in 2025 and beyond.

The Importance of Dust Suppression in Mining Operations

Dust generation is an inevitable aspect of mining activities, including drilling, blasting, crushing, and transporting ores. This inherent byproduct is not just a nuisance, but a critical environmental and operational challenge that affects the mining supply chain and mining exports at every stage.

Why is dust suppression so important in mining?

- Health Risks: Airborne particulates exacerbate respiratory illnesses (such as silicosis), cause severe long-term occupational health problems, and may even result in acute hazards during high-exposure events. Protecting worker health is central to operational safety and regulatory compliance.

- Site Safety: Dust clouds reduce visibility both above ground and in underground operations. This increases the likelihood of equipment accidents and production disruption.

- Equipment Longevity and Performance: Dust infiltrates engines, bearings, and other mechanical components, accelerating wear, corrosion, and downtime—directly raising operating costs and impacting the mining supply chain.

- Environmental Impact: Dust emissions degrade surrounding soil and vegetation, pollute water sources, and can threaten nearby communities—contributing to strained community relations, fines, and negative media coverage.

- Regulatory Pressures: Governments worldwide are imposing stricter dust emission thresholds, with robust enforcement in 2025 and beyond. Compliance is now a cornerstone for ongoing market access and export eligibility.

As demand for compliance and environmental stewardship intensifies, effective dust suppression systems are not optional—they’re fundamental to the global mining sector’s competitiveness, safety, and sustainability.

Market Trends & Innovations in Mining Dust Suppressant Technologies (2025)

The mining dust suppressant market,mining supply chain,mining exports ecosystem in 2025 is witnessing significant innovation.

Traditional water spraying methods—while still in use—are increasingly supplemented or replaced by:

- Advanced chemical suppressants: Formulated to bond dust particles, these solutions last longer than simple water, require fewer reapplications, and reduce overall water consumption.

- Eco-friendly polymers and bio-based additives: As sustainability becomes a market differentiator, more companies choose biodegradable, non-toxic products meeting international environmental standards.

- Technological integration: IoT-based, AI-driven and sensor-enabled spraying systems permit real-time monitoring and adaptive dosing. These technologies minimize waste, cut costs, and ensure continuous discharge control in line with regulatory requirements.

- Drone-based application: Drones can provide efficient, targeted delivery in areas with limited access or uneven terrain—helping optimize resource use and avoid excessive soil or water disturbance.

- Hybrid mechanical and chemical techniques: Mechanisms such as foam-based and gel-based dust suppression are gaining traction, especially for deep mining and hard-to-reach extraction processes.

These innovations not only improve the immediate effectiveness of dust suppression but also align with growing global scrutiny around environmental footprint and sustainability. In 2025, mining sites embracing smart solutions will remain competitive across global markets by ensuring consistent quality, safety, and efficiency.

“By 2025, over 60% of mining operations will adopt eco-friendly dust suppressant technologies to meet sustainability standards.”

Impact of Dust Suppression on Mining Supply Chain Efficiency

Supply chain efficiency is the lifeblood of modern mining operations and mining exports. Dust management, often underestimated, occupies a critical position in ensuring the seamless delivery of minerals from extraction to global export destinations.

How does effective dust suppression support the mining supply chain?

- Reducing downtime and equipment wear: Advanced suppressants prevent dust particles from entering motors, engines, and conveyors, thus extending equipment longevity and minimizing maintenance-related stoppages.

-

Preserving mineral quality:

Clean transport routes and enclosed, dust-controlled storage prevent cross-contamination and maintain mineral purity, ensuring each export shipment meets international quality standards. -

Optimizing transportation and logistics:

Suppressed dust reduces material loss (haulage spillage, windblown particulates) during rail, road, or ship transport—improving product integrity and lowering insurance claims across the supply chain. -

Complying with market access requirements:

Many importing nations, especially in Europe and North America, enforce strict regulations for dust and environmental emissions on mineral imports. Strong in-house suppression standards are now necessary to avoid rejections and border disputes. -

Enhancing stakeholder relations:

Proactive dust control minimizes local pollution, building goodwill with communities, workers, port authorities, and customs agencies—a non-tangible, yet critically important, supply chain asset.

In 2025, mining supply chain leaders will harness integrated dust suppression as a core operational strategy, not only for risk mitigation but also for creating a reliable ecosystem for growth and competitive advantage in mining exports.

Enhancing Mining Exports Through Sustainable Practices

Sustainability is now a defining metric for export competitiveness in mining, as importing nations, investors, and certification agencies scrutinize every aspect of the mineral supply chain—including dust suppression.

Eco-friendly and compliant dust suppressant technologies play a pivotal role in:

- Meeting global buyer requirements: Large buyers, especially those supplying automotive, electronics, and battery manufacturing, increasingly demand documentation of sustainable and safe extraction (blockchain-based traceability solutions from Farmonaut can provide vital access to these high-value markets).

- Reducing regulatory barriers: Compliance with international health, safety, and environmental standards helps companies avoid costly shipment rejections, penalties, or bans.

- Building corporate reputation: Visible, measurable efforts in dust suppression—along with emissions tracking using tools like Farmonaut’s carbon foot-printing—enhance trust among buyers, governments, and the public.

- Supporting sustainable development goals: Progressive dust control also supports local community health, soil rehabilitation, and biodiversity, which are key pillars of international SDG commitments.

By making sustainability an export asset, mining companies can command better prices, win long-term contracts, and access new global markets—fueling economic growth and supply chain resilience.

Comparative Technology Adoption & Market Impact Table: Mining Dust Suppressants (2025)

| Technology/Innovation | Estimated 2025 Adoption Rate (%) | Supply Chain Efficiency Improvement (%) | Export Growth Effect (%) | Sustainability Contribution (Qualitative Score) |

|---|---|---|---|---|

| Traditional Water Spraying | 30 | 10 | 5 | Low |

| Chemical (Salt-based) Suppressants | 35 | 18 | 8 | Medium |

| Eco-friendly Polymers & Bio-based Additives | 45 | 25 | 12 | High |

| Automated IoT-controlled Spraying Systems | 55 | 30 | 15 | High |

| AI-driven Adaptive Suppression (Predictive Dosing) | 28 | 33 | 17 | Very High |

| Drone-based Application Systems | 20 | 22 | 10 | Medium-High |

| Hybrid Mechanical/Chemical Suppression (Foam & Gel) | 18 | 28 | 9 | High |

| Blockchain-based Supply Chain Traceability* | 25 | 40 | 20 | Very High |

*Enhanced adoption possible when integrated with platforms such as Farmonaut Traceability.

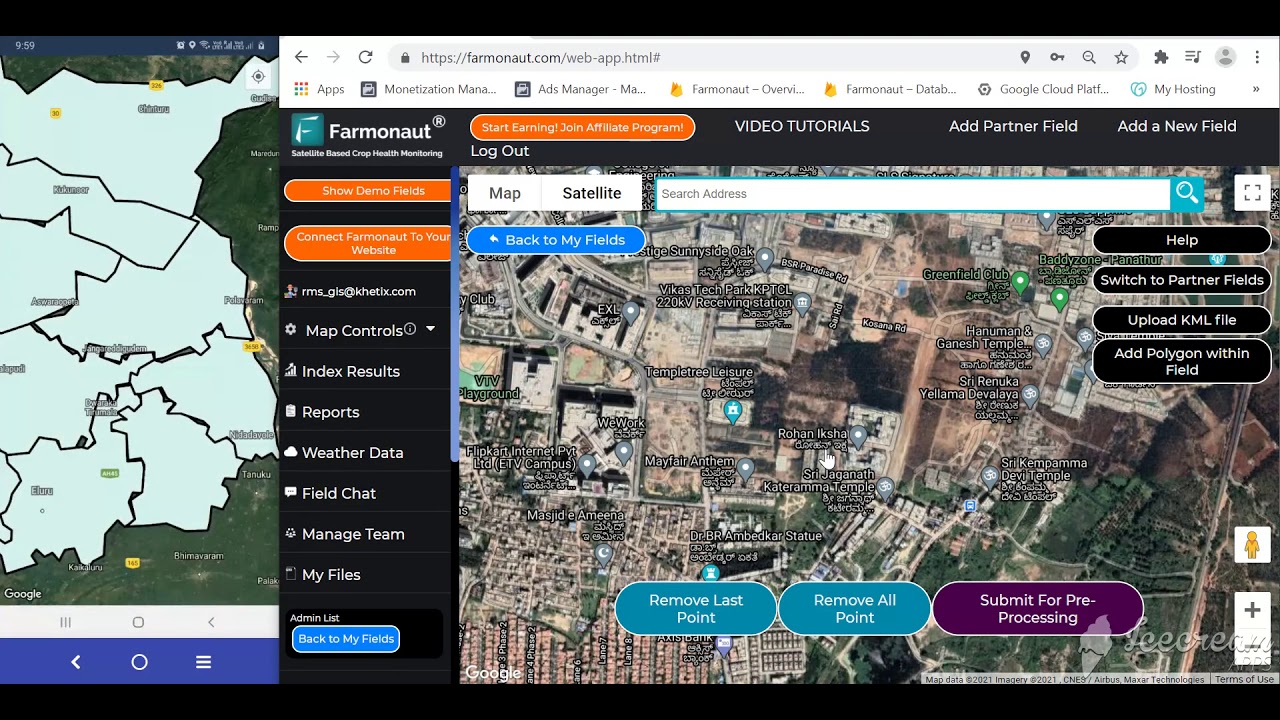

Farmonaut’s Role in Sustainable Mining Monitoring & Supply Chain Transparency

At Farmonaut, we understand that actionable data, compliance, and digital traceability are foundational to future-ready mining operations. While we do not manufacture dust suppressants, our satellite-based technologies contribute to the mining dust suppressant market,mining supply chain,mining exports in powerful ways:

- Satellite-Based Environmental Monitoring: Using multispectral images, we help mining companies monitor dust generation, vegetation health, water bodies and site changes over time—ensuring compliance with environmental standards.

- AI-powered Advisory (Jeevn AI): Our AI systems interpret environmental and weather data, guiding real-time dust suppressant application strategies to optimize efficiency and reduce water or chemical waste.

- Blockchain-Backed Traceability: Through traceability solutions, we enable transparent reporting at every supply chain stage, providing stakeholders and international buyers with irrefutable proof of sustainable practices.

- Fleet & Resource Management: Our fleet management tools optimize vehicle and equipment usage for suppressant application—cutting costs and carbon emissions.

- Carbon Footprinting: With our carbon footprint monitoring service, mining entities track and report dust-related GHG emissions, supporting ESG disclosures and sustainable market positioning.

- Regulatory & Compliance Assurance: Our data-driven insights enable companies to meet and exceed evolving local and international regulations for dust and emissions.

By integrating these solutions into the digital backbone of mining operations, stakeholders not only achieve safer, compliant, and environmentally friendly sites—but also unlock new opportunities in export markets worldwide.

Explore Farmonaut Subscription Plans

Outlook & Continued Challenges in the Mining Dust Suppressant Market for 2025

The outlook for the mining dust suppressant market,mining supply chain,mining exports is positive—but not without its challenges:

- Cost of Adoption: The up-front investment for advanced suppressant technologies, IoT spraying platforms, and compliance documentation can be significant—especially for small or mid-sized operations.

- Site Variability: Environmental conditions, ore composition, mining scale, and local water availability mean that suppressants must be tailored—requiring ongoing technical expertise.

- Water Resource Constraints: Many major mining regions now contend with water scarcity. This sharpens the focus on highly efficient, water-conserving technologies—an area where continuous innovation is crucial.

- Regulatory Complexity: Multiple jurisdictions and frequent updates demand that companies stay agile and data-driven to remain compliant and maintain export eligibility.

- Alignment with Export Standards: To benefit from booming international demand, mining companies need verifiable, digital proof of dust and emissions management throughout the value chain.

The combined forces of regulatory tightening, technological progress, and sustainability mandates are driving greater R&D investment, partnerships between mining suppliers and tech-providers, and the wider acceptance of “smart dust suppression” as an irreplaceable facet of the mining supply chain.

Frequently Asked Questions (FAQ): Mining Dust Suppressant Market, Supply Chain, & Exports

1. What is the mining dust suppressant market?

The mining dust suppressant market refers to the sector focusing on products, technologies, and systems designed to minimize dust emissions at mining sites. In 2025, this market encompasses advanced formulations and smart deployment mechanisms to ensure compliance, quality, and supply chain reliability for mining exports.

2. Why is dust suppression critical for mining operations?

Effective dust suppression protects worker health, reduces equipment wear, ensures site safety, and maintains high mineral quality throughout the mining supply chain. It is also essential for compliance with increasingly stringent environmental regulations worldwide.

3. How does dust suppression improve mining supply chain efficiency and exports?

By reducing health hazards, avoiding operational downtime, maintaining ore quality, and complying with export requirements, dust suppression increases the reliability and economic value of supply chains. It also helps secure market access and premium buyer contracts.

4. What are the latest trends in dust suppressant technology for 2025?

Key trends include eco-friendly polymer suppressants, IoT-based automated spraying, drone delivery, hybrid suppression techniques, and the growing use of blockchain for product traceability in export documentation.

5. How does Farmonaut help mining companies stay competitive in this market?

We provide satellite-based environmental monitoring, AI-powered advisory for suppression strategies, blockchain supply chain traceability, and carbon footprint tracking—all enhancing regulatory compliance, sustainability, and export readiness for mining operations.

Conclusion: Mining Dust Suppressant Market 2025 & Beyond – Optimizing the Mining Supply Chain, Compliance, and Export Growth

The rapid evolution of the mining dust suppressant market,mining supply chain,mining exports reflects far more than a regulatory checkbox; it signals a shift in the priorities of the mining industry for 2025—where advanced technologies, sustainability, and seamless supply chain integration are the gold standard.

By deploying effective suppressant solutions and leveraging smart monitoring tools, mining sector leaders advance:

- Safer, healthier worksites and nearby communities

- Reliability and quality across the mining supply chain

- Compliance and access to high-value international markets

- Efficient, sustainable, and profitable mining exports

As global pressure mounts and the demand for metals continues to rise, embracing digital innovation and environmental stewardship is no longer optional. Harnessing smart, eco-friendly suppression, traceability, and supply chain management will define success in mining’s new era.

At Farmonaut, we remain committed to making satellite-driven insights affordable and accessible for mining companies, businesses, and governments worldwide—empowering them to thrive in the next frontier of mining supply chain excellence.