Silage Advice: 7 Proven Steps for High-Quality Forage Yield

Meta Description: Discover the seven essential steps for high-quality silage production. Learn how to boost forage yield with expert advice on crop selection, optimal harvest timing, storage best practices, compaction, and modern technology to prevent silage spoilage and ensure nutrition for your livestock year-round.

“Harvesting silage at 32-35% dry matter can increase forage quality by up to 20%.”

Introduction: The Core Role of Silage in Livestock Nutrition

Silage serves as a preserved forage source that supports animal health and optimal productivity on livestock farms, especially during periods when fresh pasture or green fodder is unavailable. Its correct production preserves nutrition, safeguards against feed shortages, and enables year-round supply.

The quality of silage—shaped by crop selection, soil fertility, harvest timing, moisture content, compaction, storage, and feed-out practices—directly influences livestock performance. Expert guidance and utilizing technology give modern producers the edge to prevent spoilage, maintain optimal conditions, and boost feeding value.

In this comprehensive guide, we reveal the seven proven steps essential for producing high-quality silage. By adhering to these silage production strategies and integrating smart management practices, you’ll unlock maximum forage yield, minimize waste and spoilage, and provide superior nutrition for your herd all year round.

Step 1: Forage Crop Selection and Soil Fertility Optimization

Laying the Foundation for High-Quality Silage Production

The journey towards high quality silage starts with deliberate forage crop selection and soil fertility management. Below, we break down the critical considerations and best practices for soil fertility for silage crops:

-

Regular Soil Testing:

Continuous monitoring of soil nutrient levels (including pH) ensures a sound basis for silage crop growth. Schedule soil testing before every planting to assess nutrient availability and guide management. -

Balanced Application of Fertilizers:

Apply fertilizers based on test results and anticipated forage yield:- Nitrogen: 80-100 units per acre

- Phosphorus: 16 units per acre

- Potassium: 100 units per acre

- Sulfur: 16 units per acre

These applications propel rapid vegetative growth, ensuring bulk and nutrient density.

-

Crop Diversity:

Suitable crops for silage include corn, sorghum, high-sugar perennial grasses, and mixed legumes (like alfalfa). For example, alfalfa offers a valuable nitrogen credit, reducing synthetic nitrogen requirements and enhancing soil fertility. -

Optimal Soil pH:

Target a pH between 6.0-7.0. Acidic soils limit availability of nutrients and reduce forage yield. -

Rotation and Cover Crops:

Practice crop rotation and use nitrogen-fixing cover crops to maintain soil health and fertility over time.

Combined, these practices provide a strong foundation, improving forage crop selection, increasing potential yield, and supporting robust silage production.

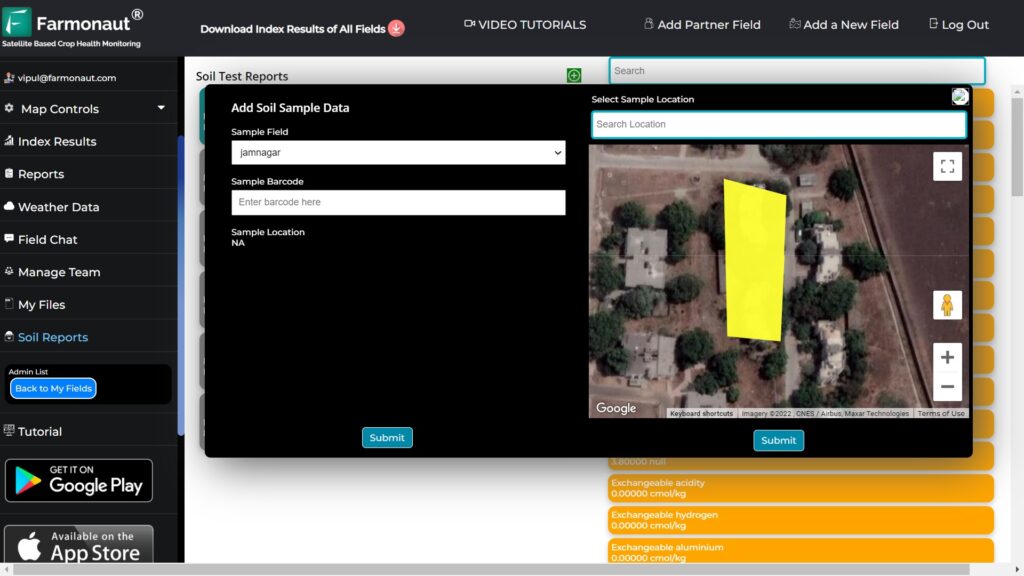

For even greater efficiency, satellite-based soil moisture monitoring available via platforms like Farmonaut Large-scale Farm Management can inform your fertilizer strategy, reduce costs, and optimize outputs, all while supporting environmental sustainability.

Step 2: Optimal Harvest Timing and Silage Moisture Content

Strategically Maximizing Yield & Preserved Forage Quality

Achieving high quality silage depends on precise optimal harvest timing for silage and controlling silage moisture content.

-

Monitoring Crop Maturity:

For corn and sorghum, harvest when kernels hit ½ milk line and plants reach 32–35% dry matter (about 65% moisture). For mixed grasses, heading but not flowering gives best digestibility and energy. -

Weather and Wilting:

Harvest during dry weather. Allow forages to wilt (typically 24 hours) to reach optimal moisture, but avoid over-wilting which causes digestibility losses. -

Target Moisture Ranges:

- Bunker/Pit Silage: 30–35% dry matter (65–70% moisture)

- Silage Bales: 40–50% dry matter

-

Avoiding Common Issues:

- Harvesting too wet promotes effluent and inadequate fermentation.

- Harvesting too dry (<35% dry matter) impedes consolidation and increases air penetration, spoilage, and heating risk.

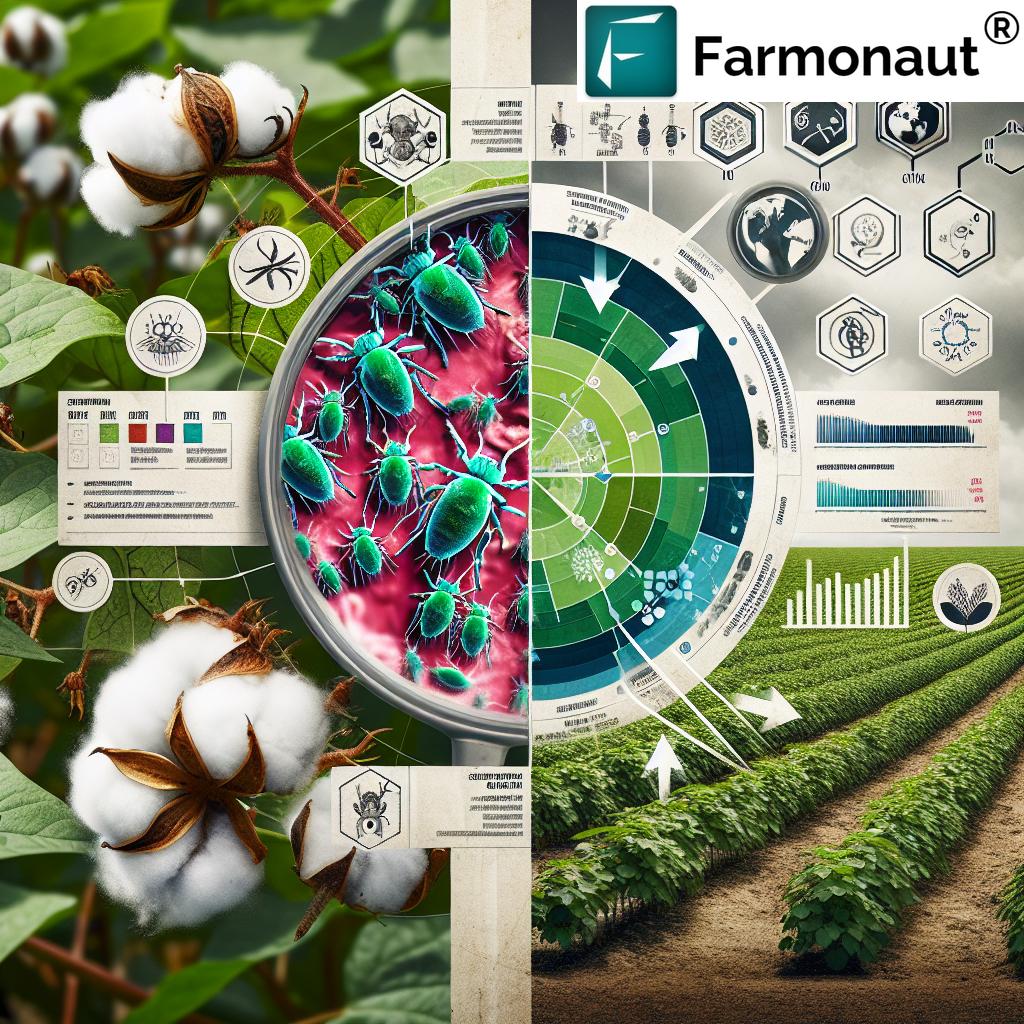

We recommend using satellite crop health monitoring tools (such as those found in Farmonaut Plantation and Forest Advisory) for real-time field assessment to determine harvest readiness and optimize timing.

Step 3: Using Inoculants for High-Quality Silage Fermentation

Promoting Rapid Fermentation and Spoilage Prevention

To improve the fermentation process and maintain high nutritive value in preserved forage, the application of inoculants is essential. These products introduce beneficial bacteria to outcompete spoilage organisms and drive lactic acid production, reducing the silage pH to levels that prevent harmful microbial activity.

-

Best Inoculant Practices:

- Apply at recommended rates directly onto chopped crops at ensiling.

- Store inoculants in a cool, dry place (heat or chlorine water can kill bacteria).

-

Benefits:

- Speeds up fermentation and preserves nutrients

- Reduces effluent and spoilage

- Improves silage stability during feed-out

Tip:

For maximum efficiency, integrate blockchain-based traceability for silage ingredient management and application records to ensure consistent and transparent quality control—an option available in Farmonaut’s solutions.

“Proper silage compaction reduces spoilage losses by as much as 15% compared to loose storage.”

Step 4: Silage Compaction Techniques and Storage Best Practices

Minimizing Air Ingress to Prevent Spoilage

Compaction and storage are pivotal in preventing silage spoilage and maintaining anaerobic conditions essential for quality preservation. Expertly executed silage compaction techniques substantially lower oxygen content, enabling lactic acid bacteria to swiftly stabilize the forage.

-

Tractor Weight & Packing Rate:

Use a tractor whose weight (in tons) matches the hourly forage delivery rate (in tons). For instance, packing 80 tons per hour requires an 80-ton machine for adequate compaction. -

Layer and Pack Evenly:

Distribute forage in thin (<5-inch) layers and drive over each pass multiple times to enhance density and reduce air. -

Immediate Sealing:

Cover silage piles or bunkers immediately after filling using high-quality, airtight plastic. Seal edges with weight (like sandbags or tires) to maintain anaerobic storage. -

Inspect for Tears & Punctures:

Regularly check and repair silage covers and plastic to prevent aerobic spoilage. -

Ideal Storage Location:

Store silage away from watercourses (minimum 10 meters) to prevent run-off and environmental contamination.

Advanced satellite monitoring (like that in Farmonaut) enables farm managers to oversee storage area conditions, identify high-moisture or poor-compaction zones, and improve consistency across silage production units.

Step 5: Feed-Out Practices to Preventing Silage Spoilage

Silage Storage Best Practices for Consistent Animal Nutrition

Proper feed-out is essential to preventing silage spoilage at the point of use and to maintain top forage quality throughout the year.

-

Face Management:

Create a clean, straight, vertical silage face. Avoid scooping inward, which allows air to infiltrate and causes spoilage. -

Consistent Removal Rate:

Advance the silage face in line with feeding—ideally, remove 15-30 cm (6-12 inches) daily to discourage aerobic conditions. -

Avoiding Delays:

Do not leave fresh faces exposed; use promptly to minimize oxygen exposure. -

Hygienic Location:

Feed and unwrap silage bales at least 10 meters from any water body to prevent runoff and contamination.

By following proper feed-out management, farmers reduce spoilage losses and maintain the nutritional integrity of the preserved forage for the animal’s benefit.

Step 6: Managing Silage Effluent for Environmental Protection

Reducing Pollution and Supporting Sustainable Practices

Unmanaged silage effluent represents major environmental and legal risks, given its high nutrient and organic acid concentrations. To prevent contamination of water sources and support regulatory compliance, it’s essential to:

-

Minimize Effluent at Source:

Harvest crops at optimum moisture and ensure adequate wilting to reduce liquid runoff. -

Cover Storage Facilities:

Install a roof or use quality covers to prevent rainwater infiltration into silage clamps, reducing total effluent volume. -

Contain and Collect Effluent:

Design and maintain containment systems for effluent; check regularly for leaks or overflow. -

Land Application:

Dilute effluent and apply as fertilizer, following local guidelines to avoid crop damage or nutrient overloading. -

Distance from Water Sources:

Store silage and effluent facilities at least 10 meters from watercourses.

Our carbon footprinting tools (see Farmonaut Carbon Footprinting) empower farms to quantify—and demonstrably reduce—their environmental impact, aligning with both production goals and responsible stewardship.

Step 7: Monitoring Silage Quality and Utilizing Technology

Data-Driven Decisions to Enhance Forage Value, Prevent Issues, and Optimize Livestock Health

Ongoing monitoring silage quality guarantees that your feed meets livestock nutritional needs and identifies process improvements. Optimal management involves:

-

Laboratory Analysis:

Test for parameters such as dry matter, protein, fiber, energy, acidity (pH), and fermentation products. -

Visual and Temperature Checks:

Monitor for signs of spoilage—mold, discoloration, odors, and heating. -

Technology Integration:

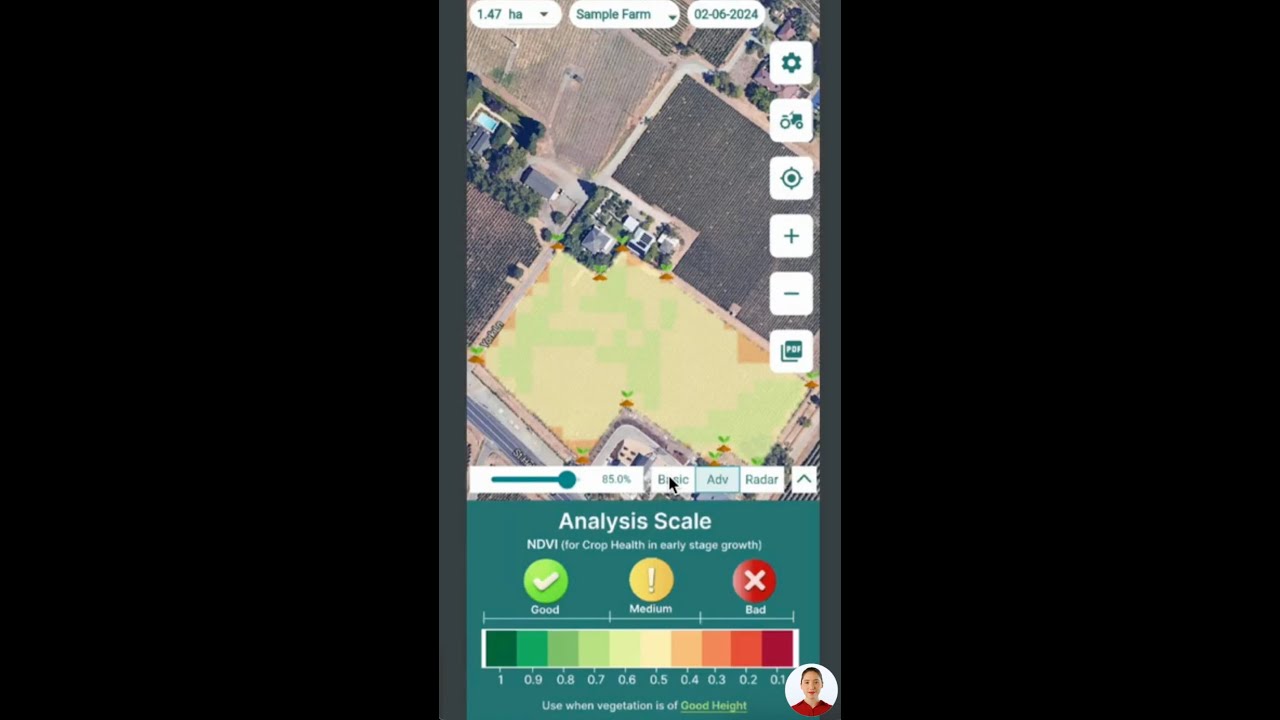

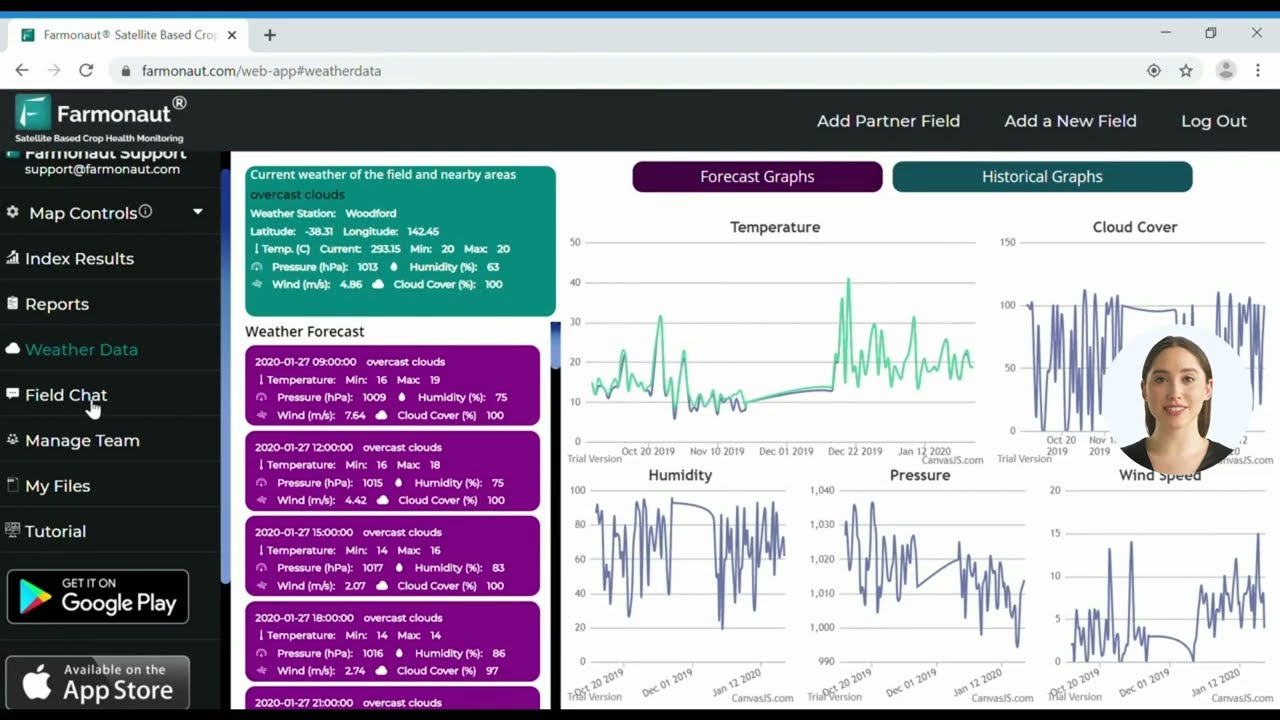

Leverage platforms such as Farmonaut for:- Satellite-based crop health and moisture monitoring—optimizes harvest timing & field management

- Fleet & Resource Management—(Farmonaut Fleet Management) tracks machinery and logistics for time-critical operations

- Data Centralization—records, reports, and supports continuous improvement across silage production years

-

AI-Based Advisory:

Utilize AI and machine learning to obtain personalized, real-time intervention suggestions, weather outlooks, and troubleshooting solutions.

Through such monitoring and the application of modern technology, you pre-empt issues and ensure your forage source consistently sustains optimal animal health and productivity.

Stepwise Silage Quality Optimization Table

| Step No. | Step Description | Recommended Practices | Estimated Yield Improvement (%) | Spoilage Risk Reduction |

|---|---|---|---|---|

| 1 | Crop Selection & Soil Fertility | Soil testing, balanced fertilization (N, P, K, S), inclusion of legumes like alfalfa | +10-15% | Low |

| 2 | Harvest Timing & Moisture Content | Harvest at crop-specific maturity, target DM & moisture, timely wilting | +10–20% | Medium |

| 3 | Use of Inoculants | Apply correct bacteria at ensiling, avoid heat/chemical damage | +6-10% | High |

| 4 | Compaction & Storage | Adequate layer packing, tractor/tonnage matching, immediate sealing | +10-16% | High |

| 5 | Feed-Out Practices | Clean face, consistent removal, hygiene, distance from water | +5-7% | Medium |

| 6 | Effluent & Environmental Mgmt | Effluent containment, harvest/wilt, covered storage, land application | +3-7% | Medium |

| 7 | Monitoring & Technology | Labs, visual/temperature checks, satellite/AI data, record-keeping | +8-12% | High |

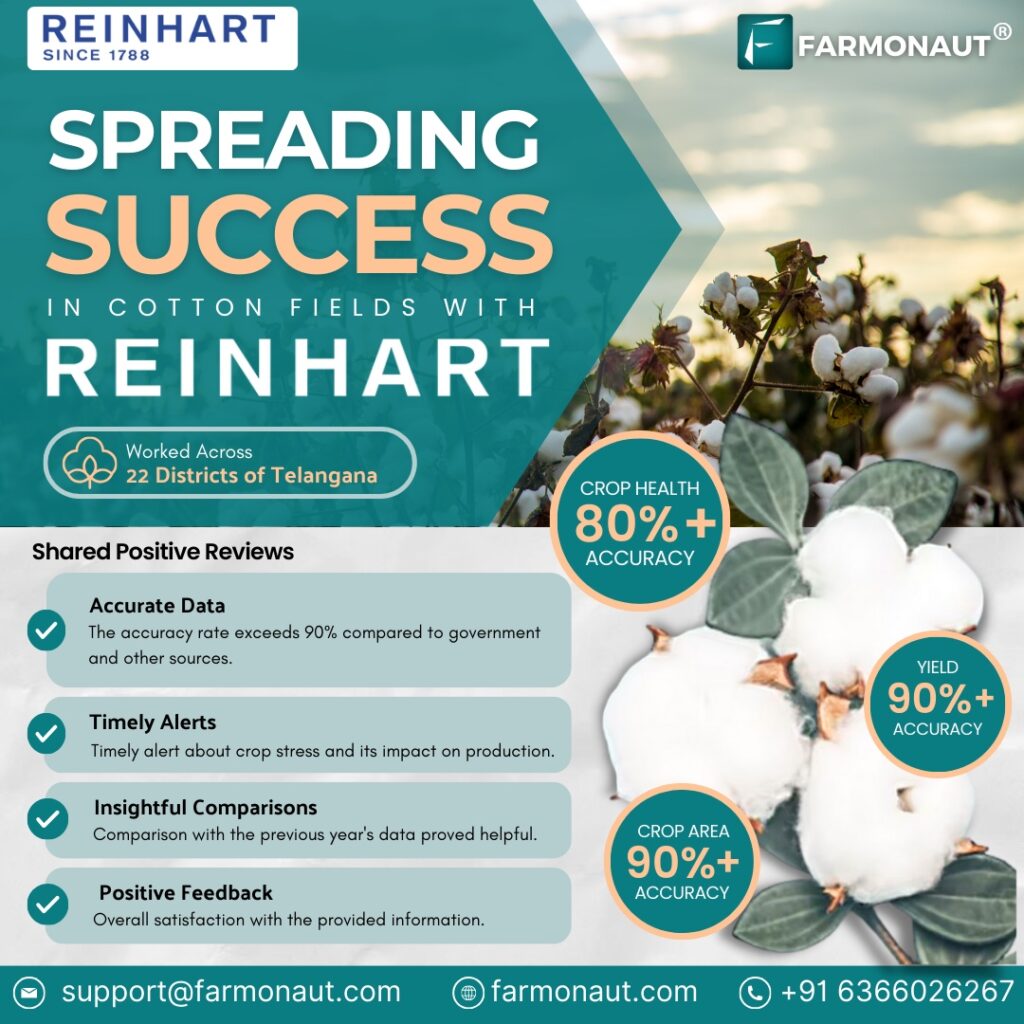

Harnessing Technology: Farmonaut’s Role in Silage Quality Enhancement

Modern silage production continues to evolve as technology becomes more integrated with traditional management practices. At Farmonaut, we believe advanced technology is the key to unlocking consistently high-quality silage and maximum on-farm profitability. Here’s how utilizing technology through our platform transformation empowers every stage of the silage process:

-

Satellite-Based Crop Health Monitoring:

Our system uses multi-spectral satellite imagery for real-time crop health assessment, soil moisture monitoring, and harvest readiness evaluation. This allows you to perfectly time your harvest, enhancing forage quality and reducing resource wastage. -

AI-Powered Farm Advisory (Jeevn AI Advisory):

Offers personalized, data-driven recommendations to optimize field activities, fertilizer application, irrigation, and crop selection. -

Blockchain-Based Supply Chain Traceability:

Transparency and integrity in the silage ingredient journey ensures consistent quality control, a crucial step for high-value farm clients and the feed industry.

Learn more about Farmonaut Traceability solutions. -

Fleet and Resource Management:

Track tractor movements, harvesting equipment, and logistics to improve efficiency in silage compaction, transport, and storage.

See how fleet management optimizes your workflow. -

Farm Management Apps (Web, Android, iOS):

Access insights, receive alerts, and manage every stage of the silage lifecycle from your smartphone or desktop.

Try out our mobile & web apps above for hands-on management. -

API Access & Integration:

For agribusinesses, developers, and large-scale managers, Farmonaut provides open API endpoints with developer documentation for direct system integration and advanced analytics. -

Carbon Footprinting & Resource Optimization:

Quantify emissions and improve sustainability of your silage production—meet regulatory requirements and boost your environmental credentials.

Our goal at Farmonaut is to make precision agriculture affordable, scalable, and practical—ensuring you maintain top silage quality year after year.

Farmonaut Subscription Options

Get started with our precision agriculture solutions and transform your silage production process:

FAQ: Silage Production and Quality Optimization

-

What is the ideal moisture content for high-quality silage?

The ideal moisture content is approximately 65% (or 32-35% dry matter) for silage destined for bunkers or pits. For baled silage, 40-50% dry matter is recommended. -

Which nutrients are most important for silage crop production?

Nitrogen, phosphorus, potassium, and sulfur are key elements for forage crops. Typical applications per acre are 80-100 units of nitrogen, 16 units of phosphorus, 100 units of potassium, and 16 units of sulfur. Regular soil testing and the inclusion of legumes such as alfalfa can optimize results and provide natural nitrogen credits. -

How can I prevent spoilage in stored silage?

Preventing silage spoilage relies on tight compaction, immediate sealing (with quality covers), maintaining anaerobic storage conditions, and minimizing the aerobic exposure at face during feed-out. -

Are silage inoculants necessary?

While not always mandatory, inoculants help establish beneficial bacteria that improve fermentation, reduce spoilage organisms, and stabilize silage—especially valuable for challenging crops or non-ideal conditions. -

Can satellite imagery and technology truly enhance silage quality?

Yes. Technology like Farmonaut’s platform provides objective data on crop health, soil moisture, and harvest readiness, leading to better-timed harvests, optimized interventions, and ultimately, improved silage quality and reduced losses. -

What environmental risks are associated with silage?

The primary risks are from silage effluent runoff, which can contaminate water sources due to its high nutrient and organic acid load. Proper containment, wilting, and storage at safe distances address these concerns. -

Is there a way to monitor silage quality after storage?

Regular visual checks, temperature readings, and laboratory analyses (for dry matter, protein, energy, pH) are important to ensure your silage stays in top condition until feed-out.

Conclusion: Ensuring High-Quality Silage Year-Round

The journey to producing high quality silage is both science and art—requiring attention to crop and soil, harvest and storage timing, compaction, fermentation, and practical management from planting to feed-out. By following these 7 proven steps, integrating precision monitoring and leveraging innovative technologies like those available through Farmonaut, you’ll ensure your preserved forage source remains a reliable anchor for livestock nutrition and productivity.

Remember—monitor every parameter, respond quickly to emerging issues, and continually improve your practices using data and expert advice. This is the path to unlocking the highest returns for your farm, preventing spoilage, and supporting healthy, productive herds throughout the year.