Used Harvesting Equipment: 7 Ways to Boost Efficiency

Table of Contents

- Introduction: The Role of Harvesting Equipment in Agriculture

- Harvesting Equipment Trends and Innovations

- Types of Harvesting Equipment and Their Efficiency

- Comparison Table of Used Harvesting Equipment Types

- 7 Ways to Boost Efficiency with Used Harvesting Machinery

- Buying Used Harvesting Equipment: Key Considerations

- How Farmonaut Supports Efficient, Sustainable Harvesting

- FAQs on Used Harvesting Equipment

- Conclusion

Introduction: The Role of Harvesting Equipment in Agriculture

Harvesting equipment lies at the heart of modern agriculture, farming, and forestry operations. These machines streamline the collection of crops and timber, replacing laborious manual processes with mechanized efficiency. Whether you are managing grain fields, sugar plantations, livestock feed supply, or forestry sites, choosing the right equipment—especially used harvesting machinery—can drive operational productivity, reduce costs, and improve the speed of harvest cycles.

With agricultural machinery continuously advancing due to automation, electronic monitoring, and precision agriculture technology, the acquisition of used harvesting equipment has become a cost-effective, sustainable alternative to buying new machinery—provided buyers make informed decisions.

In this comprehensive guide, we explore essential trends, the spectrum of harvesters, expert buying considerations, and actionable tips to ensure that your next used equipment investment not only brings the expected efficiency and savings but also supports the needs of your specific agricultural operations.

Harvesting Equipment Trends and Innovations

The global agriculture sector is experiencing a pivotal shift due to and technology and innovative solutions revolutionizing how farming is done. Here are the major trends influencing the efficiency and capabilities of both new and used harvesting machinery:

- Automation & Robotics: Autonomous machines are reducing the demand for manual labor, streamlining large-scale crop collection, and improving consistency in performance. Automated crop harvesting increases efficiency and reduces operational costs.

- Precision Agriculture Technology: Modern harvesting machines are integrating sensors, GPS, and data connectivity—enabling farmers to optimize harvesting workflows, monitor yield, and track machine performance in real time for maximized efficiency.

- Sustainability: As the agriculture industry prioritizes sustainability, an increasing number of manufacturers are deploying hybrid and electric engines and developing equipment with lower fuel consumption and reduced emissions.

- Connectivity & Data Analytics: With real-time monitoring and telematics, farmers access actionable insights about equipment health, hydraulic systems, and service requirements.

By understanding and leveraging these technological advancements, farmers can unlock the full potential of both modern and pre-owned harvesting equipment.

Types of Harvesting Equipment and Their Efficiency

Selecting the optimal type of harvesting equipment for your farm or forestry operation is essential for maximizing productivity, lowering costs, and accommodating specific operational needs. Below, we outline key harvester types, their features, and how they boost collection speed and crop yield.

1. Combine Harvesters

- Versatile machines that manage a variety of grain crops (wheat, rice, oats, corn) in a single pass.

- Combine harvester features include electronic monitoring systems, advanced threshing, automated settings, and real-time yield reporting.

- Drastically reduce labor requirements and increase throughput.

2. Feller Bunchers

- Specialized forestry machines that cut and gather (bunch) trees simultaneously for logging operations.

- Replace manual tree-felling and increase productivity in timber collection.

- Equipped with tree-grabbing devices and cutting mechanisms for efficient bulk operations.

3. Forage Harvesters

- Collect forage crops such as corn silage and grasses for livestock feeding.

- Chop forage into small pieces for easy storage and consistent feed supply.

- Modern forage harvesters utilize advanced chopping mechanisms for higher efficiency and productivity.

4. Cotton Pickers

- Mechanically harvest cotton using spindles or fingers to pick bolls from plants.

- Accelerate harvesting speed, reduce manual labor, and offer more consistent yield.

5. Sugar Cane Harvesters

- Integral in sugar cane regions; efficiently cut and strip cane stalks using powerful cutting heads.

- Decrease physical strain on labor and shorten the harvest cycle.

6. Grape Harvesters

- Automate the collection of grapes, using gentle handling to keep grape quality intact for winemaking.

- Critical for preserving grape integrity in high-quality wine regions.

7. Potato Harvesters

- Dig up and lift potatoes from the soil, with varying mechanism designs adapted to field requirements.

- Reduce physical labor and effectively streamline potato harvesting operations.

Comparison Table of Used Harvesting Equipment Types

7 Ways to Boost Efficiency with Used Harvesting Equipment

-

Leverage Cost Savings for Technology Upgrades

With lower upfront investment, buying used harvesting equipment enables farms to redirect funds toward integrating technology—such as GPS, sensors, and precision agriculture technology—even in pre-owned units. Many used machines can be retrofitted with new control modules, monitoring systems, or automation add-ons for improved productivity. -

Reduce Depreciation and Preserve Value

New equipment depreciates quickly within the first few years. Used harvesting machinery offers a better return on investment, as much of the depreciation has occurred, and value retention is higher compared to brand new purchases. -

Accelerate Deployment with Ready Availability

Most used harvesting machines are available for immediate delivery, which is invaluable during short windows at harvest cycle peaks. Unlike new orders, which may face manufacturer delays or supply chain backlogs, used machinery enables farmers to keep up with demanding harvest schedules. -

Repurpose Versatile Equipment for Diverse Crops

Combine harvesters, forage harvesters, and certain pickers are engineered for adaptability across different crops. By selecting modular or multi-crop-compatible used machines, operators can enhance utility, manage varied operations, and reduce the need for multiple dedicated units. -

Maximize Operational Flexibility and Scale

With lower equipment acquisition costs, farms can increase fleet size or introduce additional harvesters into the field, distributing labor, scaling operations quickly, and minimizing machinery bottlenecks during peak collection periods. -

Utilize Availability of Spare Parts and Attachments

Popular used harvesting equipment models often have established market availability of replacement parts, attachments, and accessories—supporting easy customization, reduced downtime, and cost-effective repairs. -

Capitalize on Experience and Proven Reliability

Pre-owned harvesting machines from reputable brands have a history of operational reliability, with well-documented maintenance records and proven field performance. This accumulated data supports sound purchasing decisions and helps minimize risk.

Buying Used Harvesting Equipment: Key Considerations for Reliability and Suitability

Before finalizing any acquisition of used harvesting machinery, it is vital to assess factors that ensure the chosen equipment meets operational requirements, offers cost-effective performance, and remains reliable over the long term.

-

1. Equipment Maintenance and Inspection

Before purchasing, perform a thorough inspection for signs of wear, corrosion, fluid leaks, or frame stress. Request full maintenance records. Consistent servicing and timely part replacements are hallmarks of reliable used equipment. -

2. Compatibility & Technology Features

Ensure the harvesting machine is compatible with your existing attachments, transport equipment, and—if applicable—precision agriculture systems. Confirm if older units can accommodate modern monitoring tech and electronic modules for future upgrades. -

3. Hydraulic System Health

Hydraulic leaks or contamination can signal costly repairs. Inspect cylinders, motors, and fluid reservoirs for contamination and pressure stability. Healthy hydraulics are crucial for harvesters relying on mechanisms for cutting, feeding, or mobility. -

4. Availability of Replacement Parts

Confirm that spare parts for your specific make and model are easily sourced domestically. Inquire about aftermarket and OEM suppliers to safeguard against future downtime delays. -

5. Warranty Options & Aftermarket Support

Some sellers provide a short-term warranty or enable buyers to purchase third-party coverage. This provides needed peace of mind. Investigate available technical support and operator training if transitioning to new equipment models.

By following these core equipment maintenance and inspection steps, you will maximize the operational lifespan, productivity, and efficiency of your investment.

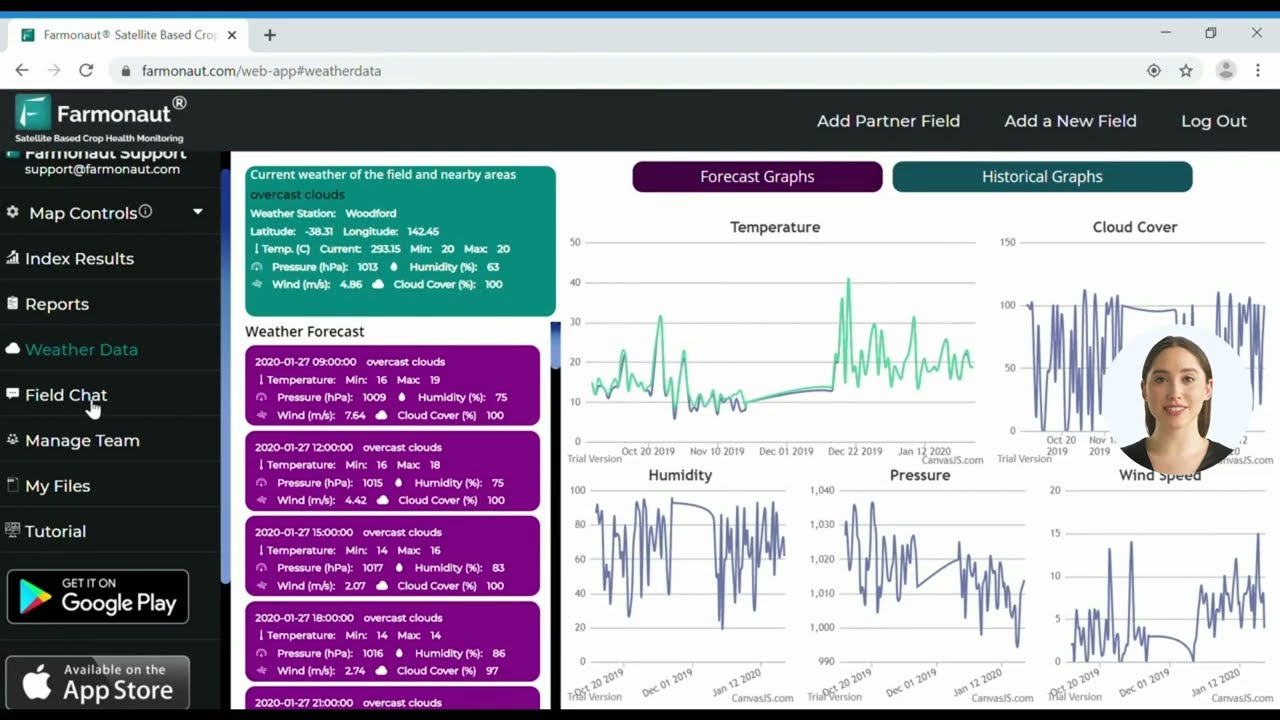

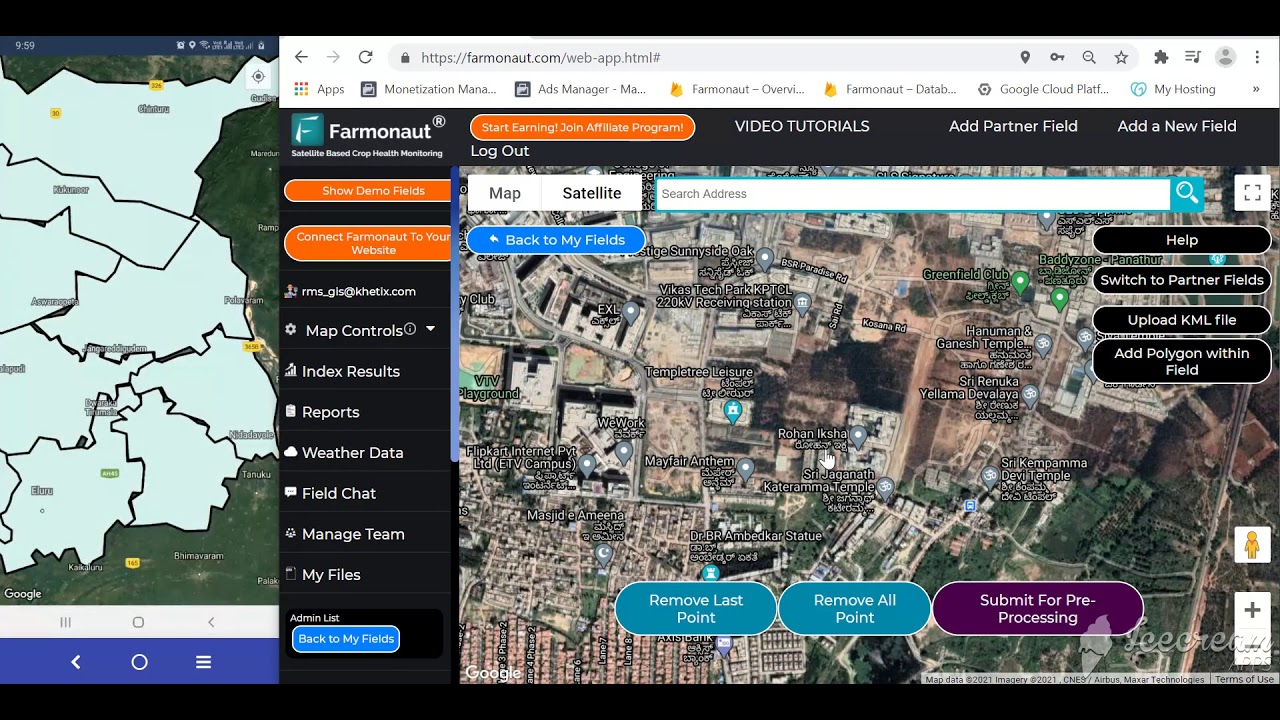

How Farmonaut Supports Efficient, Sustainable Harvesting Globally

At Farmonaut, our mission is to democratize precision agriculture technology—making advanced, data-driven farming accessible and affordable for farmers and agribusinesses worldwide. We do this through a robust suite of digital, satellite-driven solutions that enhance the efficiency and sustainability of farm and forestry operations. Here’s how our technologies support the entire equipment lifecycle and harvesting workflow:

-

Satellite Crop Health Monitoring

We offer real-time crop health monitoring via our app and API. By leveraging multispectral imagery and actionable insights, farmers can optimize irrigation, fertilizer resource allocation, pest management, and even harvest timing—drastically improving yield and reducing inputs. -

AI-Based Farm Advisory (Jeevn AI)

Our proprietary Jeevn AI provides custom, real-time advisory—ranging from weather trends to expert crop management strategies—so you make the most of your machinery and land, no matter which harvester or crop you rely on. -

Blockchain Product Traceability

For food, cotton, forestry, and allied sectors, our traceability platform tracks all stages of the product journey—building trust and transparency between farms and end consumers.

Learn about Farmonaut’s Product Traceability system—critical for crops that require stringent supply chain documentation. -

Fleet and Resource Management

Our platform reduces operational costs by optimizing agricultural machinery and fleet workflows. Practical for those running multiple used harvesters or diverse heavy machinery fleets. -

Carbon Footprinting Tools

Track, analyze, and reduce your operation’s environmental impact with our easy-to-use carbon emission tracking modules.

Explore Farmonaut Carbon Footprinting—a must-have for ensuring harvesting operations meet modern sustainability standards. -

Subscription Model

Our farm management tools are accessible on Android, iOS, Web, and via API. Flexible, scalable, and affordable for single farmers to large-scale agribusinesses and government institutions:

By integrating Farmonaut’s advanced solutions, operators of used harvesting equipment can achieve the same—or greater—efficiency as those using new machinery, while promoting long-term operational sustainability and profitability.

Frequently Asked Questions: Used Harvesting Equipment & Efficiency

Used equipment provides up to 30–50% cost savings, reduced depreciation, immediate availability, and the capacity to invest in additional upgrades like sensors and precision ag modules.

Q2. How do I evaluate the condition of a used combine or forage harvester?

Inspect for frame damage, hydraulic leaks, wear on threshing/feeding parts, and engine integrity. Request a service log and test electronic features (such as auto-steering, monitoring, or yield reporting) before purchase.

Q3. Are replacement parts and attachments widely available for older harvesting machinery?

Yes, for popular models, the availability of spare parts is typically high through dealer networks or aftermarket suppliers. Verify supplier coverage prior to committing to a unit.

Q4. Can I retrofit older used harvesters with modern technology?

Many used harvesters can be upgraded with GPS, auto-steer systems, and electronic sensors—unlocking substantial efficiency gains at a reasonable investment.

Q5. How can Farmonaut help maximize my harvesting equipment’s efficiency?

Our satellite-based platforms deliver real-time crop health data, enable AI-based advisory, and offer integrated fleet/resource management tools to help you monitor, schedule, and optimize all harvesting activities with data-driven accuracy.

Conclusion

The thoughtful acquisition of used harvesting equipment enables agricultural operators, large and small, to substantially reduce machinery costs, increase harvesting speed, and adopt cutting-edge technology and data-driven practices for better efficiency and sustainability.

From combine harvesters and forage harvesters to advanced feller bunchers and specialty grape pickers, understanding machine features, maintenance requirements, and available upgrades is key for maximizing return on investment. By following our comprehensive equipment maintenance and inspection checklist, you ensure reliability and operational readiness throughout every harvest.

We recommend leveraging the full power of digital platforms—such as those from Farmonaut—to access real-time data, streamline resource management, promote transparency, and ensure your equipment investments deliver sustained value for years to come.