Spraying Machine for Agriculture: 7 Top Types & Uses

“Over 70% of modern farms use precision spraying machines to optimize pesticide and fertilizer application.”

“There are 7 main types of agricultural sprayers, each designed for specific crops and field conditions.”

Introduction: The Role of Spraying Machines in Modern Agriculture

Modern farming has undergone a rapid transformation, driven by advanced technology and the urgent need for sustainable and efficient food production. At the heart of this transformation are agricultural spraying machines—tools designed to enhance the efficient application of pesticides, herbicides, fungicides, and fertilizers across different types of farms and operations.

As farms expand and sustainability becomes a global priority, the days of imprecise manual application and excessive chemical use are largely behind us. The evolution of sprayers—from simple handheld devices to automated, GPS-driven machines—reflects the industry’s focus on efficiency, safety, precise control, and optimal crop yield.

This comprehensive guide explores the 7 top types of agricultural spraying machines, describing their unique uses and providing actionable tips on maximizing their benefits. Along the way, we’ll touch upon the critical role of precision spraying technology, nozzles, and smart equipment maintenance—arming you with everything needed to modernize your agricultural operations.

Types of Agricultural Spraying Machines: The Essential Farm Sprayer Types

Let’s dive into the technologies, applications, and unique capabilities of today’s most important farm sprayer types. Whether managing a small garden patch or a vast commercial field, there’s a spraying machine tailored for every farming operation.

1. Handheld Sprayers & Backpack Sprayers for Farming

Handheld sprayers and backpack sprayers for farming are widely recognized for their portability and ease of use—ideal for gardens, orchards, and spot treatments.

- Lightweight and compact, these machines are perfect for small-scale operations or areas with difficult access.

- Backpack sprayers are worn on the back, distributing the weight for comfort during prolonged applications; they’re a favorite for maintenance on orchards or vegetable patches.

- Commonly used for targeted herbicides, insecticides, fungicides, and even liquid fertilizers.

- Offer precise coverage and conserve chemicals by minimizing overspray.

Use Case Example: Imagine weeding between delicate crops or targeting pests in a greenhouse—these sprayers enable precision while minimizing environmental impact.

2. Tractor-Mounted Sprayers for Efficient Field Coverage

For larger areas, tractor-mounted sprayers offer substantial upgrades in terms of tank capacity, coverage, and flexibility:

- These machines attach to tractors, and are equipped with spray booms that can be adjusted for height and width.

- Allow for even distribution of chemicals across wide swathes of fields.

- Integration with GPS technology and variable rate controls ensures optimized application and reduced chemical waste.

- Perfect for row crops like corn, soybeans, and wheat.

These sprayers are essential for farmers looking to maximize productivity while ensuring safe, efficient, and even coverage of their crops.

3. Self-Propelled Sprayers: Advanced Precision for Large Farms

Self-propelled sprayers represent the cutting-edge in precision spraying technology:

- They are engineered to travel between rows of crops without causing soil compaction, thanks to refined chassis design.

- High operational speed and the integration of automated steering and variable rate controls maximize both efficiency and accuracy.

- Advanced nozzles and flow controls enable optimal coverage with minimal drift, even at high speeds.

- Ideal for large commercial farms and operations aiming for full automation in labor-intensive processes.

Due to their size and complexity, these machines tend to be a larger investment, but the improvements in application rate, coverage, and precision often justify their cost for substantial operations.

4. Aerial Sprayers & Aerial Spraying Drones

For vast fields, rugged terrains, and urgent applications, aerial sprayers—including fixed-wing aircraft, helicopters, and drones—deliver precise chemical coverage from above.

- Aerial spraying drones are gaining ground due to their ability to maneuver low and slow, even in irregular rows or wet soil conditions.

- Enable rapid application across large areas and hard-to-reach plots, with minimal disruption to the field below.

- Advanced GPS integration ensures automated routes, accuracy, and minimal chemical drift.

- Often used for rice paddies, large cereal crop fields, or locations where tractors or self-propelled machines cannot operate efficiently.

- Establish a new benchmark in labor-saving farming technology.

Note: While highly efficient, aerial sprayers require substantial investment, permits, and operator training to ensure safe, legal use and compliance with environmental regulations.

5. Boom Sprayers for Crops: Uniform Coverage at Scale

Boom sprayers for crops are among the most reliable and widely used types of agricultural spraying machines in medium-to-large field operations.

- Booms equipped with multiple nozzles distribute chemicals evenly over wide areas for maximum coverage and minimal waste.

- The configuration can be tailored by adjusting the boom width and height, ensuring precise application for various crops.

- Perfect for cereal crops, oilseeds, pastures, and even large lawns or golf courses.

- Minimize worker exposure and enhance operational speed compared to manual spraying methods.

They offer high flow rates, customizable nozzle types, and material compatibility for a wide range of farming applications.

6. Airblast Sprayers: Best for Orchards and Vineyards

When it comes to achieving thorough coverage in dense foliage, airblast sprayers are the preferred choice, especially for orchards and vineyards.

- Use powerful air streams generated by fans to disperse droplets into the crop canopy, ensuring chemicals penetrate dense growth.

- Essential for tree fruits, grapevines, and nut orchards where high droplet coverage is required on both upper and lower leaf surfaces.

- Deliver precise application with less liquid, saving water and minimizing runoff.

- Reduce labor needs compared to manual or backpack options in perennial crop environments.

Modern airblast sprayers offer adjustable airflow and nozzle options, making them highly adaptable and efficient in specialized horticultural operations.

7. Mist Blower Sprayers: High Efficiency with Reduced Liquid Consumption

- Mist sprayers deliver accurate coverage while using less liquid, ideal in settings such as orchards, perennial crop fields, or greenhouses.

- Attached to tractors or designed as portable backpack units for spot or small-plot applications.

- Highly effective for pesticide and fungicide application where thorough, yet gentle coverage is needed.

Built for both open-field crops and protected growing environments, mist blowers ensure every part of the plant receives adequate protection with minimal chemical drift.

Other Types Worth Mentioning: High-Pressure & Low-Volume Power Sprayers

- High-pressure power sprayers: Deliver very fine droplets at elevated pressure, ideal for finishing and specialized applications such as in greenhouses or for covering large vertical surfaces efficiently.

- Low-volume power sprayers: Use technology to minimize chemical usage while maintaining or enhancing effectiveness. Perfect where environmental impact reduction is a major goal.

The broad range of agricultural spraying machines enables every farmer to find suitable equipment that matches their area, crops, and operations precisely.

Comparison of Agricultural Spraying Machines

| Machine Type | Key Uses | Suitable Crops | Estimated Coverage Area (ha/hr) | Precision Level | Average Price Range (USD) | Main Advantages |

|---|---|---|---|---|---|---|

| Handheld/Backpack Sprayers | Spot treatments, gardens, orchards, manual applications | Vegetables, fruit trees, small row crops | 0.1 – 0.5 | High | $25 – $250 | Portable, precise, cost-efficient for small areas |

| Tractor-Mounted Sprayers | Row crops, cereals, large coverage fields | Wheat, corn, soybean, maize | 2 – 10 | Medium-High | $900 – $8,000 | Large tank, automation ready, even coverage |

| Self-Propelled Sprayers | Extensive fields, rapid treatments, precision application | Commercial cereals, pulses, fiber crops | 10 – 25 | High | $50,000 – $250,000+ | Maximum efficiency, automated steering, GPS integration |

| Aerial Sprayers (inc. Drones) | Quick, remote, and large-area coverage | Rice, wheat, cotton, mountainous or wet terrain crops | 20 – 150 (aircraft); 5 – 15 (drones) | High | $2,000 – $500,000+ | No ground compaction, covers rough terrains, labor saving |

| Boom Sprayers | Uniform field coverage, cereals, pastures | Cereals, grains, golf courses | 5 – 20 | Medium-High | $1,000 – $10,000 | Even application, customizable widths, labor efficient |

| Airblast Sprayers | Dense foliage, orchards, vineyards | Fruit trees, grapes, nuts | 2 – 7 | High | $3,000 – $30,000 | Penetrates canopy, thorough coverage, reduces runoff |

| Mist Blower Sprayers | Pesticide/fungicide application, wide & vertical coverage | Orchards, vegetables, greenhouse crops | 1 – 4 | High | $250 – $7,000 | Fine mist, low liquid use, optimal droplet size |

“Over 70% of modern farms use precision spraying machines to optimize pesticide and fertilizer application.”

“There are 7 main types of agricultural sprayers, each designed for specific crops and field conditions.”

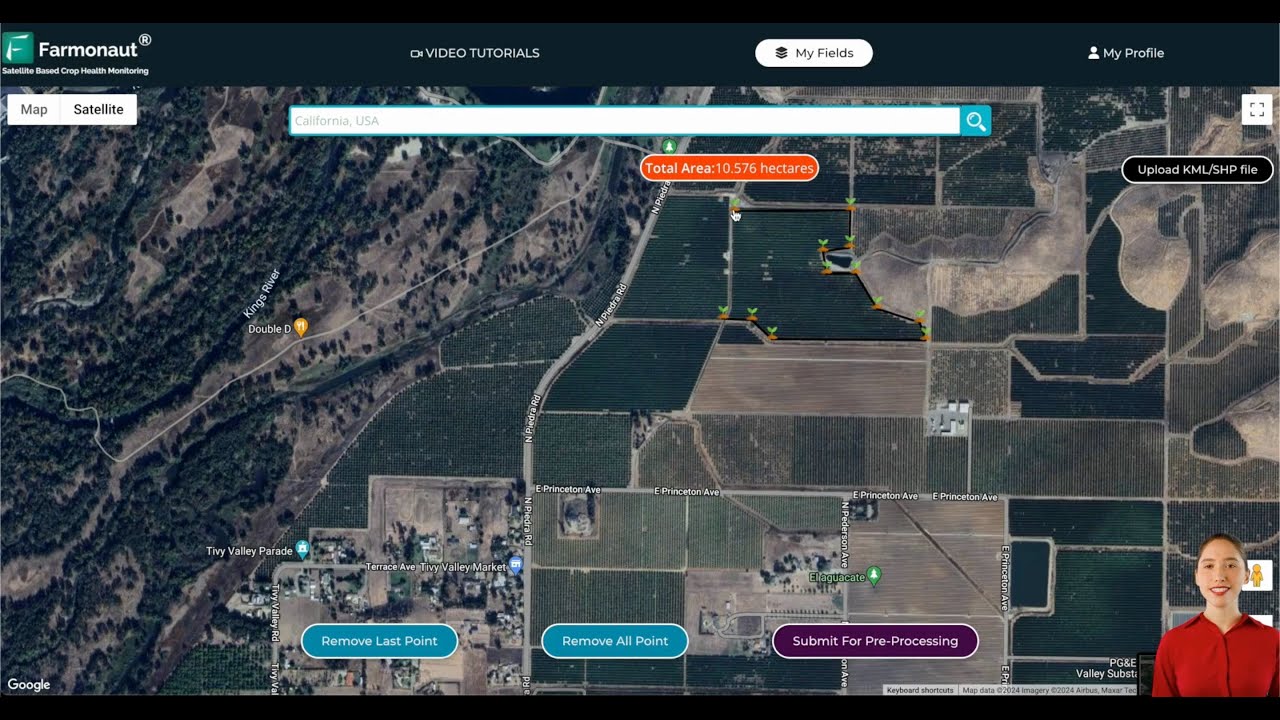

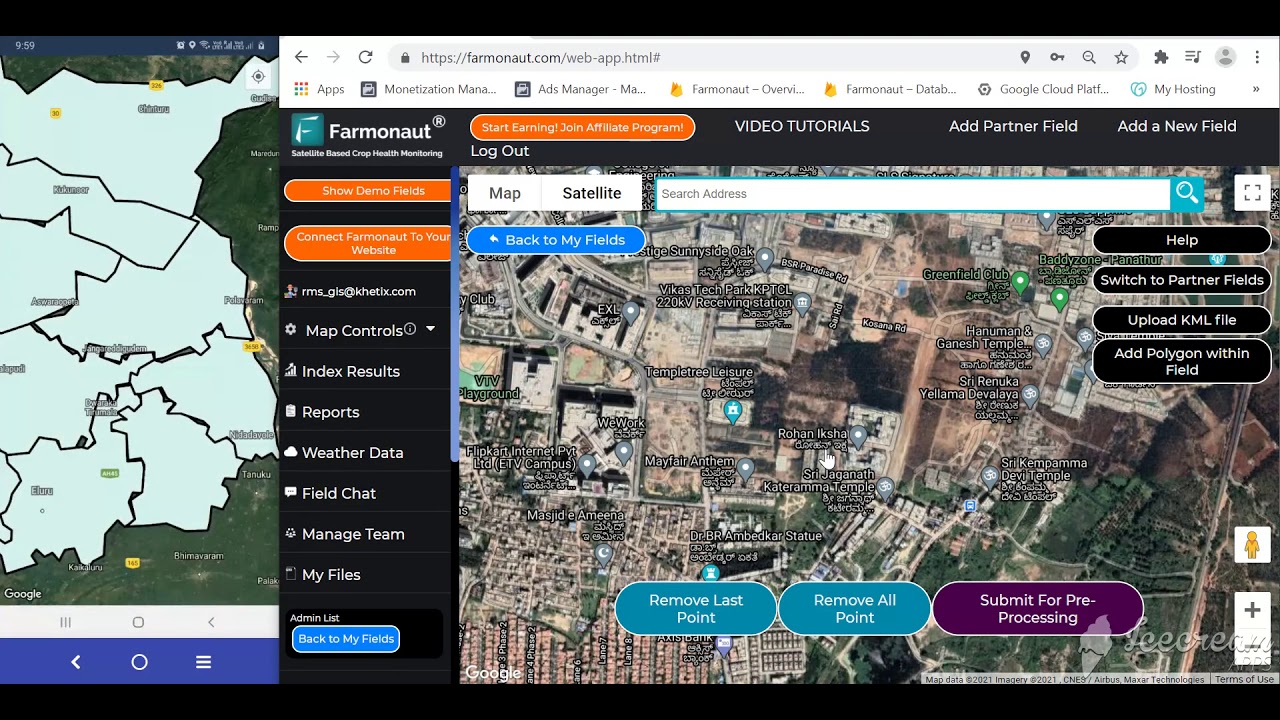

Looking to manage and monitor large-scale field spraying operations efficiently? Leverage Farmonaut Agro Admin App for real-time, satellite-based monitoring and advanced yield prediction—ideal for plantation managers and commercial farm supervisors.

Concerned about the sustainability and environmental impact of your spraying operations? Discover the advantages of Farmonaut’s Carbon Footprinting Tools for tracking and reducing farming emissions, ensuring compliance and environmental stewardship.

Need to trace crop production and pesticide usage for export or consumer trust? Utilize Farmonaut Product Traceability Solutions for enhancing transparency and building trust with buyers in the agricultural value chain.

Streamline your agricultural machinery and spray fleet logistics with Farmonaut Fleet Management, ensuring operational efficiency and asset tracking on large and dispersed farms.

Seeking easy integration of farm monitoring data? Access Farmonaut’s Satellite & Weather API and Developer Docs to integrate precision field data into your spraying machines, ERP, or custom management systems.

Ready for advanced crop advisory and field recommendations for your spraying machines? Try Farmonaut’s Crop, Plantation, & Forest Advisory Tools with AI-driven insights for pesticide, fungicide, and fertilizer applications.

Key Components of Agricultural Spraying Machines

Selecting the perfect spraying machine or optimizing the operation of existing equipment demands a solid understanding of core components. Let’s break down the critical parts that affect application rate, precision, and overall coverage in any agri-sprayer:

1. Tank Capacity and Tank Material

- The tank holds the liquid for application—types include polyethylene and stainless steel (each with high resistance to corrosive chemicals).

- Capacity can range from a few liters (backpack sprayers) to several thousand liters (self-propelled and tractor-mounted units).

- Choose tank size based on field size, refilling logistics, and desired productivity.

2. Pump Type and Power

- The pump is the heart of every sprayer machine—responsible for pressurizing the liquid and ensuring steady flow rates.

-

Common types:

- Diaphragm pumps: Best for abrasive chemicals, long-lasting and durable.

- Piston pumps: Deliver high pressure; ideal for fungicide and insecticide applications where coverage is vital.

- Centrifugal pumps: Ensure steady, high-volume flow—common in tractor-mounted and boom sprayers.

3. Nozzle Types and Spray Patterns

- Nozzles play a crucial role in determining droplet size, spray pattern, and overall coverage:

- Flat fan nozzles: Classic for herbicides—precise band spraying.

- Hollow cone nozzles: Perfect for fungicide and insecticide coverage, generating a swirling distribution pattern.

- Air-induction nozzles: Minimize drift, enhance penetration, and improve environmental safety.

- Pick sprayer nozzle types that match the chemical and target crop for optimal performance.

4. Automation and Control Systems

- Modern sprayers are equipped with GPS integration, automated rate controls, and advanced steering.

- These features enhance both accuracy and safety by maintaining consistent application rates and preventing overlapping or missed sections.

5. Safety and Monitoring Components

- Key safety components include protective shields, flow meters, pressure gauges, and automated emergency shut-off controls.

- These features prevent overapplication and reduce chemical exposure for operators.

- Onboard monitoring enables instant feedback on system health, ensuring prompt maintenance responses and safer applications.

Advancements in Precision Spraying Technology & Automation

Today’s precision spraying technology is transforming farms worldwide, as innovation brings smarter controls, higher efficiency, and lower environmental impact:

- GPS-Based Routing & Automated Steering: Some advanced tractors and self-propelled sprayers use real-time GPS navigation to follow programmed application maps—this reduces overlap (saving chemicals) and prevents skipping rows for optimum coverage.

- Variable Rate Controls: By linking sensors, soil data, and prescription maps, machines can automatically adjust application rates for herbicides, fungicides, or liquid fertilizers—delivering more input where it’s needed, less where it isn’t.

- IoT and Connectivity: Integration with weather stations, in-field sensors, and crop health monitoring tools (like those offered by us at Farmonaut) enables more responsive and adaptive spraying decisions.

- Droplet Size & Drift Management: Machine learning and intelligent sensors can automatically adjust droplet size for best penetration, reducing off-target movement and improving environmental safety.

These innovations aren’t reserved exclusively for commercial giants. Thanks to cloud-based tools, AI-guided advisory, and affordable satellite monitoring platforms like Farmonaut, precision spraying is now accessible for farms of any size.

Selecting an Agricultural Spraying Machine: Key Considerations

With such a variety of spraying equipment available, consider these critical factors for the most effective selection:

- Farm Size & Terrain: Small plots or intricate row crops often require backpack or handheld sprayers; large, open fields may justify tractor-mounted, self-propelled, or aerial spraying.

- Crop Type: Dense foliage (orchards/vineyards) benefit from airblast technology; flat field crops thrive with boom or aerial application.

- Budget & ROI: While advanced sprayers deliver high efficiency, not every operation needs full automation—choose a system that aligns investment with productivity gains.

- Chemical Compatibility: Ensure material compatibility for tanks, pumps, and nozzles based on the specific pesticides, herbicides, or fertilizers used.

- Desired Application Rate & Coverage: Evaluate estimated area, target droplet size, and rate requirements for the intended treatment.

- Ease of Maintenance: Simple design, availability of spare parts, and straightforward cleaning routines help manage long-term costs and minimize downtime.

When in doubt, consult local agri-equipment experts or leverage decision-support platforms like Farmonaut, which integrate real-time crop health insights and AI-powered recommendations to guide the type and frequency of spraying needed.

Farming Equipment Maintenance & Operator Safety

No matter your chosen spraying machine, consistent maintenance is fundamental to reliability and performance. Safety, meanwhile, starts with adherence to protocols and the proper use of protective gear.

Best Practices for Maintenance:

- Always flush tanks and hoses after spraying to prevent chemical build-up and clogging.

- Clean and calibrate nozzles regularly—check flow rates and replace worn-components as needed.

- Inspect all connections, pumps, and pressure lines for leaks before, during, and after operation.

- Lubricate moving parts and use only OEM or high-quality replacement parts for safety and effectiveness.

Best Practices for Operator Safety:

- Wear waterproof gloves, protective overalls, and respirators when mixing or spraying chemicals.

- Consult chemical safety data sheets for specific recommendations by product.

- Always follow the manufacturer’s handling, storage, and emergency decontamination instructions.

In addition, keep accurate records of spraying events and maintenance to support both farm management and compliance with certification or export standards.

Farmonaut: Advancing Precision Spraying Technology

At Farmonaut, we’re committed to making precision agriculture and data-driven spraying applications accessible and affordable for farmers, agribusinesses, and governments worldwide. While conventional spraying machines target the efficient delivery of crop treatments, our all-in-one platform elevates the process in several key ways:

- Satellite-Based Crop Monitoring: We provide real-time crop health data (NDVI), soil moisture levels, and actionable insights for timely decisions on spray rate and chemical choices—optimizing yield and reducing unnecessary treatments.

- Jeevn AI Advisory System: Our personalized AI farm advisory offers recommendations on pest management, weed control, and application timing, helping farmers use the right product, at the right time, on the right field segment.

- Blockchain-Based Traceability: For commercial and export-focused farms, our system delivers transparent, tamper-proof records of all applications—including pesticides, herbicides, and fertilizers—to support compliance, traceability, and consumer trust.

- Fleet & Resource Management Tools: Our platform seamlessly manages spray fleets, routes, and machine efficiency—lowering operational costs and ensuring optimal performance.

- Carbon Footprinting: We track emissions from spraying machines and other farm operations, helping farmers adopt sustainable practices and meet evolving regulatory demands.

Our subscription-based model is flexible and scalable, supporting everyone from smallholder farmers to large commercial agribusinesses (>100,000 ha). Access Farmonaut on Android, iOS, web, or via API—and experience a new era of data-driven crop, pest, and spraying management.

FAQs: Sprayers and Agricultural Spraying Machines

What are the 7 main types of agricultural spraying machines?

Handheld (backpack) sprayers, tractor-mounted sprayers, self-propelled sprayers, aerial sprayers (including drones), boom sprayers, airblast sprayers, and mist blower sprayers. Each is tailored for different farming needs and crop types.

How does precision spraying technology improve yield and reduce environmental impact?

By integrating GPS controls, variable rate application, and real-time field data, precision spraying technology ensures chemicals are applied only where needed, reducing waste and off-target runoff—while protecting crops more effectively and supporting sustainable agriculture.

What is the best sprayer nozzle type for herbicides vs. fungicides?

Flat fan nozzles are best for applying herbicides (band or broad coverage), while hollow cone nozzles excel in spraying fungicides and insecticides on surfaces that need thorough, all-around coverage.

How often should I perform maintenance on my spraying machine?

Perform major maintenance at least once per season, with regular checks after every use: flush tanks and hoses, clean nozzles, inspect pumps and connections, and test all safety controls.

Are aerial sprayers or drones better for large farms?

Aerial drones are best for irregular, small-to-medium fields and difficult terrains, while manned aircraft handle extensive, flat, and open areas more efficiently. Drone technology continues to evolve and is gaining ground for both versatility and reduced labor costs.

Can I use Farmonaut’s platform to guide my pesticide application equipment?

Absolutely. Our satellite-based crop health and AI-driven advisory help you plan precise spraying routes, monitor field health, and record all applications for compliance and traceability. Integrate our API with your own ERP or farm management system for seamless operation.

Conclusion: The Future of Agricultural Spraying Machines

The journey of spraying machines for agriculture is one of remarkable innovation, with a spectrum of devices—handheld, tractor-mounted, self-propelled, aerial, boom, airblast, and mist blowers—each engineered for efficiency, safety, and precision.

As digital agriculture and smart farm management advance, precision spraying technology will further reduce environmental impact, enhance food quality, and support sustainable growth. No matter your farm size or crop, integrating advanced spraying equipment with data-driven decision tools (like those offered by us at Farmonaut) unlocks new levels of productivity and opportunity.

Stay ahead in the field: regular maintenance ensures equipment longevity, and smart selection aligns your spraying solutions with business goals and compliance requirements.

Ready to modernize your farming? Download the Farmonaut App or integrate our API for actionable insights and smarter, safer, and more profitable agricultural spraying.