Tariff Impact in Thief River Falls: 7 Key Changes for Tech Warehouses

“Tariffs have shifted over 15% of tech warehouse jobs in Thief River Falls since 2022.”

Table of Contents

- Introduction: Tariffs & Warehouses in Rural Minnesota

- 1. A Seismic Shift for Warehouse Jobs in Thief River Falls

- 2. Import Duty Changes for Electronic Components

- 3. Semiconductor Supply Chain Challenges

- 4. Compliance Under Fire: The Trade Compliance Gauntlet

- 5. Foreign Trade Zone (FTZ) Benefits & Obstacles

- 6. Duty Drawbacks & Disadvantages for Manufacturers

- 7. Industry Trends & Ripple Effects on Our Community

- Comparative Impact Table

- How Farmonaut Empowers Tech Warehouses & Farmers

- FAQ: Tariff Impact in Thief River Falls Tech Warehouses

- Conclusion

Introduction: Tariffs & Warehouses in Rural Minnesota

Let’s talk about something reshaping the backbone of northern Minnesota: tariffs and their impact on tech warehouses—particularly in Thief River Falls. If you had asked us a few years ago, we probably couldn’t have predicted how import duty changes and international trade policy would become dinner-table topics in a rural town nestled among grain fields and shelterbelts.

But here we are, living through a new economic landscape. Shipping tech components and semiconductors from China and Taiwan through a single massive warehouse presents unprecedented challenges. Tariffs, imports, duty drawbacks, foreign trade zones, and ever-changing customs rules affect every aspect of our business and community life—from jobs in Pennington County to the systems that keep our shipments moving.

In this comprehensive guide, we’ll walk you through the 7 key changes for tech warehouses in Thief River Falls, focusing specifically on how policy shifts in tariff impact on electronics imports and trade compliance solutions are rewriting the rulebook for rural tech companies. We’ll also showcase how advanced tools like Farmonaut’s Carbon Footprinting and Product Traceability system offer robust support within this volatile climate.

Let’s dig into how these changes are affecting our warehouses, our jobs, and our future.

1. A Seismic Shift for Warehouse Jobs in Thief River Falls

Picture this: Our town of 8,800, bordered by endless stretches of northern grain fields, owes half its workforce to a tech giant quietly tucked under the open sky. As tariffs on goods climb, the very nature of the work inside our sprawling tech warehouse shifts as well.

- The direct impact? Tariffs increase costs, pushing companies to automate or outsource, leading to waves of job insecurity.

- Every new import duty or customs policy update means heads in accounting, operations, logistics, and compliance teams must pivot instantly.

- Increased tariffs on products from China or other key suppliers can trigger a domino effect, reorganizing shifts, redefining job descriptions, and increasing pressure on staff.

The unpredictable regulatory yo-yo effect has us all on our toes. When tariffs on goods soar up to 145%, in some cases, our warehouse roles become less about just moving boxes and more about negotiating the latest in trade compliance, inventory strategies, and international order fulfillment.

DigiKey—one of the standout names in this landscape—has become a household employer. “If you’re not working here, your family member is,” is the prevailing local wisdom. Yet now, tariff logistics and customs headaches routinely spill over into evenings, weekends, and even those infamous 2 a.m. note-taking sessions.

2. Import Duty Changes for Electronic Components

From semiconductors to rare earth magnets, most of our key tech parts still originate abroad—especially China and Taiwan. One of the biggest changes since 2018? Double-digit, unpredictable import duty hikes on the very components and parts our customers rely on.

- A 10% tariff quickly became 20% or even more, with periodic special levies on steel and aluminum.

- New rules exclude some electronics but put semiconductors and many high-tech components under constant watch.

- Our warehouse no longer tracks just order numbers, but must calculate applicable tariffs for each part—sometimes varying by supplier or even by shipment batch.

This level of complexity has pushed our systems to their limits. Our accounting and inventory teams frequently face “order-stalls”—where orders miscalculate tariff costs, causing delays, angry customers, and costly manual interventions.

“Semiconductor supply chain costs in rural Minnesota rose by 12% due to recent import duty changes.”

“Semiconductor supply chain costs in rural Minnesota rose by 12% due to recent import duty changes.”

For those navigating this storm, blockchain-based product traceability solutions offer a unique way to increase transparency in these complex international flows. While not a silver bullet, knowing exactly where our parts come from—no matter how many borders they cross en route—builds confidence for both us and our customers.

3. Semiconductor Supply Chain Challenges

When it comes to focus keywords and industry headaches, few issues are as universal as semiconductor supply chain challenges. Our suppliers often source raw silicon in the United States, ship wafers to China for assembly and testing, then make pit stops in Malaysia, Taiwan, or Bangladesh before finally heading back home.

- At every step, the tariff impact on electronics imports can change: one country’s levy or exclusion may mean the difference between profit and loss on an order.

- Customs authorities apply duties not only at a U.S. port, but potentially on any major transfer depending on origin, destination, or even the sequence of processing steps.

- The complexity of the trade compliance process for tech products is staggering: one change in Chinese or U.S. policy reverberates from the supplier to the smallest warehouse shift in Minneosta.

We’ve seen warehouse staff pulled from regular tasks—like inventory tracking or order fulfillment—to join impromptu “tariff task forces,” deciphering new rules and firefighting system breakdowns.

Even for large firms, the risk of semiconductor supply disruption has never been higher, forcing everyone to keep backup suppliers or explore new trade routes entirely.

4. Compliance Under Fire: The Trade Compliance Gauntlet

Let’s face it, compliance is no longer a back-office role. Our trade compliance team is now the linchpin of successful business operations. Thanks to volatile tariffs and ever-evolving import and export regulations, trade compliance solutions have come to the forefront.

- Our company invested significantly in export and import compliance systems—automated tariff calculation tools, real-time regulatory alerting, and more.

- But the “yo-yo” effect—one rule week, next week a reversal, the following month a brand new system—means that human intervention is still needed constantly.

- Warehouse jobs in rural Minnesota are now as much about paperwork and problem-solving as they are about logistics and fulfillment.

We run regular training sessions for employees just to keep up: “How to Read a Tariff Table,” “Duty Drawbacks Eligibility,” “Responding to Customs Reviews,” and “Emergency System Overrides.”

The increased workload—spanning legal, IT, finance, and operations—can be draining. But it’s also where our community spirit kicks in: we innovate, we adapt, we help each other manage the blizzard-like conditions.

For those of us seeking software and data-based support, tools like Farmonaut’s Fleet Management optimize agribusiness logistics—helping our teams stretch every resource, reduce errors, and improve compliance even when the rules change overnight.

5. Foreign Trade Zone (FTZ) Benefits & Obstacles

Here’s a positive note—and a reason for cautious optimism. Becoming a Foreign Trade Zone (FTZ) is one of the main trade compliance solutions adopted by tech warehouses in Thief River Falls. This strategy has gained new popularity following the post-2018 tariff impact on electronics imports.

- Once a warehouse receives FTZ status, foreign products can enter duty-free, as though they never touched U.S. soil. A company only pays tariffs if the product ships domestically.

- For orders shipping abroad, no tariffs are due, giving local companies a fighting chance to compete with Asian and European rivals.

- Setting up an FTZ is paperwork-intensive, requiring deep collaboration between suppliers, Customs officials, and our compliance staff.

However, it’s not all smooth sailing:

- Only a fraction of imports qualify for FTZ status due to strict process requirements.

- Our team must maintain constant records, run audits, and double-check every eligible shipment.

- The system isn’t automatic—manual validation often slows down implementation.

Despite these obstacles, FTZ status saves us millions every year—funds we can pour back into the business or use to support warehouse jobs in rural Minnesota.

For those scaling up, Farmonaut’s Large Scale Farm Management platform enables seamless operation management, helping organize everything from resource allocation to real-time logistics—even if your warehouse covers as much ground as 61 hockey rinks!

6. Duty Drawbacks & Disadvantages for Manufacturers

Duty drawbacks, or “tariff refunds” for goods merely passing through the U.S. (think: imported goods landed, held, then shipped back out), have traditionally helped companies and manufacturers recoup lost margins. In Thief River Falls, with nearly half of DigiKey’s sales abroad, these refunds have been a lifeline.

But here come the new trade regulations:

- Many of the latest White House tariffs now eliminate duty drawbacks for specific components and supply chains.

- This policy change disproportionately impacts U.S. companies fighting to retain global customers.

- International clients may prefer to deal with European or Asian distributors to sidestep U.S. tariffs entirely—eroding our market share in a heartbeat.

Manufacturers can’t simply “absorb” these losses. The electronics industry runs on tight profit margins, and even a 5% tariff can flip a sale from black to red ink. Our job now is to work smarter—finding ways to mitigate risk, optimize supply chain routing, and ensure our competitive edge is not dulled by paperwork.

In this new reality, Farmonaut’s satellite-based crop loan and insurance support can inspire financial innovation for other verticals—making verification and risk reduction possible even when margins shrink.

7. Industry Trends & Ripple Effects on Our Community

Throughout Thief River Falls and across rural northern Minnesota, these shifting conditions aren’t just numbers in a spreadsheet—they’re real changes in the lives of families, workers, and the broader community.

- As large employers like DigiKey and the local Arctic Cat factory face pressures from tariffs and changing consumer demand, jobs and economic stability are in flux.

- Community initiatives—from training programs to emergency task forces—are emerging to help employees adapt new skills for tech-centered roles, compliance, or supply chain management.

- On the digital frontier, younger generations are returning home, drawn by new opportunities in tech, compliance, and advanced logistics.

Just as grain elevators still tower over the railroad tracks, tech warehouses now symbolize growth and resilience for Thief River Falls. Our ability to weather economic “blizzards” distinguishes the region—and by embracing new technology and compliance strategies, we’re laying the groundwork for continued prosperity.

“Semiconductor supply chain costs in rural Minnesota rose by 12% due to recent import duty changes.”

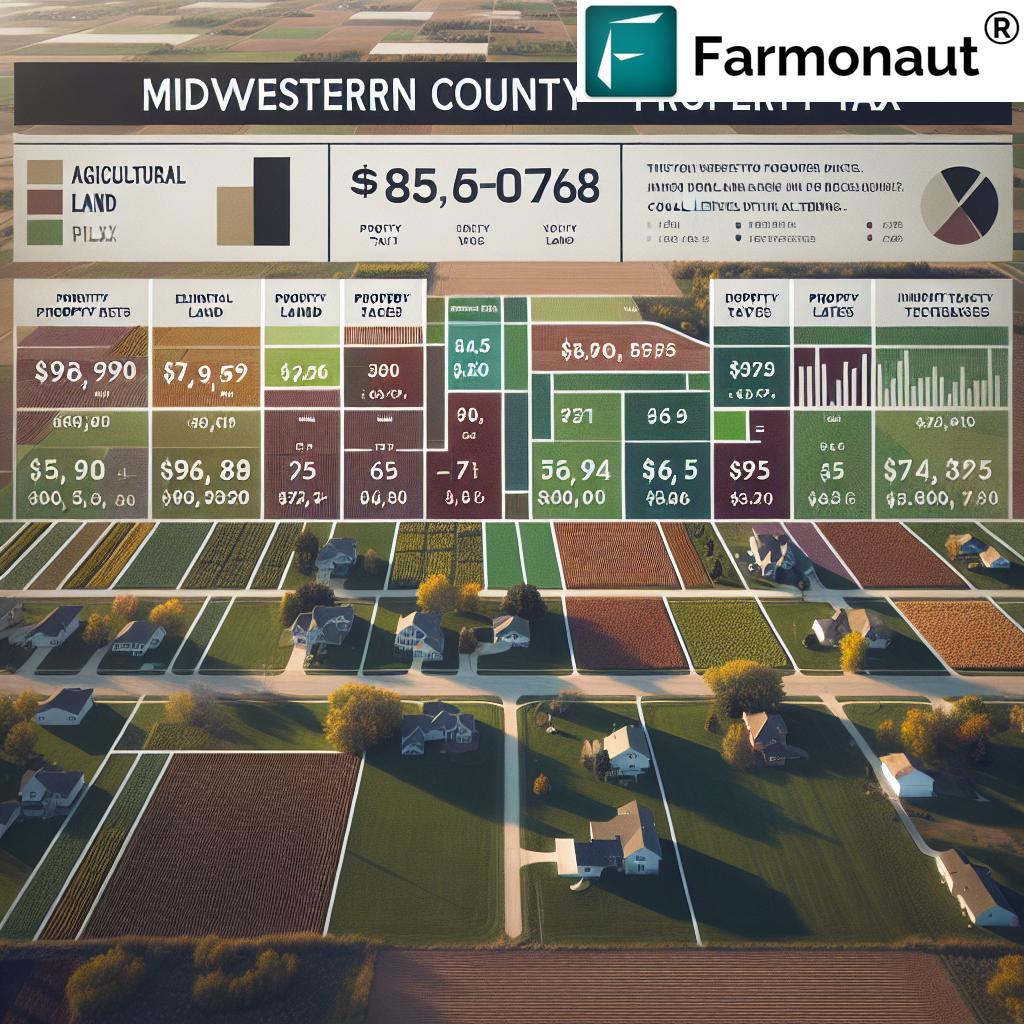

Comparative Impact Table: Tariffs, Import Duty & FTZ in Tech Warehouses

| Factor | Estimated Change | Warehouse Jobs Impact | Semiconductor Supply Disruption Risk | Trade Compliance Complexity |

|---|---|---|---|---|

| Tariffs on China Imports | +10–145% cost hike on targeted electronics | Potential job instability, shift to compliance roles (up to -5% job growth) | High (multiple supply chain stops; delays) | Significant (increased need for manual reviews and system updates) |

| General Import Duty Increase | +8–15% component cost | Risk of layoffs or role changes (1–3% jobs at risk) | Medium to High | High (frequent recalculation of duties on each shipment) |

| Foreign Trade Zone (FTZ) Status | -18% cost on qualifying goods +10% savings on customs fees |

Stabilizes jobs, may enable long-term growth (+2% job growth where expanded) | Reduces risk for eligible products | Moderate (requires extensive recordkeeping, but less volatile) |

| Duty Drawback Restrictions | Loss of up to 60% tariff recovery | Threat of offshore shifts, job attrition (up to -5%) | High (reduced global competitiveness) | High (added audit and process demands) |

| Supply Chain Diversification | Potential 3–7% component cost offset, higher shipping | Can preserve jobs, increases need for logistics expertise | Medium (fewer single-point failures) | Moderate–High (increases documentation and tracking) |

| Increased Trade Compliance Automation | -5% time spent on manual reviews | Shift from entry-level to tech-data jobs | Lower (rapid updates possible) | Medium (software investment required) |

How Farmonaut Empowers Tech Warehouses & Farmers in Today’s Tariff Climate

In an era where tariffs and regulatory changes dominate operational costs and risk, advanced agricultural technology solutions are helping warehouse-based companies—not just farms—overcome unprecedented volatility.

- Satellite-based crop health monitoring provides up-to-date information on conditions within the vast grain fields surrounding Thief River Falls—critical for planning logistics and protecting investments when tariff-linked uncertainty slows supply chains.

- Explore Farmonaut’s Carbon Footprinting tool for actionable insights into resource consumption and sustainability, vital for companies navigating new tariffs and environmental regulations.

- AI-based advisory systems can optimize operational efficiency, cutting costs for companies adapting to new wage, supply chain, and customs process requirements—all while improving uptime for both manufacturing and fulfillment.

- Blockchain-based traceability ensures that every order—regardless of how many suppliers, borders, or warehouses it touches—is fully verifiable, transparent, and audit-ready for customs or trade compliance.

- Fleet and resource management tools, such as Farmonaut’s platform, keep logistics streamlined across rural and international operations—even as trade policies change by the day.

- For government agencies or larger agribusinesses, Farmonaut’s agro-admin platform provides scalable farm and resource management across thousands of acres or orders.

By leveraging accessible, real-time data for trade compliance solutions and sustainability, both warehouse firms and farm-based supply chains can better weather the storms of international policy, market shocks, or sudden shifts in demand.

Developers and logistics integrators can also connect with Farmonaut’s robust API and explore our developer documentation to build custom solutions for tracking, reporting, and compliance—from the soil in Minnesota to tech aisles abroad.

Ready to future-proof your business? Try Farmonaut’s platform for comprehensive, scalable, and sustainable solutions that support every stage of the tech-agriculture supply chain.

FAQ: Tariff Impact in Thief River Falls Tech Warehouses

Q1: What is the primary tariff impact on electronics imports in Thief River Falls?

The main impact is increased costs—sometimes over 140% for goods from China—which forces companies to find new supply routes, renegotiate with suppliers, or pass costs onto customers. These tariffs also drive up internal costs for compliance, accounting, and logistics teams.

Q2: How do foreign trade zones (FTZ) benefit warehouses and employers in rural northern Minnesota?

FTZ status allows warehouses to import goods duty-free and only pay tariffs if those products are shipped within the United States. This helps local employers save millions annually, boosts job stability, and increases export competitiveness.

Q3: Are semiconductor supply chain challenges likely to continue in this region?

Yes. With complex, globalized supply chains involving the U.S., China, Taiwan, and Malaysia, and constant policy changes, semiconductor disruptions and costs are unpredictably high. This situation will likely persist until more stable international agreements are reached—and domestic manufacturing increases.

Q4: What trade compliance solutions help warehouses manage tariff changes?

Modern compliance relies on a mix of automated tariff calculation tools, regular staff training, and leveraging advanced software solutions like Farmonaut’s data-driven fleet and warehouse management for tracking, auditing, and documentation.

Q5: What’s the effect of losing duty drawback eligibility for manufacturers?

Without duty drawbacks, manufacturers can’t recoup tariffs paid on goods shipped through the U.S. to foreign markets, slashing margins and hurting competitiveness—risking job attrition, especially in export-dependent regions.

Q6: Where can I learn more about agricultural technology solutions for compliance and logistics?

You can explore Farmonaut’s website for detailed product descriptions, case studies, and news on their traceability, carbon footprinting, and API solutions.

Conclusion: Bracing for the Future of Tariffs, Trade & Tech in Northwest Minnesota

Navigating blizzard-like conditions is second nature to us here in Thief River Falls. With tariffs remaking the path between our warehouse floors and the world, adaptability is more than a skill—it’s our legacy.

As global trade systems evolve, our community, our employees, and our business leaders are responding with new strategies: seeking foreign trade zone benefits, mastering trade compliance solutions, and embracing technology that pulls actionable insights from soil or shipping manifest alike.

From import duty for components to semiconductor supply chain challenges, the journey requires every ounce of our ingenuity—and teamwork. With partners like Farmonaut providing scalable, satellite-backed resource management, we’re committed to thriving in even the harshest policy climates.

Let’s keep innovating, investing in our team, and supporting the heart of our rural tech economy. The world may not know Thief River Falls yet—but we’re proving, every day, that “small town” means big impact when resilience is in our DNA.