Mining Robotics 2025: Revolutionizing Safety & Efficiency

Table of Contents

- Introduction to Mining Robotics in 2025

- The Evolution of Mining Robotics: From Concept to 2025

- Core Technologies Transforming Mining in 2025

- Enhancing Safety, Sustainability & Efficiency

- Smart Mines & Autonomous Mining Operations

- Mining Robotics & Environmental Sustainability

- Industry Challenges, Limitations & the Road Ahead

- Key Mining Robotics Technologies and Their Estimated Impact (2025)

- Farmonaut: Satellite-Driven Insights Empowering Mining Robotics

- Frequently Asked Questions

- Conclusion: A Robotic Future for Mining

“By 2025, over 60% of new mining sites will deploy autonomous robots for hazardous tasks, boosting operational safety.”

Mining Robotics: Transforming the Future of Mining in 2025

Mining has long been the cornerstone of global economic development, providing essential raw materials that fuel various sectors. However, the industry is riddled with concerns: hazards, harsh working conditions, operational inefficiencies, and environmental risks. As we advance into 2025, Mining Robotics is revolutionizing the sector by addressing these challenges, transforming operations, and redefining industry standards.

Mining Robotics refers to the deployment of autonomous or remotely controlled machines and robotic systems designed to perform tasks traditionally carried out by human miners. Blasting, drilling, excavation, transportation, and environmental monitoring are just a few activities now handled by intelligent machines. The integration of AI, machine learning, and IoT with advanced sensors has created systems that not only enhance productivity and increase safety but also drive sustainable mining into the future.

This blog delves deep into how robotics and AI are transforming mining in 2025, the key innovations leading this revolution, the benefits & sustainability impacts, and how satellite-based solutions such as those provided by Farmonaut play an indispensable role in driving intelligent mining operations.

The Evolution of Mining Robotics: From Concept to 2025

Mining has seen incremental innovations—from explosives and mechanized shovels to computer-based fleet management—but robotics has become the game changer in the last decade. Initially, robots entered limited hazardous roles: inspection, sampling, or heavy load movement. The adoption of AI-controlled systems and remotely operated vehicles marked a major leap.

- 2010s: Introduction of remote-controlled underground loaders and basic robotic arms for repetitive operations.

- Late 2010s-2020: Implementation of AI-driven haul trucks and drone monitoring for site surveys.

- 2021–2024: Accelerated integration of machine learning algorithms, predictive maintenance, and automation across open-cast and underground mining.

- 2025: Mining Robotics has evolved to handle most hazardous, high-risk, and repetitive tasks without direct human involvement, with the support of satellite-enabled platforms, advanced AI, and IoT networks.

Today, the sector benefits from a spectrum of robots—from autonomous drilling rigs and smart loaders to AI-powered drone swarms for environmental monitoring and resource detection.

Core Technologies Driving Mining Robotics in 2025

Let’s explore the key technological innovations that make Mining Robotics in 2025 so powerful and indispensable for safety, efficiency, and sustainability:

- Artificial Intelligence (AI) & Machine Learning: These are at the heart of intelligent automation. AI algorithms analyze complex data—optimizing routes, predicting equipment failures, and automating decision-making across the entire operation.

- Internet of Things (IoT): Smart sensors embedded in robotic equipment continuously transmit data about machinery health, air quality, and operational hazards, enabling predictive maintenance and real-time monitoring.

- Autonomous Haulage & Drilling Robotics: Autonomous haul trucks, excavators, and drilling rigs perform demanding tasks 24/7, significantly reducing human presence in dangerous zones.

- Drones & Aerial Robotics: Drones armed with high-resolution multispectral cameras and AI vision inspect, map, and monitor safety, operational, and environmental conditions—including air quality and toxic gas levels.

- Blockchain for Traceability: Blockchain-based solutions ensure mineral traceability from extraction sites to end-users, enabling transparency in supply chains.

- Predictive Maintenance Systems: Using machine learning and sensor data to predict failures before they occur, thus actively reducing downtime and repair costs.

With this ecosystem, mining operations of 2025 not only outperform traditional methods in productivity but excel in handling hazardous conditions and driving sustainable outcomes.

“AI-powered mining robots are projected to increase ore extraction efficiency by up to 30% in 2025.”

Enhancing Safety, Sustainability, and Efficiency through Mining Robotics

Safety: Minimizing Human Exposure to Hazards

Mining remains one of the most hazardous professions globally. Traditional operations expose miners to dangerous conditions—including cave-ins, toxic gas exposure, and heavy equipment accidents. Robotic systems have created a decisive shift:

-

Autonomous Haul Trucks & Loaders

Operate continuously and independently in high-risk areas, eliminating the need for human presence underground or in unstable zones. -

Drones for Hazard Inspection

Inspect, map, and monitor air quality and structural integrity—reducing human entry into dangerous zones. -

Remote-Operated Maintenance

Robotic arms and vehicles perform maintenance tasks near toxic, high-heat, or otherwise unsafe machinery.

These robotics solutions have significantly reduced accident rates in mines worldwide.

Operational Efficiency: Boosting Productivity & Reducing Downtime

- Continuous Work Cycles: Robotics systems don’t tire or require shifts—they work around the clock, maximizing throughput and resource extraction.

- Predictive Maintenance: Sophisticated sensors and machine learning predict failures before they occur, minimizing downtime and maintenance costs.

- Route & Process Optimization: AI-driven algorithms optimize extraction routes and material transport, reducing fuel use and enhancing efficiency.

Sustainability: Enabling Environmentally Responsible Mining

As environmental consciousness grows globally, the mining industry is expected to minimize its impact:

- Precision Mining: Robots target mineral-rich zones with surgical accuracy, reducing unnecessary excavation, waste, and surface disturbance.

- Environmental Monitoring: Drones and IoT networks track and detect pollutant leaks, soil erosion, and air quality risks in real time.

- Rehabilitation Automation: Robotic systems are increasingly deployed for land reclamation—revegetating, stabilizing, and restoring mining sites efficiently.

Mining Robotics is central to enabling sustainable and responsible mineral extraction in 2025 and beyond.

Smart Mines & Autonomous Mining Operations

The vision for 2025 is the “smart mine”: a digitally integrated ecosystem where robotic operations, AI, IoT, and data analytics converge for unprecedented safety, operational efficiency, and adaptability.

- Integrated Robotic Fleets: Autonomous drills, loaders, and transporters run in sync—communicating via IoT and AI for seamless handover of tasks and real-time response.

- Real-Time Data Feedback: Sensors and drones constantly monitor everything from air quality to equipment health and environmental impact.

- Remote Operation & Automated Decision-Making: Many mining robots can be remotely controlled or fully autonomous, guided by AI to optimize resource extraction, minimize downtime, and adapt to risks instantly.

- Blockchain-Based Traceability & Compliance: Smart mines use blockchain traceability solutions to ensure every mineral is tracked from extraction to delivery, supporting ethical sourcing and compliance with ESG regulations.

Mining Robotics & Environmental Sustainability in 2025

Mining robotics is pivotal in addressing environmental concerns in the sector:

- CO2 Emissions Reduction: Robots conserve energy and reduce emissions by optimizing mining routes and resource use.

- Real-Time Environmental Monitoring: Drones and satellite carbon footprint tracking—as provided by Farmonaut—monitor emissions, track restoration, and allow companies to meet climate compliance targets.

- Efficient Resource Management: By enabling real-time detection and monitoring with AI and remote sensors, companies maximize yield while minimizing environmental damage.

- Automated Land Rehabilitation: Robotic vehicles and drones support large-scale reforestation, soil restoration, and contamination remediation.

The outcome? Mining industry operations in 2025 can be cost-efficient and environmentally responsible.

Industry Challenges, Limitations & the Road Ahead

While the shift to robotics-centric mining drives safety and efficiency, there are notable challenges:

- Capital Investment: Acquiring and integrating advanced robotic systems demands significant upfront costs—challenging for smaller companies.

- Workforce Displacement & Skills Gaps: The historic mining workforce faces displacement, necessitating re-skilling programs and AI/robotics management training.

- Cybersecurity Risks: Networked, autonomous systems are susceptible to malicious attacks, making robust security strategies essential for protecting operational integrity.

- Data Integration & Interoperability: Seamlessly integrating data between robots, sensors, and management systems remains complex, especially with legacy equipment.

- Regulatory & Social Acceptance: The rapid pace of change in mining robotics requires new safety, environmental, and employment regulations.

Addressing these challenges is key to fully unlocking the potential of Mining Robotics in the coming years.

Key Mining Robotics Technologies and Their Estimated Impact (2025)

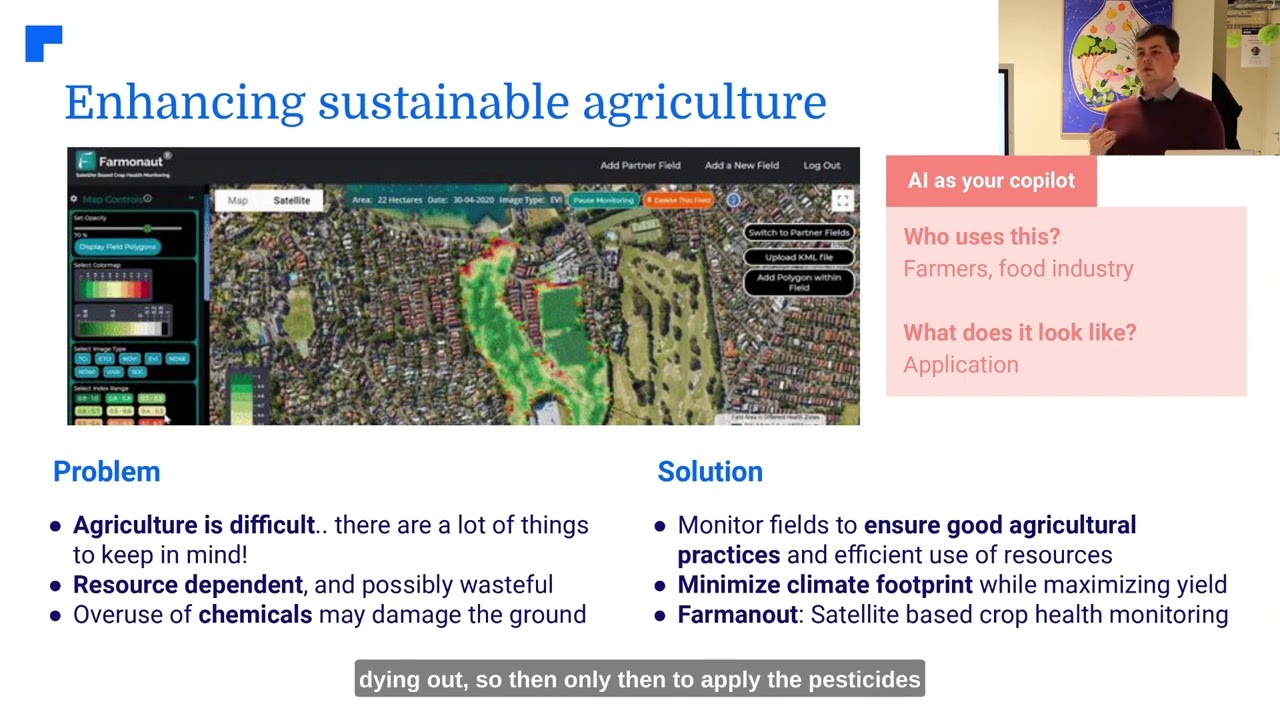

Farmonaut: Satellite-Driven Insights Empowering Mining Robotics

As mining companies transition to automated, smart mining operations, access to real-time, precise remote data is crucial. That’s where satellite-based technology platforms like Farmonaut come in.

-

Comprehensive Mining Monitoring:

Our platform delivers real-time satellite monitoring using advanced multispectral imagery for mining sites, vegetation, and infrastructure. -

AI and IoT Integration:

Farmonaut’s Jeevn AI advisory system interprets satellite and ground sensor data, providing actionable insights on resource extraction, environmental changes, and operational risks. -

Blockchain Traceability Solutions:

With blockchain-for-minerals-traceability, we ensure essential resources are ethically tracked from extraction to delivery. -

Fleet & Resource Management:

Fleet management tools help optimize robotic mineral haulage, route planning, and resource allocation to reduce costs and increase operational safety. -

Environmental Carbon Footprint Tracking:

Our carbon footprint platform monitors GHG emissions and helps companies adapt strategies in line with sustainability commitments.

Our solutions are available via web app, Android, iOS, and API integrations, ensuring decision-makers have the right data at their fingertips—wherever they are.

For developers and system integrators, our robust API and full API Developer Documentation make it easy to embed mining monitoring, environmental detection, and AI advisory features directly into proprietary control systems, dashboards, or mobile tools.

We also support satellite-based loan verification and insurance risk assessments for the mining sector, streamlining access to financing while cutting down fraud.

Frequently Asked Questions: Mining Robotics 2025

What is Mining Robotics?

Mining robotics refers to the use of autonomous or remotely controlled machines and systems to perform mining tasks such as drilling, blasting, excavation, transportation, and environmental monitoring. These robotics systems leverage AI, IoT, machine learning, and advanced sensors for smarter operations.

How do Mining Robotics improve safety?

Robotics in mining reduce human exposure to hazardous environments, minimizing risks from cave-ins, toxic gas, heavy machinery accidents, and dangerous excavation. Robots, drones, and remotely controlled equipment now handle these high-risk tasks.

What are the main benefits of mining robotics in 2025?

- Enhanced operational efficiency and productivity

- Significant reduction in accident and injury rates

- Lower environmental impact and resource waste

- Predictive and automated maintenance, reducing downtime

- Traceability and ethical supply chains via blockchain

How does AI contribute to mining robotics?

AI powers real-time data analytics, failure prediction, mining route optimization, equipment health monitoring, and smart decision-making to ensure operations are efficient, safe, and adaptive to changing site conditions.

What is the role of satellites and remote sensing in mining robotics?

Satellite imagery and remote sensing, as provided by platforms like Farmonaut, deliver crucial data for site monitoring, environmental compliance, resource management, and strategic planning—enabling smarter, data-driven mining operations.

Can mining robotics help with environmental sustainability?

Yes! Precision mining robots reduce unnecessary excavation, minimize emissions, and aid in automated rehabilitation of land post-extraction. Drones and sensors enable ongoing detection of ecological hazards and pollution events.

What are the biggest challenges facing mining robotics adoption?

- High up-front investment costs for new technologies

- Need for workforce retraining in robotics/AI maintenance

- Cybersecurity threats to interconnected robots and data systems

- Complex integration with legacy mining equipment and practices

- Keeping pace with rapidly evolving mining and safety regulations

Conclusion: A Robotic Future for Mining—2025 and Beyond

Mining Robotics in 2025 stands at the transformative leading edge of the sector. By enhancing safety, driving operational efficiency, and enabling environmental sustainability, these robotic solutions are paving the way for a new era of mining—one where the risks to human life are greatly reduced, operations are optimized, and mineral extraction aligns with global sustainability mandates.

The adoption of AI, machine learning, IoT, drones, and blockchain-powered robotics will continue to accelerate, future-proofing the industry for decades to come. With the support of platforms providing satellite-based monitoring, intelligent advisory systems, environmental impact management, and blockchain traceability, mining companies can not only maximize productivity and profitability but also build trust with regulators, investors, and communities worldwide.

As we look beyond 2025, the mining industry can finally fulfill the promise of safe, sustainable, and intelligent operations—fueling progress while taking care of people and the planet.

For advanced mining monitoring integrations, explore our API and developer documentation.

Discover more about fleet management for mining robotics or traceability solutions for ethical mineral sourcing.

It’s going to be ending of mine day, however

before end I am reading this wonderful piece of writing to increase my knowledge.

Hey there! I could have sworn I’ve been to this site before but after checking

through some of the post I realized it’s new to me.

Anyways, I’m definitely glad I found it and I’ll be bookmarking and checking

back frequently!