Professional Agri-Equipment Maintenance: 10 Key Steps for Optimal Performance & Machinery Lifespan

“Regular lubrication can reduce farm equipment wear by up to 40%, significantly extending machinery lifespan.”

Understanding Equipment Requirements: The Foundation of Effective Maintenance

A robust farm equipment maintenance strategy begins with a deep understanding of each piece of agricultural machinery in use. Knowing the unique requirements and recommended maintenance intervals for every asset is fundamental in maximizing the efficiency and lifespan of your fleet.

- Read the owner’s manual: Every farm machinery unit, from tractors to harvesters, comes with a detailed manual outlining fluid types, filters, lubrication points, and servicing intervals.

- Identify critical components: Pay special attention to hydraulic systems, belts, hoses, tires, electrical systems, and engine parts—these are vital for optimal operation.

- Document specific needs: Carefully record the parts and consumables (e.g., engine oil, filters, coolants) required for each machine.

- Review warranty coverage: Following manufacturer guidelines ensures protection for warranty claims and cultivates the best practices for preserving performance.

The knowledge you gain from reading and referencing manuals provides valuable insights into specific maintenance needs. This is the foundation for professional agricultural machinery servicing.

Adhering to Manufacturer Guidelines for Optimal Performance and Longevity

Whether you are focused on regular equipment inspections or proactive care, adhering to the manufacturer’s recommendations is crucial for:

- Maintaining optimal performance: Follows detailed instructions for fluid types, lubrication intervals, and replacement parts.

- Ensuring safety and warranty coverage: Protects your significant investment by keeping machines in good condition and within warranty parameters.

- Identifying proper service intervals: Timely inspections, filter replacements, and lubrication are all determined by the manual’s recommendations.

- Effective management: Uses smart, evidence-based guidelines for preventive maintenance for tractors and other equipment, helping to minimize downtime and extend the lifespan of machinery.

Following manufacturer guidelines is one of the best practices for professional farm equipment maintenance. Not only does it help maintain coverage, but it also sets clear standards for everyone in your maintenance team.

Regular Inspections for Farm Equipment Maintenance: Identifying Issues Early

Routine and systematic inspections are vital for detecting potential issues before they escalate. Conducting regular visual checks helps us spot signs of wear, cracks, leaks, or damaged hoses—all of which can quickly become major breakdowns if not addressed promptly.

- Check belts and hoses: Look for cracks, fraying, or stretching.

- Inspect tires: Assess condition, pressure, and signs of damage (see: Tractor Tire Maintenance Tips).

- Monitor hydraulic systems: Check fluid levels, hoses, and look for leaks. Low fluid or damaged hoses can halt operations or cause system damage.

- Examine air and oil filters: Ensure filters are clean and replace as needed to maintain engine efficiency.

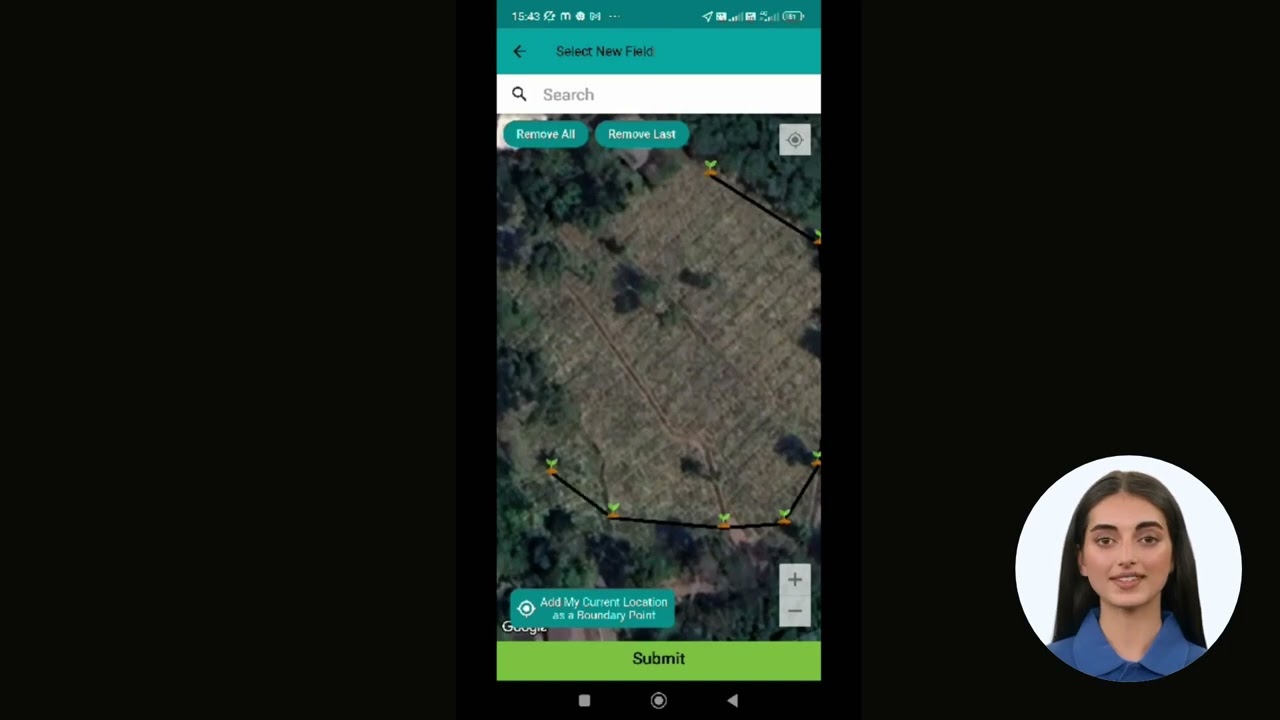

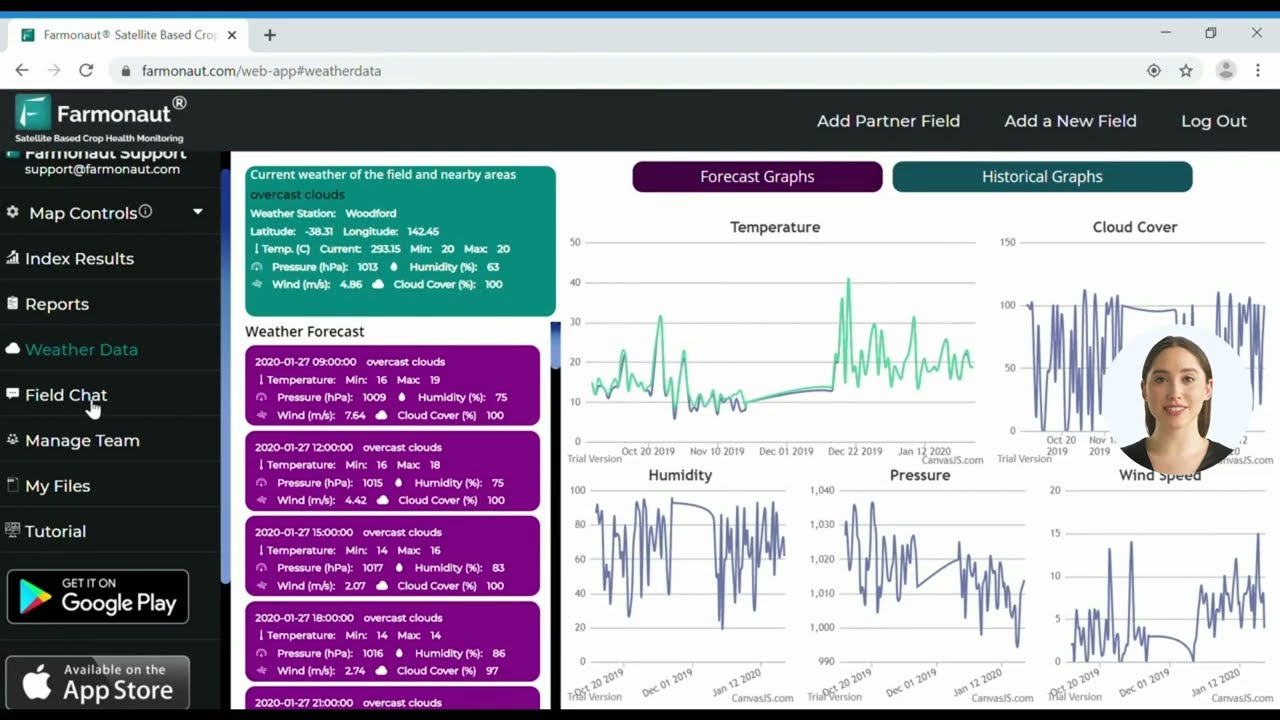

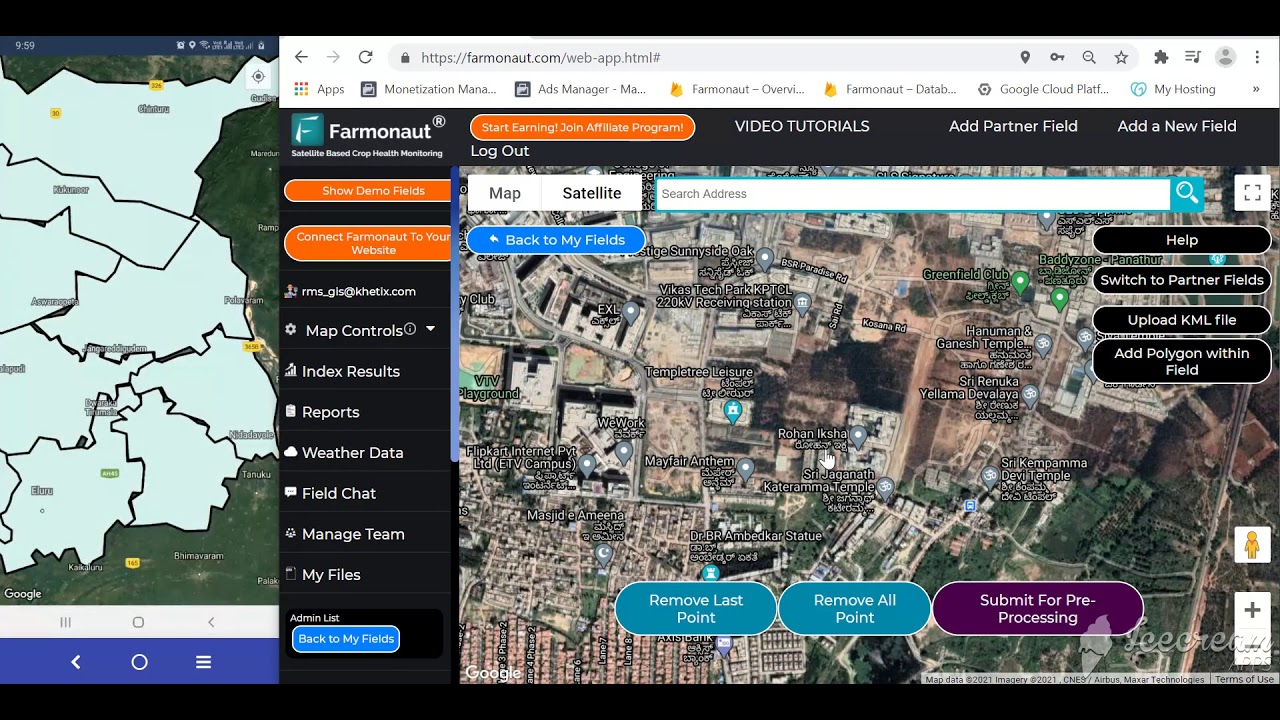

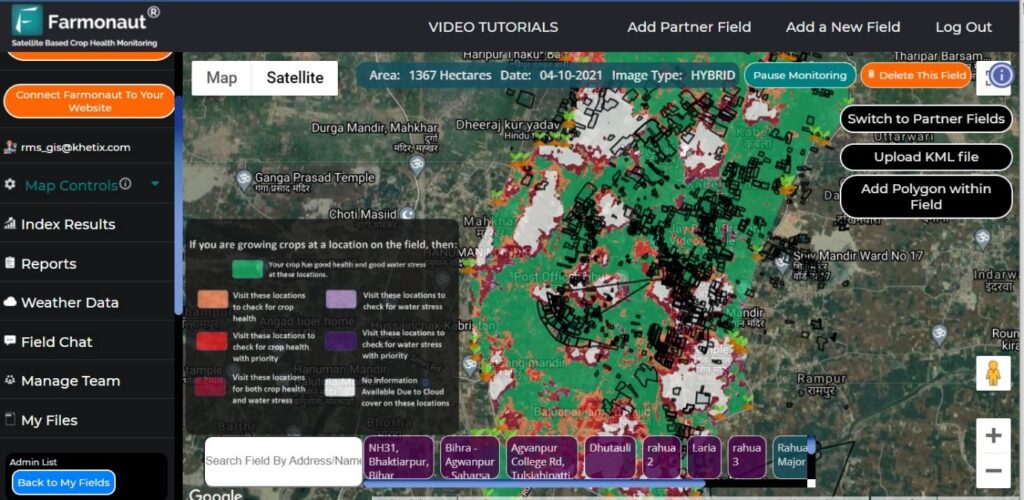

A proactive approach with checklists, logs, and management tools (such as those provided by Farmonaut’s fleet management system) makes comprehensive regular inspections manageable and reliable for all types of farmers.

Benefits of Regular Equipment Inspections

- Reduces breakdowns and unplanned downtime

- Identifies potential issues early

- Ensures compliance with warranty and safety requirements

- Extends equipment life

Fluid and Filter Management: Keeping Systems Clean

An essential part of maintenance of farm machinery is monitoring and managing fluids and filters. Modern agricultural equipment relies on several interconnected systems, all of which need regular attention:

- Engine oil: Regularly check the level and quality. Change oil and replace engine oil filters as per manufacturer’s intervals.

- Hydraulic and transmission fluids: Monitor levels and top up if needed. Only use fluids specified in the manual, as proper fluid is critical for system health.

- Coolant: Ensure the coolant level is maintained to prevent overheating.

- Fuel system: Check fuel filters to ensure clean, debris-free fuel delivery.

- Air filters: Replace or clean air filters regularly for efficient engine operation.

Well-controlled fluid and filter management is the backbone of preventive maintenance for tractors and all other farm equipment—it prevents contamination and breakdowns.

For advanced management, consider using Farmonaut’s mobile and web apps to log fluid changes and set scheduled reminders.

“Checking tire pressure monthly can improve fuel efficiency of agri-equipment by approximately 10%.”

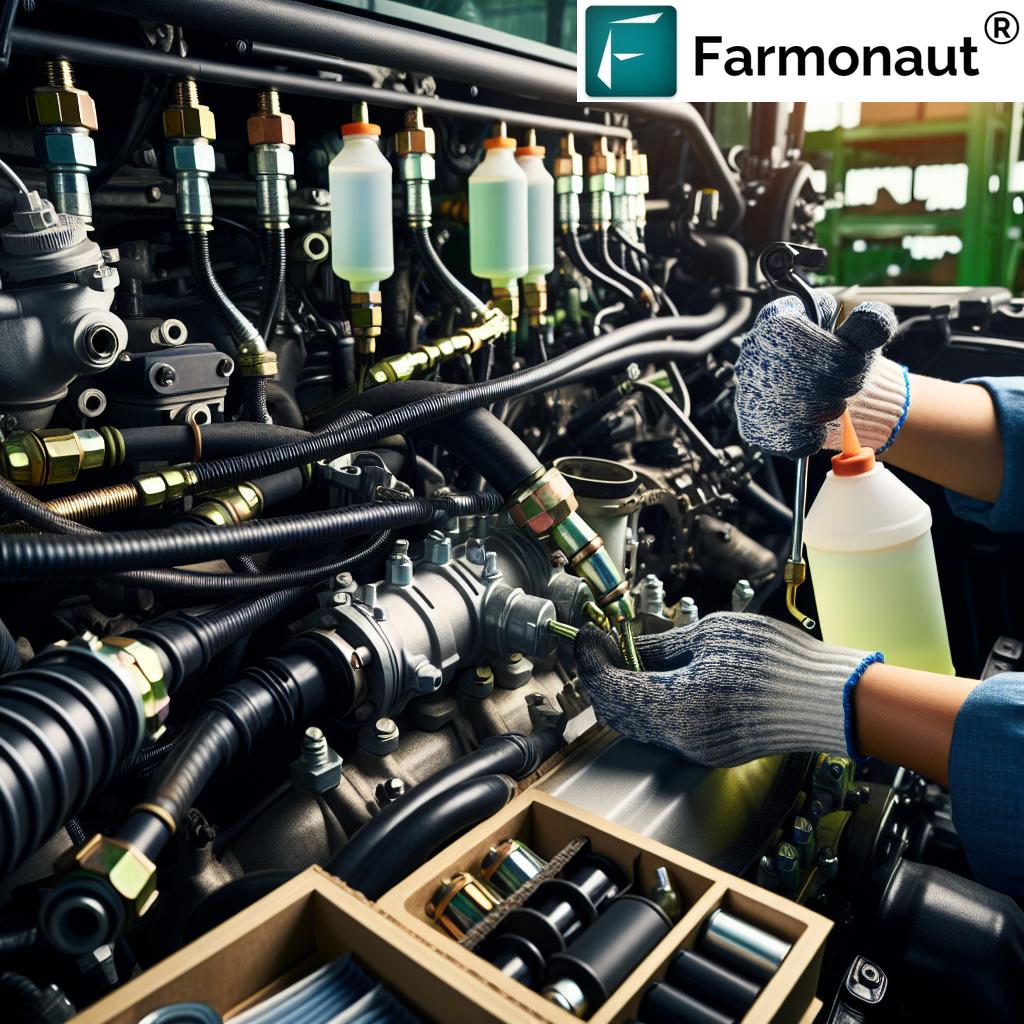

Proper Lubrication Techniques for Farm Equipment: Reducing Friction & Extending Life

Effective lubrication isn’t just about applying grease—it’s a systematic, scheduled approach to maintenance that reduces friction and wear on moving parts. Consistent lubrication prevents breakdowns, reduces downtime, and extends the service life of machinery.

- Follow intervals: Always abide by manufacturer-recommended lubrication intervals and use the appropriate type for each component.

-

Critical points include:

- Bearings, chains, gears, and pivots

- Hydraulic cylinder ends

- Drive shafts and couplings

- Document the process: Logging each lubrication task in a management system ensures nothing is missed.

Implementing proper lubrication techniques for farm equipment is a proven way to minimize component fatigue and improve operational efficiency.

Tractor Tire Maintenance Tips: Ensuring Safety, Traction & Fuel Efficiency

Tires are a critical component for safe, efficient farm operations. Proper tire maintenance leads to better traction, reduced fuel use, and enhanced stability.

- Check tire pressure regularly: At least monthly, and more often during heavy use. Tire pressure impacts fuel economy and equipment safety.

- Inspect for wear and damage: Look for cracks, bulges, or embedded debris. Replace tires that show signs of aging or excessive wear.

- Maintain proper alignment and balance: Misaligned tires lead to uneven wear and reduce efficiency.

- Clean tires and rims: Remove soil, stones, and debris that can cause corrosion or imbalance.

For those managing large machinery fleets, tractor tire maintenance tips (tracked with digital tools) prevent costly delays and improve daily operations.

Farm Equipment Battery and Electrical System Maintenance

A healthy battery and electrical system is essential for starting engines, powering lights, and ensuring all electrical systems function reliably.

- Check battery charge: Regularly test the charge level and recharge or replace batteries nearing the end of their service life.

- Clean terminals: Corrosion can build up and prevent proper electrical contact. Use appropriate terminal cleaners and protectants.

- Inspect connections and wiring: Ensure all connections are secure and wires are free from damage.

- Test alternators and starters: These components should be checked at each service interval.

- Replace faulty lights or indicators: Good visibility, both day and night, is essential for operator safety.

A proactive approach to farm equipment battery maintenance helps prevent operational disruptions and unsafe conditions.

Brake System Functionality and Safety Checks: Protecting Operators & Equipment

Brakes are one of the most important safety components on any farm machinery. Regular inspections of the entire brake system are critical for safe operation.

- Inspect brake pads, discs, and drums for wear or damage

- Monitor brake fluid levels and look for leaks

- Check brake response: Spongy or unresponsive brakes need immediate adjustment or repair.

- Replace worn parts: Failing to do so risks not only the machinery but also operator safety.

Make sure all personnel know how to test brakes and understand signs of brake system issues. Keeping brake systems functioning well also ensures compliance with safety and warranty requirements.

Cooling System and Airflow Maintenance: Preventing Overheating and Ensuring Air Quality

Overheating is a major cause of engine damage in agricultural machinery. A properly functioning cooling system and effective air filtration are essential for engine longevity.

- Check coolant level: Proper coolant level in the radiator is essential.

- Inspect radiator and hoses: Look for leaks, cracks, or debris clogs. Clean the radiator frequently to prevent overheating.

- Maintain airflow systems: Clean or replace air filters regularly, and check all ducts/vents for obstructions. Dirty air filters reduce engine efficiency and may allow contaminants to enter the system.

A routine for cooling and airflow system maintenance is a key element of professional agricultural equipment care.

Belts, Chains, and PTO Shaft Care: Preventing Breakdowns

Drive belts, chains, and the PTO shaft are critical systems in most agricultural machinery. Neglect leads to unexpected breakdowns during operation.

- Check belt/chain tension: Overly tight or loose belts and chains accelerate wear.

- Inspect for cracks or fraying: Replace at the first sign of damage.

- Maintain pulleys and sprockets: Worn pulleys or misaligned chains can damage the system rapidly.

- Ensure PTO shaft guards are intact: These protect operators from entanglement. PTO shaft care is non-negotiable for safety.

Systematic checks—integral to equipment maintenance routines—ensure efficient power transfer and help meet operator safety standards.

Training, Documentation, and Digital Maintenance Management

Proper training and meticulous documentation of all maintenance tasks support agricultural machinery servicing at all scales.

- Train operators: All staff should be trained in basic maintenance tasks (inspections, fluid checks, greasing points).

- Document every servicing action: Logs help track recurring issues, identify patterns, and are vital for warranty claims or future resale.

- Implement digital systems:

Use farm management software to track tasks, set reminders, and generate reports.

Farmonaut’s API and fleet management tools allow real-time, mobile-friendly record keeping and monitoring, making maintenance schedules consistent and transparent.

Documenting all maintenance steps not only ensures compliance—it’s a cornerstone of a culture of proactive care and preventive maintenance.

Maintenance Step Summary Table

| Maintenance Step | Description/Task | Recommended Frequency | Estimated Time | Benefit |

|---|---|---|---|---|

| Read Owner’s Manual | Understand requirements, servicing intervals, fluid specs | Initial setup; as equipment changes | 20–60 minutes | Foundation for all maintenance; protects warranty |

| Follow Manufacturer Guidelines | Stick to recommended service intervals, fluids, parts | Per manual (weekly, monthly, seasonal) | 10–30 minutes per check | Ensures optimal operation; maintains coverage |

| Regular Inspections | Visual check: wear, leaks, cracks, hoses, components | Weekly; before heavy use | 20–40 minutes | Prevents breakdown; finds issues early |

| Fluid & Filter Management | Check/change oil, coolant, hydraulics; replace filters | Monthly; as indicated by usage/hour meter | 30–60 minutes | Prevents contamination; boosts efficiency |

| Lubrication | Grease bearings, chains, PTOs, pivots | Weekly/bi-weekly; per equipment manual | 15–30 minutes | Reduces wear; extends component life |

| Tire Care | Check pressure, look for wear, inspect treads, clean | Monthly; before/after heavy tasks | 10–25 minutes | Improved safety, traction, and fuel efficiency |

| Battery & Electrical | Test charge, clean terminals, inspect wiring/lights | Monthly; before busy seasons | 10–25 minutes | Prevents electrical failure; ensures safety |

| Brake System | Inspect pads, check fluid, test responsiveness | Monthly; prior to and after major use | 10–30 minutes | Operator protection; compliance |

| Cooling/Airflow Maintenance | Check coolant, clean radiator, replace air filters | Monthly; seasonally | 15–40 minutes | Prevents overheating, extends engine life |

| Belts, Chains, PTO Shaft | Check tension, inspect for wear, secure guards | Monthly, before/after season | 15–30 minutes | Prevents breakdown; operator safety |

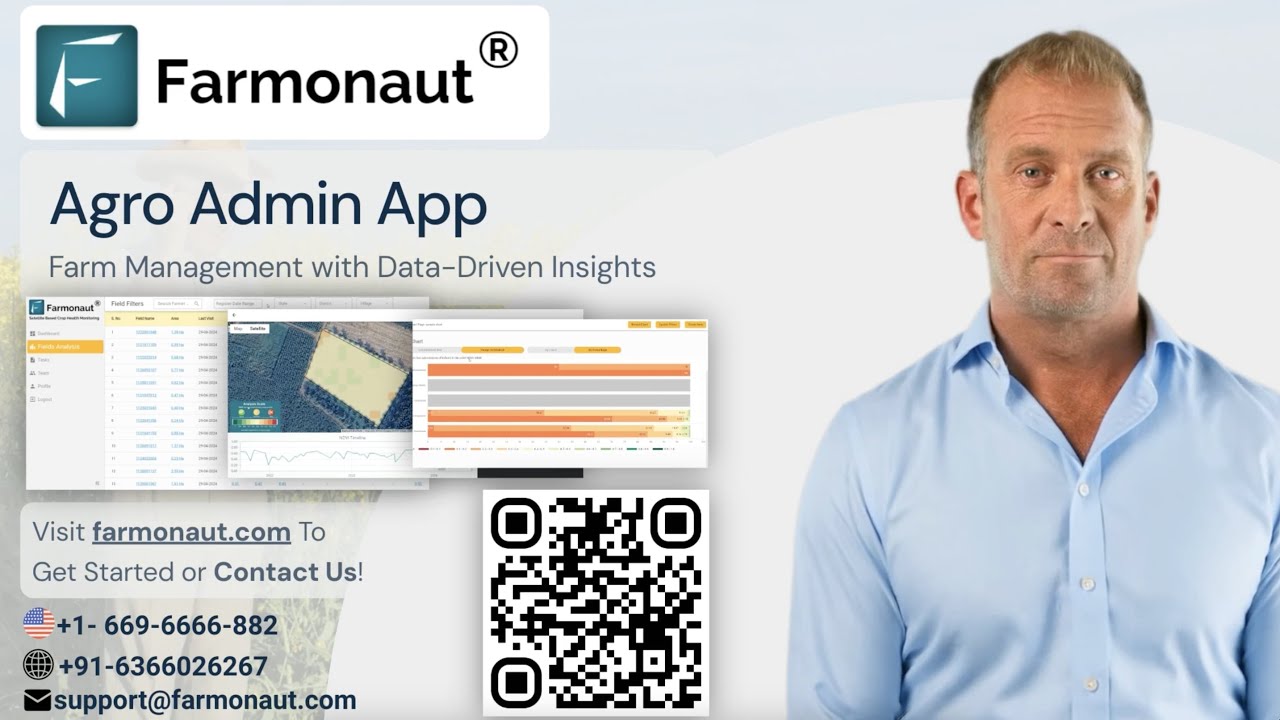

Advanced Maintenance & Management Solutions from Farmonaut

At Farmonaut, we empower farmers, agribusinesses, and organizations worldwide with innovative, data-driven farm management solutions for every operation size.

- Satellite-Based Crop Health Monitoring: Our mobile, web, and API tools monitor and track vegetation health, soil moisture, and resource use. This ensures timely intervention and maximizes the value of every maintenance activity.

- Fleet and Resource Management: Our fleet management tools let you track servicing history, schedule inspections, and improve logistics efficiency for entire fleets—essential for minimizing machinery downtime during peak seasons.

-

Traceability:

With Farmonaut’s blockchain-based traceability platform, users can record and verify every maintenance or crop production step for compliance, supply chain transparency, and consumer trust. -

Carbon Footprinting:

Our carbon footprint monitoring solution helps farmers and agribusinesses quantify emissions from machinery use, making progress toward sustainable agriculture visible and actionable.

Want powerful maintenance records and real-time insights on your desktop or mobile?

Access our comprehensive resource management platform:

And for businesses building their own systems or research projects, integrate with our API or see our Developer Docs for advanced, satellite-backed agri-management capabilities.

We believe in scalability, affordability, and sustainability: our platform supports smallholder users, agribusiness giants, NGOs, and government agencies with tailored farm management tools for every climate and market.

Ready to invest in smarter, easier agri-equipment maintenance?

Agri-Equipment Maintenance FAQ

Q1: How often should I conduct farm equipment maintenance?

A: The frequency depends on manufacturer guidelines and machine usage. Generally, perform routine inspections weekly, fluid/filter checks monthly, and comprehensive servicing seasonally. Always adjust based on local operating conditions.

Q2: What is the most essential maintenance step for extending machinery lifespan?

A: Regular lubrication and timely fluid/filter changes are crucial. These prevent wear, overheating, and contamination, resulting in longer equipment life.

Q3: How do I ensure I’m using the correct fluids and parts for my agricultural machinery?

A: Always refer to the owner’s manual and adhere to manufacturer recommendations for fluid types, filter models, and part specifications. This protects equipment and ensures warranty coverage.

Q4: Why is documentation important in farm equipment maintenance?

A: Documenting maintenance activities helps track servicing history, spot recurring issues, make warranty claims, and estimate resale value. Digital solutions like those offered by Farmonaut make this process simple and efficient.

Q5: Can I use digital tools to streamline scheduled equipment maintenance?

A: Absolutely. Farmonaut’s platform offers farm management solutions, fleet tracking, and maintenance scheduling via web, mobile app, and API, suitable for farm operators globally.

Q6: How can Farmonaut’s traceability tools benefit agricultural machinery management?

A: Farmonaut’s traceability solutions record every operational step, including maintenance. This transparency supports supply chain requirements and boosts buyer confidence.

Conclusion: Foster a Culture of Care for Maximum Productivity

Professional maintenance of agricultural equipment isn’t just a checklist—it’s a strategic, proactive approach for ensuring optimal performance, extending machinery lifespan, and minimizing downtime. By understanding each machine’s requirements, adhering to manufacturer guidelines, conducting routine inspections, and leveraging smart digital solutions, farmers build a culture of care that pays off with:

- Higher crop yields due to reliable machinery operation

- Reduced repair costs and equipment downtime

- Safer farm environments for all operators

- Extended asset lifespan and stronger resale value

- Improved sustainability through resource-efficient practices

Use this comprehensive guide to implement an effective maintenance strategy for your farm equipment, and remember—ongoing maintenance is an investment in your farm’s future.

For advanced monitoring, smart scheduling, and precision resource use, explore what Farmonaut can offer. Join us on our mission to make precision agriculture affordable, sustainable, and productive for everyone, worldwide.

For API integration, visit:

Farmonaut API |

API Developer Docs

Interested in expanding into advanced fleet management? Learn more at Fleet Management with Farmonaut. Or track carbon footprint at Farmonaut Carbon Footprinting, and boost traceability at Product Traceability.