Cannabis Vertical Grow System: Automated Farming Revolution for 2025

“Vertical grow systems can increase cannabis yield per square foot by up to 300% compared to traditional methods.”

Table of Contents

- Introduction: The Shift in Cannabis Cultivation

- Understanding the Cannabis Vertical Grow System

- Automated Vertical Farming System: The Backbone of Cannabis Automation

- Core Components of Automated Cannabis Vertical Grow Systems

- Optimizing Resource Use: Water, Energy, and Space

- Sustainability: Reducing Waste and Environmental Impact

- Comparison of Traditional vs. Automated Cannabis Vertical Grow Systems

- Economic Impact and Sector Growth by 2025

- Satellite Technology & Cannabis Automation: Farmonaut Solutions

- Frequently Asked Questions

- Conclusion: The Future of Vertical Cannabis Cultivation

Introduction: The Shift in Cannabis Cultivation

The cannabis industry is currently experiencing a revolutionary transformation, characterized by the widespread adoption of technology and data-driven solutions. As global markets shift towards medical and recreational cannabis, innovators have introduced advanced vertical grow systems and sophisticated automated vertical farming systems that not only optimize yields but also tackle problems associated with traditional cultivation methods. These disruptive technologies are dramatically altering how we approach cannabis production, resource efficiency, quality control, and sustainability in 2025 and beyond.

Focus Keyword: Cannabis vertical grow system

By capitalizing on limited space and integrating cutting-edge cannabis automation, vertical farming provides a scalable, reliable, and environmentally responsible solution for modern cultivators. The result? Enhanced productivity, consistently high-quality crops, and reduced operational costs—all critical as the sector grows alongside expanding legal frameworks and stricter regulatory requirements.

How Far Has the Cannabis Sector Come?

In recent years, we’ve witnessed a paradigm shift as the agricultural sector embraces precision farming and sustainability. New cultivation practices, spearheaded by cannabis vertical grow systems and automated technologies, are becoming central to the industry’s longevity and competitiveness. These advancements aren’t just about higher yields—they’re about transforming the very DNA of what it means to cultivate cannabis in the 21st century.

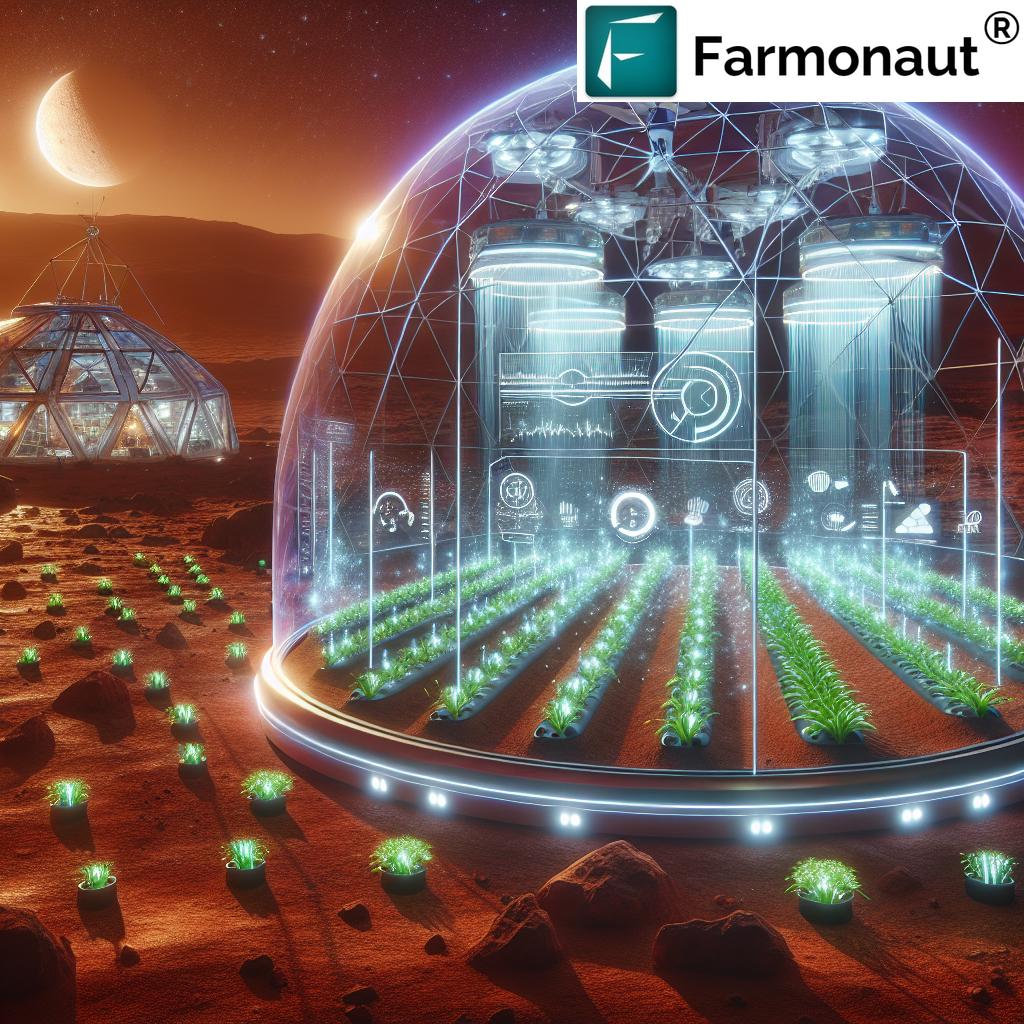

Understanding the Cannabis Vertical Grow System

At the heart of the cannabis vertical grow system is a commitment to maximizing production within a controlled, efficient, and sustainable environment. Unlike traditional methods, which expand horizontally and are often limited by land and space constraints, vertical systems allow cultivators to grow multiple layers of cannabis plants per square meter. The resulting increase in density can triple or quadruple annual yields compared to single-level indoor grow rooms.

- Tiered shelving units house trays of plants, each provided with optimal access to resources.

- Customized LED lighting arrays offer targeted light spectrums and intensities, promoting robust growth, potency, and consistent cannabinoid profiles.

- Automated nutrient delivery systems and real-time sensor feedback optimize water and fertilizer use for each crop.

- Environmental controls maintain ideal temperature, humidity, and CO2 concentrations at every level.

These controlled environments are the cornerstone of cannabis vertical grow system innovation, enabling cultivators to produce superior, regulatory-compliant products even in urban or land-constrained areas.

“Automated vertical cannabis farms can save up to 95% water compared to conventional soil-based cultivation.”

Benefits of the Cannabis Vertical Grow System

- Dramatic yield increases: The ability to stack multiple grow levels, each controlled for optimal production.

- Efficient use of resources: Advanced automation reduces water and nutrient consumption.

- Space savings: Operations can thrive in warehouses, converted industrial spaces, or urban environments with limited land access.

- Consistency of quality: Controlled parameters lead to uniform cannabinoid and terpene outputs—vital for medicinal and recreational markets.

- Lower risk of contamination: The closed, automated design reduces pest, disease, and pesticide usage.

By embracing a cannabis vertical grow system, producers position themselves to meet market demand, reduce resource usage, and edge out competitors still relying on conventional indoor or outdoor cultivation.

How Do Automated Vertical Systems Work?

The integration of automation technologies is what sets modern cannabis vertical grow systems apart. Let’s break down their core elements and how they facilitate high-efficiency cannabis production in 2025 and beyond:

-

Sensor Networks: Sensors embedded in grow trays monitor vital data including soil moisture, temperature, humidity, and EC (electrical conductivity), relaying it to a central control system.

Benefit: Immediate adjustments can be made to environmental and nutrient variables, minimizing stress and maximizing yields. -

AI-Based Climate Controls: Automated climate modules use machine learning to anticipate environmental needs (light, CO2, humidity).

Benefit: This precision improves cannabinoid consistency and reduces resource waste. -

Robotic Automation of Labor: Planting, pruning, and harvesting are handled by robotic arms programmed for cannabis morphology.

Benefit: Reduced labor costs, lower human error, and scalable operations. -

Automated Nutrient Delivery: Formulations are dispensed based on live data analysis, ensuring every plant gets what it needs, when it needs it.

Benefit: Optimizing nutrient use, reducing runoff, and maintaining a healthy root zone.

Automated Vertical Farming System: The Backbone of Cannabis Automation

The next leap in cannabis automation builds on vertical farming with integrated robotics, sensors, artificial intelligence, and IoT. By 2025, the modern automated vertical farming system will become the cornerstone of mainstream cannabis cultivation operations. This integrated approach, when applied to cannabis, results in:

- Consistent, high-quality product output

- Reduced operational costs, especially labor and utilities

- Minimization of agricultural waste

- Compliance with increasingly strict regulatory requirements

- Scalable production—from small urban facilities to multi-story industrial farm hubs

Key Technologies in Automated Cannabis Vertical Systems

- Environmental Sensors: Real-time data collection on climate parameters, soil conditions, and plant health.

- Robotics: Automates repetitive and strenuous cultivation tasks—like transplanting clones, defoliation, and harvest.

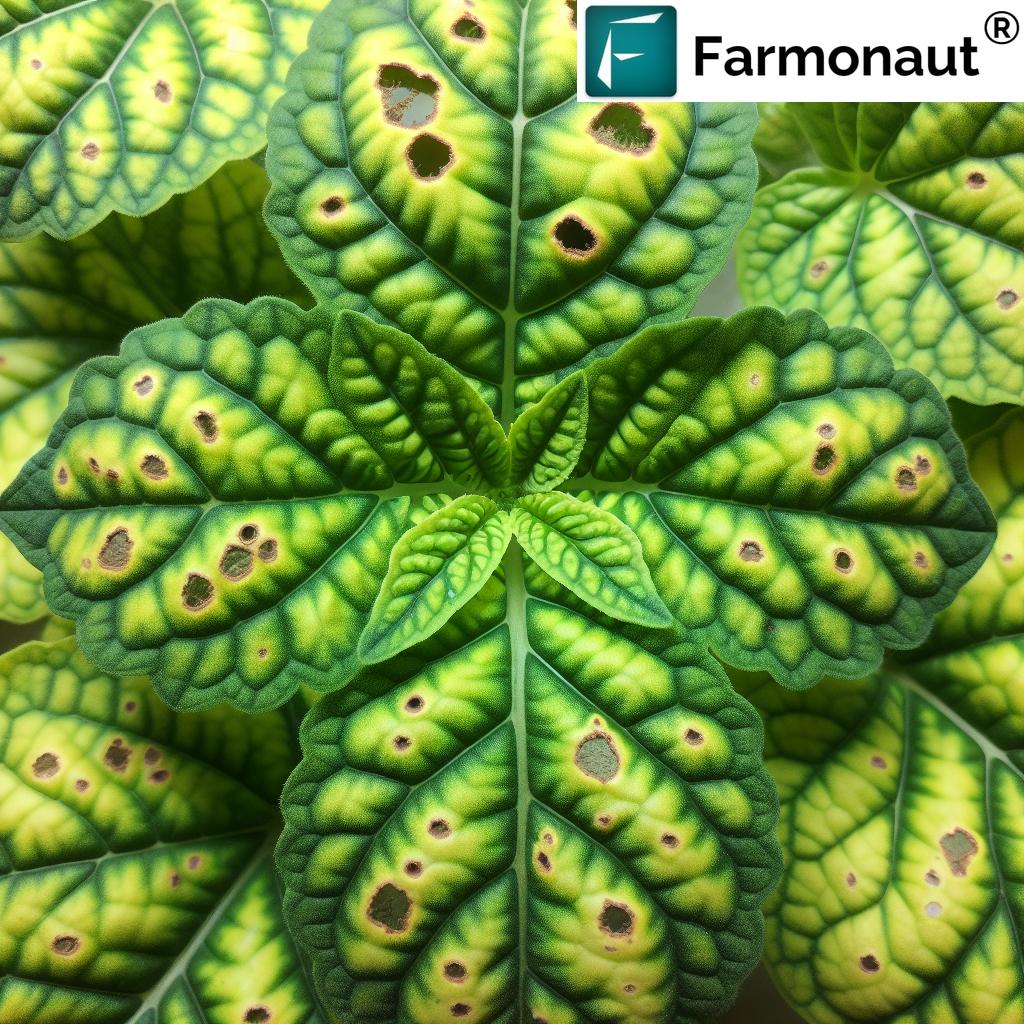

- Machine Vision and AI: Camera-aided systems monitor growth, detect early signs of deficiencies or diseases, and streamline workflow planning.

- Hydroponics and Aeroponics: Closed-loop systems dramatically reduce water usage while providing precision nutrient delivery.

The synergy of these technologies in an automated vertical farming system ensures that cannabis production meets both efficiency and quality demands from medicinal and recreational markets worldwide.

Core Components of Automated Cannabis Vertical Grow Systems

For maximal value, let’s deconstruct the core hardware and software components of a high-tech cannabis vertical grow system by 2025:

- Structural System: Tiered metal or composite shelving, supporting multiple grow trays per square meter in an optimal layout.

- Lighting System: Advanced LED arrays tailored for cannabis requirements (spectrum, PAR, intensity, photoperiods).

- Environmental Control: Temperature, humidity, and CO2 management modules for controlled environments at every level.

- Nutrient Delivery: Automated irrigation (hydroponic, aeroponic, or drip) with real-time dosing precision based on sensor data.

- Automation Controller: Centralized system using sensor networks, AI, and IoT integrations for real-time control and adjustments.

- Robotic Systems: Robots for tasks such as planting, transplanting, trimming, and harvesting, ensuring speed and uniformity.

- Data Analytics Dashboard: User interface for monitoring inputs, outputs, alerts, and for making predictive, data-driven decisions on production.

This combination is designed to facilitate growth in a repeatable, reliable manner—key to consistency and scalability in the evolving cannabis industry.

Want to integrate advanced, real-time crop health insights and environmental monitoring into your own cannabis or vertical farming operation?

Explore Farmonaut’s satellite-based crop monitoring & environmental impact platform — ideal for maximizing productivity and sustainability in both small and large-scale cannabis farms.

Farmonaut’s solutions empower agricultural producers to:

- Remotely monitor crop vigor, stress, and developmental stages using multispectral imagery (NDVI, NDRE, MSAVI, EVI, SIPI, LAI, FCVI)

- Receive AI-based irrigation and fertilization advice (Crop Plantation & Forest Advisory)

- Reduce costs by optimizing resource use—critical for water and nutrient savings in vertical grow systems

- Track and manage the carbon footprint of your cultivation with advanced environmental impact monitoring (Carbon Footprinting)

- Ensure product chain authenticity and compliance through blockchain-based cannabis traceability (Product Traceability)

Our suite is accessible on

for all vertical farming and cannabis automation stakeholders.

for all vertical farming and cannabis automation stakeholders.

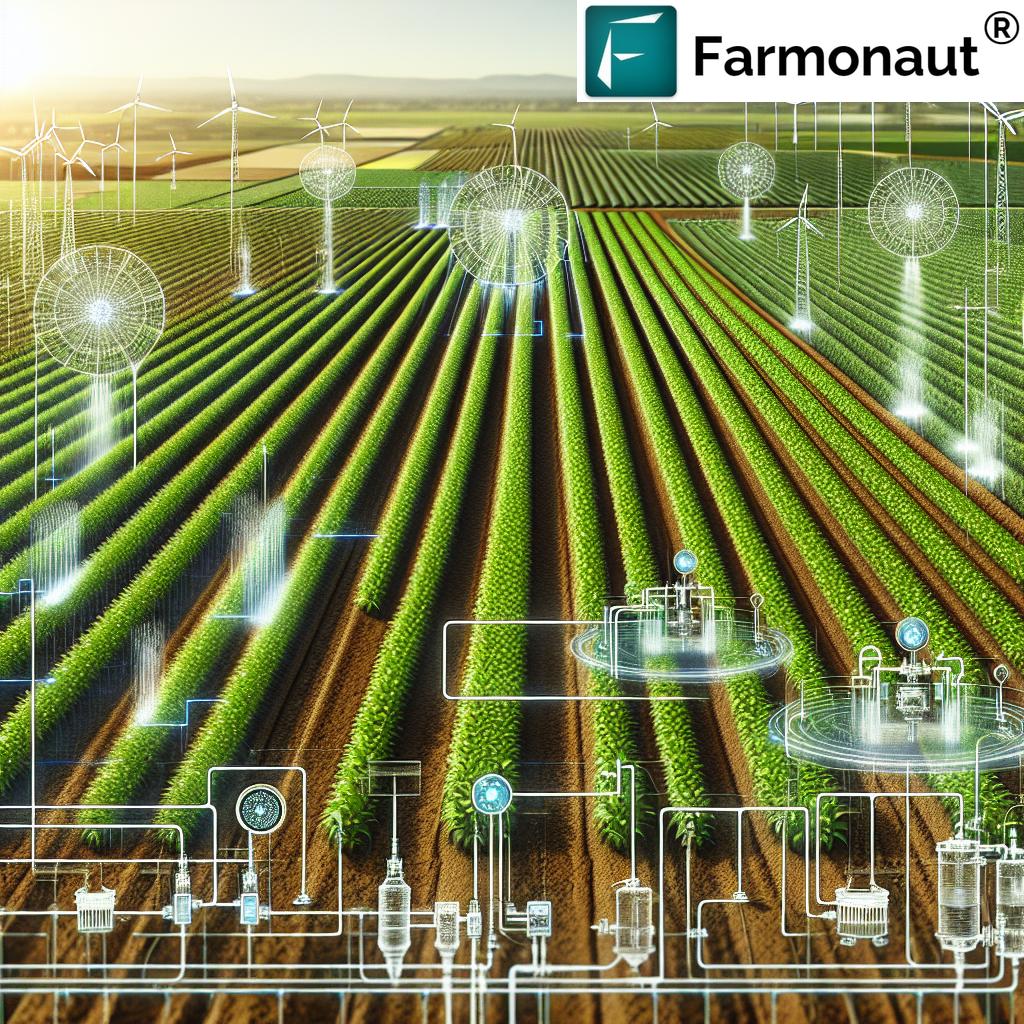

Optimizing Resource Use: Water, Energy, and Space

The value proposition of a cannabis vertical grow system extends beyond higher production. Resource efficiency is central to lowering operational costs and meeting sustainability goals—especially as global water scarcity and energy concerns intensify by 2025.

- Water Use: By relying on closed recirculating hydroponic or aeroponic methods, some automated vertical cannabis farms can reduce water use by up to 95% per cycle—representing hundreds of thousands of liters saved annually for large operators.

- Energy Efficiency: Next-generation LED lighting systems are not only spectrum-tailored but also energy-efficient, allowing precise control of light cycles and reducing power bills.

- Land Conservation: Cultivating in multiple levels inside a vertical system enables significant crop yields using a fraction of the land required for traditional horizontal or outdoor methods.

- Waste Minimization: By administering nutrients only as needed, nutrient and chemical runoff is minimized—critical for environmentally sensitive and regulated markets.

Farmonaut’s satellite-based resource management platform can further enhance decision-making by providing data on both the environmental health and productivity of your grow operations. Modern cannabis producers harness these technologies to ensure long-term profitability and sustainability.

Fleet management and resource optimization are also key for larger operations—discover more at Farmonaut Fleet Management.

Sustainability: Reducing Waste and Environmental Impact

Sustainability is no longer optional in the cannabis industry. In 2025 and beyond, environmental responsibility is both a regulatory mandate and a path to consumer trust. Automated vertical grow systems are inherently more sustainable in several ways:

- Reducing Water, Fertilizer, and Pesticide Consumption: Precisely dosed, recirculated nutrients and water mean massive savings—and far less waste discharged into the environment.

- Energy & Carbon Footprint: Modern climate and lighting controls significantly reduce energy consumption per kilogram of cannabis produced.

- Localizing Production: By enabling urban and peri-urban farms, vertical farming reduces transport requirements—directly cutting GHG emissions associated with complex supply chains.

- Minimizing Pests & Disease: The closed, meticulously controlled system reduces the risk of pest outbreaks—lowering the need for chemical treatments and further protecting soil/water quality.

- Enhanced Compliance & Transparency: Smart farming automation provides precise records for certifications, inspections, and blockchain-based traceability (read more).

Sustainable practices and real-time environmental monitoring—with Farmonaut’s carbon footprinting and environmental impact tools (learn more)—empower growers to lead in both compliance and stewardship, differentiating products in a crowded global market.

Comparison of Traditional vs. Automated Cannabis Vertical Grow Systems

To help cultivators and investors compare options, here’s a table summarizing the key differences between traditional horizontal, vertical, and modern automated vertical grow systems for cannabis:

| System Type | Space Utilization (%) | Yield per Square Meter (kg) | Water Usage (liters per crop cycle) | Energy Consumption (kWh per crop cycle) | Labor Requirement (hrs/week) | Initial Setup Cost (USD) | Sustainability Impact |

|---|---|---|---|---|---|---|---|

| Traditional Horizontal | 30-50% | 0.5 – 1 | 500 – 800 | 200 – 350 | 40-60 | $60,000+ | Low |

| Traditional Vertical | 60-80% | 1.0 – 2 | 300 – 500 | 250 – 400 | 25-40 | $85,000+ | Medium |

| Automated Vertical (Modern) | 90-95% | 2.0 – 3.5+ | 50 – 80 | 140 – 250 | 7-15 | $100,000+ | High |

Note: All values are illustrative estimates based on typical industry figures for a single grow cycle.

Automated vertical systems do require higher upfront investment but deliver the highest return on investment (ROI) through savings in labor, water, energy, and space—while providing superior yields and ecological outcomes.

Economic Impact and Sector Growth by 2025

As the cannabis industry expands globally, economic dynamics are shaped by increased demand, evolving market regulations, and ongoing integration of automation and vertical farming technologies. By 2025, the transition toward automated vertical grow systems has several economic effects:

- Reduced labor costs: Automation allows cultivators to maintain large-scale operations with smaller, highly trained staff.

- Lower incremental input costs: Precision dosing and recirculation sharply reduce water, fertilizer, and pest control expenses per crop cycle.

- Improved product traceability and regulatory compliance: Automation provides reliable, transparent logs that satisfy regulators and customers alike (see Farmonaut’s traceability solutions).

- Market democratization: As modular, plug-and-play automated vertical farming systems proliferate, even mid-sized producers can access the same productivity and sustainability gains as industry giants.

- Operational resilience: Controlled, indoor factory-style cannabis production is less susceptible to supply disruption from climate, pests, or regional labor shortages.

By leveraging these advantages, cannabis growers are better positioned to meet both current and future market demand—particularly in regulated environments where quality, transparency, and efficiency are paramount.

Satellite Technology & Cannabis Automation: Farmonaut Solutions

As satellite technology, IoT, and AI become increasingly critical for advanced cannabis vertical grow systems, having a trusted technology partner is key. Farmonaut provides a unique combination of satellite imagery, AI advisory, blockchain traceability, and resource management tools tailored to both small-scale and large-scale agriculture—including high-value cannabis operations.

How Can Farmonaut Enhance Automated Vertical Farming Systems?

-

Real-Time Satellite Crop & Resource Monitoring: Monitor environmental parameters, crop health indices, and infrastructure remotely—essential for both urban and rural vertical grow facilities.

-> Get started with our APIs: Farmonaut API | Developer Docs - AI-Based Advisory (JEEVN AI): Our Jeevn system delivers timely, actionable strategies—ranging from weather predictions for energy optimization to irrigation/fertilization advice based on live satellite imagery.

- Blockchain Traceability for Cannabis Supply Chains: Transparency is critical for compliance. Blockchain integration ensures product authenticity, safety, and regulatory adherence. Learn more about Traceability

- Fleet and Resource Management: For enterprises managing transport and equipment within large vertical facilities or multi-site operations. Improve logistics, reduce costs, and maximize asset use (Fleet Management).

- Sustainability Tracking: With carbon footprint monitoring and environmental impact dashboards, our tools help companies reduce environmental risks and promote sustainable branding.

- Crop Loan and Insurance: Satellite-driven verification streamlines loan/insurance for cannabis growers, further democratizing access to finance. Discover more about crop loan and insurance.

These solutions empower cultivators with real-time, affordable data for tactical and strategic decision-making—reducing resource consumption while maximizing output and compliance.

Farmonaut Subscription for Scalable, Affordable Smart Farming

Frequently Asked Questions (FAQ)

What is a cannabis vertical grow system?

A cannabis vertical grow system refers to a multi-tiered cultivation method that leverages vertical space. Multiple layers of plants are stacked within a controlled, often automated indoor environment, significantly increasing yield per square meter.

How does automated vertical farming improve efficiency in cannabis cultivation?

Automated vertical farming uses robotics, IoT sensors, AI, and centralized controls to regulate every aspect of the grow environment. This ensures precise control of water, nutrients, light, temperature, and humidity, optimizing plant health and reducing resource consumption.

Can vertical and automated systems reduce cannabis production costs?

Yes, while initial capital investment is higher, the reduction in labor, water, energy, and nutrient waste leads to lower operational costs and a shorter break-even timeline, particularly as technology costs decrease by 2025.

Are automated cannabis vertical systems suitable for small-scale or only large-scale producers?

Modern, modular automated vertical grow systems are designed for scalability. Both small and large producers can benefit, with plug-and-play options now available for a range of operation sizes.

How does Farmonaut support cannabis automation and vertical farming?

We offer satellite-driven monitoring, AI advice, blockchain traceability, carbon footprint tracking, and resource management solutions. These empower cannabis farmers to achieve maximum yields, resource savings, transparent supply chains, and environmental compliance.

What is the sustainability impact of automated cannabis vertical farming?

Automated vertical systems can reduce water use by up to 95%, lower energy consumption, minimize chemical/pesticide runoff, and enable year-round local production—drastically lowering the environmental impact compared to traditional cultivation.

Can vertical systems meet compliance and regulatory tracking requirements?

Yes. Automation provides real-time, reliable data logs for every step of the cultivation process. Combined with blockchain traceability, they generate transparent records that support auditing, certifications, and consumer trust.

What are the challenges to implementing automated cannabis vertical farming?

Key challenges include initial investment costs, the need for skilled staff to manage and interpret systems, and adapting workflow for automation. However, these are declining as technology advances and becomes more user-friendly.

Conclusion: The Future of Vertical Cannabis Cultivation

By 2025, cannabis vertical grow systems and automated vertical farming systems will dominate the conversation on sustainable, scalable, and high-efficiency cannabis cultivation. The integration of smart technologies, from advanced robotics and environmental sensors to AI-driven management platforms like those offered by us at Farmonaut, is poised to revolutionize how the world grows, tracks, and consumes cannabis.

Producers adopting these innovations gain a decisive edge: higher yields, superior product quality, dramatic resource savings, and robust compliance tools. They not only help address current market challenges but also set new standards for the entire agricultural sector.

If you’re looking to future-proof your cannabis farm or smart vertical operation, explore Farmonaut’s web, iOS, and Android solutions. We empower businesses to thrive with satellite insights, AI advisory, and a sustainable, technology-driven vision for agriculture.

Step confidently into the revolutionary world of automated cannabis vertical farming. The future of sustainable agricultural production is vertical—and the time to embrace it is now.

For developers and integrators wishing to harness real-time satellite-driven insights for vertical farming and cannabis automation, Farmonaut’s API and developer documentation provide everything needed to power the next generation of sustainable innovations.