Hydrogen Fuel Cell Trucks Revolutionize Anaheim Logistics in 2025

Hydrogen fuel cell trucks are set to redefine the future of zero-emission drayage fleets in Anaheim, North America and beyond. As we approach 2025, the intersection of world-class technology, urgent sustainability mandates, and logistics industry innovation brings forth a revolution—rooted in fuel cell powertrain technology, advanced hydrogen storage tanks, rapid refueling, and the collective ambition to decarbonize infrastructure.

In this comprehensive exploration, we—as logistics professionals, technologists, and environmental stewards—will traverse the landscape of hydrogen fuel cell trucks: how they work, why they matter, how Anaheim is becoming a beacon of clean freight mobility, and what lies ahead for advanced clean transportation in the rapidly transforming sector of Class 8 trucking.

Evolving Drayage: The Drive for Zero Emissions and Advanced Logistics

The drayage sector—responsible for short-haul movement of freight between ports, rail yards, and warehouses—has long depended on diesel-powered trucks. However, mounting decarbonization pressures, health concerns, and environmental regulations—particularly in logistics-dense hubs like Anaheim—are catalyzing a radical transformation.

With hydrogen fuel cell trucks at the forefront, local policy, public expectation, and industry innovation are converging to create sustainable transportation solutions that address the dual goals of fleet efficiency and climate responsibility.

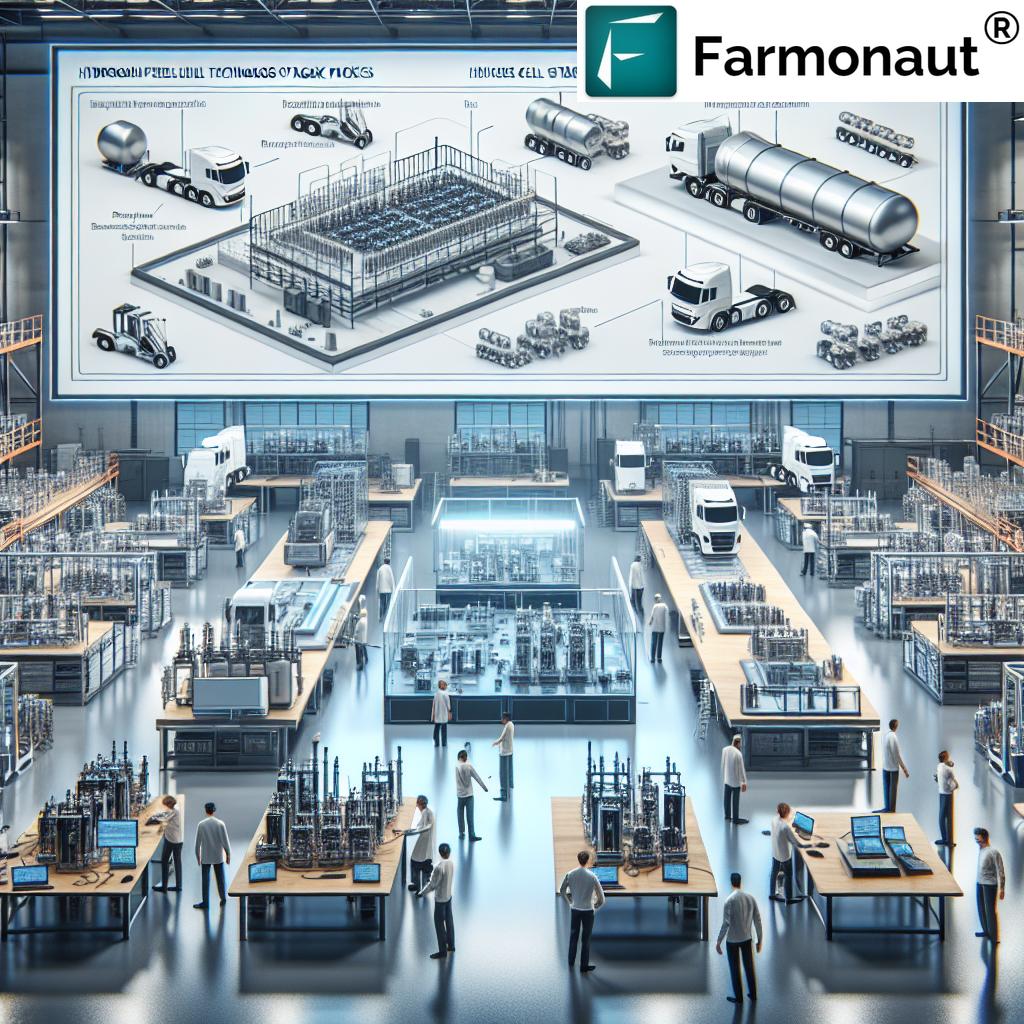

Hydrogen Fuel Cell Trucks: Technology & Innovation

At the core of this transformation are fuel cell powertrain technology and hydrogen storage tanks. But how exactly do hydrogen fuel cell trucks deliver on the promise of zero-emission drayage fleet operations?

How Fuel Cells Work

- Hydrogen fuel cell trucks use a chemical reaction between hydrogen and oxygen—inside a fuel cell stack pack—to produce electricity.

- This electricity drives electric motors, propelling the truck with only water vapor as an emission.

- Unlike batteries that need extended charging, fuel cell units can be rapidly refueled at hydrogen refueling stations.

Key Components: Powertrain, Tanks, and Stack Pack Units

The backbone of class 8 hydrogen trucks is their powertrain architecture:

- Fuel Cell Stack Pack Units: Multiple 75kW fuel cell units, like StackPack, are combined for up to 300 kW output—maximizing the power-to-weight ratio in drayage tractors.

- Hydrogen Storage Tanks: Advanced tanks store hydrogen at high pressure (up to a maximum of 34 kilograms for leading prototypes), enabling a substantial driving range per refueling.

- Electric Propulsion System: This integrates seamlessly with the chassis of purpose-built or retrofitted trucks, delivering continuous and reliable power output under diverse load conditions.

Remarkably, these technological advancements allow hydrogen fuel cell tractors to weigh only 16,000 pounds—thousands lighter than competing zero-emission technologies—freeing additional payload for logistics companies in Anaheim and across North America.

Spotlight: Anaheim’s Commitment to Hydrogen Transportation Solutions in 2025

Anaheim, California, hosts the nation’s most influential clean transportation showcase—the Advanced Clean Transportation (ACT) Expo—where the adoption of hydrogen fuel cell trucks has become a central theme.

As of 2025, leading logistics and infrastructure companies are actively testing and deploying hydrogen fuel cell tractors throughout their drayage fleets. Anaheim’s proximity to major ports, bustling intermodal yards, and vast warehouse districts makes rapid decarbonization a business imperative and an environmental necessity.

- The practical advantages—swift refueling in under 15 minutes, silent operation, and substantial range—are allowing Anaheim’s logistics sector to lead the way in zero-emission drayage fleet adoption.

- Innovative companies are leveraging advanced trucks built on robust Mack Anthem chassis, with tailored fuel cell powertrains, to ensure both efficiency and sustainability.

Comparative Benefits Table: Hydrogen vs. Diesel in Anaheim Logistics (2025)

| Vehicle Type | Estimated Range (miles) |

Refueling Time (minutes) |

Estimated Emissions (CO₂e/ton-mile) |

Payload Capacity (tons) |

Estimated Operational Cost ($/mile) |

Adoption Rate in Anaheim (2025, %) |

|---|---|---|---|---|---|---|

| Hydrogen Fuel Cell Truck | 400–500 | 10–15 | ~0 (water vapor) | 18–20 | $1.20–$1.60 | 14–17% |

| Diesel Truck | 550–700 | 8–10 | 0.26 | 20–22 | $1.55–$2.10 | 73–76% |

*Estimated values for 2025, factoring in Anaheim’s fleet composition and typical use cases. Data underscores the emissions and cost reductions achievable with hydrogen fuel cell trucks.

Fuel Cell Powertrain Technology in Class 8 Hydrogen Trucks

In Anaheim and throughout North America, class 8 hydrogen trucks are leapfrogging traditional models thanks to advancements in fuel cell powertrain technology.

Design, Engineering & Production

- Retrofitted and purpose-built chassis—such as the Mack Anthem platforms—form the structural backbone, supporting robust integration of hydrogen tanks and fuel cell stack packs.

- Modular design allows multiple StackPack 75kW units to be combined for scalable power, balancing range and payload needs on a per-fleet or per-route basis.

- Lightweight engineering ensures that operational capacity is not sacrificed; with vehicle weights under 16,000 lbs, more goods can be moved in a single trip—beneficial for agriculture, chemical, and food divisions.

This technology unlocks crucial savings in operational costs and accelerates the decarbonization of logistics operations. Logistics companies can further optimize by leveraging Farmonaut’s Fleet Management tools—combining vehicle tracking, efficient route planning, and real-time insights to maximize return on investment for hydrogen fuel cell truck deployments.

Optimize Your Logistics With Farmonaut Apps

Farmonaut’s platform delivers seamless fleet and resource management, empowering logistics teams to schedule, monitor, and optimize every aspect of vehicle usage. This results in reduced operational costs, improved safety, and enhanced productivity for hydrogen fuel cell truck fleets and traditional assets alike.

Access our applications:

Interested in integrating real-time satellite and weather data into your own logistics or fleet management solution?

Access Farmonaut’s API

|

Developer Docs

Hydrogen Infrastructure Solutions: Refueling and Storage in North America

One of the principal hurdles in scaling hydrogen fuel cell trucks is the available hydrogen infrastructure: production, storage, and hydrogen refueling stations. Anaheim and neighboring metropolitan areas are seeing targeted investment to fill these gaps and accelerate deployment.

- Hydrogen Storage Technology: New pressure vessels and centralized storage tanks facilitate rapid, high-volume refueling—supporting logistics operations that require minimal downtime.

- On-Site Hydrogen Production: On-premises solutions cut dependence on centralized supply chain bottlenecks, allowing logistics companies to guarantee continuous service and accelerate decarbonization efforts.

- Hydrogen Refueling Stations: Across Anaheim and North America, 2025 anticipates a network expansion—supported by component manufacturers and infrastructure partners—to enhance accessibility and reliability for large drayage fleets.

The outcome is a robust, practical, and scalable hydrogen economy, positioning Anaheim as a national leader in advanced clean transportation.

Sustainable Transportation Solutions: Decarbonizing Logistics Operations

Sustainable transportation is more than a buzzword—it’s a necessity, and hydrogen fuel cell trucks are central to this new era. How do these vehicles enable logistics companies to decarbonize and remain competitive?

- Zero-Emission Drayage Fleets: Emitting only water vapor, hydrogen fuel cell units remove greenhouse gases and particulates from the logistics equation—improving urban air quality and public health.

- Carbon Footprint Monitoring: Companies can leverage Farmonaut’s Carbon Footprinting solution to automatically track emissions from logistics and agricultural operations. Real-time data fuels compliance, reporting, and strategic environmental improvements.

- Resource Optimization: Innovations like AI-powered fleet management drive operational efficiency—lowering fuel consumption, reducing empty miles, and increasing overall output.

Combined with hydrogen infrastructure solutions and advanced AI tools, the logistics sector is empowered to take decisive steps toward a low-carbon future.

Transparency matters for both environmental and operational accountability. Explore Farmonaut’s Blockchain-Based Traceability to ensure full-source tracking across food and agriculture logistics, safeguarding brand trust and compliance.

Farmonaut and Advanced Logistics Monitoring

As hydrogen fuel cell trucks rise in prominence, the integration of advanced monitoring technology becomes essential. Farmonaut’s core offerings complement the next generation of logistics through:

- Satellite-Based Fleet Tracking: Monitor vehicle health, locations, and operational status in real-time—vital for logistics companies deploying hydrogen-powered fleets across large regions.

- AI-Driven Analytics: Leverage predictive models to optimize route planning, maintenance scheduling, and emission monitoring for each truck.

- Resource Management: Farmonaut’s tools help logistics teams proactively respond to changes in demand, road conditions, and refueling infrastructure availability.

By integrating Farmonaut’s technology stack, logistics companies operating class 8 hydrogen trucks in Anaheim, North America, and beyond, can streamline the path to low-carbon, high-performance transportation networks.

For large-scale operations and agri-logistics divisions, Farmonaut’s Agro Admin App offers complete large-scale farm and logistics management at your fingertips—driving maximum operational efficiency for the modern supply chain.

Frequently Asked Questions

What is a hydrogen fuel cell truck, and how does it differ from electric or diesel trucks?

A hydrogen fuel cell truck harnesses energy by combining hydrogen with oxygen in a fuel cell. This process generates electricity to power its motors, emitting only water vapor. Unlike electric trucks, which use large batteries, fuel cell trucks refuel within minutes at hydrogen refueling stations, delivering extended range and fast turnaround—crucial for real-world drayage fleet demands.

Why are hydrogen fuel cell trucks ideal for drayage and logistics in Anaheim?

Logistics in Anaheim involves frequent, intensive trips between ports, railyards, and warehouses. Hydrogen fuel cell trucks are lightweight (increasing payload), can refuel in under 15 minutes, and travel 400–500 miles per tank—enabling them to meet tight schedules and emission mandates better than battery-only alternatives.

How does hydrogen refueling compare to battery charging?

Hydrogen refueling typically takes less than 15 minutes for a full tank, whereas battery charging—even rapid—can take 45+ minutes or several hours. The accelerated turnaround is vital for drayage operations that require trucks to be on the road as much as possible.

What is the environmental impact of hydrogen fuel cell trucks versus diesel trucks?

Hydrogen fuel cell trucks produce only water vapor, resulting in virtually zero greenhouse gas emissions per ton-mile. Diesel trucks emit carbon dioxide, NOx, and particulates—contributing to pollution and climate change. Switching to hydrogen fuels is key for meeting sustainability targets and regulatory requirements.

How is the hydrogen infrastructure developing in North America?

Significant investments are underway in hydrogen production, storage, and refueling stations—especially in logistics hotbeds like Anaheim and across California. On-site production, advanced storage solutions, and public-private collaboration are rapidly scaling hydrogen availability for commercial fleets.

How do I track carbon footprint and traceability in logistics?

Farmonaut’s suite of software and API products provides automated carbon footprint monitoring and blockchain-based product traceability. This ensures end-to-end accountability and transparency, supporting compliance and building trust for logistics and agri-supply chains.

Farmonaut Subscription Plans

Transition in the Trucking Industry: Opportunities and Challenges

As we approach 2025 and beyond, the logistics and freight industries in Anaheim and across North America face both unprecedented opportunities and tangible challenges in adopting hydrogen fuel cell trucks:

- Opportunities:

- Regulatory compliance with emerging emission standards

- Market differentiation through sustainability leadership

- Increased operational efficiency from modern fleets

- Long-term cost savings as hydrogen becomes more accessible

- Challenges:

- Expanding the hydrogen infrastructure at the pace of fleet adoption

- Ensuring continuous supply and rapid refueling

- Transitioning legacy fleets and driver retraining

- Managing fluctuating hydrogen costs and availability

Advanced software platforms, such as Farmonaut’s AI-driven monitoring systems, will remain central for large and small logistics operators aiming to navigate this transition—optimizing, tracking, and accelerating return on investment in a clean energy future.

For enterprises needing robust risk mitigation in uncertain times, Farmonaut’s Crop Loan & Insurance Verification Solutions provide remote, satellite-verified documentation—facilitating financing and reducing insurance fraud in agriculture logistics.

Conclusion: Charting the Course for Greener Anaheims

As hydrogen fuel cell trucks gather momentum, we—stakeholders in logistics, technology, and sustainability—are entering an era of unparalleled transformation. The future painted by Anaheim’s evolving zero-emission drayage fleet is powered by integrated fuel cell powertrain technology, innovative hydrogen storage tanks, fast refueling stations, and data-driven logistics solutions.

Committing to sustainable transportation solutions is no longer optional. Through the clever adoption of hydrogen fuel cells, advanced infrastructure, and platforms like Farmonaut, we are laying the groundwork for a logistics sector that is cleaner, more resilient, and better equipped for the demands of modern commerce.

Whether you’re a fleet manager, sustainability officer, or industry innovator, now is the time to embrace the hydrogen revolution—and leverage smart tools that safeguard profitability and the planet alike.

Ready to Optimize Your Sustainable Logistics Fleet?

Discover how Farmonaut’s satellite, AI, and traceability solutions can boost your fleet’s performance and accountability. Integrate with your hydrogen truck operations for unparalleled visibility—from field to final mile.