Health and Safety in Mining Operations: 7 Vital 2025 Trends

Summary: Health and Safety in Mining Operations – A 2025 Perspective

Mining is a cornerstone of the global economy, supplying essential minerals and metals fundamental for infrastructure, technology, and energy sectors. With its inherently significant challenges, mining operations expose workers to complex machinery, hazardous environments, and continuous risks of accidents.

As we advance into 2025, the emphasis on health and safety in mining operations is more critical than ever, driven by increasingly stringent regulations, rapid technological innovation, and a growing focus on workforce well-being and environmental sustainability.

This comprehensive guide examines the evolving risks, modern regulatory landscape, cutting-edge technology, and key workforce-centered practices shaping safer, more sustainable outcomes for the mining industry in 2025 and beyond.

“By 2025, over 60% of mining companies are expected to adopt AI-driven safety monitoring systems for worker protection.”

Evolving Health and Safety Risks in Modern Mining

The landscape of health and safety in mining operations is undergoing rapid transformation with the expansion of mining into more challenging geographic zones and the introduction of new technological processes. However, risks remain inherent due to several interconnected factors.

- Exposure to Dust and Toxic Gases: Continuous exposure to mineral dust and hazardous gases such as methane or silica remains a critical risk for workers. Chronic issues like silicosis, respiratory diseases, and even hearing loss due to prolonged noise exposure are enduring threats.

- Ground Collapses and Structural Failures: Underground mines involve the risk of cave-ins, rock bursts, and ground collapses. These hazards are compounded in deep mines, arctic regions, and resource-rich zones with extreme environmental conditions.

- Heavy Machinery Accidents: The scale and complexity of modern mining equipment and machinery introduce significant accident potential — from striking incidents to machinery failure due to maintenance lapses.

- Mental Health Challenges: Recognition of mental health issues is increasing. The isolated, high-stress nature of mining work is gaining attention, bringing fatigue management, psychological support, and community belonging to the fore.

- Expansion into New Zones: Industry expansion into deeper, colder, and harsher regions presents further challenges in emergency response and routine safety management.

As operations become more sophisticated, the ability to proactively identify, monitor, and mitigate these hazards is a vital determinant of both safety outcomes and operational sustainability.

Regulatory Landscape and Compliance in 2025

By 2025, the regulatory landscape for health and safety in mining operations has become increasingly rigorous. International and national bodies mandate comprehensive protocols and continuous hazard assessments. Mining companies must comply with stricter reporting mechanisms, transparency requirements, and third-party audits.

Modern regulations not only focus on reactive incident handling but also emphasize proactive risk mitigation through integration of health, safety, and environmental (HSE) management systems. Failure to meet these standards can result in substantial financial penalties, potential closure, and long-term reputational harm.

Compliance is no longer an option — it is the foundation of trust between mining companies, their workforce, and the communities they impact. Transparency, through regular reporting on safety performance and environmental monitoring, is becoming a global industry expectation.

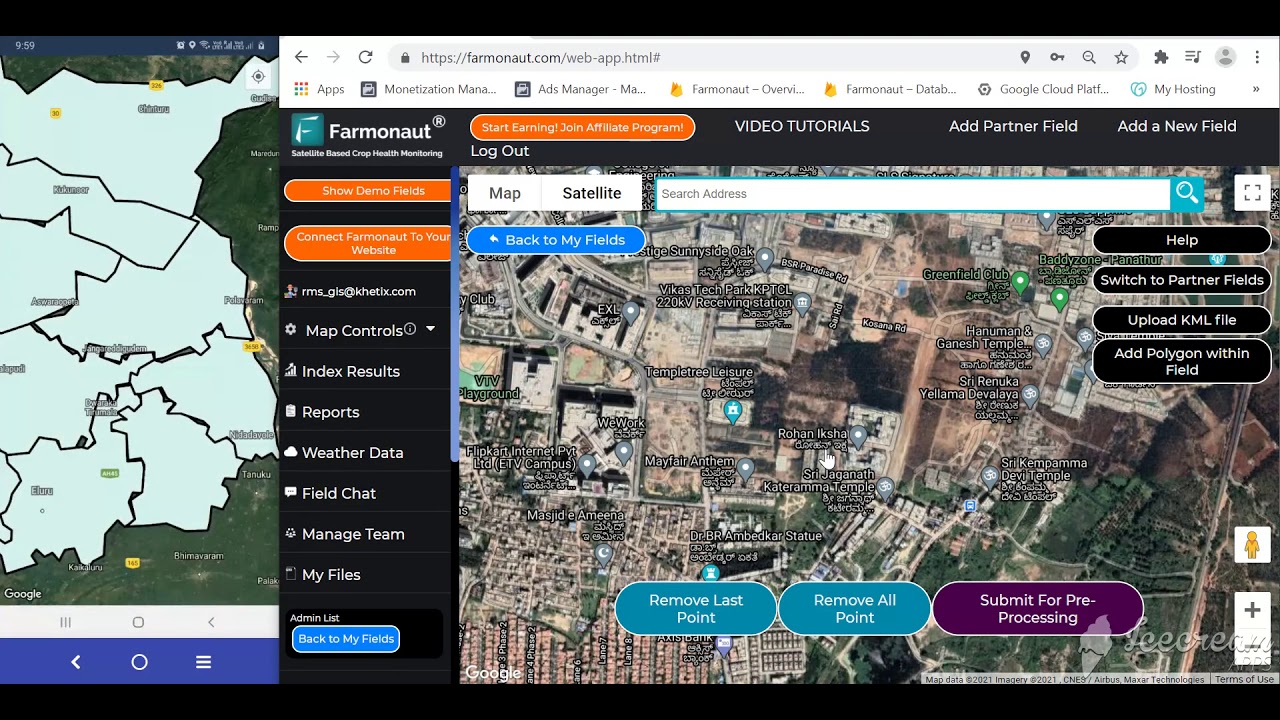

Access the Farmonaut App for satellite-driven, real-time oversight of safety and environmental conditions in mining sites—supporting regulatory compliance and sustainable operations.

7 Vital 2025 Trends Redefining Health and Safety in Mining Operations

The mining sector is rapidly adapting to a new paradigm in health and safety in mining operations. Here, we explore the seven most impactful trends reshaping worker protection, risk management, and safety culture for 2025 and beyond:

Trend 1: AI-Driven Safety and Risk Monitoring

- Deployment of artificial intelligence systems to analyze streams of equipment, environmental, and human data for early identification of hazards.

- Automated, 24/7 detection of unsafe conditions (e.g., air quality, ground instability, equipment stress).

- Estimated Incident Reduction: Up to 40% fewer workplace accidents due to predictive analytics.

Trend 2: Automation and Remote Operations

- Use of autonomous drills, loaders, and haulage equipment, minimizing worker exposure to hazardous zones.

- Remote-control centers to oversee mining operations in deep or dangerous locations.

- Estimated Impact: Up to 65% reduction in human presence in high-risk zones.

Trend 3: Wearable Safety Technology

- Smart helmets, gas detectors, and biosensors continuously monitor workers’ vital signs and surroundings.

- Immediate alerts for exposure to toxic gases, dust, heat, or signs of fatigue.

- Automated logging for compliance audits and incident investigations.

Trend 4: Immersive Safety Training: VR & AR Simulations

- Integration of virtual reality (VR) and augmented reality (AR) for immersive, risk-free emergency response training.

Scenarios include underground fire, ground collapse, and first aid training with real-time feedback. - Estimated Benefit: Up to 55% improvement in knowledge retention and real-world preparedness.

Trend 5: Advanced Environmental Monitoring and Carbon Footprinting

- Remote sensing and satellite-driven continuous monitoring of air quality, water runoff, dust emissions, and carbon footprinting for mines.

- Helps operational management mitigate environmental hazards and align with sustainability goals.

- Read more about Farmonaut’s Carbon Footprinting product—track emissions, meet regulations, and support sustainable mining practices.

Trend 6: Mental Health, Fatigue Management, and Inclusive Safety Culture

- Growing recognition of mental health’s impact on operational safety.

- Introduction of fatigue detection technologies and comprehensive well-being programs, including counseling and peer support structures.

- Open, transparent communication and reporting channels, without fear of reprisal.

Trend 7: Blockchain Traceability & Transparent Reporting

- Implementation of blockchain across mining supply chains for transparent, secure tracking of extracted minerals and compliance with operational, environmental, and ethical standards.

- Blockchain-based reporting to meet regulatory requirements and foster public trust.

- Discover Farmonaut Traceability—empowering mining operators with end-to-end transparency and compliance.

Comparative Trend Impact Table: Health and Safety in Mining Operations (2025)

| Trend Name | Brief Description | Estimated Impact on Worker Safety | Related Regulation/Standard | Example Technological Solutions |

|---|---|---|---|---|

| AI-Driven Safety and Risk Monitoring | Continuous AI analysis of operational and environmental data for proactive hazard detection. | ~40% reduction in preventable incidents | Global Mining H&S ISO 45001, MSHA Digital Safety Directives | AI-based safety dashboards, satellite monitoring, smart analytics |

| Automation and Remote Operations | Autonomous equipment/robots to reduce human exposure in high-risk zones. | 65% reduction in human presence in hazardous areas | Autonomous Systems Regulation, ISO 17757 | Automated drills, self-driving haul trucks, remote-control centers |

| Wearable Safety Technology | Deployment of sensors and biosensors for real-time exposure and health monitoring. | 30% decrease in undetected overexposure/health events | NIOSH/MHSC PPE Standards, OHS Regulations 2025 | Smart helmets, multi-gas detectors, proximity alarms |

| VR & AR Simulations for Training | Immersive safety drills and emergency scenario preparation for all workers. | 55% improvement in response preparedness | Global Safety Training Standards, ISO 45001 | VR/AR headsets, interactive simulation platforms |

| Advanced Environmental Monitoring & Carbon Footprinting | Continuous satellite/remote environmental and emissions monitoring to support safety and sustainability. | Number of environmental safety violations reduced by 50% | IFC Environmental Guidelines, Paris Agreement Compliance | Satellite remote sensing, carbon footprint calculators, air quality trackers |

| Mental Health & Fatigue Management | Comprehensive well-being programs and technology-based fatigue detection methods. | Up to 20% fewer human-error-related incidents | ISO 45003 (Psychosocial H&S), National Fatigue Codes | Wearable fatigue monitors, HR support platforms, mental health initiatives |

| Blockchain Traceability & Transparent Reporting | End-to-end supply chain tracking and secure, distributed safety records for compliance. | Enhanced regulatory trust; 70% faster incident investigation | OECD Due Diligence, Transparency Laws, Dodd-Frank 1502 | Blockchain-based traceability, digital reporting APIs |

Technological Innovations Driving Safety Improvements

Technology is an essential force for innovation in health and safety in mining operations. By 2025, mining companies are increasingly integrating advanced systems to address longstanding and emerging challenges:

- AI Safety Platforms: Automated analytics synthesize data from equipment sensors, environmental trackers, and human wearables—enabling predictive and real-time hazard alerts.

- Satellites & Remote Sensing: High-resolution, continuous satellite monitoring is becoming common to assess air quality, dust emissions, carbon output, and ground stability—ensuring constant vigilance at even the most difficult mining locations.

- Drones & Robotics: Drone-mounted sensors inspect hard-to-access infrastructure, while robotics perform hazardous maintenance and exploration tasks without direct worker exposure.

- Wearables: Smart PPE, such as biosensors and connected helmets, monitor heart rate, temperature, gas exposure, and fatigue, triggering automatic alarms or emergency interventions.

- VR/AR Training Suites: Virtual reality and augmented reality transform safety education—training workers in simulated emergencies to improve muscle memory and response.

- Blockchain Solutions: Used for supply chain traceability, blockchain records enhance safety accountability, product provenance, and rapid compliance verification.

These innovations do not replace the human element but extend it—giving teams powerful, data-driven tools to manage risk and respond to emergencies better than ever before.

Leverage Farmonaut’s platform—via web, iOS, and Android—for satellite-driven mine health, safety monitoring, and resource management.

Safety Culture and Workforce Well-being in Mining Operations

Achieving safer outcomes in mining operations is not just about technology and compliance—it demands a vibrant, continuously reinforced safety culture that values human life and worker well-being above all.

- Leadership Commitment: Sustained, visible dedication from senior management is crucial for instilling a “zero harm” philosophy throughout the organization.

- Continuous Education & Training: Regular safety drills, refresher courses, and updates on evolving hazards—leveraged through VR/AR and hazard identification apps—are essential for modern workforce readiness.

- Transparent Communication: Reporting of near-misses and unsafe conditions is encouraged without fear of retribution. Data-driven dashboards provide transparent risk overviews to all staff.

- Worker Empowerment and Inclusion: Front-line workers are given voice in safety decision-making and feedback loops; diversity is respected as a pathway to inclusive safety innovation.

- Mental Health & Fatigue Management: Proactive programs support mental resilience and reduce accidents due to fatigue or psychological strain.

A resilient safety culture, underpinned by ongoing engagement and accountability, remains the most effective foundation for health and safety in mining operations as we enter 2025.

Environmental Considerations & Community Health

Health and safety in mining operations now extends well beyond the direct workforce, encompassing the environmental health of neighboring communities and long-term sustainability of local ecosystems.

- Water & Air Quality Management: New standards require continuous satellite- and sensor-based monitoring of water discharges and air emissions (dust, NOx, SOx, and CO2) to protect both workers and the general public.

- Land Reclamation and Biodiversity: Planning for mine closure and restoration of habitats is a regulatory and ethical imperative, rewarding companies that invest in long-term stewardship.

- Community Engagement: Ongoing dialogue with local populations about operational risks, emergency response protocols, and transparency in environmental reporting is increasingly expected.

- Alignment with SDGs: Sustainable mining practices align operations with the United Nations’ Sustainable Development Goals (SDGs) to ensure positive social and environmental outcomes.

- Waste Management: Innovations in tailings storage, dust suppression, and hazardous material tracking minimize risks of large-scale incidents.

Mining’s social license to operate depends on a comprehensive, transparent approach to environmental and community health management, using real-time data and best-in-class practices.

Discover Farmonaut’s Carbon Footprinting and Fleet Management solutions for optimized resource usage and reduced emissions—meeting operational and environmental standards.

Farmonaut: Enabling Safer, More Efficient Mining Operations

At Farmonaut, we believe that access to innovative technology and affordable, real-time data is a transformative force for health and safety in mining operations. Our satellite monitoring, Jeevn AI advisory, and blockchain traceability capabilities empower mining companies to navigate the 2025 regulatory landscape with confidence:

- Satellite-Based Monitoring: We offer multispectral satellite monitoring for real-time assessment of environmental and operational hazards—delivering insights on air quality, dust, water contamination, and ground stability.

- AI Advisory System–Jeevn: Our Jeevn AI tools analyze complex operational data streams, providing predictive analytics, tailored risk mitigation strategies, and early-warning systems to prevent accidents.

- Blockchain Traceability: Blockchain-enhanced tracking ensures secure, tamper-proof documentation for compliance and stakeholder trust.

- Fleet and Resource Management: Our fleet management platform improves logistics and equipment usage, further minimizing operational risks and supporting a sustainable approach.

- Environmental Impact Tracking: By providing carbon footprinting and emissions insights, we help operations meet regulatory standards and support sustainability objectives.

To enable seamless integration into existing management systems, we provide a robust Farmonaut API and Developer Documentation. This allows organizations to connect their own dashboards or applications for custom reporting, regulatory compliance, and advanced analytics.

-

Crop Loan and Insurance Verification—supporting reliable satellite-based verification for mining-linked agricultural and rural finance.

-

Large Scale Field & Infrastructure Management—ideal for operators overseeing multiple mining sites, supporting resource allocation, and regulatory reporting.

“Modern safety regulations have reduced mining-related injuries by 35% globally between 2015 and 2023.”

Conclusion: The Way Forward in Mining Health and Safety

The future of health and safety in mining operations lies in a comprehensive approach—one that merges stringent regulatory compliance, technology-led innovation, invested organizational culture, and environmental responsibility.

As we move further into 2025 and beyond, only those mining companies that proactively adopt these vital trends, leverage advanced monitoring tools, and foster an engaged, empowered workforce will succeed in achieving truly sustainable and safe outcomes.

Whether through AI-powered analytics, satellite-based surveillance, next-generation training, or platforms like those developed by Farmonaut, safer, greener, and more comprehensive management of health and safety in mining operations is within reach—and more essential than ever for the industry’s continued growth and reputation as a cornerstone of the global economy.

Frequently Asked Questions (FAQ)

What are the major health and safety risks in mining operations in 2025?

The principal risks include exposure to dust, toxic gases, and noise, risk of ground collapses in underground mines, heavy machinery accidents, and chronic health issues such as silicosis and hearing loss. Mental health concerns and fatigue are also increasingly recognized challenges.

How are regulations for mining safety evolving?

Regulations are becoming stricter, mandating not just reactive incident management but proactive risk mitigation. Compliance now requires continuous hazard assessment, transparent reporting, and the integration of advanced Health, Safety, and Environment (HSE) management systems.

How does technology improve health and safety in mining operations?

Technology plays a pivotal role through AI-driven safety monitoring, autonomous equipment, wearable tech, immersive VR/AR training, satellite-based environmental monitoring, and blockchain traceability. These collectively reduce accident risks, enhance worker protection, and ensure better regulatory compliance.

Why is mental health important for mining safety?

The high-stress, isolated nature of mining work can lead to fatigue and psychological strain, increasing the likelihood of errors or accidents. Addressing mental health through supportive programs and fatigue management systems is now critical for safe and sustainable mining operations.

What environmental risks are addressed in modern mining safety programs?

Environmental risks include dust and air pollution, water contamination, and land degradation. Modern programs leverage remote sensing, advanced waste management, dust suppression, reclamation planning, and community engagement to address these comprehensively.

Does Farmonaut manufacture or sell mining equipment or act as a regulatory authority?

No, Farmonaut is not a manufacturer, seller, or regulatory body. We provide advanced, satellite-based technology solutions and data-driven tools to support mining operations in achieving regulatory compliance, risk mitigation, environmental management, and operational efficiency.

How can I integrate Farmonaut’s solutions into my mining company’s management system?

Farmonaut offers a robust API and developer documentation for seamless integration into custom dashboards and management platforms. This enables real-time data analysis, compliance reporting, and operational optimizations tailored to your organization’s needs.

Monitor, analyze, and act for safer outcomes in 2025 and beyond.