Vanadium Mining Australia: 2025 Industry Outlook

Table of Contents

- Did You Know?

- Vanadium Mining Australia: 2025 Industry Overview

- Australia’s Vanadium Reserves and Mining Landscape

- Technological Innovations: Driving Vanadium Mining Australia Forward

- Advanced Mining Techniques in Australia (2025): Impact Overview

- Industrial Significance of Vanadium Mining Australia

- Vanadium in Australia’s Defense and Infrastructure

- Vanadium and Energy Storage: Enabling Australia’s Renewable Grid

- Environmental Stewardship and Sustainability in Vanadium Mining

- Challenges, Opportunities, and the Future of Vanadium Mining Australia

- How Farmonaut Empowers Mining and Sustainability

- Trivia Break

- FAQ: Vanadium Mining Australia 2025

- Conclusion: Vanadium Mining Australia for a Sustainable Future

“Australia is projected to produce over 20% of the world’s vanadium by 2025, fueling global energy and steel innovation.”

Vanadium Mining Australia: 2025 Industry Overview

Vanadium mining stands at the forefront of Australia’s critical minerals industry in 2025. Known for exceptional strength, corrosion resistance, and an unprecedented ability to enhance steel and energy storage technologies, vanadium remains a vital mineral. Australia, blessed with abundant vanadium reserves, has strategically positioned itself as a global leader in vanadium mining, evolving its industry through advanced extraction, cutting-edge technology, and a vision for sustainability that matches growing global demand.

In 2025, Australian vanadium mining powers the foundation of energy, steel, infrastructure, defense, and evolving fields like agriculture and high-tech batteries. With VRFBs (vanadium redox flow batteries) gaining traction for renewable grid storage and advanced alloys needed across industries, Australia’s mining landscape has become increasingly essential for domestic and international manufacturers, supporting economic development and global sustainability.

The strategic importance of vanadium mining Australia cannot be overstated; as the world transitions to a cleaner, more resilient industrial base, vanadium is the cornerstone of robust, flexible, and future-proofed supply chains.

Australia’s Vanadium Reserves and Mining Landscape in 2025

By 2025, Australia has solidified its position among the top countries globally for vanadium reserves, primarily located in Western Australia and Queensland. Regional geology surveys show concentrated deposits across both states, with Mount Peake and Barrambie projects as flagship sites showcasing operational upgrades. The country boasts several active vanadium mining sites that have undergone technological upgrades for improved operational efficiency.

These leading vanadium mining sites demonstrate benefits through:

- Hydrometallurgical extraction to optimize vanadium yield and minimize ecological impact.

- Automation and remote-controlled machinery for safer, more productive, and cost-effective operations in vast remote regions.

- Advanced processing techniques that optimize ore extraction and purity, with emphasis on reducing byproduct generation and energy use.

With significant investments in technology, training, and environmental management, vanadium mining Australia remains a model for balancing resource exploitation and sustainability. Modern upgrades like those at Mount Peake and Barrambie are setting the gold standard for efficient, environmentally conscious mining.

Localization: Western Australia & Queensland’s Critical Resource

The Western Australia and Queensland projects hold a majority of Australia’s vanadium reserves, placing the country well ahead of many international competitors. Expansion projects continue across the landscape, with permits for new exploration and advanced pilot plant construction ongoing in 2025. Notably, Western Australia’s layered mafic intrusions provide some of the world’s most accessible vanadium ore, while Queensland’s deposits complement the nation’s total supply, making Australia a genuine global vanadium powerhouse.

The strategic location of these mining operations allows Australia to support both domestic manufacturers and international markets—from heavy industry to clean power and defense.

Economic Impact: Domestic and Global Reach

By maximizing efficient extraction techniques and leveraging the country’s abundant resources, vanadium mining Australia directly supports the country’s status as a supplier of choice for the global industry—enabling economies of scale, new job creation, and economic diversification. As demand for high-purity vanadium accelerates in batteries, steel, and strategic defense applications, Australia finds itself at the critical nexus of supply and innovation, fulfilling industry needs worldwide.

Technological Innovations: Driving Vanadium Mining Australia Forward

The competitive edge of vanadium mining Australia lies in its commitment to technological advancement. 2025 sees a robust adoption of smart mining solutions, where digitalization, automation, and process control create more sustainable, productive, and environmentally responsible operations.

- Hydrometallurgical extraction techniques offer increased metal recovery efficiency, minimizing waste, and pollutant emissions compared to traditional pyrometallurgical approaches.

- Automated drilling and ore handling machinery reduce labor risks and boost safety in remote regions, all while maintaining 24/7 productivity.

- AI-driven process optimization maximizes vanadium yield, enabling predictive equipment maintenance and efficient resource allocation.

- Integration of renewable energy sources—such as onsite solar and wind power for mine operations—substantially cuts operational carbon footprints.

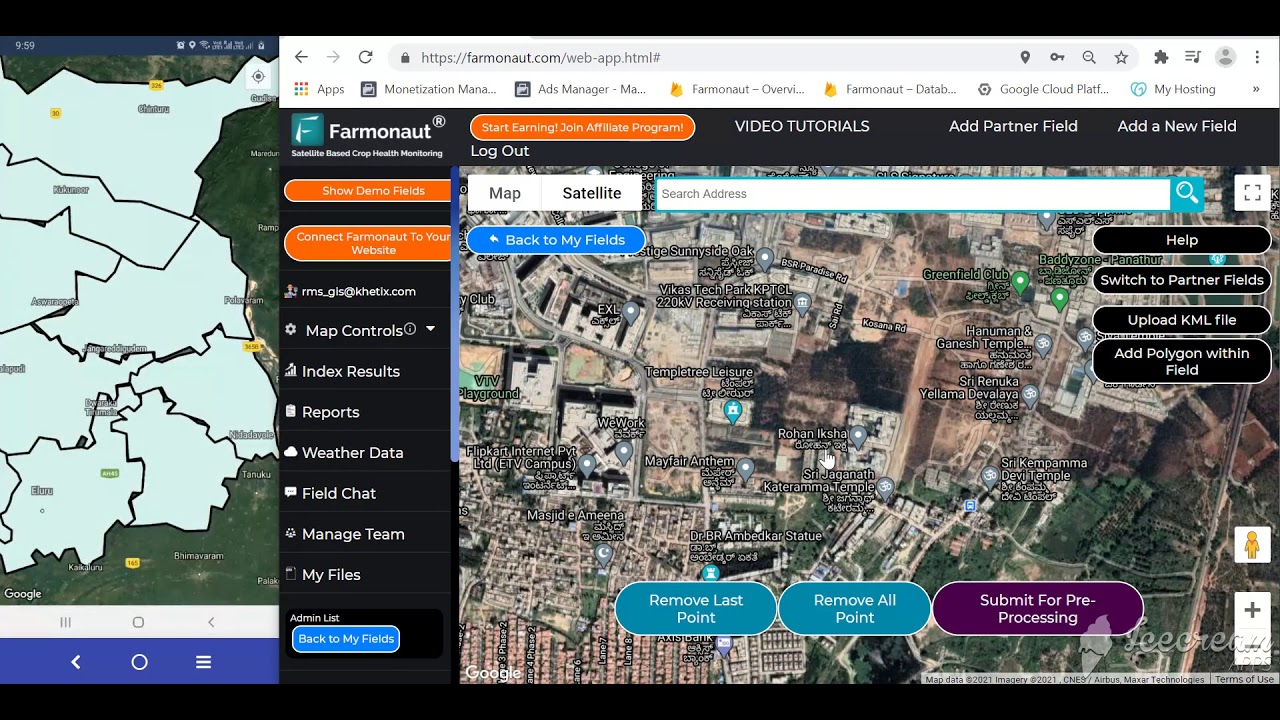

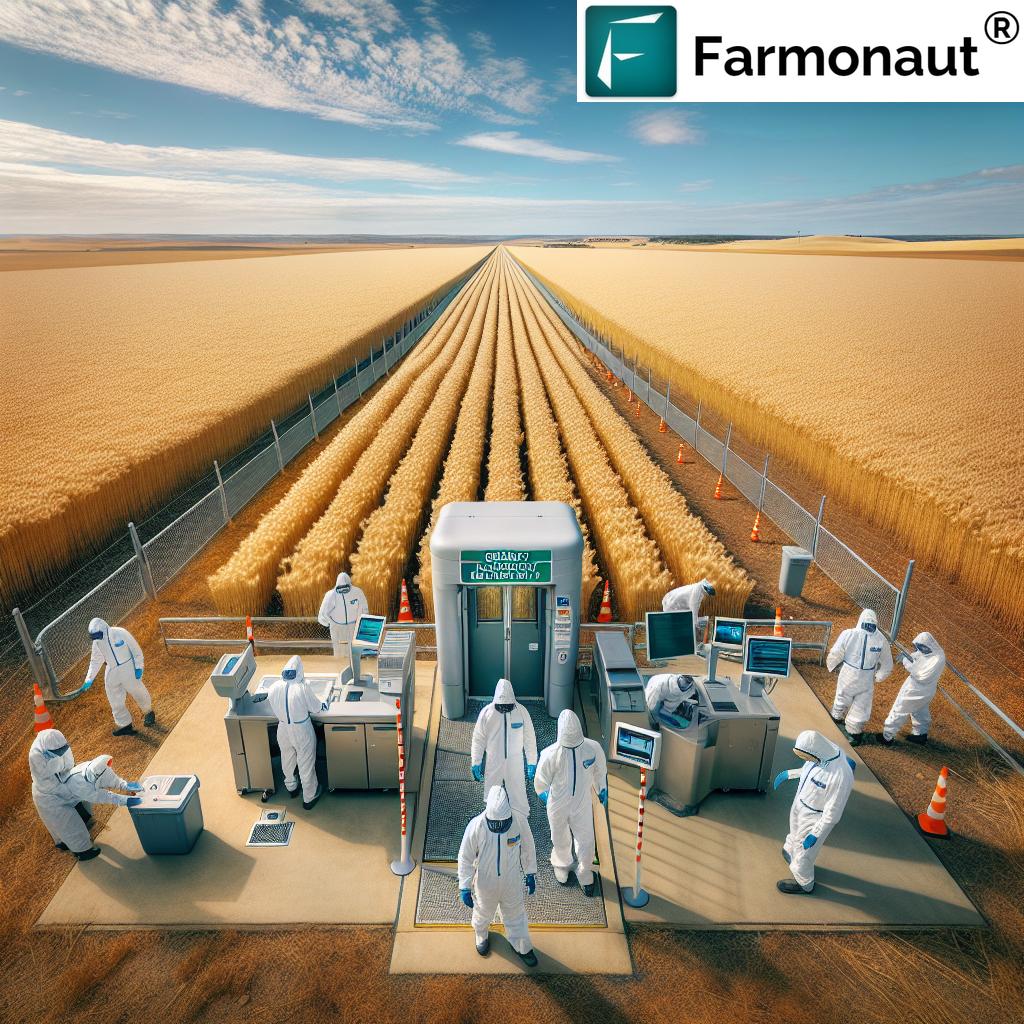

- Use of real-time satellite-based monitoring, like those provided by Farmonaut’s large-scale field & mining management solutions, ensures continuous tracking of site integrity, ecological impact, and operational workflow.

These innovations address both the challenges and goals of modern mining: maximizing extraction efficiency, reducing costs, protecting the environment, and enabling quick adaptation to market fluctuations or regulatory changes.

For operations with widespread fleets and machinery in remote regions, Farmonaut’s fleet management tools provide real-time mapping, logistical optimization, and operational safety—making resource allocation and equipment tracking seamless for the mining industry.

Advanced Mining Techniques in Australia (2025): Impact Overview

| Mining Technique | Estimated Adoption Rate (2025, %) | Energy Efficiency Gain (%) | Reduction in Environmental Impact (%) | Industry Applications |

|---|---|---|---|---|

| Hydrometallurgical Extraction | 70 | 30 | 25–30 | Energy Storage, Steel, Defense |

| Automated Drilling & Ore Handling | 60 | 25 | 15–20 | Steel, Industrial Manufacturing, Infrastructure |

| AI-Based Process Optimization | 40 | 20 | 10–15 | All Sectors: Energy, Defense, Infrastructure, Steel |

| Renewable Energy Integration at Sites | 35 | 40 | 30 | All Sectors, Including Environmental Management |

| Satellite-Based Remote Monitoring | 55 | 12 | 12–18 | Resource Management, Environmental Compliance, Risk Mitigation |

To further enhance strategic planning and integration between mining operations and real-time data, the Farmonaut API delivers satellite-backed analytics that are easily integrated into internal platforms, boosting decision-making for resource allocation, compliance, and project development.

For developers and enterprises, our extensive API Developer Docs provide step-by-step guidance for rapid implementation, helping scale mining operations responsibly.

Industrial Significance of Vanadium Mining Australia

Vanadium mining Australia is a cornerstone for several high-impact industries—each relying on the mineral’s unique properties and the nation’s ability to deliver consistent, high-quality supply.

- Steel Manufacturing: The largest consumer of vanadium globally. Its incorporation produces high-strength, lightweight steel needed for pivotal infrastructure (bridges, skyscrapers, and transportation networks) and advanced manufacturing.

- VRFBs (Vanadium Redox Flow Batteries): A critical technology for energy storage in Australia’s renewable transition, supporting grid stability as solar and wind become widespread.

- Defense Applications: Vanadium-alloyed steels offer high strength-to-weight ratios and corrosion resistance, vital for military vehicles, naval vessels, and aerospace.

- Advanced Alloys in Technology: Used in specialty tools, superalloys for turbine blades, and increasingly in new battery chemistries.

Australian miners supply both domestic manufacturers and offshore markets, integrating with international supply chains, supporting green infrastructure expansion, and contributing to resilient economic development.

Vanadium in Australia’s Defense and Infrastructure

In 2025, securing stable vanadium mining Australia operations equates to strategic autonomy for defense and major infrastructure projects. The alloying element qualities of vanadium are critical for:

- Aerospace and military vehicle armor

- Shipbuilding and naval vessels, where corrosion resistance ensures durability in marine environments

- Transport networks, including metro tunnels and railway bridges, where high-tensile vanadium steels are employed

Ongoing geopolitical risks elevate vanadium’s importance for national security, as Australia reduces supply risks by maintaining sovereign control over extraction and supply, ensuring domestic needs are prioritized while honoring allied commitments and international contractual obligations.

Utilizing domestic resources also shields Australian manufacturers from the volatility and uncertainty of international trade tensions, providing an economic moat and steady growth platform for local industry.

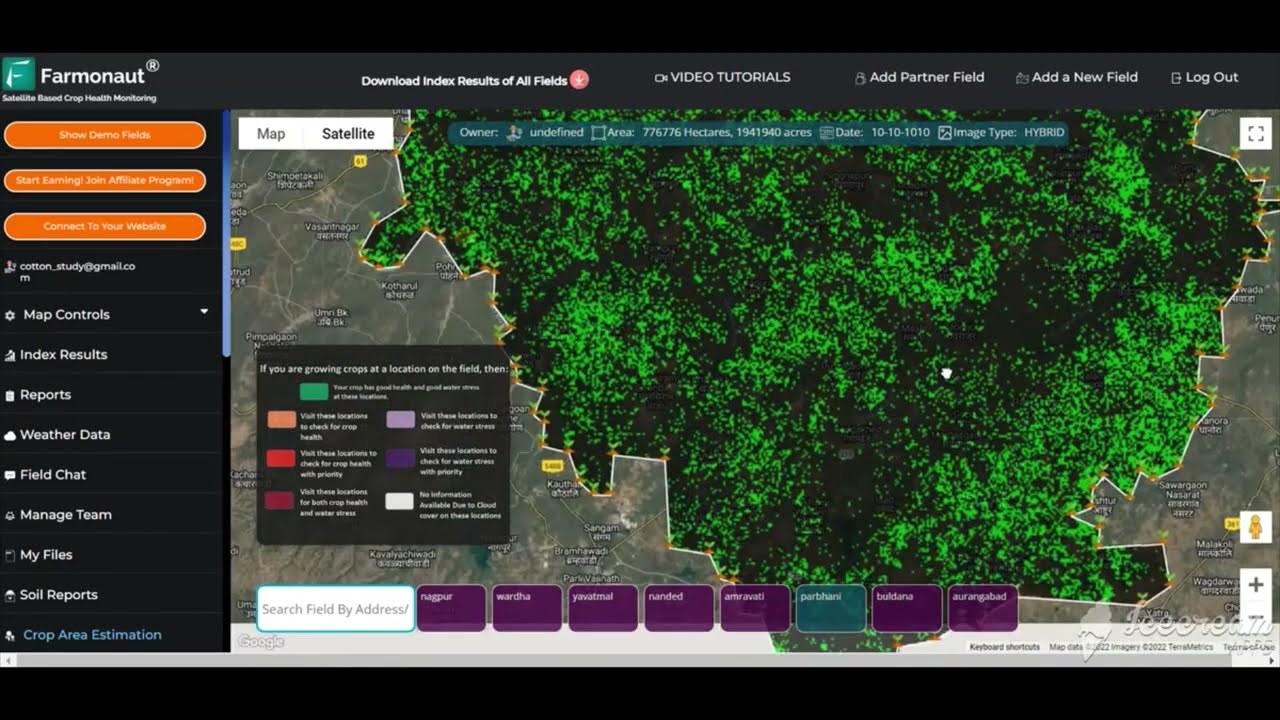

Vanadium and Energy Storage: Enabling Australia’s Renewable Grid

A transformative driver in vanadium mining Australia is the spectacular rise of VRFBs—Vanadium Redox Flow Batteries. As Australia shifts its energy mix toward renewable sources like solar and wind, VRFBs fulfill a mission-critical role by:

- Stabilizing grids—They enable consistent delivery of electricity when solar and wind production is intermittent.

- Supporting Long-Duration Storage—VRFBs provide hours-to-days of energy storage, more than most lithium-ion alternatives, making them ideal for grid-scale solutions.

- Enabling rural microgrids—Supporting electrification of remote regions where traditional grid connections are impractical.

- Recycling and Sustainability—Vanadium solutions in VRFBs can be fully reused—offering a sustainable, circular resource model for next-gen energy storage.

Understand and reduce the carbon footprint of your mining and energy operations with Farmonaut’s satellite-driven carbon monitoring—a vital integration for anyone building a future-ready, environmental-compliant energy ecosystem.

With many Australian states setting ambitious renewable targets for 2030 and beyond, vanadium mining will increasingly underpin the transition—matching energy reliability with decarbonization.

“Advanced extraction technologies in Australian vanadium mining could reduce environmental impact by up to 30% by 2025.”

Environmental Stewardship and Sustainability in Vanadium Mining

Modern vanadium mining Australia is built on strong environmental and sustainability commitments. In 2025, environmental management is deeply rooted in corporate responsibility and regulated by strict government oversight to ensure a balanced coexistence with nature.

- Ecological Management & Rehabilitation: Stringent mine rehabilitation standards restore landscapes post-extraction. Native flora is replanted, and biodiversity is protected on- and off-site.

- Water Use Optimization: Mining projects have adopted water recycling and advanced treatment systems, minimizing impact on local rivers and aquifers.

- Circular Economy: Increased focus on recovering vanadium from steel-making slags and recycling vanadium from spent batteries reduces the need for primary mining and enhances sustainability.

- Renewable-Powered Equipment: A growing portion of mining equipment runs on renewable energy. Onsite solar and wind farms now power extraction and processing, with demonstrable reductions in overall emissions.

- Real-time Environmental Impact Monitoring: Satellite technology, like our own Farmonaut carbon footprinting, enables rapid response to environmental incidents, compliance tracking, and reporting—no more waiting for quarterly reports or on ground sensors alone.

Together, these strategies reduce operational risks and make vanadium mining Australia a role model for responsible, sustainable resource management.

Challenges, Opportunities, and the Future of Vanadium Mining Australia

While vanadium mining Australia remains on a growth trajectory, 2025 brings both ongoing challenges and fresh opportunities that define the industry’s future:

- Price Fluctuations: As a strategic metal, vanadium’s price often responds to global macroeconomic shocks—necessitating risk management and stable contractual frameworks for both large mines and small suppliers.

- Infrastructure in Remote Regions: Building and maintaining supporting infrastructure in vast, sparsely populated mining regions incurs high costs and logistical complexities.

- Energy Intensive Processing: Vanadium extraction, while more efficient now, remains energy-intensive. Ongoing research—including pilot-scale renewable power integration—is essential to meet future decarbonization targets.

- Supply Chain Resilience: Ensuring robust and transparent supply chains is crucial, especially given rising geopolitical risks and the global scramble for critical minerals.

- Innovation and Regulation: New technologies, including AI process optimization and satellite monitoring, offer quantum leaps in efficiency and compliance, but require investment, skilled labor, and cohesive regulation.

Yet, with an expanding suite of applications for vanadium—from energy storage and green infrastructure to advanced defense alloys—Australia is well-placed to meet increasing global demand and lead the world in sustainable, responsible vanadium production.

How Farmonaut Empowers Mining and Sustainability in 2025 and Beyond

As innovation transforms vanadium mining Australia, we at Farmonaut equip forward-thinking mining companies, infrastructure planners, and governments with actionable satellite-derived insights. Our technologies help:

- Monitor mining operations and infrastructure projects via high-resolution, multispectral satellite imagery, supporting both daily management and long-term strategic planning.

- Track environmental compliance in real-time with dedicated carbon footprinting solutions (learn more here), helping companies meet sustainability goals.

- Guarantee authenticity and security across mining supply chains using blockchain-based traceability systems.

- Optimize machinery, fleet, and resource use with advanced algorithms, cutting costs for miners and supporting equipment safety through real-time vehicle and machinery analytics.

- Enable affordable and scalable resource management (discover how) for miners operating across large, remote landscapes.

- Deliver real-time, AI-powered advisory through our Jeevn AI system for mining and infrastructure operation optimization.

- Allow governments and financial institutions to remotely track mining projects for loan and insurance verification (see use case), reducing fraud and offering confidence to lenders and government bodies.

Our mission is to democratize satellite-backed environmental, operational, and supply chain reporting for miners large and small. With our mobile and web solutions, data-driven decisions are more accessible than ever—fueling resilience, compliance, and clear competitive advantage for vanadium mining Australia.

FAQ: Vanadium Mining Australia 2025

What is vanadium, and why is it critical for Australia’s future?

Vanadium is a transition metal with outstanding strength, corrosion resistance, and the unique ability to enhance alloys for steel, batteries, and specialty applications. Australia’s abundant vanadium reserves have made it essential for energy storage, defense, infrastructure, and modern technology development, fueling the energy transition and critical infrastructure projects nation-wide.

Where are the main vanadium reserves in Australia?

The highest concentrations of vanadium ore are found in Western Australia and Queensland, with flagship projects at Mount Peake and Barrambie, among several others. Ongoing exploration in 2025 continues to unlock new deposits across these regions.

How is vanadium mining in Australia becoming more sustainable?

By embracing hydrometallurgical extraction, renewable-powered equipment, automated and AI-driven operations, and rigorous site rehabilitation, vanadium mining Australia has minimized its ecological footprint. Additionally, circular economy principles—such as vanadium recovery from steel slag and batteries—further reduce the need for new primary mining.

Why is Australia considered a strategic supplier in global vanadium markets?

Australia boasts stable political conditions, advanced technology adoption, abundant reserves, and regulated mining practices, ensuring reliable, sustainable, and high-quality vanadium supply for both domestic and international markets.

What industries are most reliant on vanadium mining Australia?

Industries relying heavily on vanadium include steel manufacturing, energy (especially for vanadium redox flow batteries), defense, infrastructure, and advanced manufacturing—each leveraging vanadium’s unique properties for strength, corrosion resistance, battery capacity, and environmental sustainability.

Can satellite technology improve the future of vanadium mining?

Absolutely. Solutions like those provided by Farmonaut enable remote monitoring, supply chain traceability, environmental impact tracking, and resource optimization for the entire mining life cycle, from prospecting and operational monitoring to compliance and reporting.

Conclusion: Vanadium Mining Australia for a Sustainable Future

In 2025, vanadium mining Australia is more than just mineral extraction—it is a strategic, innovation-driven force supporting energy infrastructure, urban development, defense, and sustainability. With advanced extraction, digital process optimization, circular economy principles, and environmental stewardship, Australia is not just meeting but shaping global demand, acting as a critical pillar for industry and sustainability well into the future.

Farmonaut is committed to delivering the satellite-driven technology backbone needed for resilience, transparency, compliance, and operational excellence in mining, infrastructure, and supply chain management. As Australia’s vanadium sector continues to expand—enabling green steel, renewable energy storage, and next-generation defense technologies—the world will look to Australia as the template for responsible, high-tech, and sustainable resource leadership.

For those in mining, government, or heavy industry, now is the moment to leverage advanced, affordable insights to optimize operations, demonstrate compliance, and lead industry transformation. Vanadium mining Australia is the future—a future we help unlock, monitor, and shape for a sustainable, vital resource ecosystem.

Explore Farmonaut’s Platform: Efficient, sustainable, and data-driven mining management for vanadium mining Australia.

Discover cost-effective fleet and equipment management for seamless mining operations at scale.

Guarantee transparency and supply chain confidence with Farmonaut’s blockchain-based traceability.

Start building with the Farmonaut API—developer documentation here.