Biggest Manganese Mine in the World & Iron Ore Finds: 2025 Global Output, Industry Trends, and Infrastructure Impact

“The world’s largest manganese mine, South Africa’s Mamatwan Mine, produces over 5 million tonnes of manganese ore annually.”

- Summary: Manganese – The Backbone of Modern Industry (2025 & Beyond)

- Introduction

- The Role of Manganese in Industry

- The Manganese Found in Iron Ore

- Top Global Manganese Mines: 2025 Output & Trends

- Biggest Manganese Mine in the World: Groote Eylandt Mine (Australia) & Mamatwan Mine (South Africa)

- Largest Manganese Mining Companies in 2025

- Industry Trends, Global Output & Manganese Demand in 2025 and Beyond

- Satellite Technology in Mining: The Farmonaut Edge

- Why Manganese is Critical for Steel, Infrastructure & Agriculture

- Future Outlook (2026+): Manganese, Renewables, and Sustainable Practices

- Frequently Asked Questions (FAQ)

- Conclusion

Summary: Manganese – The Backbone of Modern Industry and Its Largest Mines in 2025

Manganese, an indispensable industrial metal, continues to secure its place as the backbone of modern infrastructure, steel manufacturing, agriculture, and mineral processing. By 2025, manganese’s unique properties—enhancing steel strength, durability, and corrosion resistance—will only amplify its importance to global industries.

Understanding the biggest manganese mine in the world, along with the largest manganese mining companies and key trends, informs strategic decision-making and sustainability efforts across industries reliant on this vital metal.

“By 2025, global manganese mining output is projected to exceed 22 million tonnes, powering steel and infrastructure industries.”

Introduction

The mining sector plays a pivotal role in the advancement of human civilization, with manganese standing out as a critical element for the steel industry, infrastructure projects, renewable energy, and agriculture. The biggest manganese mine in the world delivers insight into global mining efficiencies, industrial leadership, and advancements in sustainable practices as we approach 2025 and look beyond to new horizons in resource management.

In this comprehensive guide, we will explore the world’s largest manganese deposits, major mining companies, technological innovations in extraction and processing, and how Farmonaut’s satellite-driven solutions facilitate modern mining, environmental stewardship, and operational efficiency.

The Role of Manganese in Industry

Manganese is a cornerstone element that continues to be:

- Primarily used as an alloying agent in steel manufacturing, enhancing toughness, hardness, and tensile strength.

- An essential micronutrient for agriculture, sustaining plant growth and enhancing soil fertility, especially when applied as fertilizer additives for increased crop yields.

- Indispensable in batteries, ceramics, chemicals, and water treatment, especially with rising global demand for renewable energy technologies.

Manganese’s unique properties improve steel quality by neutralizing the harmful effects of sulfur and oxygen present in iron ore, ensuring a more robust, reliable, and corrosion-resistant structure—a vital trait for infrastructure and manufacturing sectors worldwide.

Key Properties of Manganese in Steel Production

- Hardness – Manganese increases strength and toughness, enabling steel to withstand heavy loads and stresses.

- Tensile Strength – It prevents brittleness in steel products, making structures more durable.

- Resistance to Corrosion – Combats rust and chemical degradation, vital for construction and industrial machinery.

- Alloying Efficiency – Reduces the need for additional alloying materials, thereby lowering costs and streamlining production.

- Deoxidation – Reacts with dissolved oxygen in iron, preventing the formation of weak spots in finished steel.

The Manganese Found in Iron Ore: Natural Occurrence and Industrial Synergy

Manganese naturally occurs in combination with iron ore, especially in various complex geological formations worldwide. Its extraction often aligns with iron ore mining, leveraging this chemical relationship to improve process efficiency.

How Manganese Aligns with Iron Ore Mining

- Geological Formations: Manganese is present in sedimentary, volcanic, and metamorphosed iron-bearing rocks. Deposits often contain varying percentages of manganese mixed with iron.

- Impact on Steel Quality: A high manganese content in iron ore boosts its suitability for alloy steel production—directly enhancing hardness, durability, and cost efficiency as less additional manganese is needed.

- Processing Techniques: The chemical relationship of manganese and iron allows for simultaneous extraction and efficient beneficiation using modern technological processes.

The synergy between manganese and iron ore mining not only drives down operational costs but also ensures a steady supply of manganese for steel manufacturers worldwide, cementing its role as a critical raw material for the sector.

“By 2025, global manganese mining output is projected to exceed 22 million tonnes, powering steel and infrastructure industries.”

Manganese Extraction and Iron Ore Finds: Technological Advancements

- Modern Mining Technologies: In 2025, new mineralogical surveying, satellite imaging, and AI-based geological analysis further optimize extraction from complex manganese and iron ore deposits.

- Environmental Sustainability: Simultaneous extraction reduces land disturbance, minimizes waste, and utilizes advanced water management techniques—lowering environmental impact for responsible operations.

Top Global Manganese Mines: 2025 Output & Trends

Here is a comparative table highlighting the biggest manganese mine in the world and key players by estimated output, ownership, and strategic relevance, including associated iron ore finds.

| Mine Name | Country | Estimated 2025 Output (Million Tonnes) | Owner/Operator | Share of Global Production (%) | Associated Iron Ore Finds |

|---|---|---|---|---|---|

| Groote Eylandt Mine | Australia | 6.5 | South32 | ~30% | Yes – High-quality iron-manganese ores |

| Mamatwan Mine (Kalahari Field) | South Africa | 5.2 | Samancor (South32/Anglo American) | ~22% | Yes – Major iron-bearing deposits |

| Moanda Mine | Gabon | 4.1 | Eramet Group | ~18% | Yes – Associated iron-manganese ore |

| Bootu Creek Mine | Australia | 1.5 | OM Holdings | ~6% | No significant finds |

| Nikopol & Ordzhonikidze/Bilylivka Mines | Ukraine | 1.3 | Ukrainian Mining Consortiums | ~5% | Yes – Integrates with iron ore sector |

| Aulakh-Mangampet Mine | India | 0.8 | MOIL Limited | ~3.5% | Yes – Iron-manganese combos found |

| Other regional mines (Brazil, China) | Brazil, China, et al. | 2.3 | Various | ~10% | Varies |

Biggest Manganese Mine in the World: Groote Eylandt & Mamatwan (Australia & South Africa)

The title of biggest manganese mine in the world is contested between the Groote Eylandt Mine in Australia and the Mamatwan Mine in the Kalahari Field, South Africa. Both represent enormous deposits, advanced extraction technologies, and staggering annual outputs—serving as lynchpins for global steel and industrial sectors in 2025.

Groote Eylandt Mine (Australia) – Output, Location, and Impact

- Located off the northern coast of Australia, Groote Eylandt Mine is operated by South32, with estimated 2025 output exceeding 6.5 million tonnes of high-grade manganese ore.

- Renowned for exceptional manganese quality, advanced processing, and minimal impurities.

- Strategic Importance: Supplies a substantial share of global manganese demand; pivotal for Asia-Pacific steel and infrastructure growth.

- Sustainable Mining Practices: Implements leading environmental stewardship, including integrated water management, rehabilitation, and minimal waste generation.

Mamatwan Mine (Kalahari Manganese Field, South Africa) – Africa’s Manganese Giant

- Part of the massive Kalahari Manganese Field, the Mamatwan Mine is estimated to produce over 5.2 million tonnes annually by 2025.

- Operated by Samancor (South32/Anglo American JV), this mine sits atop vast reserves containing both manganese and associated iron ore finds.

- South Africa remains the leading global reserve holder, accounting for the world’s greatest share of manganese resources and exports.

Why These Mines Lead the Global Market

- Resource Quality: High-grade ores enable efficient processing, cost savings, and better steel alloys.

- Technological Leadership: Investment in automation, digital mine planning, and remote environmental monitoring.

- Supply Chain Integration: Close geographic and logistical alignment with industrial steelmaking hubs in Asia, Europe, and Africa.

- Environmental Stewardship: Adoption of best-in-class practices reduces ecological impact and supports community development.

Largest Manganese Mining Companies in 2025: Key Players and Global Impact

The largest manganese mining companies wield outsized influence on global supply, pricing, responsible mining, and technological innovation. As of 2025, the leaders in this sector are:

South32 – A Global Mining Powerhouse

- Operator of Groote Eylandt Mine (Australia) and part-owner of Samancor (South Africa), South32 is recognized for exceptional output, technological investment, and sustainable mining practices.

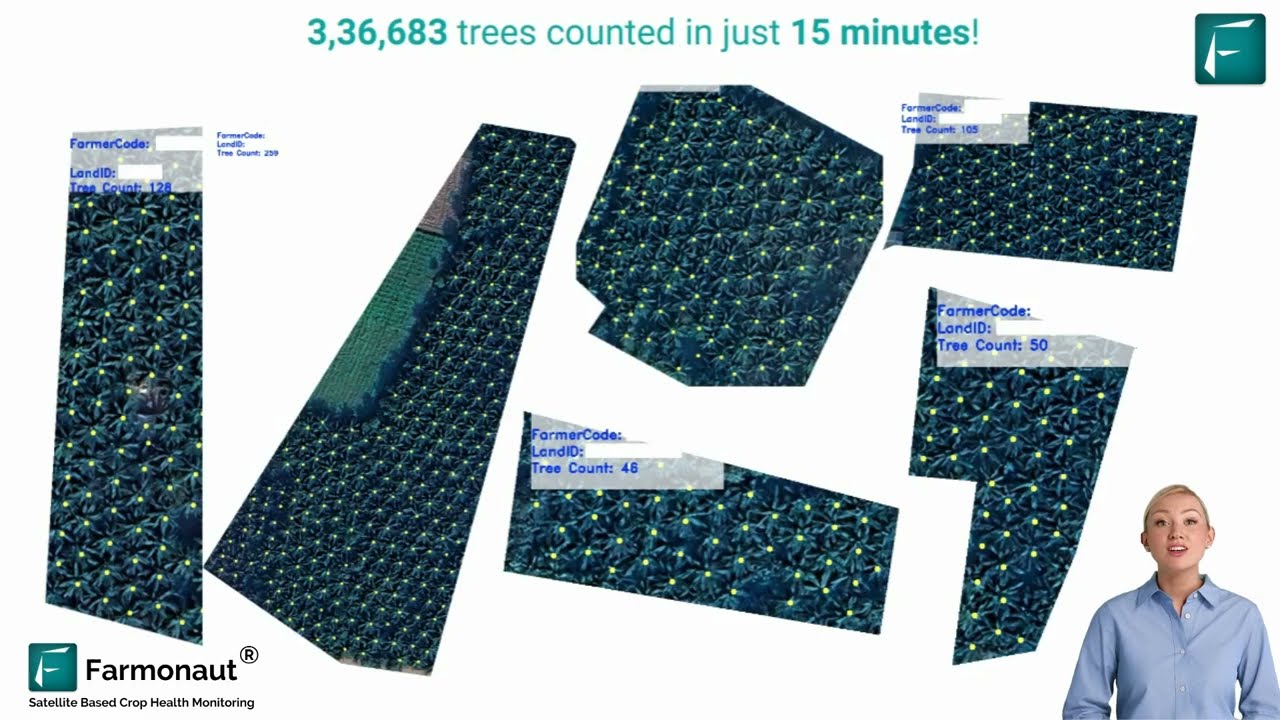

- Focuses on integrating satellite monitoring and AI for fleet management, safety, and precision resource extraction.

- Drives sustainable development in mining communities and invests in rehabilitation and carbon-reduction initiatives.

Fleet Management Solutions revolutionize operational logistics for large mining companies like South32, empowering them to optimize vehicle usage, enhance workplace safety, and cut fuel costs using satellite-based data and AI analytics.

Samancor Manganese – Africa’s Strategic Manganese Leader

- Major operator across the Kalahari Manganese Field, supporting both South Africa’s domestic steel sector and exports.

- Prioritizes environmental protection, community engagement, and worker safety alongside intensive mineral production.

- Drives innovation in beneficiation and resource sustainability through AI and satellite-based environmental monitoring.

Eramet Group – French Multinational and African Resource Power

- Operator of Moanda Mine (Gabon), with strategic reach across African, Asian, and European markets.

- Invests in digital mine management, satellite-guided resource tracking, and transparent supply chains powered by blockchain.

- Aims for net-zero mining targets and robust compliance with global sustainability guidelines.

Farmonaut’s Blockchain Product Traceability offers end-to-end supply chain visibility—boosting transparency, trust, and regulatory compliance for mining companies like Eramet operating in sensitive global markets.

Industry Trends, Global Output & Manganese Demand in 2025 and Beyond

Our analysis of the manganese mining sector in 2025 reveals several key trends set to define the industry’s future:

- Continued Output Growth: Global manganese production is on track to exceed 22 million tonnes annually, given robust demand from steel, automotive, and battery sectors.

- Integration with Renewables & Technology: Demand from renewable energy, EV battery manufacturing, and green steel technologies is pushing mining companies towards smarter, more sustainable operations.

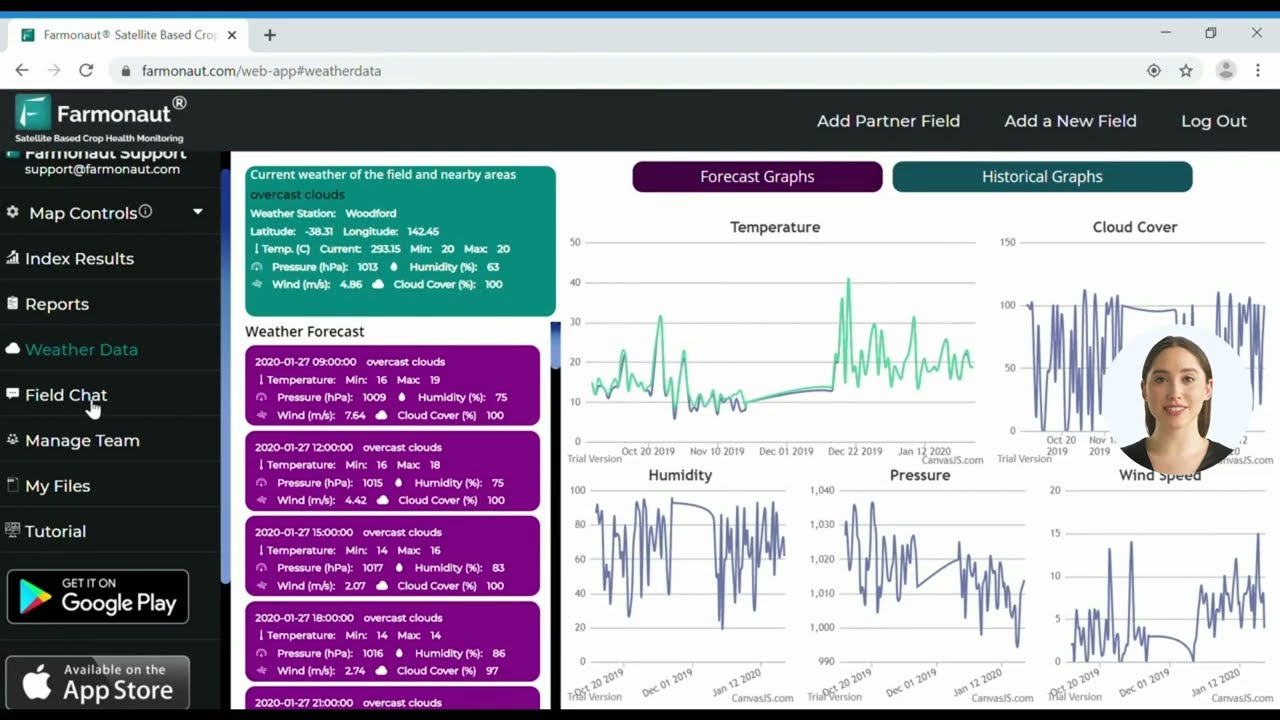

- AI & Satellite Technologies: Satellite monitoring, AI-driven analysis, and digitized fleet/resource management are enhancing mine safety, extraction efficiency, and regulatory compliance.

- Regulatory Landscape: New global standards emphasize carbon footprint reduction, waste management, and community involvement, reorganizing country and company strategic priorities.

- Supply Security & Geostrategic Competition: Concentration of reserves in Africa, Australia, and Gabon encourages nations to secure trade agreements and strategic partnerships to ensure steady manganese supply chains.

Carbon Footprinting & Environmental Monitoring solutions empower mining enterprises to track and reduce their carbon impact, regulate emissions, and facilitate compliance with international environmental standards through real-time, actionable data insights.

Projected Global Breakdown (2025-2026)

- Africa (South Africa + Gabon): Retains lead as chief global supplier, emphasizing both the quantity and quality of manganese output.

- Australia: Groote Eylandt Mine propels the nation to pivotal supplier status, especially for Asia-Pacific steel and technology manufacturing.

- Asia (India, China): India’s MOIL and China’s regional projects support their own booming domestic steel and EV industries.

- Europe (Ukraine): Ukrainian mines align manganese and iron ore finds for regional metallurgy and innovation.

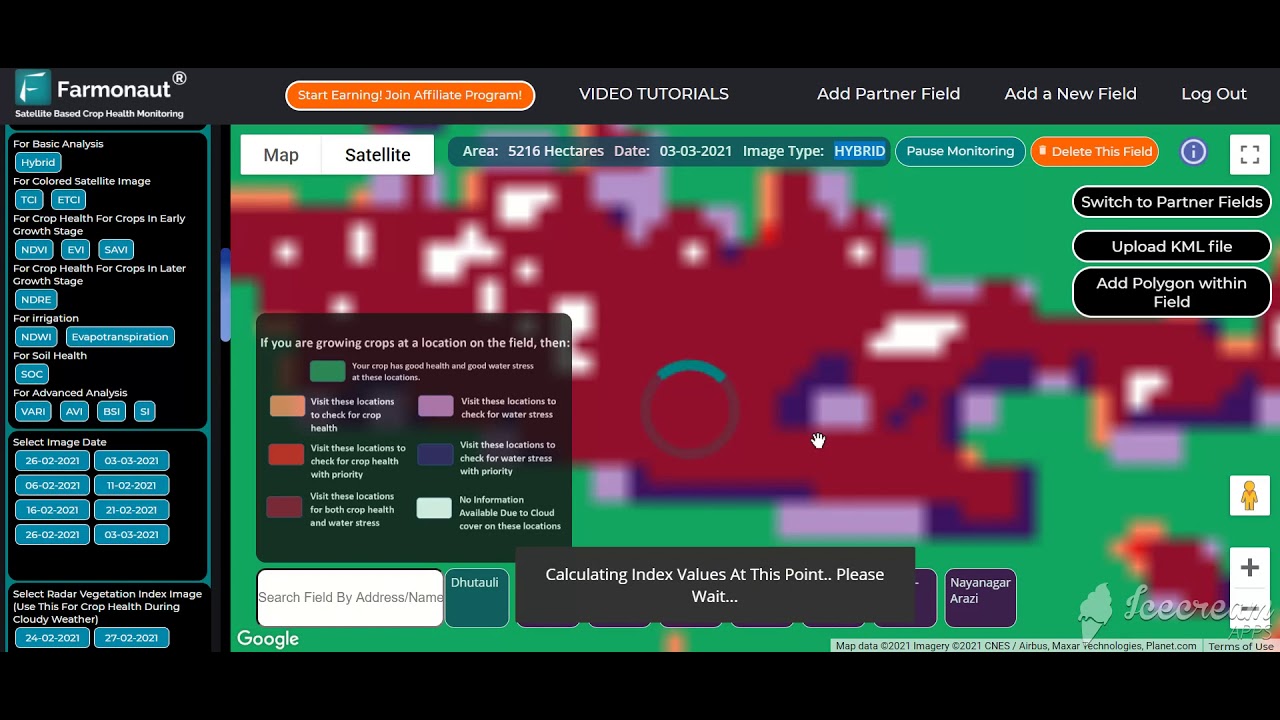

Satellite Technology in Mining: The Farmonaut Edge

As the mining landscape embraces digital transformation, our Farmonaut satellite platform brings unmatched advantages to the minerals sector, revolutionizing the way the biggest manganese mines are managed and optimized.

- Real-time Resource Monitoring: Our platform utilizes multispectral satellite imagery to monitor operational efficiency, ore extraction, land use, and environmental changes with high resolution and accuracy—offering invaluable insights for sustainable mining practices.

- AI-Based Fleet & Equipment Management: Our fleet management tools enable companies to improve the deployment of heavy mining vehicles, minimize fuel use, and ensure optimal safety and productivity across their sites.

- Environmental Impact Tracking: With our carbon footprinting and impact reports, mining organizations can adopt strategies compliant with the strictest global regulations.

- Blockchain-Based Traceability: Through secure blockchain protocols, our traceability solutions offer full transparency in the manganese supply chain, from ore extraction to refined product—enhancing trust with customers and governments.

Our Farmonaut platform is universally accessible via API (API Access), developer integrations (Developer Docs), and user-friendly web and mobile apps for remote site management and real-time alerts (

).

).

Crop Loan and Insurance Verification harnesses modern satellite analytics to provide accurate resource verification, increase transparency, and reduce fraud in agricultural and mining financing for financial institutions and producers alike.

Why Manganese is Critical for Steel, Infrastructure & Agriculture in 2026 and Beyond

- Steel Sector: Manganese remains vital for steel production—no substitute matches its all-in-one ability to enhance strength, toughness, resistance to wear and corrosion, and minimize brittleness. Every new skyscraper, bridge, and rail network depends on manganese-enriched alloys.

- Infrastructure: As nations upgrade urban architecture, ports, high-speed transport, and renewable installations, steel reinforced with manganese is the backbone of long-term durability.

- Agriculture: Manganese fertilizers are crucial micronutrients, boosting soil fertility, chlorophyll synthesis, and plant resilience. This is especially important for sustainable food security in emerging economies.

- Emerging Applications: The rise of lithium-ion, sodium-ion, and new generation batteries for electric vehicles and grid-scale energy storage drives increased demand for high-purity manganese oxide and sulfate.

Future Outlook (2026+): Manganese, Renewables, and Sustainable Practices

The story of manganese mining is evolving beyond traditional extraction. By 2026 and beyond:

- Green Steel and Circular Economy: New technologies such as hydrogen-based steelmaking and industrial recycling will increase demand for high-purity manganese ores, reducing greenhouse gas emissions.

- Battery and EV Revolution: Battery-grade manganese found in iron-manganese blends powers large-scale renewable energy storage and next-generation electric vehicles.

- Digital Transformation in Mining: Satellite-based AI analysis, remote sensing, and traceability are key to improving resource resilience, regulatory compliance, and rapid response to environmental threats.

- Global Supply Security: Nations will intensify efforts to secure manganese supply, investing in domestic resource development and international sourcing agreements.

Our Farmonaut platform is committed to supporting mines, industries, and governments worldwide with affordable carbon footprint monitoring, fleet optimization, and advanced traceability for responsible mining, ensuring the world’s largest manganese mines remain engines of progress and sustainability for generations to come.

Frequently Asked Questions (FAQ)

What is the biggest manganese mine in the world as of 2025?

As of 2025, the Groote Eylandt Mine in Australia stands as the world’s biggest manganese mine by annual output, closely followed by the Mamatwan Mine in South Africa’s Kalahari Manganese Field.

How is the manganese found in iron ore important for steel production?

Manganese found in iron ore acts as a deoxidizer, neutralizing harmful sulfur and oxygen. This improves the strength, durability, and corrosion resistance of steel, making it essential for reliable infrastructure.

Who are the largest manganese mining companies globally?

The leading companies in 2025 include South32 (Australia and South Africa), Samancor (South Africa), and Eramet Group (France/Gabon), each controlling significant market share and output.

Why is manganese considered critical for industry and infrastructure?

Manganese enhances the properties of steel and alloys, boosts agricultural yields as a micronutrient, and is increasingly crucial in battery technologies for renewable energy and electric vehicles.

How does satellite technology benefit mining operations today?

Satellite technology enables real-time monitoring of mines, efficient resource extraction, fleet management, and environmental impact tracking, leading to safer, more sustainable, and cost-effective operations.

How can I use Farmonaut for mining site monitoring and management?

You can access Farmonaut’s satellite insights via our web and mobile apps, API integrations, and specialized tools for fleet management, environmental monitoring, traceability, and crop/forest advisory.

Conclusion: Why Manganese Will Remain the Backbone of Industry Beyond 2025

Manganese is not just an industrial mineral but a vital cornerstone of the world economy. The biggest manganese mine in the world, located both in Groote Eylandt (Australia) and the Kalahari Manganese Field (South Africa), continues to supply the ever-growing global needs of steel manufacturing, infrastructure development, agriculture, and cutting-edge technologies.

With a robust future outlook marked by digital transformation, sustainable engineering, and the rise of renewable energy, manganese’s role as an indispensable resource is cemented for 2026 and beyond. Key mining companies (South32, Samancor, Eramet) will remain industry cornerstones, driving innovation, supply, and environmental responsibility. Our Farmonaut satellite technology platform further empowers miners, manufacturers, and governments to maximize efficiency, transparency, and sustainability—leading the way in modern mineral extraction and global resource management.

Explore more, make smarter decisions, and power your mining operations with Farmonaut’s satellite monitoring solutions.