Copper Processing Automation: Magnetic Separation Advances (2025 Guide)

Summary: Revolutionizing Copper Processing in 2025

Copper Processing Automation: Revolutionizing Mineral Processing in 2025 marks a transformation in the global mining sector. As demand for copper soars—driven by electrification, infrastructure expansion, energy transition, and digital industries—the need for copper processing automation and magnetic separation in mineral processing has never been more critical. In 2025, advanced techniques like AI-driven controls, real-time sensors, and smart magnetic separators are helping mining operations maximize productivity, improve recovery rates, and minimize environmental impact. This blog explores the underlying technologies, their advantages, and what this means for sustainable, efficient copper production worldwide.

The Vital Importance of Copper in 2025

Copper remains one of the world’s most vital industrial metals, integral to the growth of global infrastructure projects, the rollout of renewable energy solutions, expansion of electrical networks, and technological advancement. In 2025, the global demand for copper continues to escalate, fueled by:

- The electric vehicle revolution (electric wiring, batteries, motors)

- Smart grids and expanded electrical infrastructure

- Growth in digital and renewable energy technologies (solar panels, wind turbines)

- Expanding urbanization and modernization projects worldwide

However, satisfying this demand sustainably presents major challenges. Copper ore deposits are increasingly low-grade, complex, and dispersed. This means we must extract copper more efficiently, recover more metal from each ton of ore, and reduce environmental impact. Here is where copper processing automation and magnetic separation in mineral processing become game changers in 2025 and beyond.

Copper Processing Overview

The copper supply chain begins with extraction of ore from open pits and underground mining operations. Once extracted, copper ores undergo a series of crucial steps known collectively as beneficiation:

- Crushing & Grinding: Breaks down copper ore into smaller particles, increasing the exposed surface area for further processing.

- Flotation: Utilizes chemicals to selectively attach to copper sulfides, enabling their separation from gangue.

- Separation: Magnetic, gravity, or electrostatic techniques isolate desired copper minerals from unwanted material.

- Concentration: Elevates the copper content before smelting to produce anode copper.

- Smelting & Refining: Converts concentrates into pure copper cathode, ready for industrial use.

Conventional methods often struggle with fine-grained ores, low-grade deposits, and complex mineralogy. As high-grade deposits are depleted, the difficulty of copper processing increases—driving innovations in mineral processing technologies, automation, and advanced magnetic separation.

Magnetic Separation in Mineral Processing: How It Works

Magnetic separation in mineral processing has a long history in the mining sector, traditionally used for iron ore beneficiation. Today, it’s rapidly gaining traction in copper processing operations—especially for treating complex ores and removing magnetic gangue components.

The Principle: Magnetic Susceptibility

This technique is based on the difference in magnetic susceptibility between mineral phases. In practical terms:

- Magnetic minerals (e.g., magnetite, pyrrhotite) are attracted to a strong magnetic field.

- Non-magnetic minerals (e.g., quartz, most copper sulfides) are either repelled or unaffected.

In copper processing, magnetic separation helps remove iron-rich gangue (magnetite, pyrrhotite) and other impurities that often coexist with valuable copper sulfides. This improves concentrate grade, enhances recovery rates, and reduces downstream smelting costs.

Advancements Transforming Magnetic Separation in 2025

Recent advances in 2025 have dramatically enhanced the efficacy of magnetic separation in mineral processing:

- High-Gradient Magnetic Separators (HGMS): Harness extremely strong, precise magnetic fields to separate even fine particles and low magnetic susceptibility minerals.

- Superconducting Magnets: Enable higher field strengths with lower energy consumption, allowing for the capture of more and finer magnetic particles.

- Sensor Integration: Magnetic separators now feature real-time process sensors for mineral composition, particle size, slurry density, and magnetic properties.

- Dynamic Process Control: Automated control systems fine-tune separator parameters (e.g., magnetic field strength, feed rates, timing) for optimal performance.

The result? Enhanced selectivity, higher copper recovery rates, and reduced tailings—all essential for sustainable, cost-effective copper processing globally.

Copper Processing Automation & Digital Integration

In 2025, automation and digital control are at the heart of every major advancement in copper processing. Smart plants leverage these systems to continually optimize mineral processing parameters, decreasing operational risks and increasing recovery efficiency.

- Automated control systems analyze real-time process data, adjusting separator feed rates, magnetic field strengths, and granulometry on-the-fly.

- Sensor networks provide live feedback on mineralogy, slurry flow, ore properties, and even equipment health/maintenance needs.

- AI and machine learning predict process drift, failures, or bottlenecks—triggering corrective adjustments or pre-emptive maintenance.

The integration of these technologies in copper processing plants leads to:

- Consistent concentrate quality due to tight, digital control over process variables.

- Higher copper recovery rates through real-time parameter optimization.

- Reduced downtime via predictive maintenance and digital twin simulations.

Advanced Technologies in 2025 Copper Processing

Let’s examine the key technologies driving copper processing automation and magnetic separation in mineral processing for 2025 and the near future:

1. High-Precision Sensors & Real-Time Data Integration

- New sensor arrays analyze particle size distribution, mineral content, magnetic susceptibility, temperature, and flow rates instantly.

- Integrated with cloud platforms, this enables comprehensive digital twins and process modeling, bringing data-driven optimization to every minute of operation.

2. AI-Powered Operational Control

- Machine learning algorithms continuously monitor and adjust process parameters for maximum recovery and efficiency.

- They can model ore variability over time, adapt flotation chemistry, grinding, and magnetic separator settings accordingly.

3. Automated Magnetic Separators (Smart Separators)

- These automated separators can handle significantly larger volumes (up to 300 tons/hour) and finer particles with higher selectivity.

- Self-regulating, they adjust feed mechanisms, rotation speeds, and magnetic field intensity based on live sensor feedback.

4. Superconducting & High-Gradient Magnet Advances

- Cutting-edge high-gradient magnetic separators (HGMS) and superconducting magnets increase effectiveness for fine particle separation (sub-100 microns).

- This ensures greater copper concentrate purity and less environmental waste.

5. Digital Twins & Predictive Modeling Tools

- Digital twins simulate the entire operational process, allowing engineers/operators to test new configurations, optimize costs, and maximize metal recovery rates safely before implementation.

- Edge computing reduces latency in automation loops, critical for large-scale remote copper mines.

6. Resource Traceability & Blockchain

-

Blockchain technology is finding use in traceability for copper supply chains.

Traceability reduces fraud, verifies the provenance of minerals, and provides unprecedented transparency for manufacturers, investors, and production oversight.

See our Product Traceability solution for how blockchain can secure mining and resource supply chains.

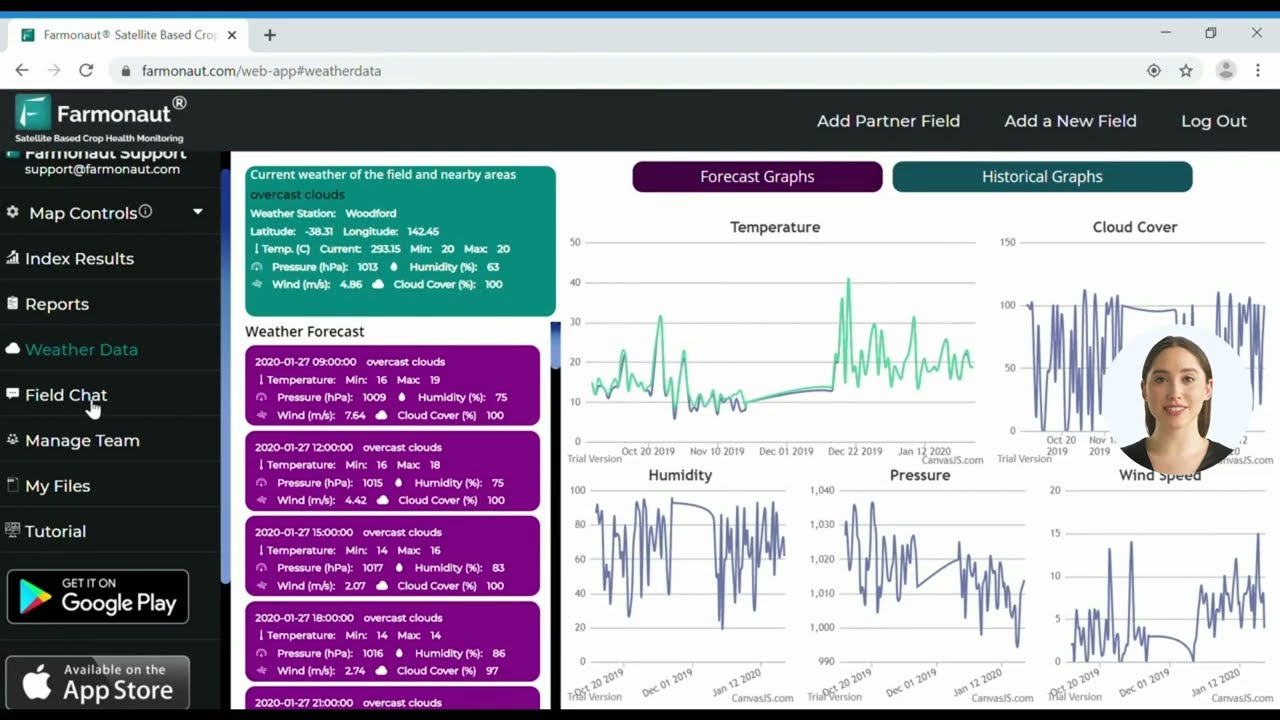

Satellite Monitoring & Automation: The Farmonaut Advantage

Global push for automation in copper processing requires accurate, continuous site monitoring and integrated data analytics. This is where advanced satellite-based technologies—such as those offered by Farmonaut—are revolutionizing mining and mineral processing.

- Satellite-Based Monitoring: Farmonaut’s multispectral satellite imagery monitors mining sites, ore stockpiles, environmental impact, and infrastructure integrity from space—in real time.

- Fleet and Resource Management: We help mining operations optimize fleet usage and equipment deployment, reducing operational costs through Fleet Management tools.

- AI Advisory Systems: Our Jeevn AI analyzes site conditions and production data, delivering tailored optimization, predictive maintenance, and strategic advice for mining operations.

- Environmental Impact Tracking: Farmonaut enables real-time carbon footprint monitoring and sustainability compliance—vital for copper mines operating under strict 2025 ESG regulations. Learn about Carbon Footprinting for Mining.

Our API also allows businesses, developers, and governments to seamlessly integrate satellite-based insights into their copper processing/monitoring workflows for operational efficiency and regulatory compliance.

Environmental & Economic Benefits of Copper Processing Automation

- Reduced Energy Consumption:

- Automated optimization of crushing, grinding, flotation, and magnetic separation means less overprocessing—and substantial energy savings.

- Lower Water Use & Waste:

- Better mineral separation techniques reduce the volume of tailings, improving water recycling and lowering freshwater requirements.

- Enhanced Copper Recovery:

- Advanced sensors and real-time parameter control can improve copper concentrate yields by up to 15%. This means more metal with less ore extraction—supporting sustainability.

- Decreased Operational Risk:

- Less human intervention, more stable processes, and predictive maintenance reduce accidents, unplanned downtime, and costly failures.

- Lower Environmental Impact:

- Reduced greenhouse gas emissions, smaller land disturbances, improved compliance with ESG standards, and shrinking carbon footprints.

In 2025, digital transformation of copper production operations is essential to fulfill global demand—safely, efficiently, and with lower costs.

Our Satellite-Based Verification for Loans & Insurance can further support compliance and financial flexibility for miners adapting to these new standards.

Comparative Table: Traditional vs. Advanced Automated Copper Processing Methods

| Processing Method | Level of Automation | Magnetic Separation Efficiency (%) | Estimated Energy Savings (%) | Throughput Increase (%) | Environmental Impact |

|---|---|---|---|---|---|

| Traditional Processing | Manual/Low | 55 | 0 | 0 | High |

| Semi-Automated Processing | Moderate | 65 | 12 | 10 | Medium |

| Fully Automated with Advanced Magnetic Separation | High/Full | 80–90 | 22–30 | 20–30 | Low |

*Estimated values for comparison; actual results may vary based on ore type and site conditions.

Emerging Trends & Future Outlook for Copper Processing Automation

- Edge Computing: Localized, high-speed data processing lets mines operate in real time with minimal lag—even in remote global locations.

- Nano-Magnetic Materials: Magnet arrays featuring nano-materials promise even more precise control and higher separation selectivity, reducing copper losses.

- Enhanced Sensors Arrays: Next-generation sensors analyze mineralogical and operational conditions at higher resolutions than ever before.

- Autonomous Mobile Equipment: Drones, autonomous haul trucks, and mobile inspection robots—all networked to central control—streamline ore logistics and on-site safety.

- Augmented Reality (AR) Tools: AR streamlines remote maintenance, training, and process diagnostics—boosting uptime and knowledge transfer.

- Integration with Renewable Energy: Future processing plants will leverage solar and wind power to further cut the carbon footprint of copper production—making SUSTAINABILITY a competitive advantage.

The 2025 landscape is defined by smarter, data-driven, and more eco-friendly copper processing automation—helping miners, businesses, and governments meet ESG targets, profitability goals, and society’s demand for responsible sourcing.

Farmonaut Platform, API & Application Ecosystem

Farmonaut delivers affordable, scalable, and integrated satellite solutions for mining, agriculture, and infrastructure.

With our Large Scale Management Platform, mining operations can monitor vast extraction sites, assess vegetation recovery around disturbed land, and coordinate logistics—driving efficiency at a region-wide or national scale.

- Web, Android & iOS Apps: Access monitoring, reports, and AI advice on-the-go—anywhere in the world.

-

API Access & Integration: Seamlessly bring satellite and mineral analytics into your digital copper processing workflow.

Check our API page and Developer Docs. - Environmental Impact & Carbon Monitoring: Real-time satellite-based carbon footprint tracking for compliance and reporting.

- Resource Traceability & Security: Blockchain-driven traceability for copper, minerals, and supply chains, enhancing trust and reducing fraud.

- Fleet & Resource Optimization: Dedicated fleet management tools maximize machinery efficiency and minimize logistics cost.

The Farmonaut platform is flexible—choosing the right package ensures mining companies and authorities can scale satellite-driven control, traceability, and ESG compliance over time.

FAQ: Copper Processing Automation & Magnetic Separation

-

What is copper processing automation?

Copper processing automation refers to the use of digital technologies, sensors, machine learning, and automatic controls to enhance the efficiency, consistency, and sustainability of copper mineral processing, from ore crushing to concentrate production.

-

How does magnetic separation improve copper recovery?

Magnetic separation removes magnetite, pyrrhotite, and other magnetic gangue minerals from copper ores. Advanced automated separators with real-time sensors can achieve higher selectivity and improved copper recovery rates—up to 15% higher than traditional approaches.

-

Why is automation important for copper mining in 2025?

Automation meets the demand for more copper, improves operational throughput, reduces environmental impact, and helps mines comply with stringent ESG requirements. It enables mining operations to process more ore, more efficiently and sustainably.

-

What are the environmental benefits of automated copper processing?

Automated copper processing typically results in lower energy and water consumption, less waste, and better management of tailings. Advanced separation techniques reduce the carbon footprint and help mining operations exceed environmental compliance standards.

-

How can Farmonaut contribute to sustainable copper mining?

We provide satellite-based monitoring, real-time environmental analytics, fleet and resource optimization, and blockchain-driven traceability, making it easier for copper mines and processing plants to manage, verify, and optimize their operations for both profitability and sustainability.

-

Is Farmonaut a manufacturer or regulatory body?

No. Farmonaut leverages advanced satellite, AI, and blockchain technologies to deliver data-driven insights, monitoring, and resource management solutions. We are not a marketplace, manufacturer, distributor, or regulator.

Conclusion: A New Era for Copper Processing, Efficiency & Sustainability

As we move further into 2025 and beyond, copper processing automation—with a powerful boost from magnetic separation in mineral processing—is revolutionizing the global mining industry. By integrating:

- Digital AI-powered process controls

- Advanced, automated magnetic separation techniques

- Satellite-enabled resource and environmental monitoring

- Blockchain-based traceability

- Fleet and operational optimization

Copper operations are delivering higher productivity, reduced environmental impacts, and substantial cost savings. These advances directly align with global sustainability mandates, industry ESG commitments, and the ever-increasing demand for copper in the electrical, industrial, and renewable sectors.

With scalability, flexibility, and a focus on data-driven decision making, copper mining and processing in 2025 is set to serve as a global model for all mineral extraction industries—and we at Farmonaut are proud to help enable this smarter, greener maritime transformation with our satellite-driven, digital-first platform.

Ready to make your mining operations smarter? Access Farmonaut’s platform today and transform the way you manage, monitor, and scale your copper processing projects.