ERP for Mining Industry: Cost Estimating Software 2025

Table of Contents

- Introduction

- Key Trivia: Digital Transformation in Mining 2025

- ERP for Mining Industry: Foundational Pillars

- Cost Estimating Software for Metals and Mining

- Synergy & Integration: ERP and Cost Estimating Systems in 2025

- Comparative Table: Features & ROI

- Technologies & Digital Platforms Transforming 2025 Mining

- Operational and Environmental Impacts

- Farmonaut’s Satellite Solutions for Mining Innovation

- Key Trivia: Impact of ERP on Cost Estimation

- Implementation Challenges and Strategies for Success

- Future Trends & Outlook: Mining Industry 2025 and Beyond

- FAQ: ERP and Cost Estimating Software for Metals and Mining

- Farmonaut Subscription Plans

- Conclusion

Introduction: Digital Efficiency in the Evolving Mining Industry

The mining industry is amidst a transformative era, defined by advanced digital solutions, operational automation, and ever-evolving challenges to regulatory compliance and sustainability. As we advance into 2025, the deployment of ERP for mining industry and cost estimating software for metals and mining has emerged as pivotal for companies striving to achieve precise financial control and sustainable competitive advantage.

From resource-rich regions like Canada and Australia, to new ventures in Africa and Latin America, mining enterprises are actively seeking to streamline complex workflows, enhance data-driven decision-making, and ensure accurate budgeting. ERP systems and modern cost estimating tools stand at the forefront, powering this new wave of efficiency and innovation.

ERP for Mining Industry: Foundational Pillars

What is ERP and Why It’s Integral to Mining?

ERP (Enterprise Resource Planning) systems have been the digital backbone of many industries for years. However, the mining industry is unique — characterized by high capital intensity, diverse activities spanning exploration to extraction and processing, rapidly changing market forces, and stringent regulatory requirements.

A tailored ERP for mining industry integrates core business processes into a unified, digital platform—connecting operations across supply chain, finance, human resources, procurement, equipment maintenance, production planning, and beyond. By consolidating disparate data flows and standardizing processes, mining ERP solutions empower companies to make informed, real-time decisions.

How ERP Systems Streamline Mining Operations in 2025

- Unified Platform & Data Visibility: Centralizes all core and supporting processes.

- Advanced Analytics & IoT Integration: Utilizes real-time data from sensors, drones, and machinery for predictive maintenance and resource optimization.

- AI-driven Modules: Improves forecast accuracy, labor allocation, and anticipates equipment breakdowns before they impact production.

- Improved Regulatory Compliance: Automates and standardizes compliance reporting, reducing manual error and supporting ESG transparency.

- Enhanced Procurement & Contract Management: Enables precise supplier negotiations and reduces supply chain risks through transparency.

By leveraging ERP platforms tailored for metals and mining, enterprises not only increase efficiency and reduce operational costs—they transform how they manage data, equipment, inventory, labor, energy use, and environmental impacts.

Key Modules in Modern ERP for Mining

- Supply Chain and Inventory Management: Enables real-time tracking of fuel, spare parts, explosives, and critical machinery components.

- Production and Operations Planning: Aligns extraction targets with downstream processing, logistics, and export schedules.

- Asset and Equipment Maintenance: Drives predictive strategies, reducing unplanned downtime and optimizing maintenance schedules.

- Financial Management and Budgeting: Seamless integration of cost estimation with project expenditure, invoicing, and compliance reporting.

- Human Resource and Labor Deployment: Dynamic scheduling and identification of skill gaps in the workforce.

Mining companies adopting next-generation ERP technologies are enabling better planning, execution, and management of every project phase. This digital migration is critical for achieving sustainability, maintaining compliance with environmental laws, and retaining market competitiveness in 2025.

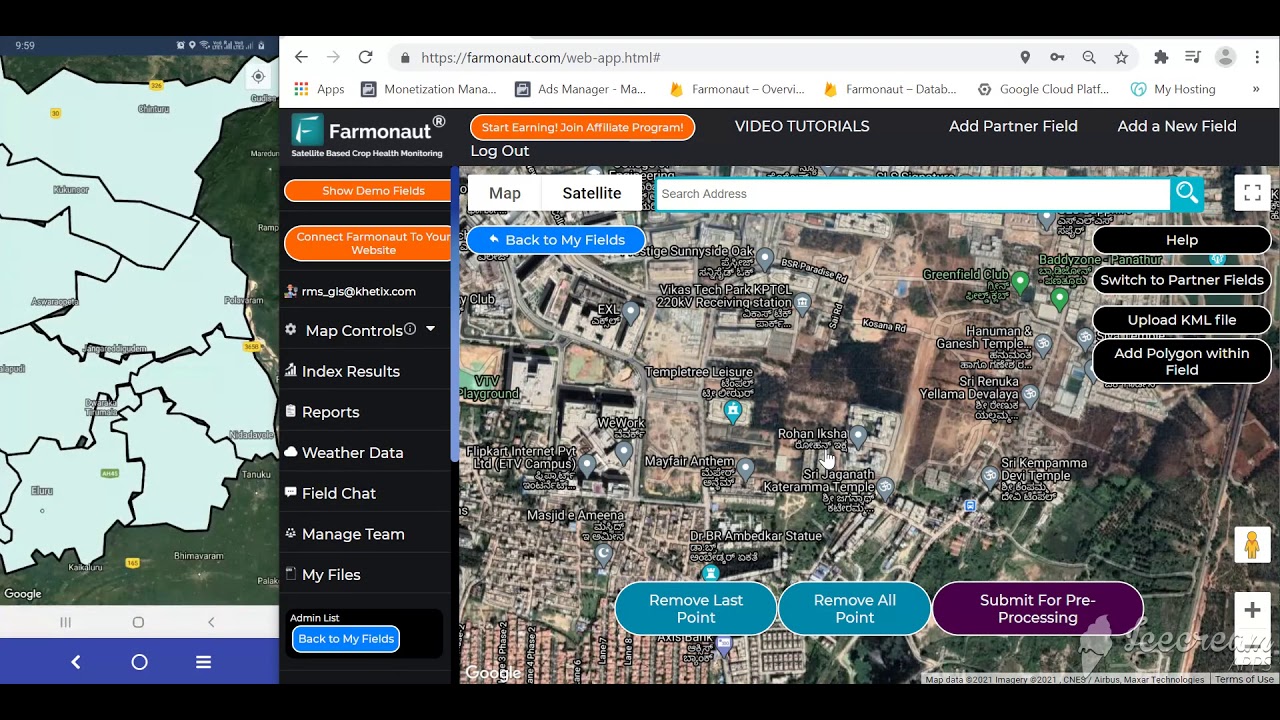

Access ERP-enabled insights and cost estimation tools for mining operations directly on web, Android, and iOS using Farmonaut’s digital platforms.

Optimize mining fleet and resource allocation with Farmonaut’s Fleet Management tools: Reduce operational costs, track machinery/equipment, and improve logistics with satellite-driven, real-time monitoring.

Cost Estimating Software for Metals and Mining: Precision for 2025

Why Accurate Cost Estimation is Critical

In mining, cost estimation is not simply a budgeting exercise—it’s the foundation for project viability, investment planning, risk reduction, and regulatory compliance. Mining projects often involve significant upfront investment in machinery, infrastructure, labor, energy, and environmental safeguards—any deviation from projections can rapidly erode returns or threaten project completion.

By 2025, cost estimating software for metals and mining has advanced to deliver highly detailed, dynamic, and scenario-based budget forecasts, directly addressing the unique volatility and complexity of the sector.

Core Features of Modern Mining Cost Estimating Software

- Integration with Historical Data: Leveraging databases from past projects for reference and risk assessment.

- Geological Modelling and Market Volatility Handling: Incorporates ore grade fluctuations, commodity pricing, and supply chain disruptions.

- Scenario Simulation & What-if Analysis: Empowers companies to evaluate outcomes under diverse economic, environmental, or regulatory conditions.

- Continuous Machine Learning Updates: Cost models improve as new data emerges from project execution, enhancing real-time accuracy.

- ESG and Sustainability Tracking: Calculates costs and ROI for environmental compliance, carbon footprint reduction, and community engagement initiatives.

Benefits of Advanced Cost Estimating Tools in 2025:

- Reduces Budget Overruns by enabling early detection and correction of cost deviations.

- Facilitates Rational Decision-Making in project initiation, supplier selection, and process optimization.

- Monitors Environmental and Regulatory Risks by factoring in compliance and mitigation costs from the onset.

- Drives Investor Confidence through transparent and auditable estimation workflows.

Leading mining companies rely on these software tools not only to control costs, but to achieve precise control across the project lifecycle. This includes feasibility studies, procurement, operational management, compliance, and long-term portfolio planning.

Integrate cost estimation with real-time environmental tracking using Farmonaut’s Carbon Footprinting platform. It’s never been easier to measure sustainability impacts while optimizing project costs and regulatory compliance.

Synergy & Integration: ERP and Cost Estimating Systems in 2025

How Integration Streamlines Financial Control and Operations

The most significant advancements in mining industry ERP and cost estimating software are found in their seamless integration:

- Cost Estimates Directly Linked to ERP Budgeting: Projected and actual expenses are compared in real time, enabling prompt corrective action.

- Synchronized Data Flows: Unified data enhances transparency for contract management, procurement, and regulatory reporting.

- Supplier and Vendor Optimization: Precise cost breakdowns support stronger supplier negotiations and reduce risk exposure.

- Dynamic Forecasting: Machine learning in estimation tools continuously updates ERP modules for better financial forecasting.

Mining enterprises that leverage this synergy enhance not only their operational workflows but also their strategic flexibility—vital for staying ahead in a volatile market and meeting environmental and social standards.

Five Key Outcomes of ERP-Cost Estimating Integration:

- Error Reduction: Automation reduces manual entry and calculation mistakes, leading to improved accuracy.

- Faster Project Execution: Real-time collaboration between departments accelerates transitions from proposal through to extraction and processing.

- Better Resource Allocation: Data-driven analysis identifies underused assets, labor, or equipment—and reallocates for higher productivity.

- Regulatory Compliance: Automated audit trails and reporting streamline government engagement and permit renewals.

- Sustainable Operations: Integrated systems enable more efficient fuel consumption, reduced emissions, and better environmental stewardship.

Combined, these systems are enabling a new era of sustainable, data-driven mining.

Comparative Table: ERP & Cost Estimating Software Benefits in Mining 2025

| Feature/Functionality | Estimated Efficiency Improvement (%) | Cost Estimation Accuracy (%) | Digital Integration Level | Projected ROI (2025) |

|---|---|---|---|---|

| Inventory Management | 35–50% | 90–96% | Full (ERP-Estimating Sync) | 18–32% |

| Project Costing | 45–60% | 95–99% | End-to-end Digital | 22–35% |

| Equipment Monitoring | 40–55% | 92–97% | AI-IoT Enhanced | 25–38% |

| Real-time Analytics | 50–70% | 95–98% | Cloud-Based Integration | 28–42% |

| Forecasting Tools | 38–60% | 92–97% | Predictive AI Module | 21–34% |

Table Analysis: Companies using integrated ERP and cost estimating software for metals and mining in 2025 are expected to improve operational accuracy and efficiency, with high projected ROI across key functional areas.

Technologies & Digital Platforms Transforming Mining in 2025

Emergent Technologies Powering the Mining Sector

- Satellite Imaging and Remote Sensing: Provides large-scale, real-time monitoring for extraction, environmental impact, and infrastructure assessment.

- Artificial Intelligence (AI) & Jeevn AI Advisory: Drives scenario modeling, equipment health prediction, and operational recommendations—empowering smarter mining operations.

- Blockchain Traceability: Ensures transparency across supply and procurement chains, from rare earths to critical metals.

- Cloud & Edge Computing: Enables on-demand, secure processing of vast workflows and geological datasets.

We at Farmonaut offer API access and developer documentation to help mining and metals enterprises seamlessly integrate satellite-derived data into their existing ERP and planning systems, driving greater digital efficiency and customized workflows.

Bolster ERP and cost estimating accuracy with Blockchain-based Traceability from Farmonaut. Ensure supply chain authenticity and meet rising regulatory expectations for transparency in metals and mining.

Operational & Environmental Impacts: Modern Digital Mining

Reducing Inefficiencies and Improving Compliance

- Resource Allocation Optimization: ERP modules monitor fuel consumption, labor deployment, and material inventory—reducing operational inefficiencies and environmental impacts.

- Preventing Equipment Breakdowns: Predictive analytics anticipate wear and tear, minimizing costly downtime and improving asset longevity.

- Scenario Planning for Market Volatility: Cost estimating software simulates fluctuations in ore grade, energy prices, and regulatory changes to de-risk projects.

- Sustainable Mining: Automated environmental reporting and emission tracking ensure compliance with global sustainability frameworks and ESG standards.

Reduce risks in project investment and machinery management using Farmonaut’s Crop Loan & Insurance Verification solution. Our platform delivers satellite-based, fraud-resistant verification specifically for the mining sector.

Mining enterprises leveraging these technologies in 2025 benefit from lower costs, reduced liability, and positive investor sentiment—vital for long-term success in the metals and mining industry.

Farmonaut’s Satellite Solutions for Mining Innovation

We at Farmonaut are committed to empowering mining companies with real-time satellite monitoring, AI-driven analytics, and blockchain traceability for optimum project oversight. Our technology suite and modular APIs ensure:

- Affordable Monitoring – Democratizing satellite and AI-driven insights for all mining operators, regardless of project scale.

- Actionable Data – Monitoring equipment & site health, tracking resource consumption, and flagging environmental impacts in near real-time.

- ESG Compliance & Traceability – Supporting corporate transparency with blockchain-backed supply chain modules and environmental reporting.

- Remote Accessibility – Our platform is accessible via Android, iOS, web, and API, enabling operational management from anywhere.

- Scalable Subscriptions – See below for Farmonaut’s flexible subscription plans designed for mining, infrastructure, and resource management.

Our large scale resource management features allow mining and infrastructure enterprises to monitor vast areas, improve fleet logistics, and plan extraction with advanced digital mapping.

Implementation Challenges and Strategies for Success

What Are the Common Hurdles?

- Data Standardization: Legacy and siloed data may impede effective ERP and cost estimating software deployment.

- Organizational Resistance: Workforce adaptation requires robust change management and training initiatives.

- Integration Complexity: Aligning ERP modules with specialized cost estimating tools or third-party platforms can be technically demanding.

- Cybersecurity and Data Privacy: Cloud and IoT integrations underscore the need for strong digital security in mining operations.

- Long-term ROI Realization: Cross-departmental collaboration and management buy-in are necessary for maximum benefit over time.

Best Practices for Successful Digital Transformation

- Start with Critical Workflows – Digitize core processes (inventory, equipment monitoring, project costing) before expanding integration.

- Invest in Change Management – Training and clear communication are crucial for workforce buy-in and adoption.

- Choose Modular, Scalable Platforms – Enable stepwise implementation at reduced risk; align investment with ROI.

- Leverage API-first Systems – Facilitate flexible plug-and-play with satellite, AI, or environmental monitoring solutions.

Future Trends & Outlook: Mining Industry 2025 and Beyond

Landscape Evolution: What’s Next for Mining ERP & Cost Estimating?

- Sustainable Mining at the Core: ERP and cost estimating software will reinforce green mining practices, carbon tracking, and regulatory transparency.

- End-to-End Automation: Advanced AI, drones, and IoT will drive dynamic, autonomous operations—reducing human error and occupational hazards.

- Real-time Global Collaboration: Decision-makers, engineers, and regulators will collaborate instantly via cloud platforms and blockchain.

- Tailored Advisory Systems: Personalized digital advisors (such as Farmonaut’s Jeevn AI) will streamline complex regulatory and operational requirements.

- Continued Cost Reduction: Ongoing adoption will steadily lower project expenditures and optimize resource utilization.

As ERP for mining industry and cost estimating software for metals and mining rapidly evolve, mining enterprises must stay agile—adopting modular digital platforms, integrating advanced analytics, and focusing on sustainable, transparent operations to succeed in 2025 and beyond.

Unlock full mining site visibility with Farmonaut’s large scale management solutions. Perfect for multi-site monitoring, supply management, and real-time operational analytics.

FAQ: ERP and Cost Estimating Software for Metals and Mining

1. What is ERP for mining industry and why is it essential for 2025?

ERP for mining industry refers to specialized digital platforms that integrate diverse business functions—like supply chain, finance, labor, equipment, and compliance—within a unified system tailored for the complex needs of mining enterprises. By 2025, these systems are pivotal for streamlining operations, boosting transparency, reducing risks, and achieving sustainable growth.

2. How does cost estimating software for metals and mining improve budgeting and forecasting?

These software tools utilize historical data, AI, and scenario modeling to provide highly accurate cost projections for project planning, equipment investment, environmental compliance, and much more. This leads to better financial control and fewer unplanned budget overruns.

3. Can ERP and cost estimating software help with regulatory compliance?

Yes, integrated solutions automate reporting, track environmental impacts, and create verifiable audit trails, reducing the risk of non-compliance penalties and enhancing your ESG reputation.

4. What are the main challenges when implementing ERP and cost estimating systems in mining?

Typical hurdles include data integration, resistance to change, technical complexity, cybersecurity, and long-term ROI realization. Addressing these early with modular solutions and training is key to success.

5. How can Farmonaut’s solutions support mining ERP and cost estimating needs?

We at Farmonaut provide API-enabled access to satellite imagery, real-time analytics, blockchain traceability, and resource management tools designed to enhance the accuracy, transparency, and digital efficiency of ERP and cost estimation workflows in mining.

6. Is it possible to start small and scale up digital mining platforms?

Absolutely. With modular, subscription-based offerings like those on the Farmonaut platform, mining enterprises can begin with specific digital solutions and scale up as they realize ongoing value and operational improvements.

Farmonaut Subscription Plans

Conclusion: ERP and Cost Estimating – The Indispensable Digital Backbone of Mining in 2025

The future of the metals and mining industry depends on advanced ERP and cost estimating software that provide precise, real-time control over financial, operational, and regulatory processes. As 2025 unfolds, digital platforms—enriched with satellite data, AI analytics, and blockchain transparency—will differentiate industry leaders.

Mining enterprises must prioritize the adoption of integrated, scalable, and sustainable digital solutions to maintain competitiveness, enhance environmental stewardship, and deliver lasting value for investors and communities.

Digital efficiency, accuracy, and transparency are no longer optional—they have become indispensable for success in the modern mining landscape.

For a deep-dive into API capabilities, integrations, and developer resources, visit our API page and Developer Docs.