Table of Contents

- Introduction: Why Compare Liquid vs Granular Fertilizers?

- Liquid vs Granular Fertilizers Cost Comparison

- Fertilizer Application Efficiency

- Environmental Impact of Fertilizers: Runoff & Leaching

- Granular Fertilizer Storage Tips & Liquid Handling

- Liquid vs Dry Fertilizer: Cost, Application, and Environmental Impact Comparison Table

- Video: Tech Innovations in Precision Fertilization Strategies

- How Farmonaut Empowers Precision Fertilization Strategies

- 7 Key Farmer Insights for Optimizing Fertilization

- Did You Know?

- Farmonaut Technologies Supporting Nutrient Uptake in Crops

- Conclusion: Best Fertilizer for Crop Yield & Farmonomics

- Frequently Asked Questions (FAQ)

Liquid vs Dry Fertilizer Cost: 7 Key Farmer Insights

In modern agriculture, making the right fertilizer choice—liquid or dry (granular)—can transform both your crop yield and economic viability. The liquid vs granular fertilizers comparison matters more than ever: differences in application efficiency, nutrient availability, cost, and environmental impacts directly affect farm productivity and profits. For farmers determined to optimize fertilization strategies, understanding the implications of each fertilizer type on their land is essential.

This comprehensive guide reveals direct, actionable insights into the cost of liquid fertilizer per acre versus granular options, explores innovations like foliar spraying and fertigation systems, examines real environmental impacts of fertilizers, and offers science-driven answers on how to reduce fertilizer runoff while ensuring best fertilizer for crop yield.

Whether you’re managing large fields or small plots, these seven key insights—backed by both agronomic research and the latest precision agriculture technologies—will empower you to make the most informed, sustainable, and profitable fertilization decisions.

Liquid vs Granular Fertilizers Cost Comparison

The choice between liquid and dry fertilizers starts with a careful look at cost. While liquid fertilizers often have a higher initial cost due to additional production, mixing, and dissolution processes, they may enhance nutrient uptake in crops and reduce overall consumption.

Key Figures: Liquid vs Dry Fertilizer Cost per Acre

- Liquid fertilizer: Concentrated liquids cost $30–$60 per gallon, typically diluted to cover 5,000–10,000 sq. ft.

- Granular fertilizer: Standard 40-pound bags cost $25–$45 and cover similar areas.

- With increased fertilizer application efficiency, liquid fertilizers can reduce waste and, according to modern estimates, reduce total fertilizer required by 15–20% for equivalent crop nutrition.

Understanding the True Cost Implications

Upfront cost is only part of the equation. Liquid fertilizer’s rapid nutrient availability often results in a faster crop response—nutrients can be absorbed within 24–48 hours. In granular products, nutrients may require 1–2 weeks to become plant-available, especially if rainfall or soil moisture is lacking after application.

- When calculating cost per acre, consider application frequency, crop type, field conditions, and your labor and transport costs.

- The greater the need for immediate nutrients (e.g. for horticulture, high-value crops, rapid deficiency correction), the more liquid can justify initial costs through higher or more consistent yield.

- For sustained field feeding, particularly for staple or commodity crops, granular fertilizers often deliver the most cost-effective solution over the long season.

Liquid vs Dry Fertilizer: Cost, Application, and Environmental Impact Comparison

| Parameter | Liquid Fertilizer | Dry (Granular) Fertilizer |

|---|---|---|

| Estimated Average Cost per Acre | $70–$120 | $55–$100 |

| Nutrient Uptake Efficiency (%) | Up to 85 | 65–75 |

| Ease of Use (1–5 scale) | 4 (requires specific equipment) | 5 (easy; broad compatibility) |

| Required Equipment Cost | Moderate–High (sprayers, injectors) | Low–Moderate (spreaders) |

| Environmental Impact Score (1–10: higher=worse) | 4–7 (possible leaching) | 5–8 (increased runoff) |

| Suitability for Precision Application | Yes | Limited |

| Storage Requirements | Sensitive; shorter shelf-life | Stable; minimal requirements |

Fertilizer Application Efficiency in Precision Agriculture

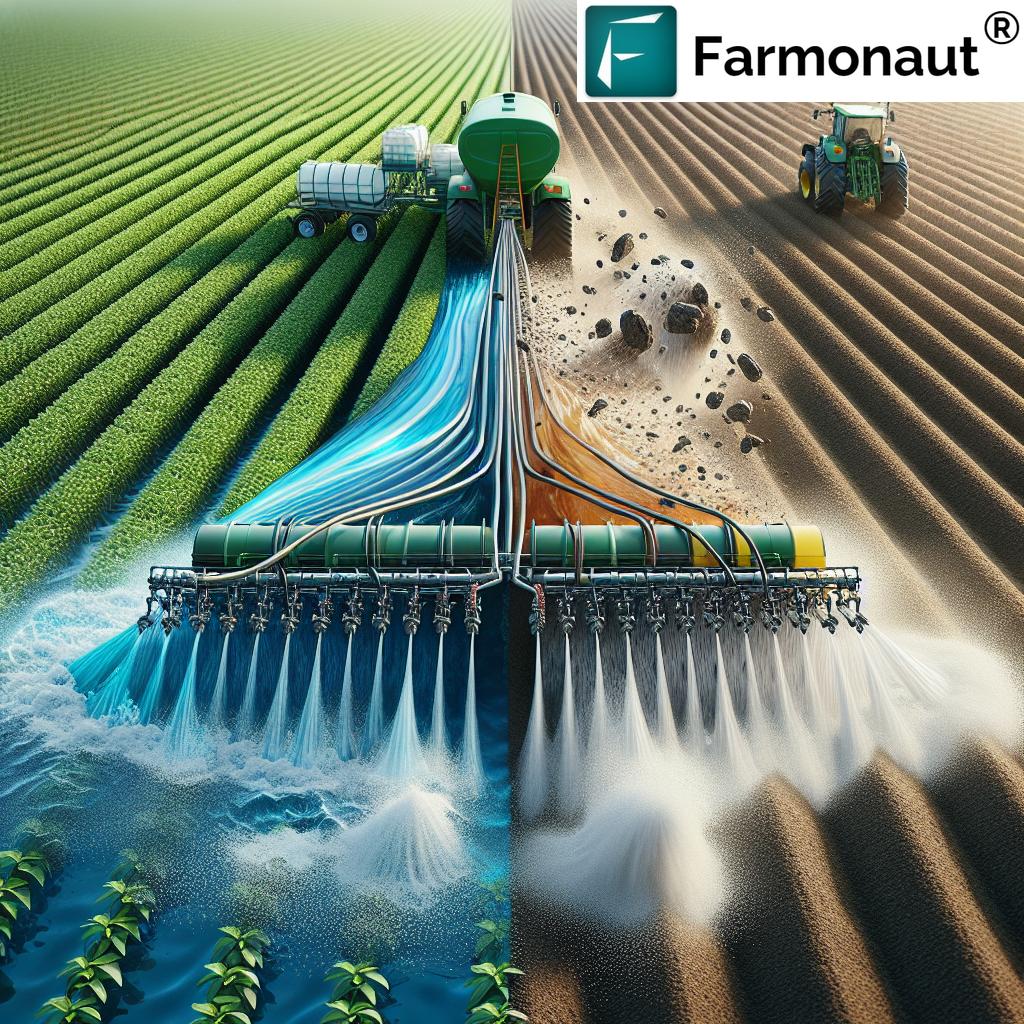

Application Methods: Liquid vs Granular Fertilizer

- Liquid Fertilizer is generally applied through fertigation systems (delivered with irrigation water) or foliar spraying (directly on plant leaves). This boosts nutrient uptake in crops and enables fine-tuning of rates per growth stage or field zone.

- Dry (Granular) Fertilizer is either broadcast over fields or banded into soil. This type excels for sustained feeding, but nutrients are only absorbed after moisture breaks granules down.

Why Application Efficiency Matters

The speed at which plants access nutrients can mean the difference between a healthy crop and lost yield opportunities:

- Liquid fertilizer offers response in hours to days (vital for correcting deficiencies or supporting fast-growing stages).

- Granular/dry fertilizer releases over several days to weeks—good for baseline or “season-long” nutrition.

Precision Fertilization Strategies for Maximum Crop Yield

- Use liquid for quick-response situations or to target high-value or sensitive crops.

- Rely on granular for ease of storage, transport, and broad-acre applications.

- Combine both: base-layer dry with liquid “boosts” timed to crop stage or nutrient analysis (precision fertilization).

Environmental Impact of Fertilizers: Runoff and Leaching

No matter which type you choose, environmental impacts of fertilizers are a growing concern—particularly nutrient runoff and groundwater leaching.

Granular Fertilizer Runoff

- Granular, or dry fertilizers, if over-applied or not incorporated well into soil, can be swept away by rainfall. This runoff leads to nutrient pollution of streams, rivers, and lakes—disrupting aquatic ecosystems and causing regulatory headaches for agriculture.

Liquid Fertilizer Leaching

- Liquid fertilizers, when overapplied, are absorbed quickly and can move beyond the root zone into groundwater—potentially leading to nitrate contamination, a serious health risk for rural and urban communities.

How to Reduce Fertilizer Runoff and Leaching

- Apply fertilizer based on soil tests and crop demand only.

- Invest in precision fertilization strategies—such as variable-rate application and satellite-based crop health monitoring (learn more below).

- Use cover crops and maintain field buffers to limit surface runoff.

- Properly calibrate equipment for uniform distribution and minimal waste.

Optimizing Fertilization for Farmers: The Eco-Friendly Path

Environmental impact of fertilizers need not be a necessary evil. Using real-time data, such as Farmonaut’s crop health and moisture insights, helps apply only the nutrients required—improving both compliance and land stewardship.

Granular Fertilizer Storage Tips & Liquid Handling

Granular Fertilizer Storage Tips

- Store dry fertilizers in a cool, dry place in their original bag or sealed bins to avoid caking and humidity compromises.

- Keep away from farm chemicals or fuels that could create cross-contamination.

- Rotate old stock first and check “expiration” guidelines.

Liquid Fertilizer Storage Needs

- Use corrosion-resistant tanks (poly or stainless steel).

- Store under cover, protected from direct sunlight and temperature extremes—which can reduce nutrient efficacy or cause crystallization.

- Always check dilution ratios before application; poorly stored liquid fertilizers may lose homogeneity.

Safety First

- Wear gloves and safety glasses when mixing or loading liquids.

- Keep emergency spill kits nearby and follow all local environmental regulations.

Summary

Granular fertilizers are easier and less expensive to store, but may require more field passes for full crop coverage. Liquid fertilizers demand careful storage but are more efficient in targeted applications and labor-saving operations.

How Farmonaut Empowers Precision Fertilization Strategies

At Farmonaut, our mission is to deliver precision agriculture solutions that empower every grower—large or small—to optimize fertilization for higher crop yield and reduced waste. We offer a satellite-based farm management platform through Android, iOS, web, and API for real-time crop health monitoring, AI-based advisory, blockchain traceability, and resource management.

With Farmonaut’s satellite and AI-driven insights, farmers gain timely knowledge of their field’s soil moisture, crop health, and resource requirements—making every fertilizer application more efficient, targeted, and cost-effective.

- Optimize fertilizer use: Pinpoint nutrient needs to apply the right type and amount in the right place at the right time.

- Boost yield and profitability: Achieve greater returns on fertilizer investments by minimizing excess or missed applications.

- Reduce fertilizer runoff: Protect your land and the environment by ensuring fertilizers support your crop, not the nearest waterway.

Try our platform to maximize the impact of every fertilizer dollar!

Farmonaut API: Integrate crop monitoring and weather intelligence into your custom systems via our FARMONAUT SATELLITE & WEATHER DATA API (API Developer docs).

- For large scale management and multiple field monitoring, our Large-Scale Farm Management module streamlines team operations and input tracking.

- Interested in carbon footprinting? Our Carbon Footprinting feature ensures you record and manage your farm’s environmental impact—critical for sustainable fertilizer use.

- Enhance supply chain trust with traceability: Our blockchain-based product traceability evidences every step in your crop’s journey, from field application to final product.

- Manage machinery and teams efficiently: Explore our Fleet and Resource Management tools for real-time logistics and input allocation.

- Secure crop loans and insurance faster with satellite-based verification via Farmonaut’s crop loan and insurance reporting.

- Need field and plantation advisory? Access field-specific advice with our Jeevn AI and crop advisory system.

7 Key Farmer Insights: Liquid vs Dry Fertilizer Cost, Efficiency, and Impact

- Evaluate Cost Per Acre, Not Just Bag or Gallon Price. The total applied cost per treated acre determines profit—include labor, fuel, and equipment depreciation.

- Match Fertilizer Nutrient Release to Crop Stage. Liquids suit rapid deficiency correction; granular works for season-long feeding.

- Leverage Technology for Data-Driven Decisions. Satellite and AI insights—like those in Farmonaut’s app—help time fertilizer applications and reduce waste.

- Prioritize Environmental Responsibility. Choose application methods and rates to reduce fertilizer runoff and leaching; integrate best management practices.

- Invest in Storage Matching Your Input Strategy. Granular fertilizers are durable and lower-maintenance; liquids demand monitoring and infrastructure.

- Consider Combined Programs. Many top performers combine a granular base with liquid in-season boosts for optimal nutrition and flexibility.

- Read Labels, Follow Recommendations. Always calibrate equipment, confirm compatibility, and apply at the correct growth stage to optimize fertilization.

Farmonaut Technologies Supporting Nutrient Uptake in Crops

Farmonaut helps users maximize their fertilizer application efficiency by:

- Satellite-based crop health monitoring—see zones of poor health, detect stress, and adjust fertilizer rates accordingly using NDVI, soil moisture, and thermal imagery.

- AI-driven Jeevn advisory—receive crop, weather, and fertilization recommendations based on real-time data and local conditions.

- Blockchain product traceability—track every step, ensuring transparency of input use for buyers and regulators.

- Resource and fleet management—reduce costs and emissions by optimizing labor, transport, and machinery for fertilizer application.

- Carbon footprinting—calculate and monitor fertilizer-related emissions to meet sustainability and regulatory standards.

These tools let farmers refine and adjust their fertilization programs, confidently adopting innovative precision fertilization strategies that reduce waste and environmental risk.

Conclusion: Best Fertilizer for Crop Yield & Farmonomics

The ideal choice in the liquid vs granular fertilizers comparison merges science, technology, and economics. Both fertilizer types play critical roles in modern agriculture, and the decision must weigh cost, application efficiency, environmental impacts, and storage requirements.

For rapid response and targeted feeding, liquid fertilizers are often the best fertilizer for crop yield—especially when used with precision tools. For long-season baseline nutrition and simpler storage, dry granular fertilizers remain a staple.

With Farmonaut’s advanced farm management platform, every farmer—no matter the location or crop—can harness data-driven insights to optimize usage, reduce fertilizer runoff, and meet financial and environmental targets.

The future of fertilization is precise, efficient, and sustainable. Take the next step in optimizing fertilization for farmers with Farmonaut’s platform.

Frequently Asked Questions (FAQ)

Q1: Which is more cost-effective: liquid or granular fertilizer?

Generally, granular (dry) fertilizers are less expensive upfront, often by 10–20% compared to liquids. However, liquid fertilizers can reduce total nutrient use by improving uptake and reducing waste, which may even out costs over time.

Q2: What is the average application efficiency of liquid vs granular fertilizers?

Liquid fertilizers can reach up to 85% nutrient uptake efficiency due to rapid absorption. Granular fertilizers generally range between 65–75%, affected by soil moisture and weather.

Q3: How do I reduce fertilizer runoff?

Calibrate equipment, use precision tools like Farmonaut’s crop health and soil moisture data, time applications before rainfall, and consider buffer strips and cover crops.

Q4: What is the best fertilizer for crop yield?

The best is context-specific: liquid fertilizers work best for immediate uptake needs and precision management; granular fertilizers remain ideal for season-long base nutrition and ease of use.

Q5: Are liquid fertilizers more environmentally friendly?

Liquid fertilizers can be more precise and have lower runoff risk, but if overapplied, they may cause groundwater leaching. Both should be managed responsibly using data-driven precision strategies.

Q6: What are the top granular fertilizer storage tips?

Store in sealed containers away from moisture and chemicals, rotate stock, and follow manufacturer storage guidance to preserve effectiveness.

Q7: How does Farmonaut help in fertilizer management?

Farmonaut delivers satellite-driven insights, AI-based recommendations, and field monitoring via web and mobile apps—helping optimize input timing, reduce waste, maximize yield, and minimize environmental impact.

Q8: Can I integrate Farmonaut data into my own farm management software?

Yes! Access Farmonaut API for integration with your custom tools: see FARMONAUT SATELLITE & WEATHER DATA API and API documentation.