Table of Contents

- Introduction: The Evolving Landscape of Agricultural Inputs in 2025

- Trivia Spotlight

- The Future of Ag Chemical Mixing Systems

- Innovative Mixing Technologies: Designs & Controls

- IoT Sensors, Data Analytics, and Real-Time Field Monitoring

- Variable-Rate Chemical Application & Dosing

- Impact Metrics: Productivity, Efficiency, and Sustainability Compared

- In-Depth: Key Trends & Solutions (Video Resources)

- CO2 Grow Systems: 2025 Advancements in Carbon Dioxide Enrichment

- Integrated Technologies for Enhanced Crop Growth

- Satellite-Driven Insight & Management with Farmonaut

- Compliance, Safety, and Traceability in Modern Agriculture

- Challenges, Outlook, and the Road Ahead

- Frequently Asked Questions

- Useful Resources & Farmonaut Solutions

Trivia Spotlight

“In 2025, precision ag mixing systems can reduce chemical waste by up to 30% on large commercial farms.”

Ag Chemical Mixing System & CO2 Grow: 2025 Innovations

The agricultural landscape of 2025 is driven by innovation, precision, and the need for sustainability. As global food demand rises, environmental concerns become paramount, prompting the industry to adopt advanced systems for maximizing output while minimizing negative effects on ecosystems. Two technological pillars—ag chemical mixing systems and CO2 grow systems—are transforming the way we approach crop production and resource efficiency. In this comprehensive overview, we’ll explore how these technologies work, their benefits, challenges, and why integration is the new norm for productive, sustainable agriculture in 2025 and beyond.

From precise chemical input management that limits waste and enhances efficacy, to carbon dioxide (CO2) enrichment strategies that accelerate plant growth, these advancements are not only increasing yields but are also supporting environmental stewardship.

Optimizing Chemical Inputs: The Ag Chemical Mixing System Revolution

Chemical inputs in agriculture—such as fertilizers, pesticides, herbicides, and growth regulators—are critical to achieving high yields and healthy crops. However, the indiscriminate use or inefficient management often leads to environmental degradation, increased costs, and potential harm to beneficial organisms. In 2025, the shift to advanced ag chemical mixing systems stands at the forefront of the solution, ushering in a new era of automation, precision, and sustainability.

- Automation and digital management reduce human error and variability

- Sensors and real-time data analytics ensure precise dosing and timing

- Adaptive systems dynamically adjust chemical concentrations based on crop needs and weather

The evolution of the ag chemical mixing system is made possible by integration with Internet of Things (IoT) technology, data analytics, and digital control platforms—making modern agrochemical formulation both efficient and environmentally responsible.

With global regulatory frameworks growing stricter to protect soil and water quality, the importance of efficient chemical input management cannot be overstated. These systems support compliance requirements while enhancing productivity and profitability for farms of all sizes.

Advanced Mixing Technology: Designs & Closed-Loop Controls

Modern chemical mixing systems have evolved far beyond the open tanks and batch mixers of the past. Today’s systems feature:

- Turbulence-enhancing mixer designs: Ensuring thorough and consistent dispersion of active ingredients.

- Closed-loop digital controls: Automatically adjusting chemical concentrations and volumes.

- Automated calibration: Reducing time and ensuring accuracy before every application.

- Real-time measurement of pH, electrical conductivity (EC), and temperature for optimal nutrient delivery.

These designs ensure every drop of agrochemical is properly blended, allowing for precise application and minimized waste. New data-driven approaches also factor in soil conditions, current weather forecasts, and individual crop requirements to further refine each formulation.

Additionally, digital dosing systems now allow seamless integration with variable-rate application equipment, meaning treatments are spot-targeted to specific field zones, elevating both efficacy and economic returns.

For operations pursuing large-scale, sustainable improvements, adopting carbon footprint monitoring tools can be transformative. These resources track the environmental impacts of chemical use and production inputs, ensuring continual improvement aligned with global sustainability goals.

IoT Sensors, Data Analytics, and Real-Time Field Monitoring

Integration of IoT sensors within agricultural fields offers game-changing advances for environmental monitoring, nutrient levels, and pest pressures.

Key features include:

- In-field nutrient sensors—provide real-time data on soil and crop health.

- Pest pressure detectors—monitor to enable adaptive chemical management.

- Weather-integrated analytics—incorporate precipitation, humidity, and wind forecasts for the timing of application.

This networked approach minimizes excessive chemical use and reduces runoff or leaching, supporting both yield optimization and ecosystem protection. By leveraging data analytics, farmers are empowered to adjust chemical input regimes on-the-fly, ensuring applications are timely, targeted, and cost-effective.

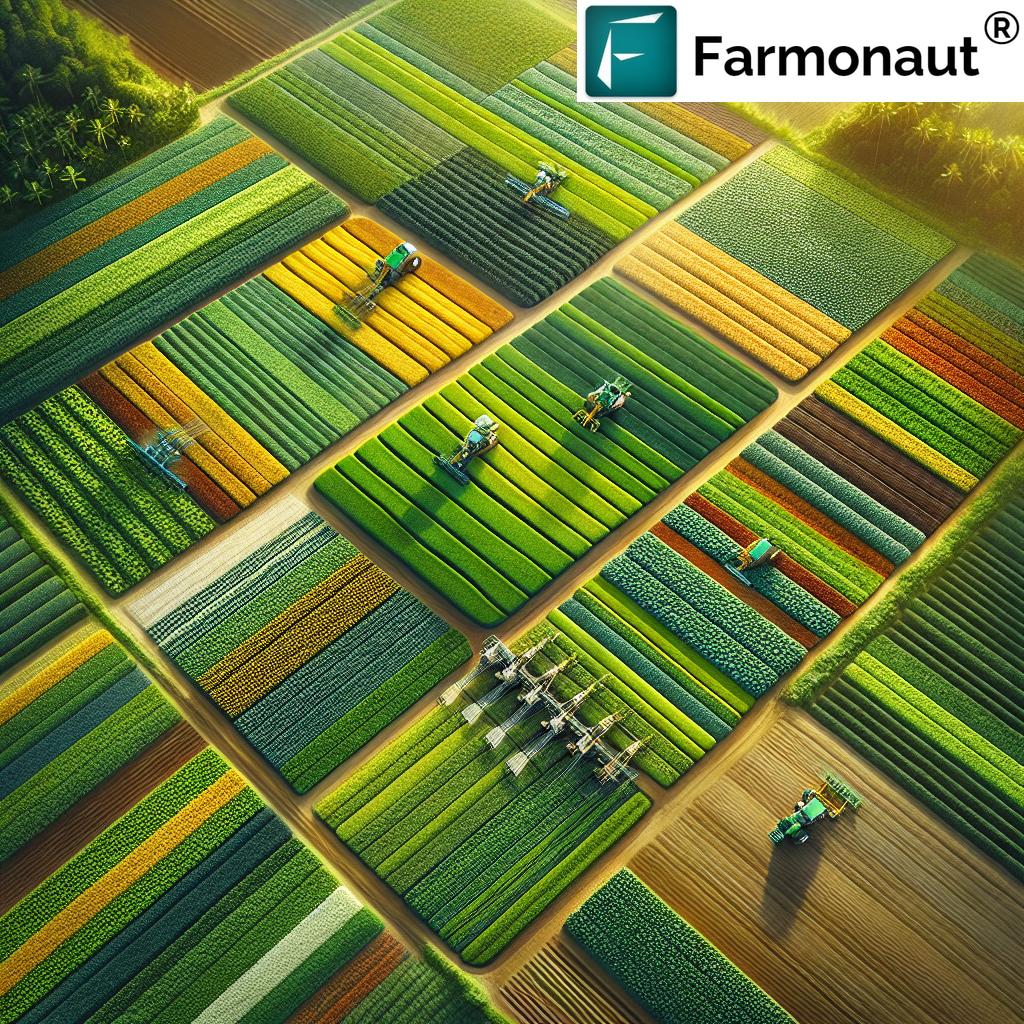

For users interested in large-scale field operations, Farmonaut’s Large-Scale Farm Management app delivers multifield satellite monitoring and actionable insights via web, Android, and iOS—enabling truly modern, data-driven decisions from anywhere.

Variable-Rate Application and Digital Dosing: Economic & Environmental Impact

A key advancement in the ag chemical mixing system is its seamless compatibility with variable-rate equipment. With precise control over dosing and application rates, it is possible to achieve:

- Site-specific treatment—ensuring each crop area gets the exact formulation required based on real-time data.

- Enhanced efficacy—active ingredients are utilized at peak efficiency, directly impacting yields and crop health.

- Reduced agrochemical input costs—farmers save money by eliminating over-application and chemical waste.

- Compliance with stricter regulatory frameworks—minimizing environmental impact is not only ethical but increasingly required by law.

For growers navigating lending or risk management, access to precision field data is invaluable. Crop loan and insurance verification services, like those offered via Farmonaut’s crop loan and insurance solutions, provide remote verification through satellite analytics, streamlining compliance and reducing fraud in the agricultural financial ecosystem.

Key Benefits of Variable-Rate Application:

- Reduced runoff and leaching—protects surrounding water bodies and non-target organisms.

- Better yields with less environmental impact.

- Improved economic returns thanks to efficient resource allocation.

“CO2 enrichment methods are projected to increase controlled-environment crop yields by over 20% in the next year.”

Comparing Key Innovations: Ag Chemical Mixing System vs. CO2 Grow System

To clarify the advantages and challenges of these leading-edge systems, compare the primary features below:

| Technology/System | Estimated Yield Increase (%) | Reduction in Chemical Inputs (%) | Resource Use Efficiency | Sustainability Rating | Integration Complexity |

|---|---|---|---|---|---|

| Ag Chemical Mixing System (2025) | 15–25% | 20–30% | High (site-specific, data-driven) | ★★★★★ (5/5) | Moderate (integration with sensors and digital platforms needed) |

| CO2 Grow System (2025) | 20–40% (controlled environments) | N/A (focus on photosynthetic gain) | Very High (maximized photosynthetic output) | ★★★★★ (5/5) | Moderate to High (specialized delivery system required) |

| Integrated Chemical + CO2 System | 30–50% (synergistic boost) | Up to 40% | Maximum (real-time adaptive feedback) | ★★★★★ (5/5) | High (requires advanced automation and cross-platform connectivity) |

Note: Data reflects industry-wide trends and 2025 projections for commercial operations in North America, Europe, India, Canada, and other major agricultural regions. Benefits may vary by local conditions, integration level, and operational scale.

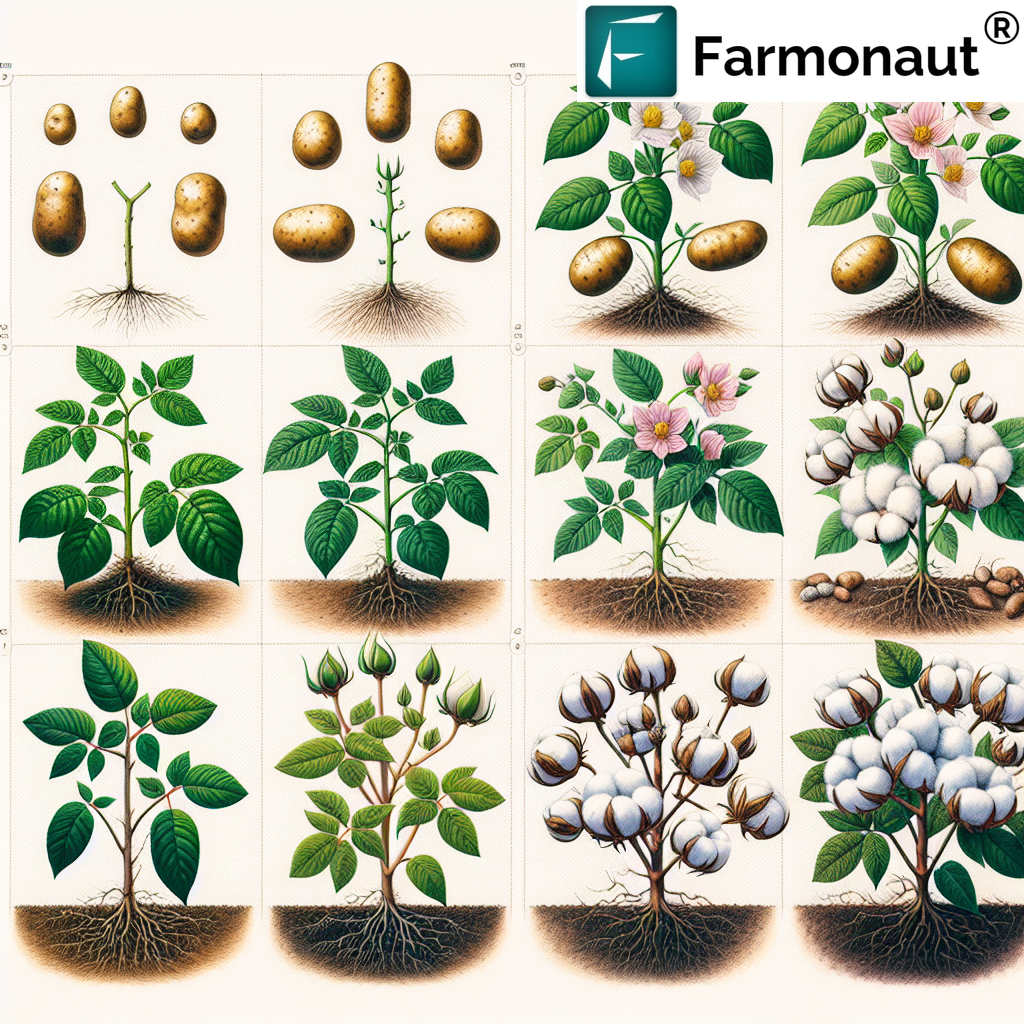

CO2 Grow System: 2025 Advancements in Carbon Dioxide Enrichment

The role of carbon dioxide enrichment in modern agriculture has become paramount—especially in controlled-environment agriculture (CEA), such as greenhouses and vertical farms.

Current CO2 grow systems are:

- Sophisticated, with programmable delivery networks—maintaining optimal CO2 levels (typically 800–1,200 ppm for most fruit and vegetable crops)

- Integrated with real-time climate and photosynthesis monitoring sensors

- Automatically adjusted based on crop, growth stage, and current levels of CO2, humidity, and temperature

- Eco-conscious, often utilizing recycled or industrially-captured CO2 for true environmental synergy

With optimizing photosynthetic rates as the goal, CO2 enrichment both supports higher productivity and reduces the time to market—key for profit margins and global food security. By enabling smart, integrated adjustment of both CO2 and chemical inputs, farms enhance yields and crop quality while contributing positively to sustainable agriculture targets.

How CO2 Grow Systems Work: Precision & Sustainability

CO2 grow systems employ networked sensors, automated valves, and environmental control units to deliver preset concentrations. In large-scale facilities, many modern systems recycle CO2 from biogas plants or industrial sources, lowering the carbon footprint associated with enrichment.

Key considerations when deploying a CO2 grow system:

- Match enrichment regime to crop-specific growth profiles (i.e., leaf crops vs. fruit crops)

- Monitor plant health, photosynthetic rates, and soil nutrient levels for balanced growth

- Integrate with chemical input management to avoid nutrient imbalances

- Regularly calibrate sensors and dosing to achieve optimal results

The blockchain-based traceability tools offered by Farmonaut can help growers and marketers demonstrate the sustainable sourcing and responsible use of CO2 and agrochemicals, enhancing food safety and market trust.

Integrated Strategies: Chemical & CO2 Systems for Maximum Crop Yields

The true promise of 2025 agricultural technologies emerges when ag chemical mixing systems and CO2 grow systems are fully integrated:

- Adaptive management—monitoring plant uptake, nutrient levels, and photosynthetic activity in real time

- Dynamic dosing and enrichment—chemicals and CO2 are adjusted for each growth stage and environmental condition

- Environmental impact monitoring—tracks emissions and runoff, further supporting sustainability and regulatory compliance

Such deeply linked systems allow growers to optimize every input—chemical, CO2, water, and energy—delivering unprecedented productivity and sustainability gains. For operations needing end-to-end oversight, fleet and resource management solutions help coordinate field machinery and input delivery across vast areas, ensuring operational efficiency at every step.

This synergy embodies the essence of precision agriculture in 2025: high-tech, data-driven, and outcome-focused.

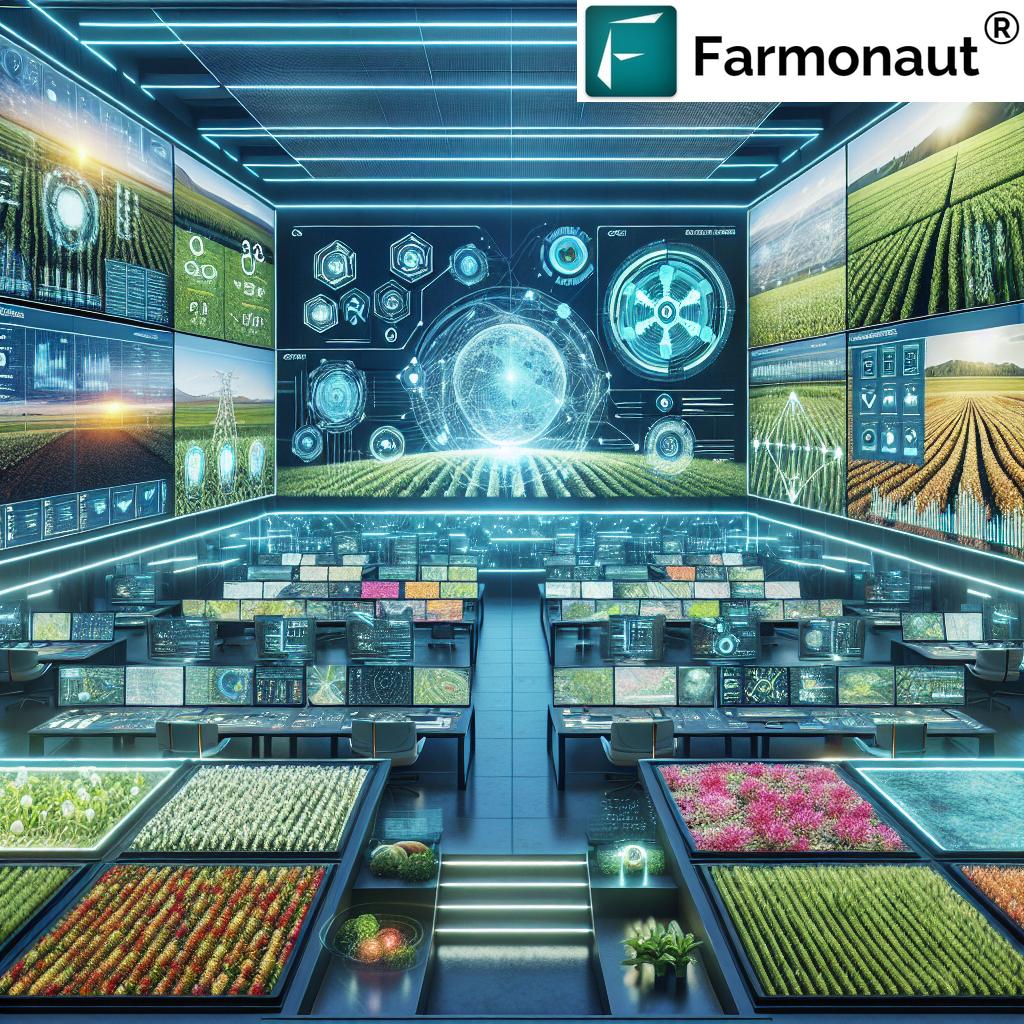

Farmonaut’s Satellite Platform: High-Tech Monitoring & Resource Management

As agricultural operations grow in scale and complexity, data-driven management becomes absolutely essential. We at Farmonaut offer a comprehensive satellite monitoring and insight platform designed to empower farmers, agribusinesses, and governments. Our solutions leverage:

- Multispectral satellite imagery—regular field health assessments (vegetation index, soil, irrigation, etc.)

- Jeevn AI-based advisory—providing instant crop strategies, weather forecasts, and treatment recommendations

- Blockchain-based traceability—for secure, transparent chemical and resource usage records

- Carbon footprinting—helps agricultural operations track and minimize emissions, integrating with chemical and CO2 input records

- Fleet/resource management—ensuring machinery use is cost-effective and energy-efficient

Our tools are available via web interface, Android, and iOS (see links below for app downloads). The Farmonaut API enables deeper integration into custom business systems, making advanced satellite and AI-driven insights accessible to all scales of agriculture.

Traceability, Compliance & Environmental Impact: Meeting the 2025 Standard

In 2025, regulations around chemical inputs in agriculture and environmental impact monitoring are at the strictest level yet. These measures are crucial for safeguarding soil, water, and ecosystems globally. Blockchain traceability is now widely adopted to guarantee that every input—be it fertilizer, pesticide, herbicide, or CO2—is accounted for from source to application.

Benefits include:

- Real-time tracking prevents inefficiency, fraud, and noncompliance

- Demonstrates responsible sourcing of CO2 and chemicals to global food chains

- Monitors environmental footprint, helping growers prove their commitment to sustainability

Environmental monitoring is further enhanced by leveraging satellite data for carbon footprinting, supporting ongoing sustainable intensification in agriculture.

Challenges, Future Trends & The Path Forward

Despite the clear benefits of ag chemical mixing system and CO2 grow system integration, several key challenges remain in 2025 and beyond:

- High initial costs—for advanced automation and sensor technology

- Technical expertise—required for optimal calibration and ongoing management

- Reliable energy supply—especially in off-grid rural sectors or developing regions

- Integration complexity—merging legacy equipment with new cloud-based or IoT platforms

However, continuous developments in AI, machine learning, and interface design are making these systems increasingly user-friendly and cost-accessible. We at Farmonaut are committed to lowering adoption barriers by offering affordable satellite insights, real-time advisory, and robust APIs. This approach democratizes data access—ensuring all scales of agricultural and agribusiness stakeholders can participate in the productivity gains and environmental protection imperative to 2025 and beyond.

Looking forward, integrated systems will see:

- Proactive pest and disease forecasting via real-time remote sensing

- Automated resource optimization—balancing chemical, CO2, and energy use for maximum profitability and stewardship

- Greater synergy between robotics, AI-driven analytics, and sensor technology

- Enhanced crop traceability and transparent food supply chains worldwide

Conclusion: Ag Chemical Mixing System & CO2 Grow—2025’s Model for Sustainable Agriculture

Evolving technology is revolutionizing the landscape of agriculture in 2025. By adopting ag chemical mixing system and CO2 grow system integration, commercial agribusinesses and growers are optimizing inputs, reducing environmental impacts, and generating higher crop yields. This results not only in increased productivity and profits but also in sustainable intensification for a world with rising food needs and tightening resource constraints.

The seamless integration of advanced monitoring, automated dosing, and carbon management stands as a model for future-facing, responsible agriculture. We at Farmonaut are proud to offer the satellite-driven insights, management tools, and API integrations you need to thrive, comply, and lead in the modern era.

Frequently Asked Questions (FAQ): Ag Chemical Mixing System & CO2 Grow in 2025

1. What is an ag chemical mixing system, and how does it work?

An ag chemical mixing system is an automated solution for blending, dosing, and applying fertilizers, pesticides, herbicides, and plant growth regulators in precise proportions. In 2025, these systems use advanced sensors, automation, and data analytics to dynamically adjust the mixture and deliver chemical inputs exactly where and when needed, minimizing waste and maximizing crop health.

2. How do chemical inputs in agriculture impact sustainability?

While chemical inputs in agriculture (fertilizers, pesticides, etc.) are critical for crop performance, inefficient use can cause environmental problems. Modern systems reduce this risk by applying only required amounts, reducing runoff, leaching, and ecosystem harm.

3. What is a CO2 grow system, and where is it used?

A CO2 grow system delivers controlled levels of carbon dioxide into greenhouses, vertical farms, or other controlled-environment horticulture operations. By optimizing CO2 concentration, plants experience bigger yields and faster growth rates, especially in high-value crops like leafy greens, tomatoes, and strawberries.

4. Can chemical mixing systems and CO2 grow systems be integrated?

Yes. Combining both systems enables real-time adaptive input management—chemical and carbon regimes can be balanced for optimal plant growth and sustainability outcomes using digital, sensor-driven feedback loops.

5. How does Farmonaut support modern input management?

We at Farmonaut offer satellite-powered crop health monitoring, AI advisory, blockchain-based traceability, carbon footprinting, and resource management solutions to help farms and agribusinesses optimize input use, comply with regulations, and enhance sustainability. Our platform is accessible via web and mobile apps and integrates seamlessly via API.

6. What challenges exist for adoption in 2025?

Barriers include initial setup cost, access to technical expertise, energy needs, and infrastructure integration. However, ongoing tech innovation is progressively reducing these issues.

Useful Resources & Farmonaut Solutions

- Download the Farmonaut App for web, Android, and iOS to start monitoring your fields with advanced satellite data.

- Integrate Farmonaut API into your business systems for real-time crop, input, and environmental insights.

- Read Farmonaut Satellite Weather API Docs for developers and agri-tech platforms.

- Learn about Carbon Footprinting in Agriculture to reduce your environmental impact.

- Implement Blockchain Traceability for chemicals, CO2, and agricultural products to increase market transparency.

- Explore Satellite-Verified Crop Loans and Insurance for simplified, fraud-free agricultural finance.

- Optimize Operations with Fleet & Resource Management—perfect for large-area fieldwork and logistics.

- Scale Up with Large-Scale Farm Management and integrate insights across multiple plots and locations.