Mining Equipment Performance Data: Migration & Recovery – Unlocking Efficiency in 2025

“Over 90% of mining firms plan to upgrade equipment data migration systems for improved accuracy by 2025.”

Introduction: The Imperative of Mining Equipment Performance Data

In the rapidly evolving mining industry of 2025, the management of mining equipment performance data has transformed into a critical operational lever. The modern mine is a showcase of technology and innovation, where digital transformation and the integration of smart machinery, IoT devices, and advanced analytics play instrumental roles in efficiency, safety, and sustainability.

A new era is here; one where vast volumes of mining equipment performance data—from sensor logs, GPS tracking, fuel consumption, to machine health reports—can be harnessed to optimize every aspect of mining operations. As these data streams become more complex and essential, five core processes have emerged as indispensable: mining equipment performance data migration, mining equipment performance data recovery, mining equipment performance data quality, mining equipment performance data accuracy, and mining equipment performance data deserialization.

Mastering these processes enables mines to achieve:

- Operational efficiency through predictive maintenance and optimized utilization

- Enhanced safety by reducing equipment failures and hazardous conditions

- Sustainability—balancing productivity and environmental stewardship

In this comprehensive guide, we explore the strategies, technologies, and best practices underpinning mining data migration, recovery, quality, accuracy, and deserialization—preparing mining operations for the demands and opportunities of 2025.

Why Mining Equipment Performance Data Management Matters in 2025

- Explosion of Data Volumes: Mining operations now generate terabytes of data daily—from haul trucks, drill rigs, excavators, and environmental sensors all communicating across sprawling sites.

- Digital Transformation: As industries migrate from legacy systems to cloud-native, AI-powered platforms, the need for seamless mining equipment performance data migration and reliable data recovery surges.

- Safety & Compliance: Regulators require granular records of machinery use, emissions, and incidents. Only robust data quality and mining equipment performance data accuracy ensure compliance and safety standards.

- Optimization through Analytics: Unlocking full value from data requires effective deserialization, data assurance, and integration—feeding real-time analytics, forecasting, and AI systems.

- Competitive Advantage: Companies that master operational data management experience less downtime, higher equipment uptime, and strategic insights—outperforming rivals in a fiercely competitive landscape.

Mining Equipment Performance Data Migration: Foundation for Operational Continuity

At its core, mining equipment performance data migration refers to the systematic transfer of equipment performance data from siloed, legacy systems to cloud-based, unified platforms purpose-built for analytics and machine learning. In 2025, this migration is no longer a one-time event; it is an engineered process that must balance continuity, data quality, and operational efficiency.

Key Drivers for Data Migration in Mining:

- Legacy System Limitations: Older systems struggled with storage, integration, and speed—making it tough to unlock full potential of accumulated historical data.

- Unified Analytics: To enable modern AI models and dashboards, data must be migrated to platforms supporting near real-time aggregation and analysis.

- Scalability & Flexibility: Cloud platforms offer scalable storage and adaptive computing power for the rapidly growing volumes of mining data.

- Digital Transformation: Mining companies must integrate diverse data types (sensor logs, GPS, maintenance records) for predictive optimization.

Challenges and Solutions in Migration:

- Heterogeneous Data: Data is often stored in different formats and protocols—binary sensor logs, CSV sheets, relational databases, and proprietary software.

- Downtime Risks: Interruptions during migration can halt mining operations, leading to high costs and safety risks.

- Data Integrity & Security: Preventing loss, corruption, or unauthorized access is imperative during the transfer process.

Best Practices: Effective Mining Data Migration

- Strategic Planning: Develop a robust migration strategy—map legacy data sources, define migration phases, establish a fallback plan for downtime.

- Data Profiling: Analyze data silos to understand formats, volume, and history. Use automated mapping tools to facilitate extraction.

- Robust Transfer Protocols: Secure, high-speed protocols (e.g., SFTP, HTTPS, block-level migration tools) are critical for large-scale, real-time data transfer.

- Transformation & Cleansing: Convert data into standardized, unified formats. Cleanse to remove duplicates, errors, and outdated information.

- Validation & Reconciliation: Automated scripts and AI-driven checks ensure all data is transferred accurately, and inconsistencies are flagged for repair.

- Minimal Downtime: Leverage redundancy, shadow systems, or phased cutovers to maintain operational continuity.

- Stakeholder Training: Ensure engineers and technicians are prepared to work with new systems, maintaining data quality and integrity in daily operations.

Example: Unified Data Streams for Predictive Maintenance

When haul trucks, excavators, and drill rigs share performance data via unified platforms, real-time analytics alert operators to maintenance requirements—preventing costly breakdowns and ensuring safety on-site.

Leverage Farmonaut’s Satellite Insights for carbon footprinting and operational efficiency in mining—essential for modern mining data migrations and regulatory compliance.

Mining Equipment Performance Data Recovery: Safeguarding Continuity and Knowledge

Mining environments are notoriously harsh. Between abrasive dust, vibration, network faults, and unpredictable power disruptions, data loss, damage, or corruption is a real and costly risk. Mining equipment performance data recovery is the process of restoring data to its original, usable state—preventing knowledge gaps and ensuring the consistency of operational analysis.

Common Causes of Mining Equipment Data Loss:

- Hardware failures (damaged devices, storage medium degradation)

- Network and power disruptions leaving data streams incomplete

- Accidental deletion or software bugs

- Corruption from malware or cyber-attacks

“Mining data recovery speeds are projected to increase by 40% with advanced deserialization technologies next year.”

Techniques to Ensure Effective Performance Data Recovery

- Automated Backups: Regular snapshots and incremental backups ensure recent data can be quickly restored after disruptions.

- Redundancy Architectures: Deploy mirrored storage, failover nodes, and distributed backups across edge and cloud systems to prevent single points of failure.

- AI-Driven Error Detection: Artificial Intelligence monitors real-time data streams, spotting anomalies, missing data, and potential corruption issues instantly.

- Self-Healing Protocols: When missing or corrupted data is detected, automated processes attempt to reconstruct or retrieve data from redundant sources with minimal manual intervention.

- Data Versioning: Maintain historical versions of key datasets for traceability and cross-checking, ensuring data integrity even in disaster recovery scenarios.

With high-quality mining equipment performance data recovery frameworks, downtime is minimized, operational knowledge is preserved, and mining teams can act on the most current and reliable data—critical for safety and financial performance in an industry where minutes of downtime equate to thousands of lost dollars.

Farmonaut Fleet Management: Use satellite-driven logistics and machinery tracking to preempt failures and automate mining equipment data recovery processes—boosting efficiency and reducing losses.

Mining Equipment Performance Data Quality & Accuracy: From Data Integrity to Reliable Insights

Mining equipment performance data quality and mining equipment performance data accuracy are the cornerstones of trustworthy, actionable analytics. As equipment becomes smarter and data collection intensifies in 2025, poor data quality or inaccurate readings can lead to persistent operational losses and compromised safety.

Understanding Data Quality: Key Dimensions

- Completeness: All necessary performance data is captured—no missing fields or interrupted streams.

- Consistency: Data remains standardized across sources, time, and equipment generations.

- Validity: Data abides by defined logic—impossible or outlier readings are flagged.

- Uniqueness: No duplicates or redundant records exist within the database.

- Timeliness: Data is up-to-date and available for real-time decision-making.

Ensuring Performance Data Accuracy in Mining

- Sensor Calibration: All sensors, from fuel consumption to bucket load, are routinely calibrated and maintained.

- Redundant Measurement: Critical parameters are measured using two or more independent systems to cross-validate accuracy.

- Automatic Anomaly Detection: AI-powered algorithms continuously monitor for outliers or drifting measurements, triggering alerts for human review or automated correction.

- Advanced Data Filtering: Noise, environmental interference, and data spikes are filtered out using sophisticated algorithms and machine learning models.

Impact of Poor Data Quality and Accuracy:

- Cost Misestimation: Inaccurate sensor data (e.g., fuel or payload) leads to wrong cost projections and budgeting errors.

- Equipment Misuse: Misleading performance metrics can drive incorrect operational actions, accelerating equipment wear or leading to unsafe procedures.

- Loss of Trust: Engineers and analysts lose confidence in decision-making tools—slowing innovation and increasing manual oversight.

Mining firms are embracing continuous improvement frameworks: regular data quality audits, operator feedback loops, and automated assurance systems all help maintain a high bar for mining equipment performance data accuracy and data quality.

Farmonaut’s Satellite-Based Loan & Insurance Verification streamlines compliance and risk mitigation—backed by reliable mining equipment data quality and accuracy!

Mining Equipment Performance Data Deserialization: Making Raw Streams Actionable

With hundreds of sensors and dozens of machine types operating continuously, mining companies must process data in a medley of compressed, encrypted, proprietary, and often binary formats. Mining equipment performance data deserialization is the process of converting these raw data streams into visually actionable data—ready for analytics, dashboards, and real-time alerts.

Why Deserialization is Critical:

- Efficiency: Directly processing compressed or binary streams is computationally expensive and error-prone.

- Latency Reduction: Fast, reliable deserialization enables near real-time monitoring and response to equipment issues.

- Data Integration: Accurate deserialization ensures seamless interoperability between equipment of varying makes, ages, and technologies.

Advanced Techniques for Deserialization in 2025

- Vendor-Agnostic Frameworks: Use abstraction layers and universal schemas for data from different manufacturers, easing integration.

- Middleware & Protocol Translation: Middleware tools translate between MQTT, OPC-UA, REST APIs, and custom industrial protocols.

- Real-Time Data Pipelines: Implement streaming architectures (e.g., Apache Kafka, AWS Kinesis) with built-in deserialization and error-handling.

- Automated Schema Evolution: Machine learning algorithms adapt to new data structures from firmware updates or next-gen sensors.

Result: Fast, accurate, low-latency delivery of actionable information—feeding the AI-driven decision-making engines that define next-generation mining operations.

Leverage Farmonaut’s Product Traceability Solutions for full lifecycle visibility of mining assets—ensuring authentic, audit-ready performance data deserialization and supply chain trust.

Mining Equipment Data Management: Migration and Recovery Comparison (2025 Estimated Values)

| Migration Step | Estimated Data Accuracy (%) | Estimated Downtime (hours) | Recovery Success Rate (%) | Main Technology Used |

|---|---|---|---|---|

| Data Extraction (Legacy to Staging) | 96–98 | 0.5–2 | 98 | Cloud-Driven ETL, AI Data Profiling |

| Data Transfer (Staging to Cloud) | 99 | ~0.2 | 99.5 | Secure Transfer Protocols, AI Validation |

| Quality Check/Assurance | 99.9 | 0 | 99.9 | AI/ML Anomaly Detection, Automated Scripts |

| Deserialization into Unified Schema | 99.7 | 0.1 | 99.8 | Middleware, Real-Time Pipelines, AI Adaptation |

| Automated Recovery Protocols | 99.95 | 0 | 99.9 | AI-Based Backup, Blockchain Verification |

| Manual Intervention Post-Recovery | 98 | 0.5–3 | 95 | Traditional Methods, Expert Review |

Farmonaut Technology for Mining Equipment Performance Data Management

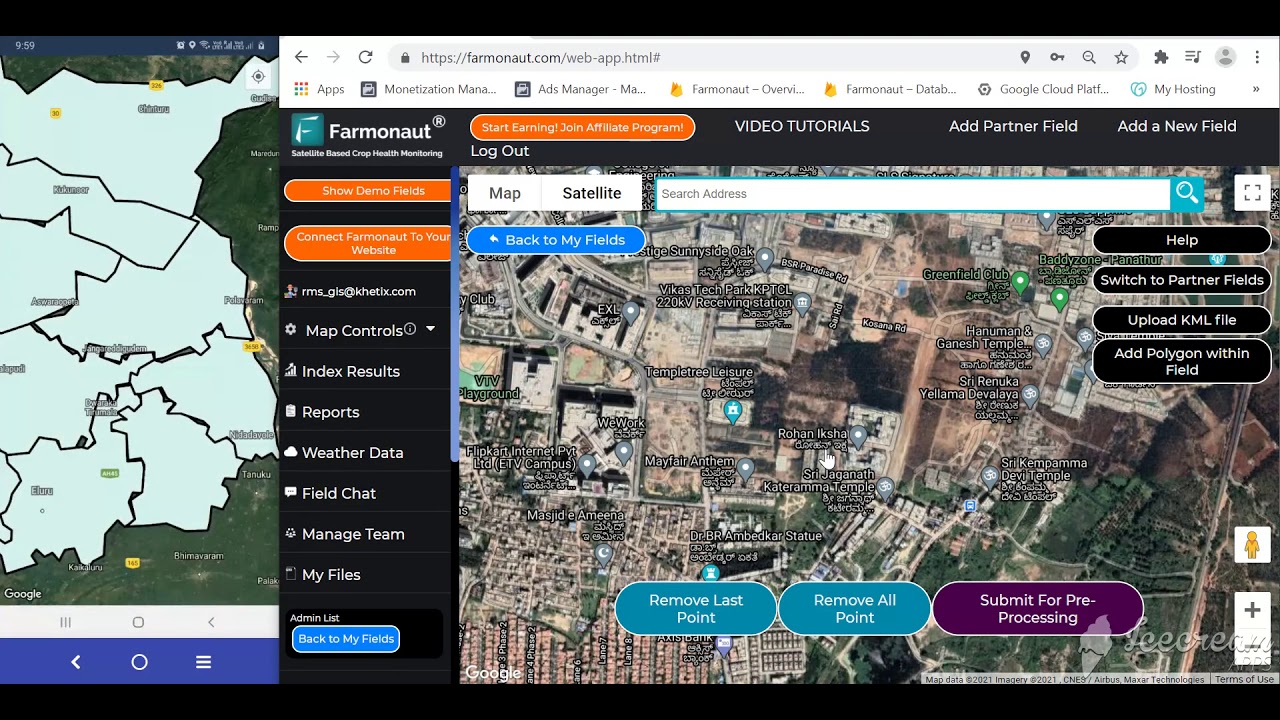

We at Farmonaut deliver satellite-driven, AI-powered tools that fundamentally enhance mining equipment data workflows—from proactive monitoring to seamless mining equipment performance data migration and mining equipment performance data recovery. With technology accessible via API, Android/iOS/web apps, and blockchain, Farmonaut addresses all five focus areas of modern mining data management:

- Multispectral Satellite Monitoring: Capture and analyze equipment fleet activity, mining site conditions, and environmental impact from orbit, enabling real-time operational analytics.

- AI-Driven Analysis: Our Jeevn AI system synthesizes raw streams, detects anomalies, supports deserialization workflows, and recommends maintenance—ensuring high data quality and mining equipment performance data accuracy.

- Blockchain Traceability: We secure every step (migration/quality/backup) via blockchain ledgers, ideal for audit trails and compliance—especially for high-value operations and regulatory reporting.

- Resource Management Tools: Optimize the scheduling, tracking, and utilization of mining assets—reducing downtime and maximizing operational returns.

- Environmental Impact Tracking: Monitor carbon footprints and compliance using satellite and ground-based data fusion, supporting sustainability goals alongside operational KPIs.

Our Satellite API and Developer Documentation enable technical teams to integrate Farmonaut insights directly into custom mining applications, ensuring a tailored fit for every operation—large or small.

Farmonaut’s Large Scale Mining Site Management empowers mining leaders to leverage satellite data, enabling efficient migration, ongoing monitoring, and seamless data recovery at scale.

Farmonaut Subscription Plans

Access Farmonaut Platform & Tools for Mining Equipment Data Excellence

- Click here to access the Farmonaut Web App for satellite monitoring, mining equipment fleet management, and actionable performance data migration.

-

Mine developers and analysts can read developer docs and access APIs here to automate:

- Fleet status extraction

- Mining equipment condition monitoring

- Automated alerts for backup/recovery events

- Data validation and environmental compliance

FAQs: Mining Equipment Performance Data Migration & Recovery (2025)

What is mining equipment performance data migration, and why is it critical in 2025?

Mining equipment performance data migration is the systematic transfer of data (e.g., sensor logs, maintenance records, GPS) from legacy storage systems to modern, unified platforms—often in the cloud. In 2025, this is critical for integrating IoT devices, enabling AI-driven analytics, and maintaining a competitive edge via predictive maintenance and optimized operations.

How do advanced data recovery mechanisms enhance mining operations?

With mining environments vulnerable to data loss, recovery mechanisms (like automated backups, AI error correction, redundancy systems) ensure lost or corrupted equipment performance data is restored instantly. This prevents costly downtime and maintains knowledge needed for safety, compliance, and efficiency.

What makes data quality and accuracy so important for mining analytics?

High-quality and accurate data ensures that operational decisions (scheduling repairs, asset allocation, cost tracking) are based on reality, not erroneous or incomplete readings. Inaccuracy directly leads to equipment misuse, budgeting errors, and safety hazards—making rigorous quality assurance processes essential.

What are the benefits of using deserialization frameworks in mining data management?

Deserialization frameworks convert raw streams—often in proprietary or binary formats—into actionable, structured data. In 2025, these enable interoperability between equipment brands, fast analytics, near real-time alerts, and low-latency integrations—critical for advanced mining operations.

How does Farmonaut support mining companies in managing equipment performance data?

We provide satellite-based, AI-fueled monitoring, Blockchain-backed traceability, and API-driven resource management tools—tailored to mining. Our technologies empower robust data migration, rapid recovery, ongoing quality/accuracy checks, and advanced integration, enabling mining businesses to scale efficiently and sustainably.

How can mining operators try Farmonaut’s products and technologies?

Click here for web access or download our Android/iOS apps above. Developers and analysts can explore Farmonaut’s API to automate mining equipment performance data workflows.

Conclusion: Unlocking Full Potential with Robust Mining Data Management

In the relentless pace of digital transformation defining the mining industry in 2025 and beyond, mining equipment performance data migration and mining equipment performance data recovery have become the backbone of seamless, efficient, and safe operations. By mastering migration, recovery, data quality, accuracy, and deserialization processes, mining firms unlock not only higher productivity and lower costs, but also the agility needed to sustain long-term industry leadership.

The journey towards smart mining operations underpinned by data is ongoing. Those who invest strategically in robust data management frameworks—supported by advanced technology providers like Farmonaut—will lead the way in both profitability and sustainability, setting the pace for a brighter, data-driven future.